- Is Morning Always the Best Time to Harvest Vegetables and Herbs?">

- Insects in Tropical Stores (A Poster)

- Use of Vegetable Oils to Protect Stored Beans From Bruchid Beetle Attack

- Banana Juice Protects Seeds From Insects

- The Simplest Way to Control Bean Beetles

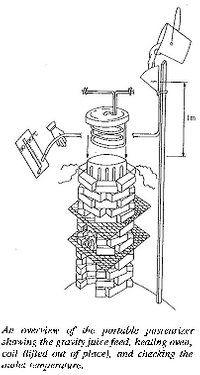

- Appropriate Technology Juice Pasteurizer

- Large Capacity Solar Rice Dryer

- Wood Ash to Preserve Tomatoes for Months

- Cashew Fruit Drying and Nut Processing

IS MORNING ALWAYS THE BEST TIME TO HARVEST VEGETABLES AND HERBS? Not in the case of basil. National  Gardening magazine (July/August 1994) reports findings from a University of Michigan project that basil picked in the evening stored twice as long as basil picked in the morning. A possible explanation is that basil picked in the evening has just spent the day building up sugars. This may somehow help it to survive the shock of being cut longer than basil that has been actively growing all night (and using up sugars).

Gardening magazine (July/August 1994) reports findings from a University of Michigan project that basil picked in the evening stored twice as long as basil picked in the morning. A possible explanation is that basil picked in the evening has just spent the day building up sugars. This may somehow help it to survive the shock of being cut longer than basil that has been actively growing all night (and using up sugars).

No extrapolation was made to other plants. In light of the magnitude of the effect, however, it might be worth checking the influence of harvest time on leafy vegetables or herbs if you are having trouble with storage life.

INSECTS IN TROPICAL STORES (A POSTER). The Natural Resources Institute has a poster with color pictures of 14 insects which are found where food is stored in the tropics. Accompanying an enlarged photo of each insect are the scientific and common names, a guide to actual size, and notes on the commodities they damage and their biological development and behavior. From NRI, Publications Distribution Office, Central Ave, Chatham Maritime, Kent ME4 4TB, UK.

USE OF VEGETABLE OILS TO PROTECT STORED BEANS FROM BRUCHID BEETLE ATTACK. Steve Mason at Purdue University sent us this interesting article on research done at CIAT in Colombia, which was inspired by an ancient Indian method. African palm oil or crude (i.e. unpurified) cottonseed oil were applied to dry beans, Phaseolus vulgaris, at a rate of 5 ml of oil per kg of beans, and tumbled at 35 rpm for 5 minutes. They were then infested with bruchid beetles, Zabrotes subfasciatus, at 1 day and again at 75 days. After 6 months the adults were counted. The untreated controls averaged 251 beetles, the African palm oil had none and the crude cotton seed oil averaged 0.2 beetles per 100 g sample of beans. Treatment with 1 ml of oil per kg of beans was less effective (6.4 and 5.2 beetles per 100 g). It is not clear how the oils work. Dormant oil sprays on fruit trees are thought to interfere with insect respiration. Their action must be more complex, however, because other work has shown that insects completely deprived of oxygen still live longer than those treated with oil.

Other oils (purified cottonseed, maize or corn, purified soybean, crude or purified coconut palm) averaged roughly 75% reduction in the number of beetles, but this may not be enough for consumer needs. Cottonseed oil even reduced the number of beetles emerging when the oil was applied after the larvae had penetrated the seeds, but only from 650 to 387. The added oils did not decrease germination of the beans. Manual mixing of the oil and beans for 5 minutes in a glass jar was much less effective than tumbling, apparently because the surface of the beans was less completely covered. Crude oils are not only cheaper than refined oils, but also contain more antioxidants. These delay rancidity, which might affect taste. Of course the treatments are not toxic. Based on prices of oil and beans in 1978, the oil would cost 0.5% of the market price of beans.

