VITA

This technical bulletin briefly describes a new technique for using the spent lubricating oil removed from automobiles. This oil normally has no immediate use. It is often discarded in ways that can foul local groundwater or upset wastewater treatment systems.

The "waste oil" can be burned as fuel by using a special "oil-drip" technique. A ready supply of waste oil can usually be found at nearby gas stations.

The oil-drip method is based on an original application designed by Ali H. Sheriff with the aid of Bashir M. Lalji. Sheriff is the owner and operator of a number of small-scale industries in Arusha, Tanzania. The oil-drip technique was developed at his pottery works. It is currently in use there and at a number of schools and institutions in the Arusha area. Sheriff is a long time VITA Volunteer.

This bulletin is not intended to serve as a construction guide for building a waste-oil burner. It does provide a description of a new technique for using a resource that otherwise would be wasted.

VITA makes this material available to generate ideas among as wide an audience as possible. Readers are asked to write VITA about their experience with the design. Please send test results, suggestions, and requests for further information to:

Technical Bulletins

VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info @ vita.org

12:81 ISBN 0-86619-160-7

VOLUNTEERS IN TECHNICAL ASSISTANCE

VITA TECHNICAL BULLETINS

This Technical Bulletin is one of a series of publications that offer do-it-yourself technology information on a wide variety of subjects.

Technical Bulletins are idea generators, intended not so much to provide a definitive answer as to guide the user's thinking and planning. Premises are sound and testing results are provided, if available.

Users of the information are asked to send us their evaluations and comments based on their experiences. Results are incorporated into subsequent editions, thus providing additional guidelines for adaptation and use in a greater variety of conditions.

INTRODUCTION

HOW IT WORKS

- The Pottery Works

- Clay Preparation

- Collecting The Waste Oil

- Cleaning The Oil

- The Modified Kiln

- Firing The Kiln With Waste Oil

- A Cook Stove

2 INTRODUCTION

The increasing price and decreasing availability of petroleum products continue to be serious problems, particularly in developing countries. It is thus especially important to make maximum use of current petroleum supplies. The lubricating oil removed from automobiles is an example of a valuable reusable petroleum product. It cannot be used for the same lubricating purposes without expensive re-refining techniques. But it can be used for other purposes.

In the past, waste oil has been used in a variety of ways: as a coating to protect wood against insects, to control the dust on unpaved roads, and to fire simple stoves. Most stoves that burn waste oil use a drip technique. However, few of them mix the oil with water and none uses the system of splash plates described here.

WARNING!

Waste oil from engine crankcases or gear boxes can be a useful, low-cost fuel in certain applications. However, users of waste engine oil are warned that the oil might contain lead from leaded gasoline. The lead would be released into the air as the oil burned. It could possibly contaminate pottery fired in the kiln, and be a hazard to kiln operators.

Users of waste engine oil should have the oil tested to find out if it contains lead. The combustion chamber of the kiln should be sealed, and the chimney should be high enough to carry combustion products well away from the work area. The kiln should be operated in a well-ventilated place.

Do not use engine oil to fire space heaters or food dryers. Waste oil from electric transformers should not--repeat, not--be used as fuel in any circumstances. Transformer oil contains poly chlorinated biphenol (PCB) compounds. PCB is highly toxic and should not be burned at all. It should not even be handled at all. If you think your waste oil supply might come from electric transformers, do not take chances. Do not burn the oil.

HOW IT WORKS

Waste oil by itself will not burn. However, it can be made to burn under certain conditions. The waste oil is mixed with a small amount of water and dripped onto a hot surface in a fire box chamber. The water vaporizes instantly and the oil becomes a flammable mist. If the chamber has been sufficiently preheated, the oil mist will burst into flame. The heat of the burning oil will then maintain a high enough temperature in the firebox to continue the burning process.

