- Out-of-Season Vegetable Production in Bangladesh

- Mushroom Cultivation in the Tropics

- Before You Get Excited about Spice Production, Consider This

- Comments from Dr. Tony Lamb on Spices (and Other Topics)

- A New Rearing Method for Cochineal Insects

- Passion Fruit Project is Especially Successful in Puerto Rico

- A Small Canning Business Sealing in Metal Cans

- CECOCO Sells Equipment for Cottage Industries

- The Wood-Mizer Company Helps Christian Missions and Schools with Portable Sawmills

- Eden Valley Institute Offers Training in Organic Farming and Marketing

- Has Anyone Tried Making and Selling...?

OUT-OF-SEASON VEGETABLE PRODUCTION AND BANYAN LEAF POTS IN BANGLADESH. We have enjoyed our visits from Joshua Tsujimoto. Joshua retired early from a career as a commercial vegetable grower in New York to become an agricultural advisor in Bangladesh. Though he could think of some things that might increase yields, he faced a serious dilemma. Crops are planted near the end of the rains in the fall. Consequently, all growers come to market at the same time in the spring, causing a large surplus and forcing prices to unprofitable levels. If he helped them increase yields it would only cause an even greater oversupply.

His solution was to develop techniques to grow vegetables outside their normal season. Farmers who could come to market even a few weeks before or after the normal season would get premium prices and provide much-needed vegetables when they were not available to the population.

Joshua begins by making very high raised beds (about 1 foot or 30 cm) just before the rains begin. This ensures plenty of oxygen for the roots even during heavy rainfall. He mixes compost and organic material into the beds. Sloping drainage canals help carry water out of the fields. Then he constructs a "rain umbrella" or mini-greenhouse. This is a shelter made  from 1.25 cm (0.5 inch) thick bamboo hoops placed one meter apart on top of the bed and covered with a one meter wide sheet of clear polyethylene plastic. This protects the soil from puddling and erosion in the monsoon rains. The leaves of plants are also less susceptible to disease because they are not wet so much of the time. The mini-greenhouse allows farmers to grow their own seedlings, since the erosion and heavy pounding of the rains usually make it difficult to start seedlings.

from 1.25 cm (0.5 inch) thick bamboo hoops placed one meter apart on top of the bed and covered with a one meter wide sheet of clear polyethylene plastic. This protects the soil from puddling and erosion in the monsoon rains. The leaves of plants are also less susceptible to disease because they are not wet so much of the time. The mini-greenhouse allows farmers to grow their own seedlings, since the erosion and heavy pounding of the rains usually make it difficult to start seedlings.

The same structure also serves as a "sun umbrella" unless the plants get too large. "As tomato vines became too large under the plastic shelter, we began to train them to grow outside on top of the umbrella. Where the row was under a banyan tree the growth was still normal, but in the full sun the growing tips were stunted, with leaves curled and puckered and showing symptoms which everyone had assumed were caused by viral diseases. We now believe it is caused by the intense direct sunlight. We are planting leucaena trees 3 meters apart in both directions to provide shade. Until the leucaena trees are large enough to provide light shade, the plastic structures can be redesigned to handle larger plants." When they are new it may be necessary to make them more opaque by painting the underside with muddy water, but soon the intense sun will make the plastic itself sufficiently cloudy. Joshua has also grown Sesbanias (tolerant of waterlogged soils) in the drainage canals as green manures for the raised beds.

Growing Vegetables in Fiji by Kirk Dahlgren (available from ECHO) has a chapter on growing vegetables under plastic. The main work there has been with tomatoes, but there are many possibilities. "A wide variety of vegetables can be grown in the off-season. Heat-tolerant varieties of cauliflower form tight curds when protected from rain and direct sunlight. Heat-tolerant cabbage forms good heads under plastic. Lettuce forms large and relatively tight heads with no bitterness. French beans also grow well."

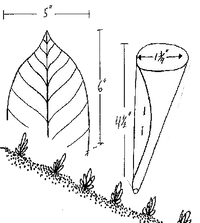

Joshua also makes seedling starting pots from banyan leaves. Root damage in transplanting can set plants back  considerably, especially in the intense tropical sun. The leaf seedling pots avoid disturbing the roots, and Joshua says that this one simple trick gives farmers a harvest about two weeks early. He uses a leaf from a banyan tree and curls it into the shape of an ice cream cone (see drawing). If you do not have banyan trees, you can find some local leaf that will give the same shape, perhaps after cutting with scissors. The outer flap is pinned into place with a short bamboo toothpick. The new pots should be nested into each other as they dry to remain perfectly round. (With a little practice a person can make 100 an hour. Sometimes people come to Joshua with financial needs that he wants to help, and he finds it convenient to pay them for making a few hundred of these pots.) When needed the pots are nearly filled with moist soil, leaving space to hold enough water to soak the soil when watering. The whole pot can be planted in the field. Be sure that the leaf is entirely covered with soil or it might act as a wick and pull moisture from the soil.

