VITA

1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org March 1984

[C] 1984, Volunteers in Technical Assistance, Inc.

TABLE OF CONTENTS

Acknowledgements

1. Introduction Objectives

2. Procedures Selection of techniques Efficiency tests Economics

- Acceptability Raw material

3. Results and discussion Efficiency

- Economics Acceptability Raw material Charcoal quality

4. Conclusions

Appendixes

I. Construction and use of carbonizing techniques Montserration coal pit 3-pipe Mini CUSAB kiln Montserratian kiln Tongan kiln New Hampshire (Black Rock) kiln Jamaican retort with tar condenser Jamaican retort with gas ports

II. Relative efficiency testing procedures for charcoal kilns

III. Charcoal kiln test data sheet IV. Species of wood commonly used in charcoal production

Bibliography

ACKNOWLEDGEMENTS

The information presented here is the result of the cooperation of many people in several organizations. A partial list includes: C.T. John, John Pitman, Nymphus Meade, and Franklyn Margetson of the Government of Montserrat; Dan Chalmers, Jeffrey Dellimore, Carolyn Cozier, and David Moore of the Caribbean Development Bank (CDB); and Richard R. Fera, John M. Downey, Jane Kenny, Margaret Crouch, and Julie Berman of VITA.

The people directly involved with the authors at the project site were Joseph Daniel, Meredith White, and James Silcott.

Gratitude is extended to the many secretaries, coal burners, craftsmen, and others that made this project possible.

1. INTRODUCTION

Before the energy crisis of 1973, the majority of people in Montserrat used liquid petroleum gases (1pg) for cooking. Since then, many households have switched to more traditional fuels to combat the resulting price hikes and scarcities of 1pg, with the result that the 1980 Commonwealth Caribbean Population Census (GOM, 1980) estimated that 40 percent of Montserratian households cooked with wood and charcoal. In 1981 the Government of Montserrat (GOM) was spurred into action by these revelations. Realizing that a massive return to traditional fuels could have disastrous effects on the local environment, and suspecting that traditional pit methods of converting wood into charcoal were inefficient, the GOM acted to put together the resources and expertise to study ways to increase the efficiency of charcoal production. This effort would help assure a future supply of local renewable fuel from forest resources.

With financial and supervisory help from the Caribbean Development Bank (CDB) and financial and managerial help from Volunteers in Technical Assistance (VITA), the Montserrat Fuelwood/Charcoal/ Cookstove Project began in 1982. [1] The Project was an integrated approach to finding the best ways to substitute local renewable energy for imported, liquid-based fuels. This report presents the findings of the charcoal portion of the project.

Montserrat is a small island in the Caribbean with an area of 39 square miles and a population of 11,606 (GOM, 1980). Approximately 270 tons of charcoal are produced each year by about 150 part-time producers (Wartluft, 1983). All of this charcoal is produced in pits dug into the earth.

The world literature on charcoal production presents the pit method as inefficient. For example, several publications report a maximum efficiency of 15 percent for pits (Agarwal, 1980; Roos, 1979; Earl, 1975). One goes so far as to state that for this kind of yield on a dry weight basis the carbonization has to be perfect, and the pit fitted with a vent pipe. Deal reports a much higher efficiency of 20 percent (20 stacked cubic yards of wood yields 1 ton of charcoal) on a green weight basis for earth kilns in Uganda (Earl, 1974). In these publications, all other types of kilns are reported to give higher yields than earth pits, averaging around 25 percent on a wet or air-dry weight basis. Some mention is made of the high variability of yields from the pit methods. In some cases percent efficiencies are given with no reference to the base used (dry, air-dry, or wet weight) or whether measurements were actually taken.

[1] CDB and VITA funds in this project were from USAID's renewable energy project.

When wood is converted to charcoal, over half of the energy value is lost. Why then even consider charcoal if efficiency is the issue? The most convincing reason is that charcoal is preferred. It is preferred because it is lighter and less bulky, making it easier to transport. Charcoal stores indefinitely, whereas wood is attacked by insects and fungi that reduce its energy value. And charcoal is a more concentrated heat source and puts out less smoke than wood. A less obvious reason is that carbonization of wood is an easy way to break down large pieces to a size easy to use for cooking. Otherwise, the large pieces might rot on the forest floor (FAO, 1983).

OBJECTIVES

The objectives of the project were to:

1. substitute local renewable fuel for imported fuel, 2. use the forest resource wisely, and 3. create local industry and employment.

More specifically for the charcoal portion of the project, we wanted to find the best charcoal production techniques in terms of efficiency, economics, and acceptability. An efficient technique would produce the greatest quantity of good quality charcoal from the smallest amount of wood and labor input. But it would have to be economical as well. And regardless of efficiency or economics, to make an impact the technique would have to be acceptable to the charcoal producers.

2. PROCEDURES

To meet these objectives, we selected eight designs to compare with the standard 'coal pit." Our research marked the first time that so many simple charcoal technologies were scientifically tested by the same team in the same location and under the same conditions.

SELECTION OF TECHNIQUES

Several criteria were used in selecting carbonization techniques for comparative testing. We wanted simple, inexpensive techniques using equipment that was capable of being fabricated locally. To save time, we selected techniques that had already been tried and reported on in the literature.

At the outset, five designs were selected:

* the 12-pipe mini CUSAB (Little, 1978), * Costa Rican kiln (Instituto Tecnologico de Costa Rica), * Tongan kiln (BuLai and Rocholson), * New Hampshire kiln (Baldwin, 1958), and * Jamaican retort with tar condenser (VITA, 1978) (Jamaica Scientific Research Council) (Appendix I).

Of these, two were modified before testing. The round, tapered New Hampshire kiln was built with straight sides and in an octagonal shape due to shop limitations. The 90-cubic-foot size was dictated by the size of steel sheets available. The Jamaican retort as presented in the literature is built with six or eight used 50-gallon oil drums. For our research purposes, and to make the retort more portable, we used just two drums welded together.

Other modifications were made in order to improve the operation of the equipment. Our first modification was to the Costa Rican kiln, which took too long to carbonize wood, and produced many brands (not fully carbonized pieces of wood). We dropped the Costa Rican model, and dubbed our modified kiln the "Montserratian." In place of two 6-inch square holes in the drum bottom, we put one round 6-inch diameter hole in the center of the bottom. To eliminate having to turn the drum upside down to seal it off for cooling, we left a 1-1/2-inch lip around the edge when cutting out the top. On this, a full top from another drum or a round piece of galvanized sheet metal rested. Sand was piled on top of this to seal any openings. The operating procedure was also changed. Rather than cutting all wood to 17 inches and stacking the bottom half solidly, wood was cut the length of the drum and stacked vertically, leaving a 6-inch diameter full-length opening in the center for ignition and air flow.

The 12-pipe mini CUSAB was very troublesome to operate, with tin cans falling off and air leaking from cracking clay. From the literature we found a modification using just three pipes instead of clay-filled tin cans to seal the pipe ends. The pipes were threaded and end caps were simply screwed on by hand. We also sealed this model in the same way as the Montserratian to eliminate the necessity of turning the drum upside down. The 12-pipe model was discontinued in favor of the 3-pipe model.