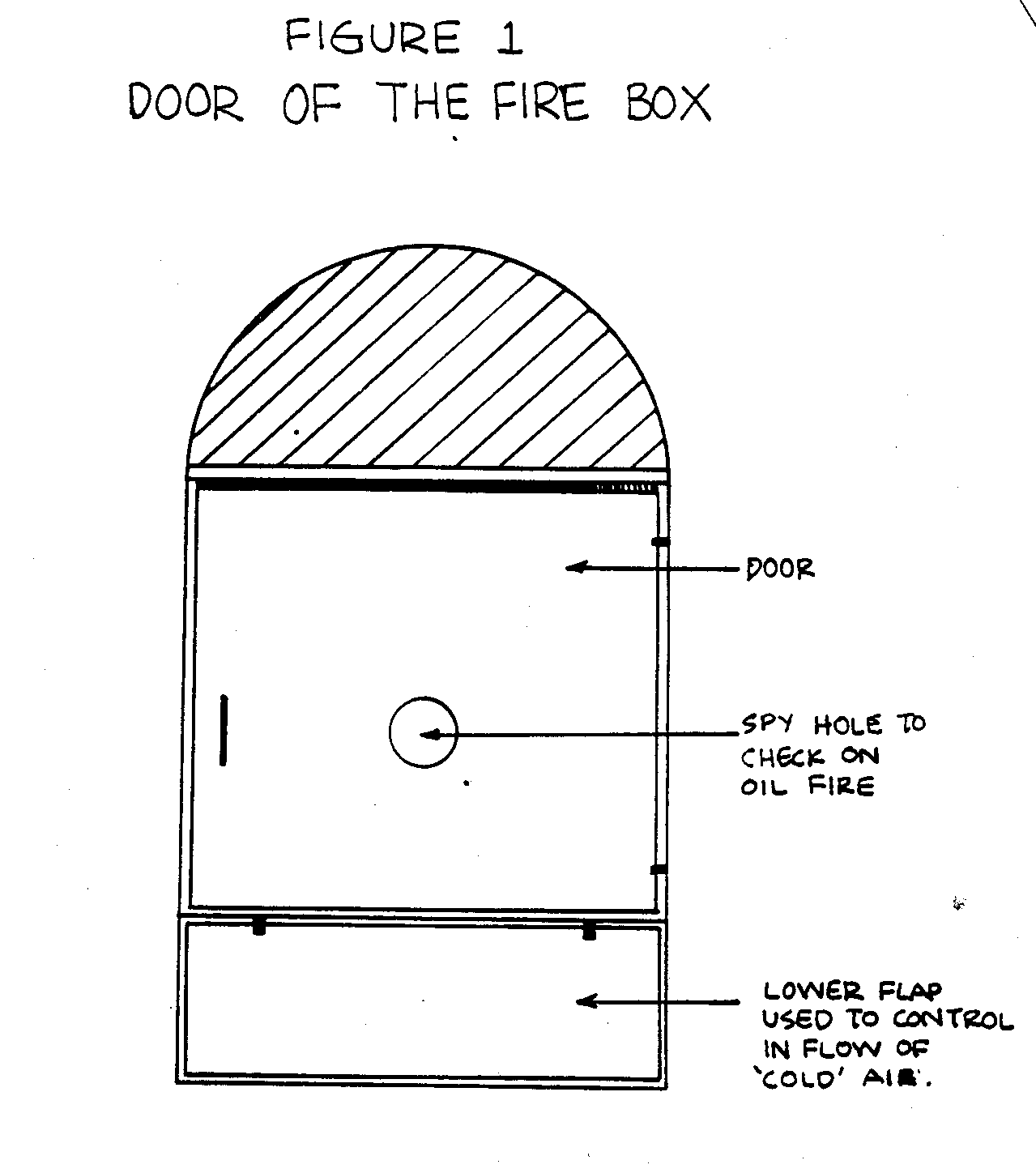

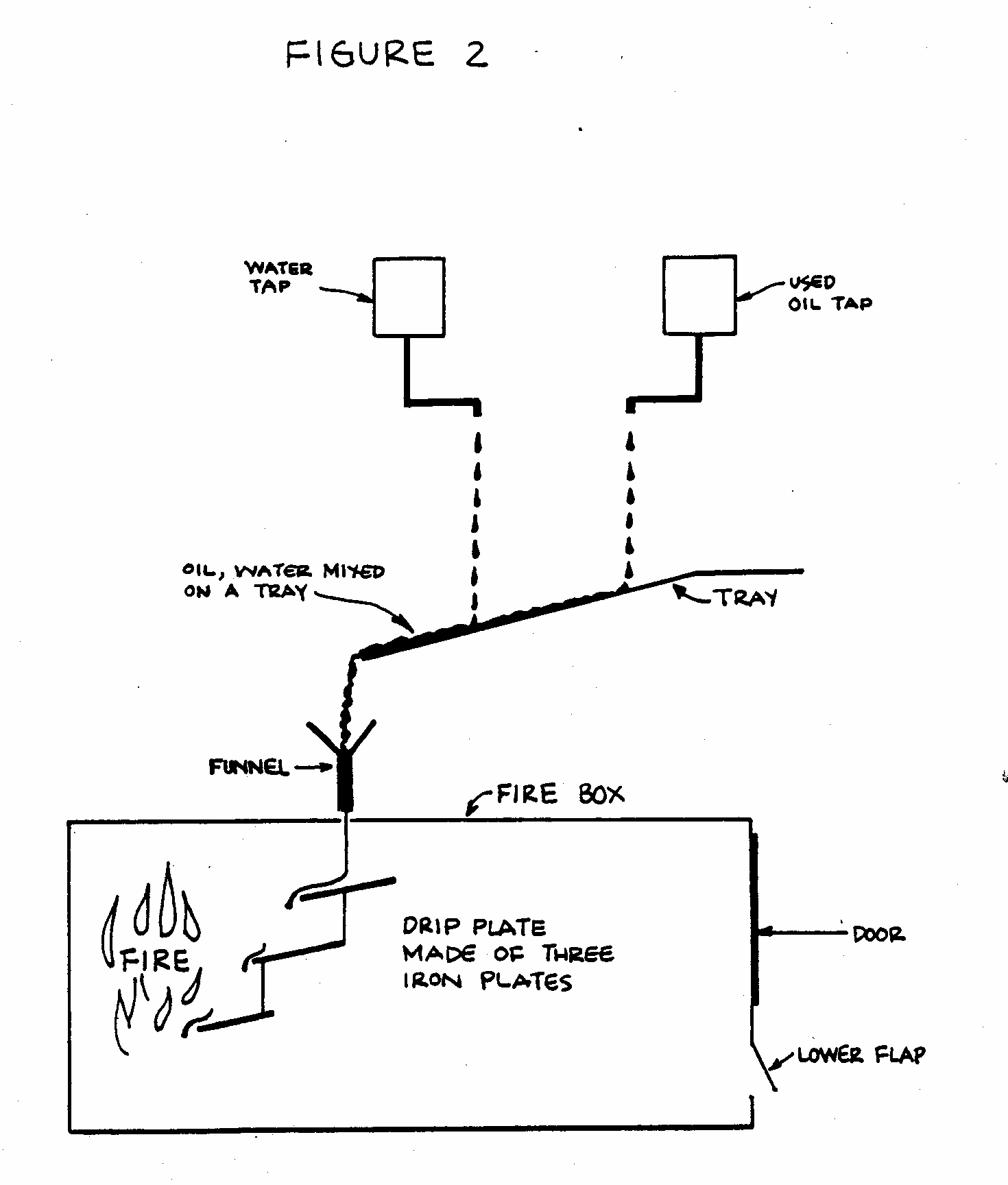

The operation of the waste oil burner is very simple. It does require frequent attention and a specially designed firebox. The firebox is fitted with two metal doors. A large upper door allows the loading of the wood or charcoal fuel used to preheat the firebox. A smaller door, positoned below the large door, permits control (see Figure 1). Inside the firebox, three cast-iron plates are slant-mounted

in a stair-step fashion (see Figure 2). These plates are called "splash-plates."

Separate oil and water containers are positioned above and to the side of the firebox. Tubes lead from the containers to a short metal trough located on top of the firebox. The oil and water are gravity fed into the trough where the two liquids mix. The mixture then flows through a hole in the top of the firebox and drips onto the splash-plates.

The splash-plates are first heated by a charcoal or wood fire beneath them. Gate valves on the oil and water containers are adjusted to permit a flow of four drops of oil to one drop of water. The oil and water mix in the metal trough on the firebox. The mixture then drips onto the hot splash plates in the firebox. The waste oil ignites after splashing off the iron plates. The heat generated by the burning oil keeps the splash-plates hot and the charcoal or wood fire is allowed to die out. It is important to control closely both the amount of oil and water dripping into the firebox and the draft through the lower firebox door.

The height of the chimney for the firebox will depend on the intensity of the heat required. The higher the chimney, the hotter the fire.