considerably, especially in the intense tropical sun. The leaf seedling pots avoid disturbing the roots, and Joshua says that this one simple trick gives farmers a harvest about two weeks early. He uses a leaf from a banyan tree and curls it into the shape of an ice cream cone (see drawing). If you do not have banyan trees, you can find some local leaf that will give the same shape, perhaps after cutting with scissors. The outer flap is pinned into place with a short bamboo toothpick. The new pots should be nested into each other as they dry to remain perfectly round. (With a little practice a person can make 100 an hour. Sometimes people come to Joshua with financial needs that he wants to help, and he finds it convenient to pay them for making a few hundred of these pots.) When needed the pots are nearly filled with moist soil, leaving space to hold enough water to soak the soil when watering. The whole pot can be planted in the field. Be sure that the leaf is entirely covered with soil or it might act as a wick and pull moisture from the soil.

MUSHROOM CULTIVATION IN THE TROPICS. Nigel Florida with CUSO in the Gambia wrote, "I see no reference in EDN to mushrooms. Is anyone in the ECHO network having success with mushroom cultivation on a small scale, village-based industry?"

Dr. Jason Yapp, Agricultural Services & Development Manager, Rural Development Corporation, in Malaysia wrote, "I would like to reply to Nigel Florida's inquiry. Our organization has been successful in introducing the cultivation of shiitake mushrooms to our target poor farmers (income less than M$500 [about US$200] per month). The elevation is 700-1500 m and night/day temperatures are 15 deg./30 deg.C. We have a central factory to pack, sterilize, and inoculate spawn. Currently we have over 250 contract farmers involved and are expanding to produce 10,000 bags per day. Our current efficiency is only 0.18 kg mushroom per 1.2 kg bag. Main problems are high contamination of the bags, high temperature and low humidity leading to small thin mushrooms (grade C). Trials are in progress to produce other lowland mushrooms." He sent us a 1-page leaflet on the production of shiitake mushrooms. If you want to correspond with Dr. Yapp, his address is Korporasi Pembangunan Desa, Beg Berkunci 86, 88998 Kota Kinabalu, Sabah, MALAYSIA.

We can heartily recommend the book Technical Guidelines for Mushroom Growing in the Tropics (155 pp.). This color-illustrated guide is a must for anyone contemplating such a project. (Overseas readers can order from the FAO, Distribution and Sales Section, Via delle Terme di Caracalla, 00100, Rome, ITALY, or through the FAO sales agent in your country. U.S. and Canadian readers can order for $20 plus postage from Unipub, 4611-F Assembly Drive, Lanham, MD 20706-4391, USA; phone 800/274-4888; fax 800/865-3450; e-mail query@kraus.com.)

Nutritionally, mushrooms contain more protein than leafy and root vegetables and fruits and rank high for vitamin content. Although devoid of vitamin A, mushrooms make up for this with their high riboflavin, thiamine and nicotinic acids. "Their content of the anti-pellagra vitamin, niacin, is nearly equal to levels found in pork or beef." They are also good sources of essential minerals such as calcium and phosphorous. Low in cholesterol and calories, mushrooms are often referred to as "slimming foods."

Mushrooms can be grown almost anywhere as long as the conditions for their growth and cultivation are provided. "Mushroom cultivation, however, is not a simple business. It involves a number of operations that must be coordinated. These include selection of a suitable ... culture of the mushroom, preparation of spawn and substrate, inoculation of the substrate, crop care, harvesting, preservation of the mushroom, and marketing. Introduction of a mushroom technology does not take place in a vacuum." In many successful mushroom growing regions, higher technology operations of preparing spawn and substrate are done by a central business with the specialized technology. This is then distributed to individual farmers.

Mushrooms can be grown almost anywhere as long as the conditions for their growth and cultivation are provided. "Mushroom cultivation, however, is not a simple business. It involves a number of operations that must be coordinated. These include selection of a suitable ... culture of the mushroom, preparation of spawn and substrate, inoculation of the substrate, crop care, harvesting, preservation of the mushroom, and marketing. Introduction of a mushroom technology does not take place in a vacuum." In many successful mushroom growing regions, higher technology operations of preparing spawn and substrate are done by a central business with the specialized technology. This is then distributed to individual farmers.