Several modifications were made to the retort. A serious problem was that nuts oxidized onto the bolts when heated, making them difficult to loosen. First we tried welding a 1/2-inch rebar around the drum opening, to which the cover bolt heads were then welded. This prevented the bolts from turning with the nuts. But our second modification with tabs, slots, and wedges was most effective. The reinforcing ring was retained as a sturdy base on which to weld the slotted tabs.

Because so little tar was produced--about 1 pint per charge--we tried and preferred the retort with gas ports. There was about a 50 percent savings in the scrap fuel and labor time needed to run the process with gas ports, but little similar advantage to tar production. We found the best placement for gas pipes was in the front third section of each drum. Another effective innovation with the gas port model was the use of a piece of tin to cover the firebox opening once the gas ports were lit. This helped keep heat in and cool breezes out. Without this, the retort produced more brands near the cover.

The last modification to the retorts was an insulated cement block and poured, reinforced concrete housing over the retort. The drums, mounted on one foot high legs, slide in or out for repair or replacement. This was done after the eighth burn on one retort burned out the tin that supported the earth insulation. The cost of replacing the tin every eight burns represented about half the value of the product. The economics of this modification remains to be proven, as it was built near the end of testing. However, cement and cement blocks hold up well under heat in Montserrat.

EFFICIENCY TESTS

At least five tests were made on each kiln and retort design. Tests were made to measure the yield in pounds of marketable charcoal in terms of the oven-dry weight of wood used. Marketable charcoal was that which did not pass through a 1-inch mesh screen. To arrive at oven-dry weights of wood, we determined the moisture content of sample disks that were cut from the wood going into each test charge (Appendixes II and III).

The same wood supply, location, and operators were used for all tests except for those on "coal pits." Measurements were made on actual coal pits being operated by Montserratian "coal burners."

Results of these tests were expressed as percent yield on an oven-dry basis: the number of pounds of charcoal produced from each 100 pounds of oven-dry wood used. As a matter of interest, they were also expressed as the percent net heat value; that is, the Btu's of charcoal yielded from each 100 Btu's of wood input.

ECONOMICS

In order to determine the economics of using the different carbonizing techniques, records were kept on labor and materials costs to build equipment, any maintenance costs incurred during operation, and the number of person hours of work involved in operating the equipment. Along with data from yield tests on the average amount of charcoal per burn, the number of burns possible in a year, and equipment life, we were able to calculate the proceeds per dollar of investment, with and without labor costs.

Proceeds over the life of the equipment were calculated by using the average yield of charcoal per burn, times the estimated burns per year (50 weeks) for full-time operation, times the estimated number of years of equipment life, times the price of charcoal, estimated at EC$.50 per pound. Since charcoal is sold by volume at EC$5 per tin (9 x 9 x 14 inches), its price per pound varies with the bulk density of charcoal. A typical tin of charcoal weighs from 10 to 12 pounds (EC$.50 to $.42 per pound).

Investment over the life of the equipment was figured as the total purchase cost plus any maintenance costs incurred during the life of the equipment. Investment and labor costs included the above plus the person hours needed to operate the equipment times EC$3 per hour labor rate.

The comparative figures used were the proceeds divided by investment plus labor. The results showed the expected income derived from each dollar of expenditure with and without labor costs.

ACCEPTABILITY

Feedback from field tests of different techniques with Montserratian coal burners helped us judge the relative acceptance of the techniques. To introduce the techniques to coal burners, we held a well-advertised demonstration of all models. To help assure an audience we sent a letter to each known coal burner, and offered lunch and bus fare. During the demonstration we offered to lend kilns and retorts to interested parties in exchange for feedback on what they liked or disliked about the different techniques, and why.

RAW MATERIAL

From observations of local methods of charcoal production and conversation with coal burners, we gained an appreciation for the preferred species, sizes, and moisture conditions of the wood used.

We took a number of moisture content samples of fresh-cut wood to determine which species were the driest, and therefore more efficient for carbonizing without seasoning. For three of the most popular species, we took periodic moisture content samples from piles seasoning under roof for 10 months. This was to indicate the amount of time necessary to season these species to air dry condition, about 20-25 percent moisture content (green basis).

3. RESULTS AND DISCUSSION

EFFICIENCY

Out of the 16.56 oven-dry tons of wood processed in 51 tests, the most efficient carbonization technique in terms of yield was the retort. The retort with tar condenser averaged 34 pounds, and the retort with gas ports averaged 33 pounds of charcoal per 100 pounds of oven-dry wood (see Table 1.)

Table 1. Average Yields of Charcoal by Carbonization Method

Yield Average Wood Yield Moisture Oven-dry Net Content Oven-dry Yield Heat Carbon- (percent) Weight Coefficient Value ization No. of (green Basis of Basis Method Trials basis) (percent) Variation (percent)

Retort 11 21 34 .22 51 with tar condenser

Retort 7 25 33 .29 50 with gas ports

Montser- 7 32 29 .10 45 ratian coal pit

New 6 27 26 .37 40 Hampshire kiln

Tongan 6 24 23 .45 36 kiln

Mini 5 27 22 .24 35 CUSAB kiln

Montser- 9 26 21 .35 32 ratian kiln

Among the kilns, the yields decreased with decreasing kiln size. The largest kiln, the coal pit, had an average yield of 29 pounds and the three small single-drum kilns had yields averaging 22 pounds of charcoal per 100 pounds of oven-dry wood. In between these was the New Hampshire kiln yield of 26 pounds for every 100 pounds of oven-dry wood. It is interesting to see that the coal pit yields varied less than any of the others. This is most likely due to the extensive experience of coal pit operators.

With the exception of the coal pits, our results were comparable to results of trials in other parts of the world. Our Mini CUSAB and Tongan models were within 1 percent of the yields found for these models in Fiji (Rocholson and Alston). The New Hampshire kiln yield of approximately 24 percent in a cold climate compares with our average yield of 26 percent (Baldwin, 1958). The well known Tropical Products Institute (TPI) kiln of similar design and capacity had yields averaging 26 percent in trials from seven countries (Paddon and Parker, 1979; FAO, 1983). And in Ghana a similar kiln had yields from 22 to 26 percent (Lejeune, 1983).

Retorts have higher yields because all of the wood is converted to charcoal. In kilns, some of the wood is burned away to provide process heat, while any scrap fuel can be used to carbonize the wood in the retort. For instance, during our tests we used coconut husks, scraps from a neighboring wood working shop, drift wood, wood from species not suited for conversion to charcoal such as flamboyant, branches of acceptable charcoal species that were too small to be marketable, and cardboard scraps from the supermarket. Retorts use the gases coming out of the wood, while kilns waste most of these gases. In the model with the tar condenser, gases are condensed into tar, which is useful in preserving wood and metal and in patching roofs. In the model with gas ports, the gases become part of the fuel for the process.