The Pottery Works

A kiln using waste oil as a fuel operates at a pottery works in Arusha, Tanzania. VITA Volunteer Ali Sheriff, one of the principal developers of the oil-drip technique, owns and operates the pottery works. The small factory is set up in a warehouse in an industrial area of Arusha. Clay and the waste oil are obtained locally and brought to the pottery works by truck.

Clay Preparation

The pottery factory produces cups, bowls, and other household containers. Typically, the clay is mixed with water to form a slurry. It is then dried to obtain a consistent lump free quality. After each of the items has been formed, it is dried, heat treated to improve the clay's strength, and dipped in a glaze mixture. The "green ware," as it is called, is placed in rounded clay containers to protect the glazed pieces from direct flames and the containers are stacked inside the kiln.

Collecting The Waste Oil

The waste oil for the kiln is collected from gas stations located within Arusha. At each of the stations the oil is either extracted from the gas stations's containers or a full barrel is exchanged for an empty 55-gallon drum. Occasionally, the waste oil collector offers to leave a 55-gallon drum at a gas station which is discarding its oil by pouring the oil over the land in back of the garage or dumping it down drains. The oil is then cleaned as described below.

Cleaning The Oil

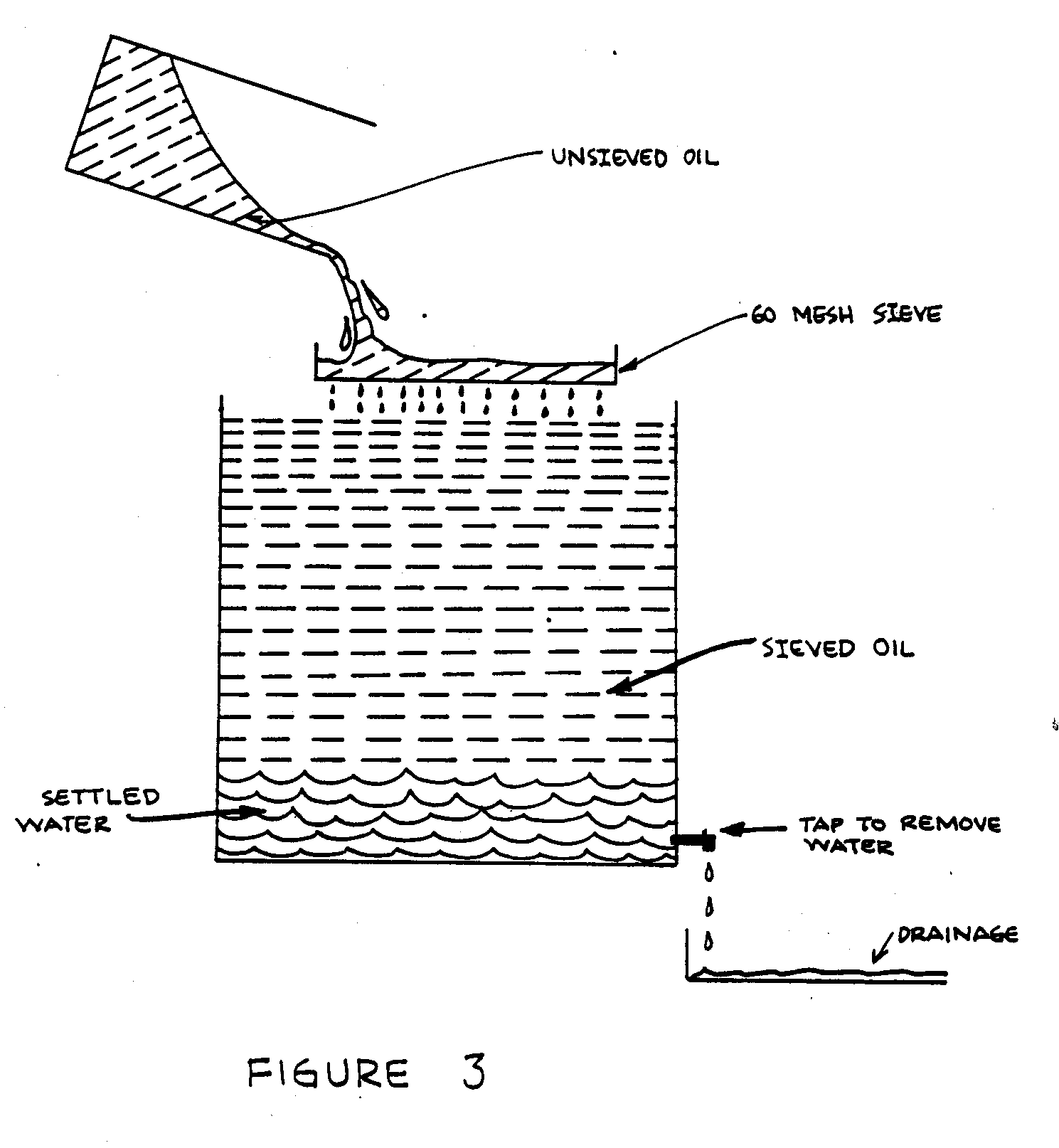

Waste oil requires simple treatment before it can be used as fuel. Drums left at gas stations will often contain metal filings, rocks, sand, water, and other debris. All of these foreign solids and the water must be removed as illustrated in Figure 3.

The oil is first poured through a screen (60 mesh or finer) into a clean drum that is equipped with a tap located as near the bottom as possible. The oil is left to stand for a few minutes and the water settles to the bottom of the barrel. The water is removed by opening the tap. The tap remains open until only oil flows from the drum. The waste oil is now ready for use.