The book covers the following topics: introductory considerations, biology of the mushroom (life cycle, identification, poisonous mushrooms, genetics and breeding, food value), equipment of a mushroom laboratory, culture and media preparation, culture of the fungus, preservation of mycelium, growing techniques, environmental factors, cultural problems and solutions, major contaminants of mushroom culture, pest prevention, mushroom preservation and processing, and utilization of spent mushroom compost.

The type of substrate [growing medium] depends upon the species of mushroom. For example, the shiitake mushroom fruits on logs or sawdust; the straw mushroom on rice straw, banana leaves and other materials, whether composted or not; the button mushroom fruits only on composted substrates.

While mushroom growing may be possible and profitable in your location, it is going to take a lot of attention to detail to develop the techniques. People who have tried growing mushrooms at ECHO have had both complete failures and moderate successes. It does take some determination.

You may be fortunate enough to have someone in the community who already has perfected the techniques. Hopefully someone also sells spawn and perhaps medium. In that case, you would only need to pay attention to detail and do what you were taught. For example, those working in or near the Philippines can attend one of the workshops offered by one of the book's authors, Dr. Quimio, whose Quality Control and Training Center has offered training courses on mushroom farming specific to the type of mushroom and the technology desired. To inquire about the course (not to order the book) you may write to her at the Dept. of Plant Pathology, University of the Philippines at Los Banos College, Laguna, PHILIPPINES. (We were unable to contact her during 1995 at this address.)

The Ghana Export Promotion Council is attempting to make Ghana a major exporter of mushrooms. They are involved in production of pure spawn for mushroom growers and run three-week training courses for commercial growers. Write them at P.O. Box M146, Accra, GHANA. (Condensed from Spore, December 1992.)

A U.S. company with a free color brochure and an 80-page catalog ($3 plus $2.50 international postage) for mushroom growers worldwide is Fungi Perfecti, P.O. Box 7634, Olympia, WA 98507, USA; phone 800/780-9126; fax 206/426-9377; e-mail mycomedia@aol.com; http://www.halcyon.com/mycomed/fppage.html. They are "a complete resource for equipment, cultures, and technologies for growing mushrooms." Another source offering books, teaching videos, information, and supplies is Mushroompeople, Box 220, Summertown, TN 38483-4495; phone 800/386-4495 (also fax) or 615/964-2200.

BEFORE YOU GET EXCITED ABOUT SPICE PRODUCTION, CONSIDER  THIS. (Condensed from Spore, December 1992.) Perhaps growing up on a small farm in Ohio made me a cynic, but it seems that any farm product that is at all profitable will be overproduced within a few years. It is happening to spices.

THIS. (Condensed from Spore, December 1992.) Perhaps growing up on a small farm in Ohio made me a cynic, but it seems that any farm product that is at all profitable will be overproduced within a few years. It is happening to spices.

Three years ago black pepper sold for US$2,428 per ton. By mid-1992 it had fallen to $1,000. The price of cloves dropped from $5 per pound a decade ago to 80› (because Indonesia, which imported vast quantities to flavor cigarettes, now produces its own). In Madagascar, clove trees are being cut for firewood. Vanilla pods dropped from $74 per kg to $50. Madagascar had vanilla stocks at the end of 1990 equal to 2-3 years' total world consumption!

Are there any [temporary] bright spots? Markets for chili and paprika peppers remain strong and there is some room for growth. The market for cassia and cinnamon is steady because of their use in cola drinks. Allspice is in short supply and prices have risen. The use of spices which are used as a natural coloring (e.g. paprika and turmeric) may increase. Some spices, e.g. black pepper and vanilla, can be successfully intercropped. Black pepper grows well using coconut tree trunks as part of its support. "It is quite clear that 'Will it grow?' is not the first question to be asked. 'Will it sell?' is a better starting point."

COMMENTS FROM DR. TONY LAMB ON SPICES (AND OTHER TOPICS). Dr. Lamb of the Tenom Agriculture Experiment Station shared these interesting insights during a tour of Malaysia. (1) The standard ground cover mix used in rubber plantations is centrosema and pueraria. The latter does not produce seed in Malaysia, so must be imported. (2) Fruit consumption per person in Malaysia is going up a lot as people become more health-conscious. The result is a large increase in imports of temperate fruit. They are trying to improve the quality and diversity of locally grown fruit. (3) In choosing trees to provide shade crops, he prefers Leucaena leucocephala or L. diversifolia to Gliricidia sepium (sometimes called mother of cacao). L. diversifolia produces a lighter shade than gliricidia. A drawback to L. leucocephala is that it produces too many seedlings, but a sterile cross with L. diversifolia produces no seeds. However, it must be propagated asexually.