Even though the retort extends the usable resource and gives higher yields, it requires more work gathering fuel. About 350 pounds of scrap wood fuel were used per five-hour firing of the retort with tar condenser. Close to half that much fuel and person hours were used by the retort with gas ports. Three hundred fifty pounds of 1- to 6-inch diameter wood is less than half of a pick-up load. The same weight of light branches could take up to two pick-up loads. The typical pick-up load of crooked green wood weighed 1500 pounds.

The "coal pit" earth kiln did much better than expected. The slower carbonizing process and lower temperatures used in the coal pit did not drive off as many volatiles from the wood as the faster, higher temperature kilns and retorts. As a result, the charcoal from coal pits was heavier than that from kilns and retorts. We operated our kilns and retorts fast, as one of the advantages was supposed to be a shorter turnaround time giving potential for greater production. Since the greater weight per volume of coal pit charcoal was due to volatiles, the heat value per volume was greater. One tin of coal pit charcoal weighed 12 pounds, whereas the kiln and retort charcoal from our tests weighed about 10 pounds per tin. Kilns and retorts can be operated more slowly, yielding charcoal of greater weight.

Research in Germany has shown that it takes more energy to drive moisture from wood during fast carbonization than it does in slow carbonization. [2] This energy savings in slower-burning coal pits contributes to their good yields too.

Another difference in the operation of the coal pits versus the kilns and retorts in terms of our research, was the operator experience. Coal pits were operated by veteran coal burners, while the kilns and retorts were operated by first timers. With more experienced operators, the metal kilns could probably be expected to give better yields.

[2] Personal communication with Dr. Arno Fruhwald.

In order to find out the strength of fire needed under a retort to raise the internal temperature to the optimum 900 degrees F (USDA Forest Service, 1961), we used a pyrometer with thermocouple placed in the center of the charge. When we fired the retort as hard as we could, the internal temperature reached a maximum of 1250 degrees F at the end of the burn, five hours after ignition. From this we learned that a vigorous but not all-out fire was necessary.

Regarding efficiency in terms of person hours, there was less wood cutting for coal pits, but more hard work gathering grass and shoveling "mold" or dirt, and then separating the mold from the finished product. All metal kilns required several well-timed adjustments. The operation of the New Hampshire kiln was relatively controllable. Any adjustments were definite and stayed that way until the next adjustment was made. Adjustments to the coal pit were less definite as the mold could shift at any moment and create an unwanted vent hole, or close an intentional one. The single-drum kilns required the most constant attention. Adjustments such as shaking the drum were only temporary and had to be repeated frequently.

In contrast to kiln operation, all that was necessary in retort operation was to stoke the fire. The successive stages of carbonization were easy to discern in the retorts, which gave a sense of confidence in the expected results. A group of 8- to 14-year-old boys successfully operated a retort on their first try without supervision.

ECONOMICS

With practically no initial investment, the coal pit was clearly the most economical (see Table 2). Including the cost of labor, the coal pit returned an estimated US$8.60 for every dollar spent. The next closest method, the New Hampshire kiln, returned an estimated US$4.60 per dollar of expenditure. Single drums because of low yields, and retorts because of short lives, managed to earn only $1.34 and $1.05 respectively for each dollar of outlay. None of the methods lost money according to our estimates.

These comparisons were done on one unit of each type. Some favorable adjustments could be made to several of the techniques. Simultaneous operation of several units of the smaller drums with very little addition to labor cost should increase returns. In the case of the retorts, a favorable change in economics could be made by increasing the size of the unit.

Table 2. The Economics of Different Charcoal Techniques

Coal New Single Item Pit Hampshire Drums Retort

Charcoal product/charge 654 285 41 77 (pounds) [a]

No. charges/week for a 1 3 5 3 single unit

Charcoal proceeds/year 16,350 21,375 5,125 5,775 (EC$) [a]

Initial investment 5/burn 3,000 40 400 [c] (EC$)

Equipment life 10 2 .05 0.1 (years)

Proceeds/dollar of 65 14 64 3 investment (EC$)

Person hours/week to 11 21 25 25 operate a single unit [d]

Proceeds/dollar of 8.60 4.60 1.34 1.05 investment and labor (EC$)

[a] Charcoal yields based on 5-18 trials per technique.

[b] Charcoal price = EC$.50/pound.

[c] First installation, thereafter EC$150.

[d] Labor rate = EC$3/hour; exchange rate: EC$2.70 = US$1.00.

ACCEPTABILITY

The time available to spend with coal burners while they field-tested kilns and retorts was limited. However, we were able to get some feedback from Montserratians who tried them. Approximately half the island's coal burners (74) were present at our day-long demonstration. After the demonstration, six Montserratian kilns, four retorts, one Tongan kiln, and one New Hampshire kiln were lent for field testing.

The island's largest charcoal producer field-tested the New Hampshire kiln. It took him several burns, one with our kiln operator, to learn how to operate it. He has slowed the process down by closing all vent holes almost entirely and using just two of four chimneys. This has given his customers the heavy charcoal they want. They complained about the lighter charcoal he made when he burned it within 12 hours. He maintains that they are starting to prefer the metal kiln charcoal to the coal pit charcoal because it lights more easily. This, he figures, is because he does not need to douse embers with water as he does with the coal pit product. The only problem is that it does not carbonize well pieces of wood over 6 inches in diameter. In the coal pit, he fully carbonizes pieces up to 16 inches in diameter. He claims that his yield is better with less work with the New Hampshire kiln. He has purchased a used chain saw, and wood cutting is no problem. Before the chain saw, he tried our bow saw and saw horse and liked them very much.

For coal pit modification, we had some 4-inch diameter pipe made into 6-foot long chimneys with tripod legs welded on the bottom to keep them upright. This same coal burner has tried and likes a chimney at the end of his coal pit. He claims that the process is speeded up, the product is more uniform, and the yield is better than without the chimney. The chimney changes the air flow by removing smoke from the bottom of the pit rather than the top. This forces more heat lower into the charge and results in fewer brands at the bottom of the pile.

The retorts have been well received; one man tried 11 successful burns, and the boys at the Boy's Home ran successful burns, too. It was not necessary to have project personnel help operate retorts. one man found out, though, that large, green pieces did not carbonize well in the retort. The tar-condensing feature has not been embraced by any field tester--all have gas port models.

The single-drum kilns were solicited by a number of Montserratians who wanted to make charcoal for their own use. To date, we have not received any enthusiastic response from field testers of these models. Problems seem to be smoke in the eyes, and too much attention needed compared to a small coal pit. Again, we have not had the time needed to meet with these people to help get them started. At the outset of the project, portability of kilns was to be of major importance. We learned, however, that the great majority of coal pits are near the coal burner's houses so they can control them better. They told us of the wasted efforts of setting a pit in the forest only to have it "blow" to ashes because it could not be monitored well. Coal burners routinely pay for transporting wood to their houses. The distance is rarely more than three miles. They do their own cutting and piling at the roadside.

RAW MATERIAL

From years of experience, coal burners have found out which species are most suitable for charcoal production. These appear in a list in Appendix IV in approximate order of priority.

