Soap is an essential cleaning agent, helping people to keep themselves and their surroundings clean. When soap is mixed with water, it forms a lather that washes out dirt and grease far better than water alone.

Soap can be made on a small scale in the home or village cheaply and easily. The main ingredients are fats and lye, both of which can be made from materials found throughout the world. Making soap at home is practical when there is waste fat or oil and when there is no cheap source of soap.

TWO BASIC METHODS

The two basic methods for small-scale soap making are:

Method 1. With commercial lye: This method is used when commercially-prepared lye or caustic soda (sodium hydroxide crystals) is available.

Method 2. With lye leached from ashes (potash): This method is patterned after a process used by early settlers of North America.

The first method, soap-making with commercial lye, is recommended because it is simpler and more reliable.

INGREDIENTS FOR SOAP

Fats and Oils

Soap can be made from either animal fat or vegetable oil. Mineral oil cannot be used. Animal fats commonly used are tallow, mutton, and lard. Vegetable oils used include coconut, palm nut, maize, olive, cottonseed, soybean, groundnut, safflower, and castor. Chicken fat, which is not a hard fat, is considered an oil. The best soap is made from a mixture of fat and oil.

- If you want a hard soap for use in hot water, use only tallow, made from melting rendered sheep, cattle, or horse fat.

- If you want a good laundry soap, use 1 part tallow to 1 part lard or cooking grease from melted hog fat, skin, and bones.

- If you want a fine toilet soap, use 1 part tallow to 1 part vegetable oil.

The best vegetable oils are made from crushing dried coconut meat, palm nut kernels, or the outer pulp of the palm nut. The last makes a harder soap than the coconut meat or kernels.

Lye

Either commercially-prepared lye, also called caustic soda or sodium hydroxide (NaOH) crystals, or lye leached from ashes, called potash, can be used. Caustic soda is cheap and is sold in the markets of most countries.

* * * CAUTION * * *

Lye is a corrosive poison. It can cause serious burns. Do not let the lye crystals, dust, or solution touch your skin. Wear rubber gloves and protective eye wear. If any crystals do touch your skin, wash with water and then with a vinegar solution. If any of them are swallowed, take as much vinegar, citrus juice, or rhubarb as possible and call a doctor.

* * * KEEP LYE AWAY FROM CHILDREN * * *

Borax

Borax is not necessary for making soap, but it improves the soap's appearance and increases the amount of suds produced.

Perfume

Artificial perfumes or essential oils are not necessary ingredients but they can be used to make a more pleasant soap, particularly if rancid fat is used. If soap is made from tallow, citrus oil or juice will improve its smell and help preserve it.

Water

The best water to use is soft water. Water that is not too hard can be used, but if it is very hard it is best to soften it. Hard water contains mineral salts that hinder the cleansing action of soap. To soften hard water: Add 15ml (1 tablespoon) of lye to 3.8 liters (1 gallon) of hard water, stirring the water as it is added. Let the mixture stand for several days. Pour off the water from the top. This is the soft water for soap making. The water and particle mixture at the bottom of the container can be thrown away. Soft water can also be obtained by collecting rain water.

SOAP MAKING WITH COMMERCIAL LYE

The directions given here will make 4.1kg (9 pounds) of good quality soap. But the amount can be changed as long as the techniques and proportions are followed.

Equipment and Materials

Bowls, buckets, pots, or tubs made of enamel, iron, or clay. Never use aluminum; lye destroys it.

Measuring cups of glass or enamel.

Wood or enamel spoons, paddles, or smooth sticks for stirring.

Wood, cardboard, or waxed containers for molding soap. The molds can be of any size but those that are 5cm to 7.5cm (2" to 3") deep are best. Gourds or coconut shells can also be used for molds.

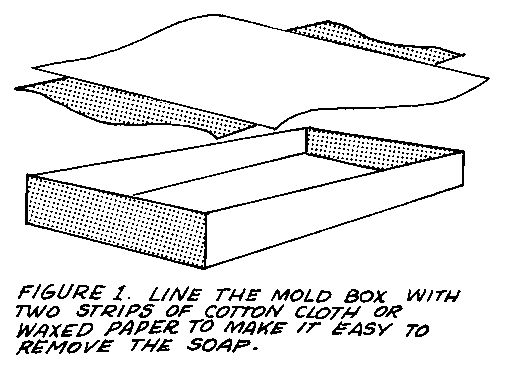

Cotton cloth or waxed paper for lining the molds. Cut the cloth or paper into two strips: one should be a little wider than the mold and the other should be a little longer. This lining will make it easier to remove the soap from the molds.

A thermometer that ranges from -18 [degrees] to 65 [degrees] C (0[degree] to 150[degrees]F) is helpful, but not necessary.