The Modified Kiln

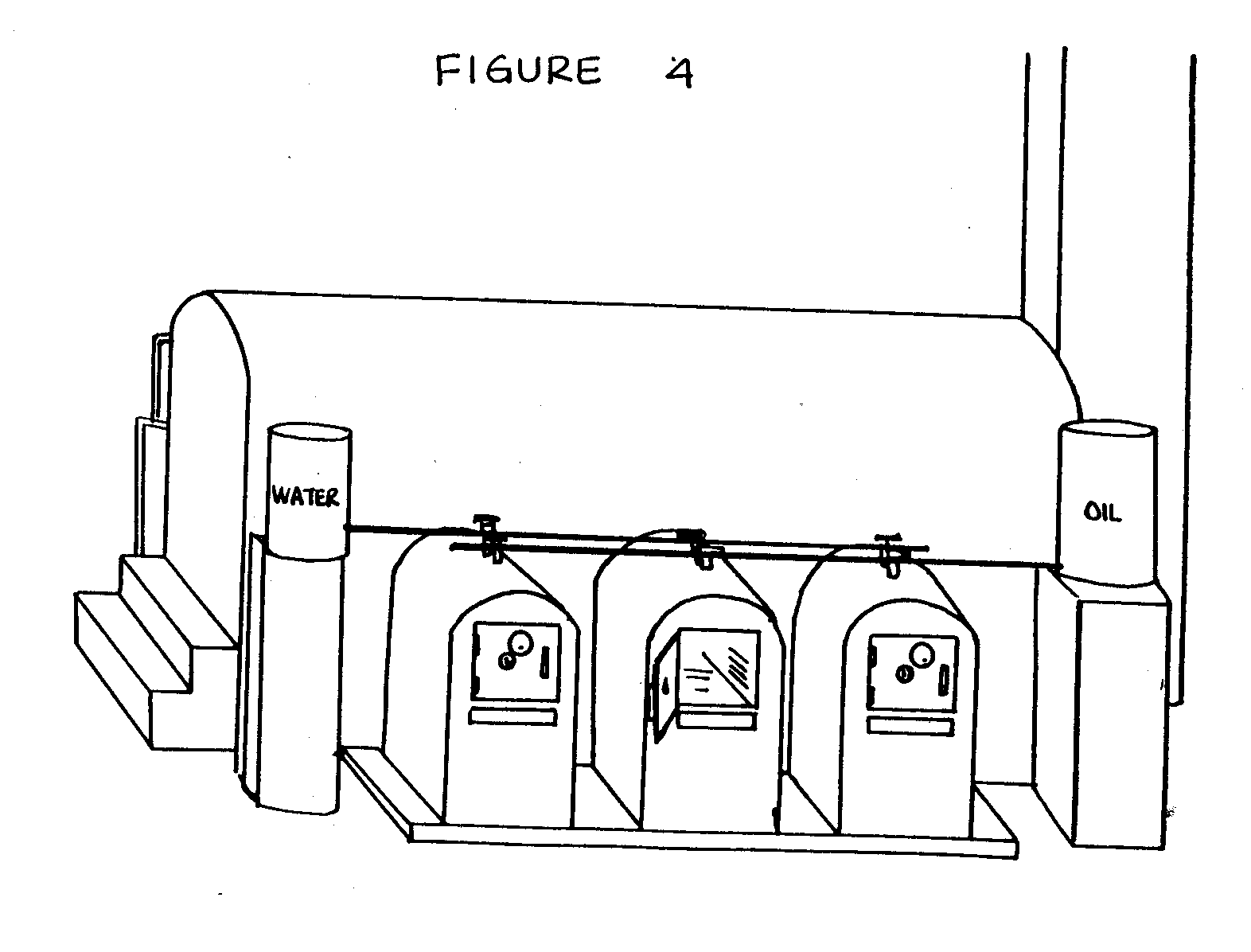

The kiln is a down draft type that normally would be fired by the more expensive process of injecting fuel oil under pressure to vaporize it in the firebox. The kiln has been modified to use waste oil (Figure 4). The modified kiln has three

fireboxes on each side. Each firebox contains three cast iron plates measuring 18 by 13 centimeters and slant mounted in stair-step fashion (Figure 2).

Each firebox has two doors. The larger top door is used for loading the wood or charcoal that is burned to preheat the metal plates. The smaller lower door acts as a damper to control the flow of air into the kiln. Careful operation of the lower door is very important. The kiln does not require a blower, as the draft through the lower door and out the chimney is sufficient.

A tank of water and a tank of waste oil are located on each side of the kiln. Tubes leading from the tanks have gate valves located above each of the fireboxes. The gate valves are adjusted during operation to allow a mixture of about 4/5 oil and 1/5 water to drip through a hole into the firebox. The oil-water mixture splashes off the hot iron plates, vaporizes, and ignites.

Firing The Kiln With Waste Oil

The firing of the kiln requires two men, one for the three burners on each side. The fireboxes are loaded with wood kindling through the large, upper doors and fires are started in all of the chambers. This heats up the iron splash-plates and starts a good draft. Openings at the top of the kiln let out the smoke and hot air until a draft is moving wall in the large chimney. Both the upper and lower doors on all the fireboxes are left open during this preheating of the kiln. After about half an hour the iron splash-plates are hot enough to vaporize the oil-water mixture. The vents on top of the kiln are closed with brick and clay, and the oil and water are turned on. The gate valves above each of the fireboxes are adjusted so that four drops of oil enter for each drop of water. The oil and water mix in a short metal trough, fall through a hole on the firebox top, and onto the splash-plates.

There is a sharp sizzling noise as the water is vaporized, and the oil bursts into a bright, wild flame that shoots toward the kiln with the increasingly strong draft. Proper adjustment of the oil and water flow requires frequent attention. The draft control doors on the fireboxes may also need to be checked frequently. The operators remain with the kiln all night, to be replaced by two more men in the morning. The burning rate is controlled so that the temperature inside rises at approximately 100[degrees]C per hour (so as not to crack the worked clay containers). The peak temperature is reached approximately 18 hours after the start of the firing. At this point all entrances, including a damper for the large chimney, are closed, the oil and water are turned off, and the kiln is allowed to cool slowly. Two firings a week is normal and each firing consumes approximately 300 liters of waste oil.