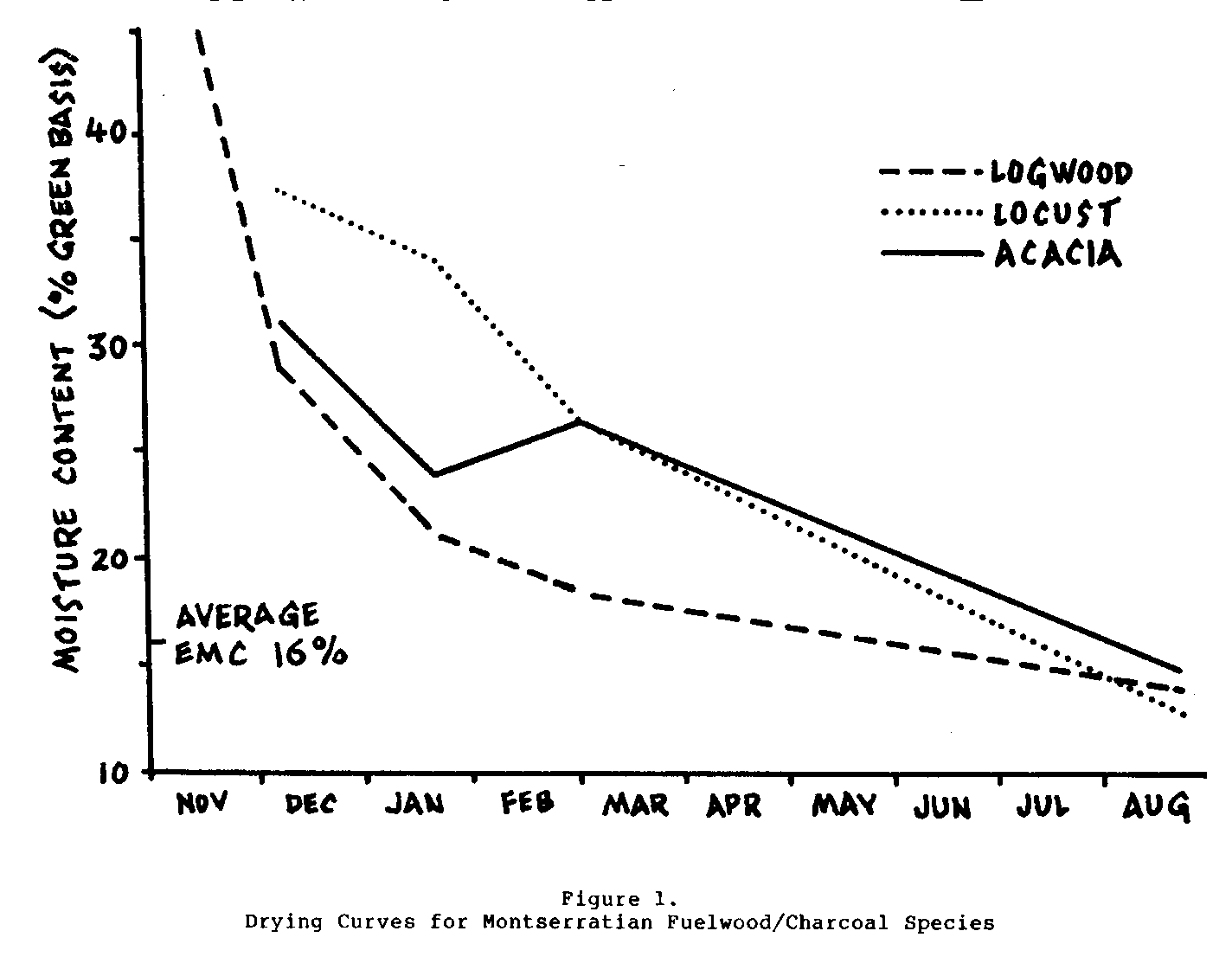

The moisture in wood has a negative effect on charcoal yield, both in quantity and in time. Coal burners know this, but much green wood is carbonized for reasons of expediency. Fresh-cut moisture contents are listed in Appendix IV for the species we measured. Three of the most common species dried to optimum conditions in about two months (Figure 1). After this time,

drying slowed considerably and insect destruction built up. Montserratian coal burners often season their wood for two to four weeks, sometimes more. We calculated the effect of seasoning on charcoal yield. For those trials where the wood was above 35 percent moisture content (green basis), the average yield was 24 percent. For wood with less than 20 percent moisture content (green basis), the average yield was 28 percent. These measurements were taken over all the different kiln models.

For converting green weight of wood to stacked cubic volume and vice versa, a number of measurements were made during the resource assessment phase of the project. Table 3 gives the results for the species listed in Appendix IV.

Table 3. Conversion Factors for Green Weight of Wood to Stacked Cubic Volume

Conversion (green pounds Type of Wood per stacked cubic foot)

Suitable for charcoal -- 22 less than or equal to 3. 8 inches diameter breast height (dbh)

Greater than 3.8 inches dbh 27

Not suitable for charcoal 19

Overall 23

These conversion factors may be helpful in estimating yields where no scales are available. Or they can be used to convert commonly used forestry measurements of stacked volume to weight for fuel value or charcoal conversion estimates.

CHARCOAL QUALITY

What is good quality for cooking? Montserratians like charcoal in big, heavy pieces. The higher density gives more "substance" or heat content per volume, and so lasts longer in a stove. It also does not readily break up into fines. Because it has a relatively high percentage of volatiles, it lights more easily too. The fact that it smokes a bit more is of lesser importance. This type of charcoal comes from coal pits in the way they are normally operated, but with experience, can come from kilns and retorts too.

4. CONCLUSIONS

Our testing shows that, in spite of the energy losses incurred in converting wood, charcoal is a worthy cooking fuel for Montserrat and that traditional production methods are not unnecessarily wasteful. The traditional Montserratian coal pits can provide yields of charcoal that are comparable to the yields from larger metal kilns and retorts, and are superior in yield to single-drum kilns. They are the least expensive method of carbonizing wood. Moreover, the coal pits can be modified with a simple chimney to increase charcoal yield and uniformity.

Metal kilns and retorts can be burned at a slower rate to improve yield and charcoal quality, according to our tests, but require extra wood cutting, although less overall physical work than coal pits.

We also found that large, green pieces of wood do not give good results in metal kilns or retorts. Seasoning wood before carbonizing does give better yields, with two months as the optimum time for seasoning.

Our research experience also leads us to the following suggestions for future research and other programs:

* A retort made with steel sheet (3/16 or 1/8 inch thick) rather than used drums might favorably alter its economics.

* Clean, bagged charcoal could replace the small amount of imported charcoal briquettes.

* More information should be gathered on species' green moisture contents, seasoning rates, specific gravities, and conversion factors for weight to stacked cubic volume.

* A dissemination program should be mounted to get maximum exposure of the past year's results. The theme should be "charcoal is an alternative fuel for everybody."

* Additional work on the use of simple chimneys to improve coal pit performance could be beneficial. Yield measurements should be used to help judge the effectiveness of chimneys.