The April 1986 issue of Agricultural Science Digest summarized a report in Agriculture, Ecosystems and Environment showing  good control of rice weevils in stored corn (maize). Shelled corn was shaken with peanut, coconut or palm oils at a rate of 1, 5 and 10 ml of oil per kg of grain, until the grain was evenly coated. Adult weevils were then introduced. Most were killed within a day and all were dead within a week at the 5 and 10 ml/kg concentrations. Few eggs were laid and fewer offspring hatched. After 60 days the 10 ml treatment was reinfected with adult weevils. Again nearly all were dead within one day, except for the palm oil treatment. (Palm oil gave the best resultsin the earlier study.) The oil treatment did not affect germination of treated seed corn, nor water uptake during cooking.

good control of rice weevils in stored corn (maize). Shelled corn was shaken with peanut, coconut or palm oils at a rate of 1, 5 and 10 ml of oil per kg of grain, until the grain was evenly coated. Adult weevils were then introduced. Most were killed within a day and all were dead within a week at the 5 and 10 ml/kg concentrations. Few eggs were laid and fewer offspring hatched. After 60 days the 10 ml treatment was reinfected with adult weevils. Again nearly all were dead within one day, except for the palm oil treatment. (Palm oil gave the best resultsin the earlier study.) The oil treatment did not affect germination of treated seed corn, nor water uptake during cooking.

Burus Ali in Nigeria reports they have had success controlling weevils in their community projects by adding 1 tablespoonful (about 5 ml) of peanut (groundnut) oil to each kilogram of cowpeas. In this way, 1 liter of oil will treat about 200 kg (440 pounds) of peas. After thorough mixing, peas treated this way can keep 4-6 months without any problem. Beetles lay their eggs on the surface, then larvae bore into the seed and later emerge as mature beetles leaving a characteristic hole. Oil interferes with egg laying and development of larvae. Once inside the seed, oil has no effect. If about 6 months after treatment farmers begin to see holes left by emerging beetles, they can extend protection easily up to a year by a second identical treatment. This is based on a procedure recommended by the International Institute of Tropical Agriculture in Nigeria. (Oil treatment reportedly works with cereals too. We would like to hear of your experiences with oil treatment.)

BANANA JUICE PROTECTS SEEDS FROM INSECTS. Duane Neuenburg wrote from Mozambique, "While working at a German hospital/orphanage in Uganda I observed an effective seed storage method to protect against insect damage. They  immersed beans and maize kernels momentarily in a vat of banana juice. The juice is the material from which they ferment an alcoholic beverage (rombe), only they used it before fermentation in this application. They then spread the seeds on a rack to dry. As soon as they were dried they were placed in sacks. The seeds showed no damage 4 months later." This is a new one to us at ECHO. Has anyone else seen this method? How is the banana juice prepared? Have you seen it tried with an untreated control to prove whether or not there is a difference? Do you have any idea why it works (if it does)?

immersed beans and maize kernels momentarily in a vat of banana juice. The juice is the material from which they ferment an alcoholic beverage (rombe), only they used it before fermentation in this application. They then spread the seeds on a rack to dry. As soon as they were dried they were placed in sacks. The seeds showed no damage 4 months later." This is a new one to us at ECHO. Has anyone else seen this method? How is the banana juice prepared? Have you seen it tried with an untreated control to prove whether or not there is a difference? Do you have any idea why it works (if it does)?

THE SIMPLEST WAY TO CONTROL BEAN BEETLES. According to the Michigan State University News-Bulletin, a graduate student from Tanzania, Martha Quentin, and her research advisor, Dr. J.R. Miller, developed a simple solution to one of the world's major food storage problems. The following is taken from that article and the authors' technical publication, "Bean Tumbling as a Control Measure for the Common Bean Weevil."

THE SIMPLEST WAY TO CONTROL BEAN BEETLES. According to the Michigan State University News-Bulletin, a graduate student from Tanzania, Martha Quentin, and her research advisor, Dr. J.R. Miller, developed a simple solution to one of the world's major food storage problems. The following is taken from that article and the authors' technical publication, "Bean Tumbling as a Control Measure for the Common Bean Weevil."