A Cook Stove

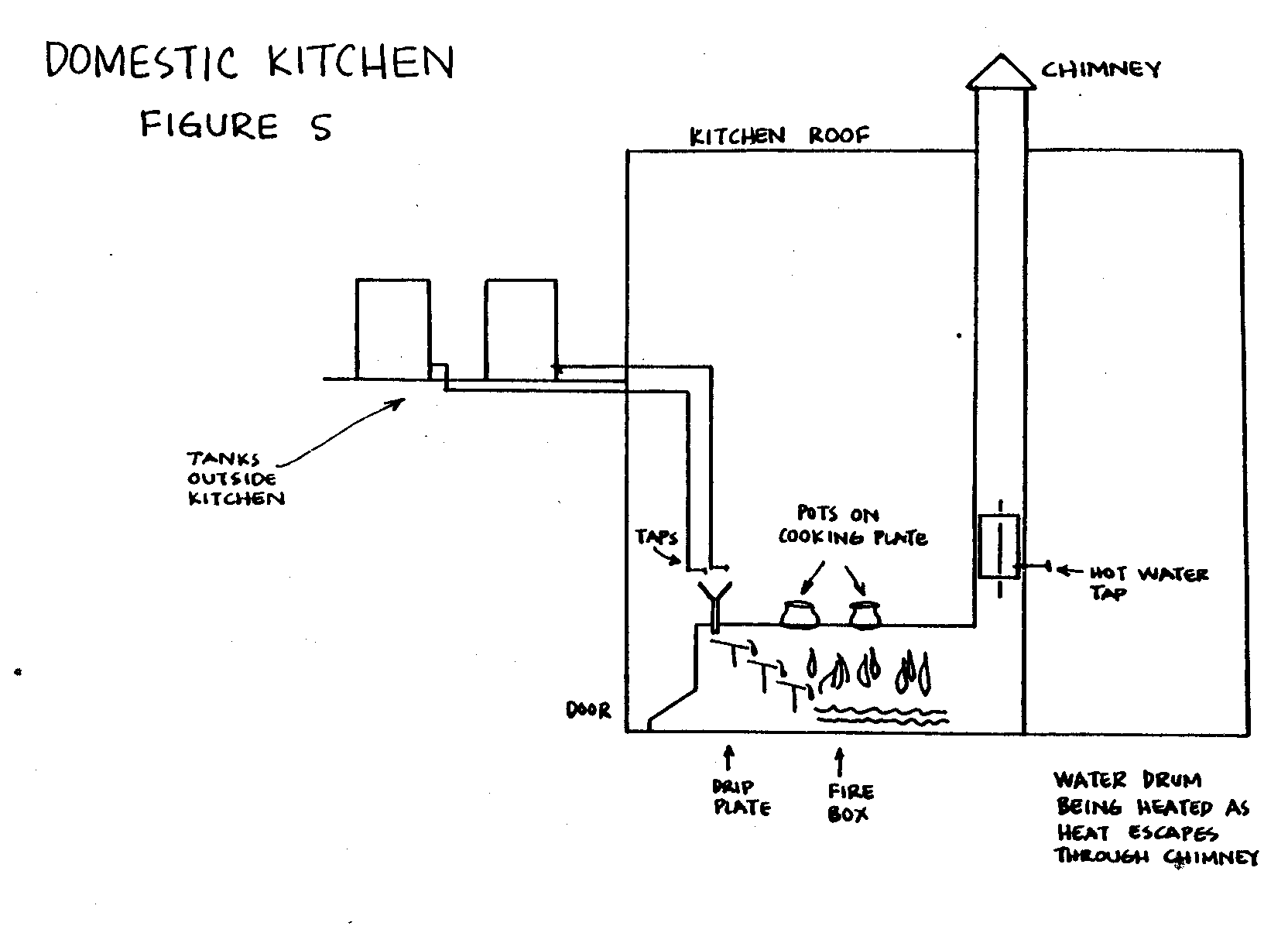

The waste oil-drip method has also been used for a domestic stove as shown in Figure 5.

An oversized brick box serves as the burner housing through which oil and water drip together onto the splash-plate inside. The flames then shoot through a narrow space underneath a 3/4-inch steel plate, which serves as the cooking surface. This plate measures approximately 0.75 x 1.0 meters. It supports large flat-bottomed cooking pots. Exhaust from the stove passes through a 13 centimeter diameter duct, welded through the inside of a 55-gallon metal drum. Water in the drum is heated to near-boiling by the exhaust gases. The hot water is used for washing in the dormitory next door to the kitchen.

VITA Technical Bulletin #51060 Waste Oil-Fired Oven, describes a different technique of burning waste oil to heat an oven for baking bread and other foods. VITA VOLUNTEERS IN TECHNICAL ASSISTANCE

ABOUT VITA

Volunteers in Technical Assistance (VITA) is a private, nonprofit, international development organization. Started in 1959 by a group of concerned scientists and engineers, VITA maintains an extensive documentation center and worldwide roster of volunteer technical experts. VITA makes available to individuals and groups in developing countries a variety of information and technical resources aimed at fostering self-sufficiency --needs assessment and program development support; by-mail and on-site consulting services; information systems training. It also publishes a quarterly newsletter and a variety of technical manuals and bulletins.