* An educational program should be set up on "good forest harvesting practices" for coal burners.

APPENDIX I

CONSTRUCTION AND USE OF CARBONIZING TECHNIQUES MONTSERRATIAN COAL PIT

CONSTRUCTION

Tools

* shovel (spade), cutlass (machete)

Materials

* loose dirt, green leaves and/or grass

Method

Excavate a pit four to six feet wide by five to 100 feet long, by one to four feet deep in the ground. Orient the pit length parallel to the prevailing winds. Provide for drainage by digging a small canal as deep as the pit and sloping away from the pit. Lay two parallel stringers (sticks or poles) about three to four inches in diameter and three fee apart on the bottom, along the length of the pit. On top of and perpendicular to the stringers, pile the wood to be carbonized. All the wood should be cut to the same length. Pile the wood tightly to minimize void spaces. Short cut-offs can be used to fill in void spaces. Leave three or four inches of clearance between the piece ends and the sides of the pit. Put two five feet long stakes into the ground at each end of the stringers at stringer width. These stakes will hold up the ends of the pile and will be used to help control the draft when the kiln is in operation. Stack larger and smaller diameter pieces together, but most of the larger pieces should be in the top half of the kiln. At the end chosen for lighting (usually the windward end), stack dry sticks and brands from previous burns. This will help the burn get started. After stacking, cover the entire pile with green grasses and leaves so that the wood canot be seen. About a two inch layer will do. Then shovel about three inches of dirt over top of the entire pile. The four stakes should be sticking about six inches above the dirt. In pits longer than 10 feet, stakes can be jammed into each side of the pit so they stick into the wood pile and protrude from the dirt on the outside. They can be supported by a Y shaped stake on the outer end for stability. At the bottom center of the windward end where the pile will be lighted, leave a one foot square opening in the dirt and grass.

To light the kiln build a small fire, and when well underway with good coals, shovel the coals into the base of the pile at the lighting point. Alternate ways of lighting are to use a kerosene soaked rag or a few hand-size pieces of old rubber tire inserted in a hole under the lighting point and lit. In a matter of minutes smoke will be seen coming out the opposite end of the pit (or part way along the sides in a long pit). A small opening can be left near the top at the leeward end to help promote an initial draft. After 15 minutes or so when the smoke is readily coming out of the leeward end of the kiln, both holes can be filled in first with grass, then with dirt. As long as the kiln is emitting thick white smoke, carbonization is proceeding as planned. When blue smoke is spotted, too much air is getting in at that spot and the hole there, which will be obvious, should be covered with grass and dirt until the blue smoke stops. As carbonization progresses, the height of the pile will slowly collapse to about one half the original height. If white smoke slows way down or stops emitting, air can be let in the pile by wiggling the protruding stakes. The rate of burning will depend on the amount of moisture in the wood, the size of the wood, the density of the wood, and the amount of air allowed to pass through the kiln. About 40 stacked cubic feet of wood will be processed each day. So a stack of wood five by four by 10 feet would take about five days to carbonize. When carbonization is complete, allow the pit to cool off as long as there is no smoke coming from the pile, for at least one day. When extracting charcoal, keep a water bucket nearby to douse any live embers. The charcoal should be allowed to air out in a place where there is no fire hazard for at least 24 hours before storing it where it could cause damage if lit.

MONTSERRATIAN COAL PIT

AFRICAN 3-PIPE MINI-CUSAB (MODIFIED FROM THE 12-PIPE MINI CUSAB)

CONSTRUCTION

Tools

* welding/cutting equipment, chisel, hammer

Materials

* 50 gallon drum * cover from another 50 gallon drum, or equivalent piece of flat tin * 3 pieces of threaded 2" pipe about 3" long * 3 threaded caps for the pipes.

Method

Cut 3 holes along the length of the barrel the same distance away from each other. Weld a piece of pipe to each hole, threaded end facing away from drum. Cut out the top of the barrel, leaving a 2 inch lip around the top edge.

OPERATION

To operate the mini-CUSAB, unscrew the cap from the bottom pipe and face the pipes into the wind. Start a brisk fire in the bottom of the drum. Begin to add wood about 3' long or shorter until the kiln is about half full. Allow the kiln to burn until red coals can be seen in the bottom of the kiln through the hole. Close off the bottom hole with the cap and open the second one. Continue to add wood to the kiln. Allow it to burn until red coals can be seen in the second hole. Close this hole and open the top and final hole. Allow the kiln to burn until it is full of charcoal. Then close the final hole, put the cover on and seal the kiln by putting sand on top of the cover around the edges. Be sure that no air is getting into the kiln. Throughout the burn, be sure that thick white smoke is coming from the kiln. If the smoke is blue that suggests that too much air is in the kiln and the charcoal is being burnt up. The kiln can be controlled by shaking the kiln, packing it tightly with wood and putting the cover on to reduce the quantity of air getting into it,

AFRICAN 3-PIPE MINI-CUSAB

AFRICAN 12-PIPE MINI-CUSAB

MONTSERRATIAN KILN (MODIFIED FROM COSTA RICAN KILN)

CONSTRUCTION

Tools

* hammer, chisel, tape

Material

* 50 gallon drum * cover from another 50 gallon drum, or equivalent piece of flat tin.

Method

Cut a 6 inch diameter round hole in the center of the bottom of the drum.

Cut out the top of the drum, leaving a 2 inch lip around the edge.

OPERATION

Set drum about 4 inches off the ground on some logs or rocks. Load 32-33 inch long sticks vertically in the drum, leaving an open 6-inch diameter column in the center. Pack the sticks so as to leave as little air space as possible. In the open center column put paper and dry sticks right into the top. Light the kiln by pushing a lit ball of paper underneath the drum at the open hole. As the kindling burns, add more fuel, dry at first and greener wood later. When the top outside of the drum gets too hot to touch, knock out the logs (stones) from underneath the drum so that it sits on the ground. Continue to add fuel as the burned wood falling down permits.

After an hour or so a load of wood is put in with some sticks protruding slightly above the top of the drum lay the lid on top. This will slow down the burning rate. At about hourly intervals wood can be added for the next 3-6 hours. If the fire threatens to go out, take the lid off. A more extreme measure would be to tilt the drum for a short time. Set it on a small stick or rock to let more air in the bottom. Load brands from a former burn last. To slow down the burning at any time, shake the drum to settle the wood down. This reduces the air spaces between wood pieces. When smoke turns from mostly white to mostly blue, and (by inspection under the lid) all the wood has apparently carbonized on the outside of the pieces, seal the kiln by putting fine, clean (no sticks, leaves, etc.) sand around the base and around the edge of the lid. Make sure no air can get in or smoke get out. Let the kiln cool down overnight before unloading charcoal the following day.

-

MONTSERRATIAN KILN

-

COSTA RICAN KILN

-

TONGAN KILN

CONSTRUCTION

Tools

* chisel, tape, hammer

Materials

* 50 gallon drum

Method

Cut out an 8" strip down the length of the drum. Keep the piece cut out to be used as a cover.