Weevil larvae bore entry holes in the bean surface and eat the insides, leaving empty shells. Fumigation methods are effective, but are not always possible [or desirable] in the third world. Quentin attacked the problem by studying how soft-bodied larvae are physically able to bore through the smooth hard surface of a dried bean.

They learned that the larvae scrape the holes with their mouths, but first must brace themselves against a hard surface--a neighboring bean or the wall of a container holding the beans. A bean that does not abut another bean or other hard surface cannot be invaded.

They also learned that it takes 19-24 hours for a weevil to bore an entry hole. They hit on the idea of occasionally tumbling stored beans in order to dislodge weevil larvae before they could finish scraping their holes.

They calculated that it would be highly unlikely after tumbling that a previously started hole would still be close enough to an abutting surface to be useful to a larva. The larvae would have to start new holes.

Experiments proved them right. "Rather than the normal 20-fold increase per generation, beetle populations in tumbled beans fell to 1/3 of the starting population." Tumbling intact beans morning and evening in a variety of glass and plastic containers, as well as burlap bags, consistently gained excellent results. The tumbled containers had 97 to 98% fewer weevils than were found in stationary control containers. Even when many of the beans had been cracked during harvesting, results were excellent (95%). After only two or three days, the larvae, except for the few that manage to enter a bean, either starve or are crushed by the tumbling.

How was the tumbling done? "Sacks of beans were twice turned end-over-end 2-3 times a day. Tumbling was faithfully conducted until about one week after inspection revealed no live adults."

Will tumbling be a useful control for other storage pests? "Tumbling is unlikely to be as disruptive to the cowpea weevil, whose larvae bore directly into beans from eggs glued to the seed surface." Several criteria of pest biology are listed to help in evaluating the likely success of tumbling. But even if the pest biology is not known, "regular tumbling could be attempted, just to see if there were benefits worth the modest effort."

APPROPRIATE TECHNOLOGY JUICE PASTEURIZER. The "tubular juice pasteurizer," as it is formally called, strikes me as an "appropriate technology" with unusual promise.

It is designed for situations where a large quantity of fruit is available for a limited period of time and for which there is no ready market or where marketing is not feasible because of difficulties in transporting the fruit to market. It also assumes a segment of the population would benefit either financially or nutritionally if it could produce an inexpensive pasteurized fruit drink.

The technology was developed in the late 1980s by Dr. Phil Crandall and colleagues while he was with the University of Florida's Lake Alfred Experiment Station. Dr. Crandall's team developed the pasteurizer specifically for difficult third world situations. His criteria included: low cost, no moving parts, easy to build, easy to move, rugged, and providing agitation (for even heating). Heating lowers quality, so an emphasis was placed on what he called HTST (high temperature short time). The result is a pasteurizer which can be carried by one person to the most remote site.

The technology was developed in the late 1980s by Dr. Phil Crandall and colleagues while he was with the University of Florida's Lake Alfred Experiment Station. Dr. Crandall's team developed the pasteurizer specifically for difficult third world situations. His criteria included: low cost, no moving parts, easy to build, easy to move, rugged, and providing agitation (for even heating). Heating lowers quality, so an emphasis was placed on what he called HTST (high temperature short time). The result is a pasteurizer which can be carried by one person to the most remote site.

ECHO waited on this innovation for several years in hopes that the pasteurizer would become available commercially. It now appears that this will not happen. We had a volunteer, Dale Fritz, make four units for ECHO and are convinced that this simple device can be made in any country with no special tools or mechanical skills for a little over $100 counting accessories. So here are the details.