(4) Cloves bear in 6 years in Malaysia and bring a good price. Indonesia planted 200,000 hectares, now it is being wiped out by disease! (5) Cinnamon prices are very poor ($2 per kg), making this labor intensive crop economically feasible only where labor is exceptionally cheap. (6) Branch bores are a terrible problem with mangos. Even 3 inch branches fall off the tree. (7) We are interested in backyard fruit to reduce imports, e. g. using the jaboticaba tree as a substitute for grapes. [ECHO's jaboticaba tree is producing a bumper crop. We can send a few seeds to overseas readers. Trees take about 9 years to bear, and there are no short cuts. They must have plenty of moisture and acidity, so only order if this fits your situation.]

(8) According to a USDA publication, a fruit is considered to have been introduced when 20% of the population recognizes the fruit. (9) Farmers make $2,000-$2,400 per acre per year from mandarins, but must destroy the trees after about 6 years due to disease buildup. Each orange brings 20 cents. (10) Nutmeg trees are hard to start in a dry climate, but then they do well. All of his are female. Be cautious if you are thinking of starting a big nutmeg project. A single 300-acre farm could supply the entire world market.

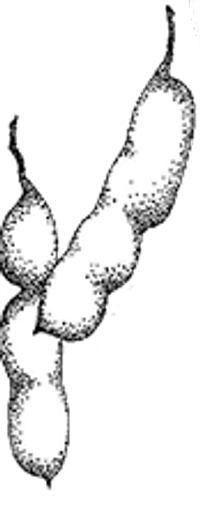

A NEW REARING METHOD FOR COCHINEAL INSECTS. The red dye, carmine, comes from the bodies of female cochineal insects, Dactylopius coccus. In Peru and the Canary Islands, these have for centuries been reared on prickly pear cactus plants, Opuntia ficus-indica. The insect can only survive on varieties of this plant. With use of synthetic dyes for human consumption coming under increasing criticism, the demand for natural dyes is increasing.

A NEW REARING METHOD FOR COCHINEAL INSECTS. The red dye, carmine, comes from the bodies of female cochineal insects, Dactylopius coccus. In Peru and the Canary Islands, these have for centuries been reared on prickly pear cactus plants, Opuntia ficus-indica. The insect can only survive on varieties of this plant. With use of synthetic dyes for human consumption coming under increasing criticism, the demand for natural dyes is increasing.

In parts of southern Africa there are large, aggressive wild stands of prickly pear, but rainfall patterns and intensity make it impossible to grow the insects on plants in the open. Any rainfall washes insects from the plants and they do not survive. A new rearing method allows them to make use of the vast supply of healthy plants, according to Economic Botany (vol 4, pp. 154-162, 1993). "Healthy, fully mature terminal [pads] are suspended from hooks inside large sheds (90 m2) after they have been seeded with crawlers (immature stages of the insect)." After three months in the summer to five months in winter, the mature females are harvested by placing the pad over a container and blowing compressed air over them. Some females are allowed to reproduce. All females are eventually dried at 60øC for 2 days before exportation.

"Preliminary estimates are that annual production of dried cochineal insects for a rearing unit of 90 m2 will be 75 kg. Based on a world price of US$40 per kg, this represents a gross income of US$3,000." They estimate that 3-4 rearing units could be maintained for every densely populated hectare of cactus."

This work was done by Dr. H. G. Zimmermann, director of the Plant Protection Research Institute in South Africa (Agricultural Research Council, Private Bag X134 Pretoria 0001, Republic of South Africa). He told ECHO that his research had to be stopped for lack of funding. The original research paper he sent us lists the following problems that still need to be solved. (1) 80% or more of immature crawlers are lost. (2) Optimum temperatures are not known. Also conditions leading to periodic excessive decay of pads are unknown. (3) Contamination of the insect population by D. opuntiae can be a problem. (This insect was brought into South Africa as a biological control of prickly pear cactus.)