OPERATION

Firing

Lay the kiln on its side with the opening facing toward the wind. Prop the kiln with a stone so that the bottom edge of the opening is about 3" from the ground. Start a fire in the kiln (with twigs, etc.) across its full length. Add dry sticks. Be prepared to turn the kiln into the wind at all times in order to maintain an even and vigorous fire.

First Loading

When there is a good, strong and even fire going, add more wood slowly, the small pieces first to ensure that the fire maintains its vigorous state. Stop adding wood when its level comes up to just above the bottom edge of the opening. Leave sufficient time for the wood to burn into embers, then roll the kiln back by removing the stone that is propping it in preparation for the second loading. Brands, which are the partly burned wood from previous burns, can be loaded into the kiln when the fire is burning vigorously or at any stage after the first loading.

Second Loading

Prop the kiln so that the bottom edge of the opening is now about 6" - 8" from the ground. This will help to block air from the charcoal already formed during the first loading. Add more wood, making sure that even burning and strength of the fire are maintained. Stop adding wood when its level comes above the bottom edge of the opening. Leave sufficient time for the wood to burn into embers, then roll the kiln back in preparation for the third loading.

Third Loading

At this stage the opening should be about 12" - 16" from the ground. Add the larger wood, making sure that even burning and strength of the fire are maintained. Stop adding wood when the level comes up to the top edge of the opening. Allow the wood to burn into embers.

Final Loading

Rotate the kiln so that the opening is pointing straight up. Add wood, making sure that even burning and strength of the fire are maintained. When the kiln is filled with wood, allow sufficient time for burning into embers.

Sealing Off

When all wood from the final loading has carbonized, take the cut-out piece obtained during the construction of the kiln and cover the opening with it. Roll the kiln over so that the sealed opening lies flat on the ground. Using gloves, hold the cover in place while rolling the kiln. Seal the bottom edges with sand to make the kiln airtight. Leave sufficient time for the kiln to cool off, usually about 4-5 hours, before taking out the charcoal.

TONGAN KILN> NEW HAMPSHIRE (BLACK ROCK) KILN

CONSTRUCTION

Tools

* welding/cutting equipment, tape, straight edge

Materials

* Two sheets of 1/8" or 3/16" plate steel 61' x 101' * 24 lineal feet of 4" galvanized pipe * Four 4" galvanized pipe elbows (optional) * 40 inches of 1/2" reinforcing rod (5 handles) * 40 lineal feet of 2" angle iron * eight pieces of tin seven inches square or eight paint can lids.

Method

For the kiln body, cut one steel sheet in half lengthwise. On each half mark three perpendicular lines across the width so that the length is quartered. Each section should be two and one half feet wide. Along each marked line cut three slots which represent about one half the total line length. This is to weaken the sheet to facilitate bending along the line. Cut a cardboard model of an angle of 135 degrees. Bend each sheet along the lines so that each bend fits the cardboard model. A temporary jig can be made to hold the sheet during bending. After bending, weld the two pieces together to make an octagonal shape. Weld the bending slots so that they are air tight. Reinforce all the way around the bottom by welding on angle iron.

Weld angle iron right around the top so that it acts as reinforcement and a cup to hold sand and support the cover. At the bottom center of each section, firmly weld an eight inch square piece of sheet steel. Cut a hole through each of these and the body so that the holes are centered in the reinforcing plates. These eight holes should be slightly larger than the outside diameters of the pipe elbows to allow for easy insertion of the pipes, but small enough to hold the flue pipes vertically without further support.

From the second sheet, cut the cover so it has a conical shape, fits inside the top angle iron and has an eight inch diameter hole at the top. The eight triangles that make up the cover are measured on the sheet with bases of 30 inches and sides of 38 inches. To minimize expensive cutting, two or three adjacent sections can be cut out as one piece. In this case the slot method can be used to bend on the lines between sections.

Before welding the sections together, present them in place with the bases of triangles resting on the top angle iron of the body and the tops resting on some makeshift support in the center. Since it is difficult to cut and bend precisely this is the chance to custom fit the cover to the body. Any overlaps of one section over another can be marked to guide final cutting. When all sections fit, they are welded together. Then an eight inch diameter hole is cut in the top center of the cover. An eight inch diameter chimney, eight inches tall is welded around the hole. Then a cap is made to fit over the chimney. Sides of the cap should extend down to the cover. A two inch high collar is welded around the bottom of the chimney to hold the sand that seals off the bottom of the cap when it is on the chimney. Using 1/2 inch reinforcing rod, handles are welded on top of the chimney cap and on the cover. Four handles are spaced on the cover for two persons to put it on and take it off.

Four flue pipes about six feet long are made from four inch pipe. If elbows are available, they are threaded or welded onto the bottom end. If elbows are not available, a six inch long piece from the bottom end can be cut off at 45 [degrees], rotated, and welded into a 90 [degrees] bend.

OPERATION

Loading the Kiln

Cut wood to a length approximately equal to the height of the kiln (3 feet in our case). Prepare the core about which the wood will be stacked by tying three sticks together at one end to make a tripod. Place the tripod in the exact center of the kiln. Crumpled paper, dry sticks, and twigs are piled between the tripod legs. The wood to be made into charcoal is carefully leaned vertically against the tripod and is piled equally around all sides. The longer pieces of wood should be placed near the center.

Larger diameter sticks should be packed about a quarter of the way from the center to the outside. Stick diameter should be limited to 6 inches. Larger pieces can be split lengthwise. Continue to pack the kiln until there is no open space between the wood and the kiln. Short chunks and brands should be placed on top and used to fill empty spaces. If desired the kiln can be set on its side until the pile is half completed, then carefully let down over the pile. Make sure the tripod is in the center of the kiln.

Firing the Kiln

Put the cover on but leave the cap off. Pour about 1 pint of kerosene through the hole in the cover. Make sure that the kerosene goes down to the fuel in the tripod. Light the kiln through the top hole. Add small pieces of dry sticks if necessary to maintain the early fire.

Allow the kiln to burn for about 20-30 minutes. Lightly cover the bottom of the kiln with sand to seal it with the ground. Sand or dirt should be fine and free of sticks, leaves, and rocks. Sea sand seals well, but accelerates oxidation of the steel due to the salt. Keep the sand from entering or blocking draft and flue holes. Examine the flue pipes to make sure that they are not clogged with tar. Hold the elbows of the pipes over the flame coming from the cap hole to warm them. (This helps with getting a good draft.) Quickly put the pipes in every other hole. If smoke leaks from other parts of the kiln, these places should be sealed with clean sand. When all the pipes are in place it is time to put on the cap and seal around its edges with sand. The flue pipes should now be putting off white smoke, feebly at first but getting stronger. If a pipe stops or does not start drawing it should be removed, cleared, warmed up, and replaced in the kiln.

Care of Kiln While Coaling

During the early stages, if smoke stops coming through the pipes or stays very feeble, take the cap off for a short time and allow the fire to flame up through the caphole, adding more dry sticks if necessary. Kilns that are lit in the afternoon can be left overnight but must be slowed down by almost closing the open holes with the pieces of tin (paint can lids work well).