Recipes

For 4.1kg (9 pounds) of soap:

Oil or clean, hard fat: 13 cups (3 liters) or 2.75kg (6 pounds) Borax (optional): 57ml (1/4 cup) Lye (sodium hydroxide crystals): 370g (13 ounces) Water: 1.2 liters (5 cups)(*) Perfume (optional), use one of the following; Oil of sassafras: 20m] (4 teaspoons) Oil of wintergreen: 10ml (2 teaspoons) Oil of citronella: 10ml (2 teaspoons) Oil of lavender: 10ml (2 teaspoons) Oil of cloves: 5ml (1 teaspoon) Oil of lemon: 5ml (1 teaspoon)

(*) Note: Some experienced soap makers prefer to use twice this amount of water (i.e., 10 cups) and to boil the solution for three hours. Your own experience and the amount of water and fuel you have available are your best guide.

For one bar of soap:

Oil or clean, hard fat: 230ml (1 cup) Borax (optional): 5ml (1 teaspoon) Lye (sodium hydroxide crystals): 23.5g (5 teaspoons) Water: 115ml (1/2 cup) Perfume (optional): a few drops

How to Make the Soap

The fat used in making the soap should be clarified. To do this: put the fat in a kettle with an equal amount of water; boil this mixture. Remove the kettle from the fire and strain the mixture through a sieve or a piece of cheesecloth. Add 1 part cold water to 4 parts of hot liquid. Do not stir the mixture; let it stand until it cools. The clarified fat can then be removed from the top. To help in cleaning the fat, a sliced unpared potato can be added before the mixture is boiled.

Measure carefully the amount of fat required and melt it down in the kettle to be used for soap making.

Measure the amount of water required.

Measure the lye required.

To the water previously measured slowly add the measured lye. For safety always add the lye to the water, never add water to lye. The resulting solution will become very hot and may spatter. Cool the lye mixture down to a body temperature. To test when the solution has reached body temperature, place your hand under the vessel holding the lye solution: there should be no noticeable difference between the temperature of your hand and that of the vessel. DO NOT PUT YOUR FINGER IN THE SOLUTION.

Cool the melted fat to body temperature. If borax is used, add it to the fat when it has cooled.

Then add the lye mixture to the melted fat. The lye mixture should be poured into the fat very slowly in a small stream. As this is being done the whole mixture is stirred slowly and evenly in one direction. After the lye solution is added, the mixture is stirred until the spoon makes a track. This usually takes about 30 minutes. After this let the mixture stand, stirring it once or twice every 15 or 20 minutes for several hours. When the mixture is very thick and honey-like in consistency, pour it into the molds lined with cloth or waxed paper (see Figure 1).

Cover the mold and let it set for 48 hours. Keep it dry and at room temperature. If it is moved or struck while it is setting, the ingredients may separate.

At the end of this period, the soap should be firm and can be removed from the mold. If it is not firm, let it set longer until it is.

If grease is visible on the top of the soap at the end of the 48-hour curing period, the soap should stand a while longer. If there is liquid at the bottom of the box, cut the soap into bars and let them stand a day or two to see if the liquid will be absorbed.

How to Know Good Soap

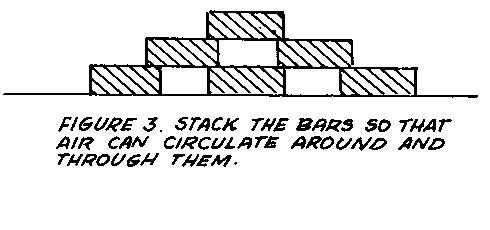

The soap should be hard, white, clean smelling, and almost tasteless. It should shave from the bar in a curl (see Figure 4). It should not be greasy or taste harsh when touched by the tongue.

Reclaiming Unsatisfactory Soap

If some of the ingredients are still separated after this curing period, if the soap is curdled or grainy, or if you want a finer, smoother soap, do this:

Cut the soap into small pieces and put it into a pot with 2.8 liters (12 cups) of water and any liquid left in the molding box. Avoid touching the soap with your hands by wearing rubber gloves if possible, as there may be some free lye on the surfaces of the pieces of soap.

Bring it slowly to a boil and boil for 10 minutes, stirring occasionally. If you wish, you can add 10ml (2 teaspoons) of wintergreen, lemon, or other oil at this stage for perfume. Pour into a mold box, let stand 48 hours, and follow the procedure below.

