Figure 1. Production of high quality charcoal and raw wood vinegar after a single burn with the ‘do-all’ biochar burner. Photo taken at the ECHO Asia Small Farm Resource Center, Chiang Mai, Thailand.

[Editor’s Note: There are many biochar burner designs currently in existence, intended for various scales and end uses in mind. This particular design has become a favorite of the ECHO Asia farm staff, for its ability to produce larger quantities of pyrolyzed material and wood vinegar at the same time. This design was innovated by a local Thai partner and credit should be given accordingly. Thank you Mr. Arun Waikham for allowing us to share your design with the ECHO network.]

Key Terms |

|---|

| Combustion: Another word for burning. A reaction when fuel is heated and it reacts with oxygen. |

| Pyrolysis: A process of thermal decomposition (burning) in the absence of oxygen. |

| Organic Material: Any carbon-containing material, e.g. sticks, bamboo, rice hulls, dried manure, etc… |

| Wood Vinegar: Also known as ‘liquid smoke’, this byproduct of pyrolysis can be used as natural pesticide or plant growth regulator. |

What is Biochar?

Biochar is a form of charcoal made from a variety of organic materials that have undergone a process of pyrolysis, i.e. a high-heat, low-oxygen environment.

This simple, but unique process, allows for the retention and preservation of the carbon typically lost in the burning (combustion) process. During the process of combustion (a normal fire), carbon comes into contact with oxygen and is lost to the atmosphere through carbon dioxide (CO²) in smoke. This distinction in processes is critical and can be leveraged on the small-scale farm to provide valuable carbon-based materials used for amending soils, filtering water, and even running combustion engines.

By definition ‘biochar’ can only be called by that name once charcoal is mixed or ‘charged’ with a biological material such as compost, fertilizer, manure, or urine. This combination of materials forms the basis for the word ‘biochar’. On its own, charcoal has relatively limited use and value. However, when combined with any of the aforementioned materials, [bio]char can become a valued soil amendment and fertilizer.

A high quality charcoal retains its original carbon structure, making it highly porous, electrically charged, with large surface area. In this form, charcoal can act as a sponge and can be used to hold nutrients, water, and especially biological life such as microorganisms (Read: ‘Biochar – an Organic House for Soil Microbes’). When ‘charged’ as previously described, carbon can be used to hold onto and retain these vital elements, making it a beneficial substrate for garden beds, plant-potting mixes, and other types of soil improvement. Biochar is also useful in acidity control of soils. With a high pH, biochar has the ability to increase pH over time when applied to acidic soils, of which the tropics have many.

What is Wood Vinegar?

Wood vinegar, also known as ‘liquid smoke’ or ‘wood acid’ is a by-product of the pyrolysis of carbon-based materials. Known chemically as pyroligneous acid, it

Figure 2. Producing wood vinegar, a by-product of pyrolysis. Also known as ‘liquid smoke’, wood vinegar is produced by condensing smoke created during charcoal prodution.

contains acetone, acetic acid, and methanol, but is made up primarily (90%) of water. Of its many potential uses, wood vinegar is primarily used as a natural pesticide and as plant growth regulator. It is important to note that wood vinegar must be diluted with water before application to plants (Burnette, 2010).

In order to refine wood vinegar for use, the brown condensed liquid collected during charcoal production is left sealed in a barrel for two to four months, during which time the components will settle into four distinct layers. The first and second layers at the bottom of the container will be black, containing wood tar and tar pitch. The third layer (located beneath the top strata of liquid) is the usable portion of wood vinegar. This component will be light yellow to reddish brown. The fourth (top) layer is classified as light oil and will have a skim of wood tar at the top (Burnette, 2010).

Other On-Farm Uses of Charcoal

Water Filtration

When high quality charcoal is created (activated charcoal), it is suitable for water filtration systems, and is one of the key components in the commonly used bio-sand water filter. This highly porous form of charcoal has the ability to soak up and attract various harmful chemicals and compounds in water.

Livestock Feed Supplement

Similar to the filtration uses in water, activated charcoal can also be used as a medicinal supplement in livestock feed, both for its ability to soak of harmful compounds, and to neutralize acids with its low pH properties.

Growing Media for Nursery Plants

See ECHO Technical Note #97 ‘Small-scale Nursery management’ for ways to incorporate biochar.

The Wider Implications of Biochar Production

Biochar production on this scale offers a small, but critical opportunity to address the wider climate related challenges faced globally. This process offers an opportunity for carbon sequestration, the ability to capture and store carbon that would have otherwise been lost to the atmosphere through smoke. In addition to the benefits of using biochar to improve soils, it is also an alternative to burning of crop residues and waste, and subsequent loss of carbon to the atmosphere. This is especially critical in parts of the world where crop residue burning is common and leads to poor air quality.

Design Specifications

The following designs refer to a multi-use aluminum kiln capable of efficiently producing quality charcoal and wood vinegar. This particular design is unique in that it limits contact of organic material with oxygen and direct flame, and features an attached condensation chamber whereby wood vinegar is collected from smoke. Many other kiln designs exist, including the more common, but rudimentary 200-L Barrel Kiln (Burnette, 2013).

**Note that the primary heat source is separate from this design. This particular kiln has been designed to sit on top of a fire, or heat source, and avoids any direct contact between the flame and the carbon material inside (refer back to Figure 1).