When all the wood in one section of the kiln is turned into charcoal, the coals glow red at that hole and the adjacent pipes only send off thin, blue smoke. To assure an even burn throughout the kiln, pipes can be shifted to holes with glowing coals until the original flue pipe holes show glowing coals. As each section shows glowing coals, remove the pipes and close the holes with tin, and cover them with sand. If allowed to burn too hot, the kiln sides will warp permanently, making chimney placement difficult. And the steel will oxidize faster, reducing kiln life. After red coals have shown at all holes, remove all pipes and seal all holes with steel or tin covers backed by clean, fine sand. This may be eight to 12 hours after lighting, depending on the moisture content of the wood. Make sure after you seal that there is no smoke escaping from anywhere. Leave about 12-24 hours for cooling before opening. If the kiln still feels warm it should not be opened. If a slower burn is desired for a heavier, more solid product, only two pipes on opposite sides of the kiln can be used, and all vents should be nearly closed with tin. In this mode, the burn will take at least 15 hours.

Care of Kiln Between Charges

To protect welded joints, handle the kiln with care. Do not let the kiln stand for long periods on its side. Let the kiln down from its side gently. To protect from oxidation when not in use, set the kiln up on three rocks spaced evenly around the edges to keep it off of the moist ground.

NEW HAMPSHIRE KILN

JAMAICAN 2-DRUM RETORT WITH TAR CONDENSER

CONSTRUCTION

Tools

* welding/cutting equipment, pipe wrench, shovel

Materials

* 1 - 2" pipe, 2 feet long, threaded at one end * 1 - 2" pipe, 10 feet long, threaded at both ends * 1 - 2" pipe, 3 feet long, threaded at one end * 1 - 2" pipe T * 1 - 2" pipe collar * 1 - 3/16" sheet steel 36" x 36" for door, tabs, and wedges * 1 - 3' x 6' of tin sheeting * 2 - 50 gallon drums * 15 linear feet of angle iron * 7 linear feet of 1/2" reinforcing rod * 50 - 6" cement blocks * 5 bags of cement * sand * gravel * soil * reinforcing mesh, 6' x 6'

Method

Remove both the top and bottom from one drum. Remove only the top from the other drum. Weld these two drums together, leaving the closed end to the outside. Put the least damaged end of the drum without top or bottom toward the outside. Weld the threaded collar into the top of the closed end.

Weld angle iron to the front, middle, and rear of the chamber bottom for support (see sketch). Weld the reinforcing rod around the outside front of the chamber just behind the drum lip.

Weld 5 or 6 slotted tabs to the outside of the reinforcing ring so they protrude beyond the front of the chamber. Space them equidistant around the circumference. Cut slots in the appropriate places in the steel door so the tabs can pass through when the door is on the chamber.

Make wedges to drop through the slots in the tabs. They tighten the door on the chamber. From the tin sheeting, fashion a curved drawer to fit inside the chamber. Folding over the front edge twice provides a handle to pull the drawer out.

Excavate a trench (or build a cement block or rock wall to form a "trench") 1 foot deep, 1 foot wide, and several feet longer than the retort length (2 to 4 drums can be welded together to form the chamber). Set the retort over the trench with about 4 inches of the trench protruding from the rear of the retort. Using cement blocks, build a wall around both sides and the rear to a level halfway up on the chamber. Continue the rear wall to above the chamber. Form, reinforce, and pour an arched roof over the retort, leaving about two inches space between it and the chamber. Location of the rear wall should leave 4 inches clearance to the back of the chamber. Above this space in the center of the roof leave a 4 inch hole for a smoke outlet. There should be a hole in the rear wall to allow the 10 feet piece of pipe to pass through to the threaded collar. At the other end of the long pipe, the middle of the T is threaded. Then the short pipe is threaded to the bottom and the eight feet piece is threaded to the top, sticking straight up in the air. A simple tripod tied with wire can be used to support the weight of this tar condenser near the end with the T. The long pipe coming from the retort should slope downwardn toward the T. A bucket is placed directly under the vertical pipes of the T to collect the condensed water and tars.

OPERATION

Wood to be carbonized is loaded into the retort chamber leaving as little void space as possible. Once loaded, the door is put on the front of the retort and secured and tightened by wedges inserted in the tab slots.

A vigorous, but not all-out fire is built for the entire length of the fire box under the retort. This fire is maintained for five or six hours until the smoke coming from the vertical pipe diminishes to almost nothing. Fuel can be any scrap wood having no better use.

Let the retort cool overnight before taking off the door and extracting the charcoal. Then allow the charcoal 24 hours to air out in a place where if it ignites, it will not be a hazard.

-

JAMAICAN 2-DRUM RETORT WITH TAR CONDENSER

-

JAMAICAN 2-DRUM RETORT WITH GAS PORTS

CONSTRUCTION

Tools

* welding/cutting equipment, shovel

Materials

* Same as retort with the tar condenser, except substitute two four-inch lengths of 2" pipe for the three pieces of 2" pipe.

Method

Same as retort with tar condenser except threaded collar at rear of chamber, and all connected pipes.

Substitute two pipes welded to the bottom of the chamber as gas ports. The bottom ends of the pipes should angle toward the rear of the chamber at about 45 [degrees]. Each pipe should be located in the front third of each drum. The drawer should have holes punched in it at the locations of the gas ports to facilitate passage of the gases.

OPERATION

Same as the retort with tar condenser, except the addition of fuel under the retort can stop after the gas ports are flaming (after 2-1/2 to 3 hours). Once fueling is stopped, an old piece of tin can be placed across the fire box opening to keep cool breezes from blowing the flames out, and to hold heat under the front end of the retort.

JAMAICAN 2-DRUM RETORT WITH GAS PORTS

APPENDIX II

RELATIVE EFFICIENCY TESTING PROCEDURES FOR CHARCOAL KILNS

In order to compare different designs of kilns, all variables other than kiln design that might affect efficiency such as fuel species, moisture content and size; operator and operating sequence and schedule; and weather are to be held as nearly consistent as possible.

The testing procedure is:

1. Take a representative sample of the wood going into the kiln to determine moisture content (MC). One inch thick disks should be cut from different diameters and from the middle portions of the sticks. Approximately five samples per ton of wood should be adequate. (10-15 per standard cord.)

2. Each disk should be labeled (with magic marker) to identify the test and disk number.

3. Weigh the disks immediately and record the weights opposite the identification. Weigh to the nearest one-tenth ounce.

4. Record the weight of all the wood going into the kiln.

5. Carbonize the wood.

6. After carbonization, record the weight of all marketable charcoal.

7. Record the weight of all uncarbonized brands.

8. Weigh and record the weight of (or estimate) the fines below one inch cube size (use of a sieve with one-inch holes would facilitate the particle size separation).