Pasteurization of fresh citrus juice requires a temperature of 90 deg.C (194 deg.F) for a few seconds. Calculations showed that an acid fruit juice could be pasteurized by passing it through a stainless steel coil of precise dimensions that was immersed in a container of boiling water. Dr. Crandall bent a 6 m (20 ft) length of stainless steel tubing into nine coils 19 cm (7.5 in) in diameter by wrapping by hand around a cylinder of the appropriate size (he said the cylinder could be something as simple as a log). The tubing used was grade 316 seamless, 9.5 mm outside diameter and 7.7 mm inside diameter. Inlet and outlet tubes protruded 30 cm over the sides of the can and were connected to plastic tubes. The coil rested on a block of wood to prevent it from touching the bottom of the can.

The length of time the juice is in the coil is controlled by hydrostatic pressure. The inlet to the coil is attached via a tube (he used tygon) to a plastic funnel into which the juice is poured. The higher the funnel, the greater the pressure and so the faster the juice flows. In practice it is usually fastened about 1 meter above the coil. The temperature of the juice as it leaves the coil is periodically checked. If it is too low, the funnel is lowered to reduce the flow rate; if too high, it is raised.

Juice is collected in recycled bottles. Dr. Crandall used brown beer bottles, but soft drink bottles would also work well. After attaching a cap, bottles are laid on their side for 3 minutes to sterilize the cap, then are cooled in running water (if available).

Dr. Crandall says that juice can be stored without refrigeration for some months. Pasteurization did not significantly decrease vitamin C content, but 3 months' storage at 21øC did, by about the amount that would be expected for pasteurized juice stored at that temperature. However, each bottle (375 ml) still contained over three times the US recommended daily allowance of 60 mg. Effects on color were similar. An instrument that measured the vacuum in the bottle showed that no fermentation had occurred after 3 months. Though there is no microbial degradation, chemical oxidation of canned or pasteurized foods still occurs. So the lower the storage temperature the better.

To keep the water boiling efficiently, construct a simple oven with loose bricks (see illustration). Dr. Crandall built it from used housing bricks to make a 40 cm diameter circle with an air draft in the front and out the top. An iron grate at 55 cm supported  the fire and another at 75 cm supported the can.

the fire and another at 75 cm supported the can.

A tasting panel of 21 experienced assessors graded juices from 1 (dislike extremely) to 9 (like extremely). The fresh orange juice was rated 7.2 (liked moderately); pasteurized 4.2 (disliked slightly). Dr. Crandall suggests this may be due to the panel's familiarity with commercial juice, which has flavoring oils added after heating.

I tasted the orange juice while visiting the Small Farm Resource Development Center in Belize (Christian Reformed World Relief Committee). Tom Post took me to a small store operated out of a home. If I recall correctly, the owner spent about 10 cents on juice and labor and sold the juice for 30 cents, about half the price of a bottle of cola. I found the taste similar to other pasteurized orange juice, which is always a much different taste than fresh juice. The next season Tom took the pasteurizer to different communities which kept the bottles for their own use during the Christmas season. This was in 1991.

In 1994 I called Tom for an update. He had been assigned outside the country for some time and then returned. The pasteurizer was not being used. He cited three reasons. Belize is relatively well off for a third world country; the cost of a drink is not prohibitive for most, so they are not that motivated to use the pasteurizer. "If I had been around promoting it, they would have been happy enough to use it. But their interest is not great enough to take the initiative in seeking it out." Also there are fewer oranges around than appears at first sight, especially when large quantities are picked for processing. Finally, the season of excess ripe fruit is extremely short there, only a couple weeks or so. The pasteurizer would have been much more successful if there was some juice available for processing at many other times of the year.

This brings up the subject of what other juice can be processed. About the only limit is that it must be an acidic juice (pH<4.5; safer to say <4.0). This includes apple, some tomatoes, lemon, lime, passion fruit, cashew etc. Dr. Crandall only experimented with orange and apple juice and a drink similar to one liked in Nepal called "orange squash" (25% orange concentrate, 42.5% sugar and 32.5% water).