PASSION FRUIT PROJECT IS ESPECIALLY SUCCESSFUL IN PUERTO RICO. George Gaskins initiated a cooperative venture among small farmers in the mountains south of San Juan in the late 1970s. They purchased used processing  equipment from Hawaii and began selling passion fruit juice. One key to their success was careful advance marketing work. Another key was crosses they made between local passion fruit varieties and varieties from Hawaii and South America. Farmers are now earning $3,000 per year per acre of steeply sloped mountain land! When I visited I asked whether he could help small farmers around the Caribbean by purchasing fruit from them. He writes, "I have been pondering that issue for some time. I may suggest that we can buy and process tamarind. This fruit is probably abundantly wild in most of the Caribbean and can ship well.... We would be able to buy this 'pulp' in quantities. ...This may work out for other fruits and/or

equipment from Hawaii and began selling passion fruit juice. One key to their success was careful advance marketing work. Another key was crosses they made between local passion fruit varieties and varieties from Hawaii and South America. Farmers are now earning $3,000 per year per acre of steeply sloped mountain land! When I visited I asked whether he could help small farmers around the Caribbean by purchasing fruit from them. He writes, "I have been pondering that issue for some time. I may suggest that we can buy and process tamarind. This fruit is probably abundantly wild in most of the Caribbean and can ship well.... We would be able to buy this 'pulp' in quantities. ...This may work out for other fruits and/or  products as well."

products as well."

The Wall Street Journal did a story on this project in 1985. "Starting from nothing in 1976, Puerto Rico now produces more than 3,000 tons of passion fruit a year. Two dozen new juices and drinks have come out using the juice. The industry's annual sales are estimated at $10 million and rising."

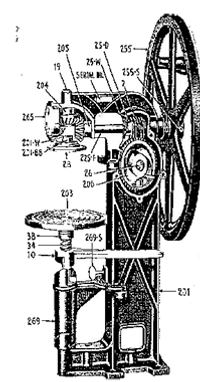

A SMALL CANNING BUSINESS SEALING IN METAL CANS. Don Mansfield in Mali wrote that he knew of household businesses among Eskimos in Alaska in which fish were canned in tin cans. It is of course simpler to preserve food in glass jars. This is fine for home use where the jars can be recycled, but may make competition in the marketplace impossible. Don mentioned the Wisconsin Aluminum Foundry Co. as the source of the equipment so we contacted them. You may have a local source for such equipment, but we provide this information for those who do not. If you wish to follow up on this discussion, you can write Attn: Philip Jacobs, P.O. Box 246, Manitowoc, Wisconsin 54221, USA; phone 414/682-8627; fax -4090.

Mr. Philip Jacobs responded with helpful literature, but no details of small-scale operations in the third world. When asked, he said he knew that they were used that way, but would not disclose any specifics. Although they do not actively court such business, he will be happy to quote prices to any of our readers. They are willing to sell in units as small as one, but be sure to specify how many you are interested in purchasing to receive the quantity price. He will then send a pro-forma invoice. The Master Can Sealers cost US$299-1295; Senior Can Sealers (with Fly Wheel, pictured) are $895-1995.

Mr. Philip Jacobs responded with helpful literature, but no details of small-scale operations in the third world. When asked, he said he knew that they were used that way, but would not disclose any specifics. Although they do not actively court such business, he will be happy to quote prices to any of our readers. They are willing to sell in units as small as one, but be sure to specify how many you are interested in purchasing to receive the quantity price. He will then send a pro-forma invoice. The Master Can Sealers cost US$299-1295; Senior Can Sealers (with Fly Wheel, pictured) are $895-1995.

Hand operated can sealers indeed cost less than I would have expected. Their "Automatic Master Sealer" ($299) is equipped to seal can sizes 1,2,2 1/2, and 3 (half pint, pint, 30-ounce and quart). (The price includes equipment only for #2. It is not clear what that equipment is, but hopefully it is a rather inexpensive adaptor.) Their "Senior Automatic Sealer" ($895) will seal sizes 10 and 12 (4 and 5 quarts) as well as the smaller ones if you have the right equipment (adaptor?). They also have other models, some with motors. The company also has a line of aluminum pressure cookers with large capacity that appear to be heavy-duty equipment. They use a metal-to-metal seal, so you would not have problems replacing gaskets. Ask about those too, when you write.