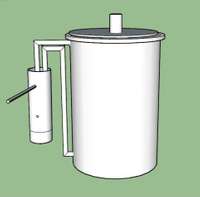

Figure 3. Overall sketch-up of the ‘do-all’ biochar burner. In this design smoke is diverted through a condenser (attached to a hose to cycle cool running water) for the production of wood vinegar and back into the main chamber where it is ‘re-burned’.

Figure 4. Standing 90cm tall and 59cm in diameter, this design includes an inner chimney, whereby smoke is pulled out and through a condenser, and is then redirected back into the top of the chamber for a secondary burn.

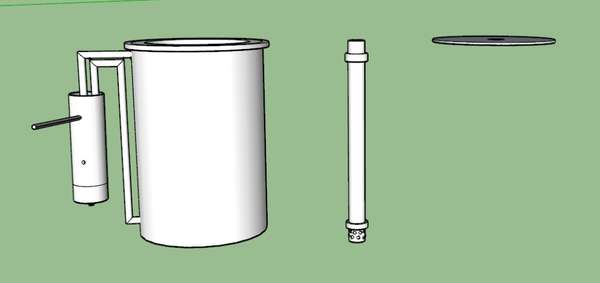

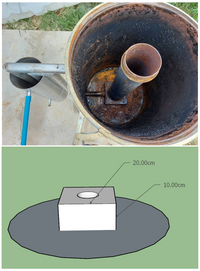

Figure 5. Inside view of the ‘do-all’ biochar burner. Fuel (any carbon- based material) is placed in and around the chimney and sealed up entirely to avoid contact with flame and oxygen.

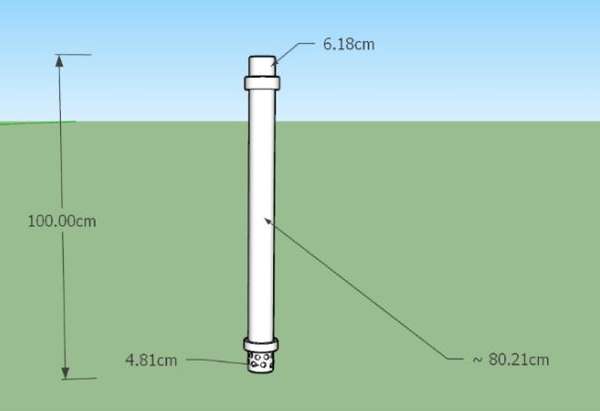

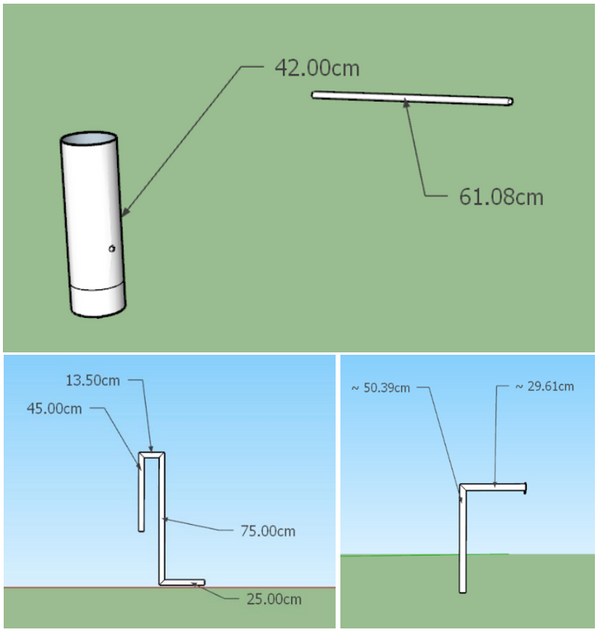

Figure 6. Design specifications of inside chimney.

Figure 7. Design specifications of side-mounted condensation chamber (17cm diameter). Designed for the attachment of a water hose, for the cycling of cool water through the chamber. At the bottom of the chamber, condensed wood vinegar will collect and subsequently exit through the overflow valve for collection.

Biochar Yield

This kiln design is about 250 L in volume. When loaded with small pieces of wood (used chopsticks from the local market), we found the kiln to hold about 35 kg of dry material. After pyrolyzing for approximately 4 hours, the output was roughly 10kg of finished biochar and 10 L of raw wood vinegar.

Conclusions

Biochar differs from charcoal primarily by its end use, typically as a soil amendment and a ‘carbon-neural’ material. As such, it is important to reiterate that biochar in this form is most effectively leveraged through on-farm waste materials. Feedstock (carbon materials) produced for the sole purpose of biochar production will miss the mark in terms of carbon sequestration. It is recommended that on-farm waste products and other by-products be used for the purpose of biochar creation.

References

Burnette, R. 2010. An Introduction to Wood Vinegar. ECHO Asia Notes. 7: 4-10. Available: https://www.echocommunity.org/en/resources/01ccd8a8-aa01-44c0-bd61-d62d8206eb26

Burnette, R. 2013. Charcoal Production in 200-Liter Horizontal Drum Kilns . ECHO Technical Notes. 76: 1-8. Available: https://www.echocommunity.org/en/resources/069529b4-0ce4-475c-99b8-326957e3afa7

Fifer, G., T. Motis. 2021. Small-scale Nursery Management. ECHO Technical Notes. 97: 1-20. Available: https://www.echocommunity.org/en/resources/f18a5550-662c-4838-86b4-a1b8a2b2347f

Hugill, B. 2013. Biochar – an Organic House for Soil Microbes. ECHO Technical Notes. 75: 1-4. Available: https://www.echocommunity.org/en/resources/070b6c33-4118-43c2-a26c-af58c60fe51a