The apple juice only required a temperature of 80 deg.C, so the height of the funnel was raised accordingly. The taste panel rating was essentially unchanged (7.0 and 6.7 for fresh and pasteurized juice respectively). The "orange squash" was not evaluated.

If someone was willing to do some "recipe developing," it should be possible to come up with some very tasty juices. Different fruits, mixtures of fruits, and adding sugar or flavorings could all be tried. Concentrates to be mixed with water or lemon juice and sugar by the consumer might be popular. If the juice is not quite acidic enough, it could be adjusted with a bit of lemon, lime or passion fruit. Also consider: Andean blackberry, guava/passion fruit, tamarind, grapefruit, soursop, red mombin, etc.

Dale Fritz said it cost him $25 to make a coil (made from seamless stainless steel 3/8 inch od x 20 ft long, type 316 tubing). He checked out the current retail price of other accessories that would be needed. Input and outflow tubing $1.60; thermometer $11.90 - $19.95; bottle capper $29.95; bottle caps, 10 gross for $19.00; a potato ricer/fruit press, $8.99; funnels about $1.50. You would also need a 5 gallon metal bucket with lid, bottles, container for the extracted juice, a pitcher for pouring, a stick to support the funnel and material for the fire box. He points out that the USA and Canada use different sized beer bottles, so one must be sure the size of caps and bottle capper is right for the country. [Dr. Crandall has never found this to be a problem.] He said that both are readily available in stores that sell supplies to people who make their own beer.

I phoned Dr. Crandall to clarify some points. The interview follows.

Q. Your article states that orange juice was heated to 90 deg.C and apple to 80 deg.C. How do we know what temperature a juice will require?

A. I would just recommend that every juice be heated to 90 deg.C. The microbes in orange juice are probably killed at a lower temperature, but it must reach that temperature to inactivate an enzyme called pectin esterase. Have you noticed that a  couple days after you extract fresh orange juice there is a clear layer on top and "crud" on the bottom? When this enzyme breaks down esters in the juice, some complex acids are formed. These combine with calcium to make something that at the molecular level might be described as a `fish net,' which settles to the bottom. Apple juice does not have this enzyme, so it does not need the extra temperature. Solids still settle out in apple juice for a different reason. This is going to happen even with the most sophisticated equipment.

couple days after you extract fresh orange juice there is a clear layer on top and "crud" on the bottom? When this enzyme breaks down esters in the juice, some complex acids are formed. These combine with calcium to make something that at the molecular level might be described as a `fish net,' which settles to the bottom. Apple juice does not have this enzyme, so it does not need the extra temperature. Solids still settle out in apple juice for a different reason. This is going to happen even with the most sophisticated equipment.

Q. What is the margin for error in temperature?

A. This depends on how great a content of microbial life is in the juice and on the pH. A target temperature of 90 deg.C allows some margin for error. The pH (a measure of acidity) is really important. Below 4.5 clostridia spores will not germinate even if they are present. Over pH 4.5 one bottle could kill a person! You should have some pH test paper which turns different colors based on pH. With simple equipment, it might be well to shoot for a pH of 4.0 for an extra margin of safety.

Q. How is the pH lowered?

A. Just add lemon or lime or any other very sour juice. Be sure not to have acidic juices in contact with lead, aluminum or copper containers as the acid can react to produce toxic heavy metals compounds.

Q. At what pH is food too sour to enjoy? Give us a perspective.

A. Apple and pineapple juices are less than 4.5. Tomato juice is borderline (caution!). Most citrus juice is about 3.5; lemons and limes are about 2.0.

Q. Are all citrus equally suited for pasteurizing?

A. The citrus that are easy to peel, like mandarins, make terrible juice. A chemical is formed (a lactone) that tastes like kerosene. That is why you almost never see pasteurized tangerine juice on the market. Use oranges that are difficult to peel.

Always run the raw juice through a strainer or colander to remove larger particles, which might plug up the coil. We chose a small diameter coil because it makes the "ride" through the coil more turbulent for the juice. This assures that every bit of it is in contact with the hot sides of the tube and reaches 90 deg.C.