Another source of hand-operated can sealers is Ives-Way Products, 2030 North Nicole, Round Lake Beach, IL 60073, USA; phone 847/740-0658. Prices look very reasonable: $115-495. They sent us some very helpful information and a catalog  illustrating their models which "offer many choices in can sizes for fruit, vegetable, meat, poultry, and fish canning. The same basic sealer is used for all models. The required chucks, spacers, and extensions are furnished with each model to adapt the basic sealer to the can sizes shown. The durability...has been proven by over forty years of consumer use. Complete operating instructions and recipes are included with each sealer." They explained the standard naming of can sizes: "Each dimension is expressed as a three-digit number. The first digit gives the number of whole inches, while the next two give the additional fraction of the dimension expressed as sixteenths of an inch. The first number given in the size of each can is the diameter, and the second number is the height. For example, the 303x406 can is 3-3/16" diameter x 4-6/16" high." Dimensions are "overall," including the entire seams. Ives-Way does not carry pressure canners, gauges, or other canning equipment.

illustrating their models which "offer many choices in can sizes for fruit, vegetable, meat, poultry, and fish canning. The same basic sealer is used for all models. The required chucks, spacers, and extensions are furnished with each model to adapt the basic sealer to the can sizes shown. The durability...has been proven by over forty years of consumer use. Complete operating instructions and recipes are included with each sealer." They explained the standard naming of can sizes: "Each dimension is expressed as a three-digit number. The first digit gives the number of whole inches, while the next two give the additional fraction of the dimension expressed as sixteenths of an inch. The first number given in the size of each can is the diameter, and the second number is the height. For example, the 303x406 can is 3-3/16" diameter x 4-6/16" high." Dimensions are "overall," including the entire seams. Ives-Way does not carry pressure canners, gauges, or other canning equipment.

Mr. Jacobs mentioned two free mimeographed bulletins that are exceptionally practical and thorough. "Home Preservation of Fishery Products" (22 pp.) and "Home Canning of Fishery Products" (44 pp.) are both available from the U.S. Dept. of the Interior, U.S. Fish and Wildlife Service, Bureau of Commercial Fisheries, Washington, D.C. 20240, USA. The former discusses preservation methods other than canning: corning, brine salting, dry salting, drying, smoking, pickling. The latter discusses canning with detailed discussions for specific fish and shellfish. For example, the author points out that if tin cans are to be used with fish or shellfish, the cans should be lined with "C" enamel, unless vinegar is added. The reason is that fish and shellfish liberate sulfide compounds when heated to high temperatures. This causes a discoloration of the inside of plain tin cans than can be transferred to the food. Because of thinner walls and greater ability to conduct heat, tin cans require a shorter cooking time than glass, and cool more rapidly. You might also wish to obtain "Home Canning of Meat and Poultry", Home and Garden Bulletin #106, free from the Office of Govt. and Public Affairs, USDA, Washington, DC 20250, USA. By the way, the latter says that plain tin cans should be used for canning meats, rather than C-enamel, R-enamel and sanitary-enamel. Fat in meat or poultry causes the enamel to peel off inside the can, making it appear unappetizing (though not harmful).

If you have had experience with small-scale commercial canneries I would appreciate hearing as many details as you have time to write. It is a subject of interest to many. I am interested in both technical details and a perspective on the potential of canning for small businesses based on your own experience.

CECOCO SELLS EQUIPMENT FOR COTTAGE INDUSTRIES. There is great potential for small scale industries in the third world, both to generate employment and to reduce the need for imports. The CECOCO company in Japan has a fascinating array of machinery for rural cottage and small and medium scale industries. When you write for information you are sent a few sheets of prices and short descriptions. To really understand what is available and, especially, to make decisions about purchase you should see their 160-page catalog (we got it in 1985 for US$20). I have not personally seen any of their equipment, but it sounds great. To give you an idea, let me share some items as I leaf through the catalog. Their address is CECOCO, P.O. Box 8, Ibaraki City, Osaka 567, JAPAN.

With their equipment you could make any of these products: tooth picks, wooden ice cream spoons, paper clips, hair pins, safety pins, snap buttons, wire, barbed wire, window screen, nails, screws, nuts, bolts, springs, chains, zippers, chalk, paper boxes, tapioca and potato starch, rope and straw mats. The section on rice begins with hand and foot operated equipment (thresher, winnower, two-man hand huller, paddy separator, and polisher) followed by quite a variety of power machinery.  Other food processing sections include flour milling, noodle machine, oil expeller, bakery equipment, coffee pulping, roasting and milling equipment, power and hand sugar cane squeezers, all kinds of equipment to handle fish for food or fish meal. Then there is cotton processing machinery, a wide variety of pumps, all kinds of mills for feeds, egg incubators, peanut roaster, peanut butter machine, rice straw softener, small and medium scale saw mills, equipment for tilling fields, printing presses, basic manpower units to drive other machines, many coconut husk processing machines, pulverizers and grinders, and cane processing machines. Happy shopping!