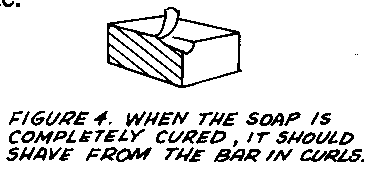

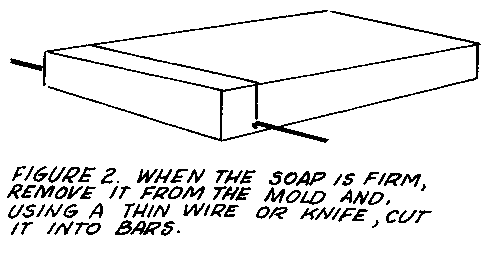

Empty the soap from the box and cut it into bars with a string or wire (see Figure 2). Place the bars in an open stack so that air can circulate around and

through them (see Figure 3). Leave them in a warm, dry place for 2 to 4 weeks.

References:

Bramson, Ann, Soap. New York.: Workman Publishing Co., 1975

Donkor, Peter, Small-Scale Soapmaking. London: Intermediate Technology Development Group, 1986

Francioni, J.B. and Collings, M.L. Soap Making. Extension circular 246. Baton Rouge, Louisiana: Louisiana State University, 1943

Making Soaps and Candles. Pownal, Vermont: P.H. Storey Communications Inc., 1973.

SOFT SOAP WITH LYE LEACHED FROM ASHES

This method, patterned after one used by the early settlers of North America, produces soft soap by combining fat and potash (lye obtained by leaching wood or plant ashes.) The recipe has been tried successfully with waste cooking grease, olive oil, peanut oil, and cocoa butter.

Leaching the Lye

Tools and Ingredients

Several medium sized rocks A flat stone with a groove and a run-off lip chipped into it. 19-liter (5-gallon) wooden bucket with several small holes in the bottom. A hollowed log with the same capacity can be used. Collection vessels for the lye. These should be made of iron, steel, enamel, or clay. An aluminum vessel should not be used, since lye would corrode it. Small twigs, straw 19 liters (5 gallons) of wood ashes. The ashes may be from all types of woods. Ashes from hardwoods yield the best lye, but ashes from the burning of plants and leaves of trees may be used (see Table 1). Ashes of burnt seaweed are particularly useful as these produce a sodium-based lye from which hard soap can be made. Lye leached from the ashes of plant life (excepting seaweed) is potash or potassium carbonate ([K.sub.2][CO.sub.3]), an alkali. This alkali reacts with fat to form soft soap. Ashes from other materials such as paper, cloth, or garbage cannot be used.

7.6 liters (2 gallons) of soft or medium-hard water.

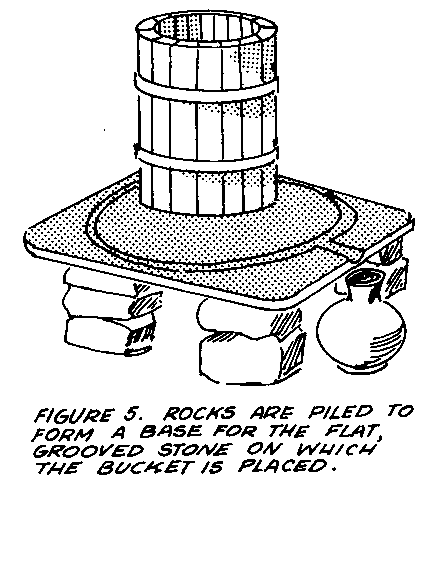

Pile the rocks so that the flat, grooved stone rests evenly on top (see Figure 5). Set the wooden bucket on this stone.

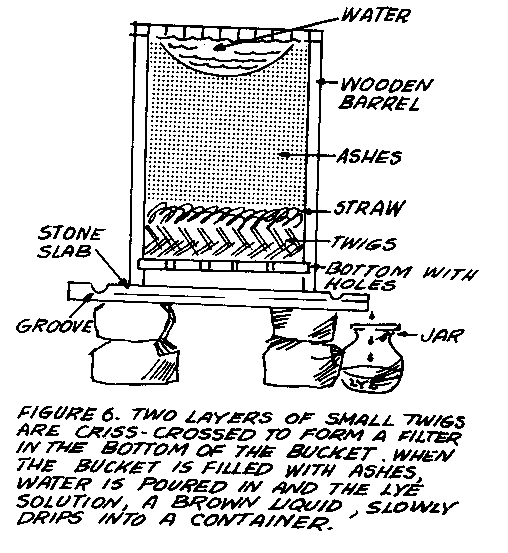

In the bottom of the bucket, make a filter to trap the ashes by crisscrossing two layers of small twigs and placing a layer of straw on top (see Figure 6).

Fill the bucket with dry ashes. To keep the lye from being leached accidentally, the ashes must be kept dry before they are used.