Q. Do you have any thoughts on mixtures of juices and flavorings?

A. Almost any culture will prefer a colored, sweet and acidic juice. Add some passion fruit for color, acid and flavor and sugar for sweetness. For a first test, heat some juice in a pan on the stove, let it cool, then taste. If you like it, you will love it when pasteurized in the coil (which is a lot gentler treatment than heating in a pan).

Q. Where do you buy bottle caps in the third world?

A. I recommend recycling bottle caps. You can simply flare out the sides on an appropriately sized rock, then cap it down tightly on the bottle with the bottle capper.

Q. Is there danger of using bottles in which chemical poisons have been stored?

A. Every bottle must be cleaned in hot, soapy water. After that if the human nose cannot detect a smell it is very unlikely that enough of something will be present to cause a serious health problem.

ECHO recommends that you purchase all the parts that you can in the country where you work. Dale is putting together 4 complete kits for ECHO. One we will set up at ECHO (and demonstrate during our agricultural missions conference!) and one we are sending to Haiti where we are helping with a Small Farm Resource Center (at Bohoc near Pignon).

LARGE CAPACITY SOLAR RICE DRYER. Harry Leightner in Costa Rica asked me to keep my eyes open for a solar dryer with a capacity large enough to dry beans. They must be harvested during the wet season and dried before they can be shelled. We obtained plans for a one ton solar rice dryer from the Renewable Energy Resources Information Center (RERIC) in Thailand which appears to be well tested and is recommended for the drying of many products in addition to rice, including beans, fish, cocoa, coffee, cassava, maize, bananas, coconuts, et. al. For a handbook, contact the Director/RERIC, AIT., P.O. Box 2754, Bangkok, THAILAND. Part One is intended mainly for agricultural scientists and officials and gives general information on the background, design calculations and principles involved. Part Two is intended for those who will make and use the dryer. This part includes 86 photographs and 45 figures and is in considerable detail. They estimate the cost of materials in Thailand to be $112, or $57 if free locally grown bamboo is available (1982 prices). If you give this a try, please consider sharing your experiences with us and our other readers.

LARGE CAPACITY SOLAR RICE DRYER. Harry Leightner in Costa Rica asked me to keep my eyes open for a solar dryer with a capacity large enough to dry beans. They must be harvested during the wet season and dried before they can be shelled. We obtained plans for a one ton solar rice dryer from the Renewable Energy Resources Information Center (RERIC) in Thailand which appears to be well tested and is recommended for the drying of many products in addition to rice, including beans, fish, cocoa, coffee, cassava, maize, bananas, coconuts, et. al. For a handbook, contact the Director/RERIC, AIT., P.O. Box 2754, Bangkok, THAILAND. Part One is intended mainly for agricultural scientists and officials and gives general information on the background, design calculations and principles involved. Part Two is intended for those who will make and use the dryer. This part includes 86 photographs and 45 figures and is in considerable detail. They estimate the cost of materials in Thailand to be $112, or $57 if free locally grown bamboo is available (1982 prices). If you give this a try, please consider sharing your experiences with us and our other readers.

WOOD ASH TO PRESERVE TOMATOES FOR MONTHS. Ken Hargesheimer sent us a copy of the "From Garden to Kitchen" newsletter published by UNICEF. It provides a way for Pacific Island populations to share gardening and nutrition information suited to the local region. If you are in the Pacific Islands, you are eligible to receive this newsletter (no fee). Write South Pacific Commission Community Education Training Centre, c/o UNDP, Private Mail Bag, Suva, FIJI; phone 300439; fax (679) 301667. The following is from issue #10.

Farmers know all too well the problem of large quantities of tomatoes (and low prices) during season, followed by short supply and higher prices. The Bureau of Education in the Philippines says you can extend the season in which tomatoes are available. Fresh tomatoes can be preserved in wood ash for up to three months.