Other food processing sections include flour milling, noodle machine, oil expeller, bakery equipment, coffee pulping, roasting and milling equipment, power and hand sugar cane squeezers, all kinds of equipment to handle fish for food or fish meal. Then there is cotton processing machinery, a wide variety of pumps, all kinds of mills for feeds, egg incubators, peanut roaster, peanut butter machine, rice straw softener, small and medium scale saw mills, equipment for tilling fields, printing presses, basic manpower units to drive other machines, many coconut husk processing machines, pulverizers and grinders, and cane processing machines. Happy shopping!

THE WOOD-MIZER COMPANY HELPS CHRISTIAN MISSIONS AND SCHOOLS WITH PORTABLE SAWMILLS. In some parts of the world lumber is most expensive where trees are most abundant--in remote forested sites. Since these remote locations do not have processing equipment, logs are hauled away and lumber is hauled back.

For twelve years the Wood-Mizer Sawmill Company has helped missionaries and organized local Christian ministries who need wood for building schools and churches by donating half of the cost of a portable sawmill. They also like to see the local people reap more of the benefits from their own trees. One example is Pacific Island Ministries in Papua New Guinea (PNG). This mission, which has a school in a remote area, intends to establish a sawmill in each nearby village so they can produce their own lumber. These small sawmills can produce 500-800 board feet per day. The mission will buy some lumber from them for school construction, and the communities will market the rest.

The project began when the mission learned that Japanese businessmen had met with the community leaders. The missionary realized that if each community had a sawmill, it could easily make 10 times what the foreign companies were offering. And since the local people cherish their forest, they want to cut on a selected basis rather than clear-cut.

In another PNG community, Beechwood Ltd. bought logs as cheaply as 5 cents per board foot for sale within the country. They still went out of business because of the high cost of transporting logs out of the remote area. With a portable sawmill, people do not move the sawdust, water and slabs, but only dried lumber. Wood has two kinds of water, free and bound. Free water between the wood cells is 80-90% removed by a week or two of air drying. (A typical rain forest tree is 60-80% water, but the water content of air-dried boards is about 20%.) Bound or intracellular water is harder to remove, but this extra drying step, accomplished with solar kilns or other methods, can significantly increase the value of the lumber.

"Value added" is the key concept. The sawmills enable people to sell boards rather than rough logs, and well-dried boards bring an even better price. For this reason, solar kilns are also part of Wood-Mizer's donations program where appropriate (two 1500-board-ft kilns may be needed with each sawmill). For example, the cheapest sawn lumber might be worth 80 cents-$1 per (air-dried) board foot when sold in country. Exotic species roughly sawn (not dried) might only bring 25 cents, but may sell for at least $2-4 per board foot after solar kiln drying. At these prices, solar kiln-dried exotic species could even be profitably flown out of the area for export.

There are other situations where a lumber project could fit the goals of a development organization. Darryl Mortensen in Mexico wrote us this summer that a field survey by AMEXTRA, a Mexican developmentorganization, turned up some incredible statistics. He writes, "200,000 trees have been ordered for the reforestation program in Chiapas. Many trees have been cut down ... to clear land for planting. A recent survey showed that there is salable lumber in logs that are just lying on farmland which farmers want to clear for crops. AMEXTRA is looking into ways to market this lumber rather than burning it, as there is sometimes more than $500 worth of lumber on a single farm which would be more income for the farmer than 2-3 years of planting corn." A portable sawmill may be used in this situation.

Envision the following scene. Fell a tall tree. After removing the branches, cut the tree into logs of the desired length, so the cut logs remain end-to-end. Carry the sawmill to the site and set up beside the first log. This 10-minute set-up involves fastening the mill to skids 10-12 feet (3-3.6 meters) long to give it stability. Two to three people roll the first log onto the mill with cant hooks. As soon as this log is sawn into lumber, slide the mill along the length of the tree to the second log. Repeat the process until the entire tree is sawn. If the log is on a hillside, place blocks under the mill to make it level before sawing. Stack the boards criss-crossed (X) against a strong tree for 10-12 days to air-dry before carrying them out of the area, perhaps to the site of the solar kiln.

Envision the following scene. Fell a tall tree. After removing the branches, cut the tree into logs of the desired length, so the cut logs remain end-to-end. Carry the sawmill to the site and set up beside the first log. This 10-minute set-up involves fastening the mill to skids 10-12 feet (3-3.6 meters) long to give it stability. Two to three people roll the first log onto the mill with cant hooks. As soon as this log is sawn into lumber, slide the mill along the length of the tree to the second log. Repeat the process until the entire tree is sawn. If the log is on a hillside, place blocks under the mill to make it level before sawing. Stack the boards criss-crossed (X) against a strong tree for 10-12 days to air-dry before carrying them out of the area, perhaps to the site of the solar kiln.