Pour warm water into the bucket, making the ashes moist and sticky. To make sure that the water passes through the ashes at the correct rate for leaching the lye, move the ashes up at the sides of the bucket to form a depression in the center.

Add all the remaining water in small amounts in the following manner: Fill the center depression with water; let the water be absorbed; fill the depression again. When about two-thirds of the water has been added, the lye or potash, a brown liquid, will start to flow from the bottom of the bucket. Use more water, if necessary, to start this flow. The lye flows over the flat stone into the groove and then into the collection vessel below the run-off lip. It takes about an hour to start the flow of lye.

The yield from the amounts given here is about 1.8 liter (7 3/4 cups) lye. The results vary according to the amount of water loss from evaporation and the kind of ashes used.

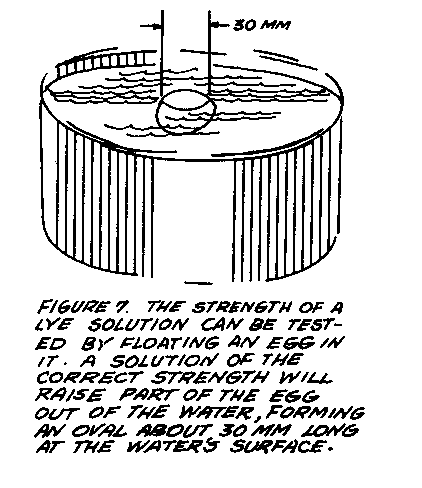

If the lye is of the correct strength, an egg or potato should float in it. A chicken feather dipped in the solution should be coated, but not eaten away. If the solution is weak, pour it through the barrel again, or through a new barrel of ashes, or concentrate it by boiling. Thirty-five liters of ashes is about the right amount for 2 kilograms of fat (a bushel of ashes for 4 pounds of fat). This proportion is cited in soap-making recipes of the colonial period in the United States, but many of the recipes of that era differ on the proportion of ashes to fat.

Here is a list of tropical plants whose leaf ashes yield lye for soap making:

Scientific Name Common Name Prominent Location

Arthrocnemum indicum mangrove Indian coast Atriplex repers salt bush Indian coast Avicennia nitida mangrove Philippino swamps Cocos nucifera coconut palm Coasts of all tropical regions Halocharis violocea Indian coast Haloxylon recurm camel food Indian coast Haloxylon multiflorum Indian coast Haloxylon salicornicum Indian coast Kochia indica Indian coast Salicornia brachiata Indian coast Salsola foetida Aden balsam Indian coast Suaeda fruticosa Indian coast Suaeda monoica Indian coast Suaeda maritima Indian coast Suaeda nudiflora Indian coast

Making the Soap

Equipment and Materials

Iron kettle Wooden spoon or stick for stirring Measuring vessels Wooden, steel, iron, glass, or clay vessels for storing the soap

Clarified fat (see the entry on Soap Making with Commercial Lye for cleaning process)

Lye that floats an egg or potato (see Figure 7)

Put 115ml (1/2 cup) of lye in the kettle for every 230ml (1 cup) of fats or oils.

Add the measured amount of fat.

Boil the lye and fat together until the mixture becomes thick, rubbery, and foamy.

Remove the kettle from the fire and let it cool.

The soap is a thick jelly substance that ranges in color from tan to dark brown depending on the fats or oils used and the length of boiling time.

Upon strong mixing in water, the soap will lather up into white suds and serve as an effective cleaning agent. This soap greatly improves with age. Store it in a container for at least a month before using it.

230ml (1 cup) of fat yields 230ml (1 cup) of soft soap.

Sources:

Marietta Ellis, VITA Volunteer, Bedford, Massachusetts Dr. S. K. Barat, VITA Volunteer, Adyar, Madras, India

Earl, Alice Morse. Home Life in Colonial Days. New York: MacMillan Company.

Make Your Own Soap. Washington, D.C: Federal Extension Service, U.S. Department of Agriculture.

LARGER-SCALE SOAP PRODUCTION

In many areas in developing countries soap-making can be an important small business, providing a needed product and earning income with minimal investment. The Intermediate Technology Development Group, for example, has worked with the University of Science and Technology in Ghana to develop equipment for small manufacturing operations. One such set up uses specially made tanks heated by wood fires. The diagrams below show the parts for the tank. Soap-making

processes are the same as those described above. Recipe quantities change according to the amount of soap produced. For example, one small manufacturer in Brazil supplied the following recipe for 45 kgs (100 lbs):

10 kgs tallow 2 kgs lye 2 kgs rosin 36 liters water

Sources:

Donkor, Peter, Small-Scale Soapmaking. London: Intermediate Technology Development Group, 1986

Rezende Iriner, VITA correspondent, Recife, Brazil