Preserve only newly picked tomatoes which are ripe but not soft and overripe. They must be free of bruises and blemishes. Select a wooden or cardboard box or woven basket and line it with paper. Gather cool ash from the cooking fire and sift to remove sharp particles. Spread the ash evenly on the bottom, 1.5 inches (4 cm) thick. Arrange the tomatoes upside down (stem end facing down) in one layer and pour another thin layer of ash on top. Continue layering tomatoes and ash until the container is full. Cover and seal the container and keep in a cool dry place. [The article does not say how to cover and seal. My best guess is to cover with ash then a loose-fitting cover to keep the ash from being disturbed.] The skin will wrinkle but the pulp inside will remain juicy.

The article does not mention what effect the wrinkling of the skin has on marketability. If you try this method, I would be interested in your observations.

CASHEW FRUIT DRYING AND NUT PROCESSING. [Summarized from an article in the September 1990 Appropriate Technology.] The cashew "apple" is a bell-shaped pseudocarp which holds the "nut" below it. The "apple" (or fruit) is often used for juice, preserves, candy, and jam in Asia. The first step in drying the fruit is to boil the apples in salty water for 15 minutes to remove the bitter taste that is unpleasant to some. Then the apples are perforated and compressed in specially cured wooden devices. The compressed apples are then boiled in sugar for two hours. Some 350 kg of sugar are used with every 1,000 apples with enough water to cover the apples. The sugar is re-used twice.

The boiled apples are then dried in a solar drier. The apples are put in 1.2m x 0.6 m wire trays to a depth of 2.5 cm, inside a 1.5 m x 1.2 m wooden cabinet which is covered with plastic film. Underneath the wire trays there is a black collector plate. The cabinet is inclined at 80ø, set toward the east in the morning and moved during the day. The apples are dried in one day and have a shelf-life of 6-8 months.

This has been extremely successful. By 1985, over 5,000 kg of cashew produce had been marketed and orders for 1987 were more than 35,000 kg. This provides employment for 2,000 families at œ5.00 (rather than œ1.50) a day.

Ian Wallace, Igreja Evangelica da Guine-Bissau, wrote on cashew: "On the whole I am not greatly enamored with cashew as a crop and would advise anyone thinking of large-scale cashew production to proceed with caution." His letter arrived just as I had visited some sites in the Amazon basin where cashews seemed to produce well and was wondering if I had been too negative (see page 123). Perhaps someone in our network knows of a very successful cashew project. If so, please drop me a line. I would like to correspond with you. Ian's helpful observations follow:

"I was interested in your article on cashew production. Here vast areas of virgin bush have been cleared and planted with cashew trees in the past 10 years. Certainly the crop has not fulfilled all that was expected of it. Perhaps expectations were too high, or orchards are inadequately tended. Because the initial stages of raising the trees is so straightforward, there is a tendency to sit and wait for the tree to do its stuff with many orchards remaining uncleaned. The crop is unreliable.

"The little that is processed locally is of poor quality, the toxic skin being burnt off in an open fire. The majority of the nuts are exchanged by the government for rice then shipped raw to foreign processing centers. The true value of the crop remains unrealized since much of the profit is only added after processing. We have seen a disastrous fall in rice production as well. It is easier to collect cashew nuts and exchange them for imported rice than it is to work the rice fields. Although this is obviously a fault of the exchange policy, it is hard to see an alternative. There are no other markets for unprocessed nuts and the government has no other means of paying.

"You are right in saying that it is a labor intensive crop. Harvest time involves an army of workers, many of whom are children from age 6 upwards who are taken out of school for that purpose. It is rare to see men involved in the harvest. It appears that the system which is evolving is oppressive to the weaker members of the community, who rarely see any great benefit from the harvest.

"Cashew production has aggravated another social problem, drunkenness. The squeezed juice ferments quickly and without human intervention, to make a strong alcoholic drink in days. The cashew wine is available in far greater quantities than palm wine. Cashew season sees a very marked increase in drunkenness."