How portable is the sawmill? Wood-Mizer makes many models of portable sawmills, any of which can be transported where there is a road. For really difficult sites, they recommend the LT20 (see photo), a model that is no longer produced, but which the company occasionally takes in on trades. It can be dismantled and put in the back of a truck in 10 minutes. The heaviest piece is 67 pounds. Twelve people can carry the sawmill and accessories into off-road sites; some have been carried as far as 15 miles.

"One of our questions before giving a sawmill is whether they know the local Forestry Department people. We require that recipients replant trees at a ratio of 100:1. Any Wood-Mizer sawmill and future parts and supplies are available at a 50% discount. Any non-profit organization actively involved in meeting human need may apply. Christian missions in developing countries are given priority. Decisive factors are the organization's goals and prospects for long-term use." The first step is to write Wood-Mizer to explain your program and how the sawmill would fit into it. If this meets the company's criteria, you will be sent a formal application. It could be three months to four years before you get the mill, depending on the waiting list. Even if you do not meet their donation criteria, any licensed, accredited educational institution can receive a 25% discount.

Glen Munro is the coordinator of the sawmill donations. You can write him at Wood-Mizer, 8180 West Tenth Street, Indianapolis, IN 46214-2400, USA; phone 800/553-0182 or 317/271-1542; fax 317/273-1011.

EDEN VALLEY INSTITUTE OFFERS TRAINING IN ORGANIC FARMING AND MARKETING. We enjoyed getting to know farm director Joel Meyer when he spent some days using ECHO's library. The school farm specializes in small farm operation for schools, missions and family-based market gardening. They offer a course "designed especially for small farm management, with emphasis on food production for schools and market gardening through an apprenticeship experience for one full growing season. Classroom instruction and field application are blended together. The course trains individuals in the science of biological gardening so they are prepared to instruct others." The program is run by and for Seventh-Day Adventists, but is open to all Christians interested in agricultural missions (US or overseas). The main focus is commercial-scale, hands-on organic and vegetarian market gardening.

EDEN VALLEY INSTITUTE OFFERS TRAINING IN ORGANIC FARMING AND MARKETING. We enjoyed getting to know farm director Joel Meyer when he spent some days using ECHO's library. The school farm specializes in small farm operation for schools, missions and family-based market gardening. They offer a course "designed especially for small farm management, with emphasis on food production for schools and market gardening through an apprenticeship experience for one full growing season. Classroom instruction and field application are blended together. The course trains individuals in the science of biological gardening so they are prepared to instruct others." The program is run by and for Seventh-Day Adventists, but is open to all Christians interested in agricultural missions (US or overseas). The main focus is commercial-scale, hands-on organic and vegetarian market gardening.

The course outline includes: A philosophy of agriculture and medical missionary work; Biblical principles in nature and  agriculture; practical Christianity; biological crop management; food preservation and storage; agriculture equipment and maintenance; energy efficient greenhouse design and operation; fruit culture; methods of crop marketing. This course usually runs mid-January through mid-October and costs about $1850, including room and board.

agriculture; practical Christianity; biological crop management; food preservation and storage; agriculture equipment and maintenance; energy efficient greenhouse design and operation; fruit culture; methods of crop marketing. This course usually runs mid-January through mid-October and costs about $1850, including room and board.

In December they offer an intensive seminar "for the serious gardener or commercial producer" on various topics, which in the past have included participatory food production and balancing soil fertility. (The 5-day course costs $325 including room and board.) Contact Steve Meyer or Paul Kidney for more information at 6263 North County Road 29, Loveland, CO 80538-9598, USA; phone 303/667-9225.

HAS ANYONE TRIED MAKING AND SELLING...? We always appreciate letters from our network which give details of how people in your community have found ways to process and market their products in new ways. ECHO sometimes receives requests for help evaluating the market potential of some crop, product, or industry in an area. While we cannot address that from our office, you should know that several publishers have many case studies on marketing and microenterprise which may be of interest to you. Consult the NRI, IT, IIRR, and GTZ catalogs reviewed in this book for a wide selection of resources. (Some in our library include: Traditional Candlemaking and Making Wheels from IT; Microenterprise Development in the Philippines from IIRR; and one in Spanish on small garbage collection businesses, sponsored by GTZ.) The catalogs of FAO (Viale delle Terme di Caracalla, 00100 Rome, ITALY) and UNIPUB (4611-F Assembly Drive, Lanham, MD 20706; phone 800/274-4888; fax 800/865-3450; e-mail query@kraus.com) have many economic development resources.