9. Record person hours to tend the kiln.

10. If desired, extract a representative sample of about two pounds of charcoal for proximate analysis.

11. Back in the test center, put moisture content samples in oven at 220 degrees F (105 degrees C) and intermittently weigh and dry until no further weight loss is shown. Record the oven-dry weight. Be certain not to lose any pieces of bark or wood.

12. To calculate kiln efficiency on a green weight of wood basis (EG):

Weight of marketable charcoal EG = ----------------------------- (100) Green weight of wood

or on an oven-dry weight of wood basis (ED), which eliminates most of the variability in efficiency due to moisture content:

Weight of marketable charcoal ED = ----------------------------- (100) Oven-dry weight of wood

Oven-dry weight of wood = 1 minus wood MC (green basis) in decimal form times green weight of wood.

Wood MC (green basis) = Original sample green weight minus Sample oven dry weight Original sample green weight

MC sample weights can be totaled for green weight and for dry weight to arrive at the average MC.

Results might seem low, but calculated this way, the maximum efficiency can only reach slightly more than 30 percent.

An efficiency based on net heat values (ENHV) can also be calculated using the following assumptions:

* Oven dry wood gives 8,500 Btu's per pound. * Moisture requires 1,200 Btu's per pound for evaporation. * Charcoal gives 12,500 Btu's per pound and the formula:

Pounds of marketable charcoal x 12,500 ENHV = ----------------------------------------------------------- (Pounds of oven-dry wood x 8,500) minus (pounds of moisture times 1,200)

Pounds of moisture = wood MC (green basis) in decimal form times green weight of wood.

Pounds of oven-dry wood = 1 minus MC (green basis) in decimal form times green weight of wood.

In practice it is not necessary to consider the charcoal MC unless water has been used to quench hot spots. The same procedure is used for calculating wood or charcoal MC. Charcoal is weighed and dried in a container, and tare weight is subtracted.

If possible, kilns should be tested on a cement slab to reduce the detrimental effect of ground moisture.

APPENDIX III

CHARCOAL KILN TEST DATA SHEET

DATE: KILN TYPE: OPERATOR(S): MODIFICATIONS: TEST NUMBER: PERSON HOURS NEEDED:

MOISTURE CONTENT (MC) SAMPLES

IDENT. DIAM. FRESH WEIGHT OVEN-DRY WEIGHT MC (FW) (DW) (GREEN BASIS)

COMMENTS ON THE BURN (TIMES, ADJUSTMENTS, TEMPERATURES, PROBLEMS, ETC.)

WEIGHTS

RAW MATERIAL MARKETABLE UNCARBONIZED CHARCOAL (RM) CHARCOAL (AC) BRANDS (UC) FINES (CF) APPENDIX IV

SPECIES OF WOOD COMMONLY USED IN CHARCOAL PRODUCTION

Green Moisture Content (percent Local Name Botanical Name green basis)

French cusha Prosopsis juliflora 39 Logwood Haematoxylon campechianum 45 Locust Hymenaea courbaril 38 Cusha Acacia spp. (mostly tortuosa) 32 Red wood Cocolobis diversifolia -- Bread -- and cheese Pithecellobium unguis - cate -- Wild tamarind Leucaena leucocephala 39 Fiddlewood Cetharexylum fructicosum -- White birch Eugenia spp. -- Black birch Myrcia citrifolia -- Spanish oak Inga laurina -- Snake wood Ormosia monosperma -- White beech Symplocos martinicensis -- Black beech Ilex sideroxyloides -- Manjack Cordia sulcata -- Cinnamon Pimenta racemosa -- Rainfall Gliricidia sepium 44 Tamarind Tamarindus indica 40 Casuarina Casuarina equisetifolia 40 Neem Azadirachta indica 44 Sesbania (grandi) Sesbania grandiflora 61

BIBLIOGRAPHY

Agarwal, Bina. The Woodfuel Problem and the Diffusion of Rural Innovations. Report by University of Sussex Science Policy Research Unit To U.K. Tropical Products Institute, 1980, 186 pp.

Baldwin, Henry I. The New Hampshire Charcoal Kiln. New Hampshire Forestry Recreation Commission, 1958, 84pp. Illus.

Bulai, S., and Richolson, J.M. Fabrication and Use of a Tongan Charcoal Kiln. Department of Forestry, Fiji. 10 pp. Illus.

Earl, D.E. Charcoal - An Andre Mayer Fellowship Report. Rome: Food and Agriculture Organization, 1974, 98 pp. Illus.

Earl, D.E., and Earl, A. Charcoal Making for Small-Scale Enterprises: An Illustrated Training Manual. Geneva: International Labour Office, 1975, 26 pp. Illus.

Food and Agricultural Organization. "Simple Technologies for Charcoal Making." Rome: FAO Paper 41, 1983, 154 pp. Illus.

Government of Montserrat. Preliminary Data of the 1980 Commonwealth Caribbean Population Census, Part I: Household and Housing Information, 1980, 26 pp.

Instituto Tecnologico De Costa Rica. Como Hacer Carbon Vegetal Usando un Estanon. Serie Informativa Tecnologia Apropiada No. 5. 9 pp. Illus.

Jamaica Scientific Research Council. Make Charcoal the Easy Way. 22 pp. Illus.

Lejeune, J.M. The Development of Forest Energy Resources: Ghana. FAO GHA/74/013 Field Document No. 32, 1983, 48 pp. Illus.

Little, E.C.S. "Mini-CUSAB Kiln for Rapid Small-Scale Manufacture of Charcoal from Scrub, Coconut Wood, and Coconut Shells," Appropriate Technology Vol. 5 No. 1, May 1978, pp. 12-14.

Paddon, A.R., and Harker, A.P. The Production of Charcoal in a Portable Metal Kiln. London: Tropical Products Institute Report G119, 1979, 29 pp. Illus.

Richolson, J.M., and Alston, A.S. Part I: Production With Simple Steel Drum Kilns. Department of Forestry, Fiji. 24 pp. Illus.

Roos, Werner, and Roos, Ursula. Survey of Simple Kiln Systems and Recommendations for the Selection of Kilns. German Appropriate Technology Exchange Report, 1979, 49 pp. Illus.

USDA Forest Service. Charcoal Production Marketing, and Use. Forest Products Laboratory Report No. 2213, 1961, 137 pp. Illus.

Volunteers in Technical Assistance (VITA). Making Charcoal: The Retort Method. Arlington, Virginia: Volunteers in Technical Assistance (VITA), 1981, 29 pp. Illus.

Wartluft, J.L. "Forecasting Charcoal and Woodfuel Demands and the Level of Kiln Operation and Natural Forest Acreage Needed to Satisfy Demand." Memo to CDB, VITA, and GOM, 1983.

ABOUT VITA

Volunteers in Technical Assistance (VITA) is a private, non-profit, international development organization. VITA makes available to individuals and groups in developing countries a variety of information and technical resources aimed at fostering self sufficiency--needs assessment and program development support; by-mail and on-site consulting services; information systems training; and management of long-term field projects. VITA promotes the application of simple, inexpensive technologies to solve problems and create opportunities in developing countries.

VITA places special emphasis on the areas of agriculture and food processing, renewable energy applications, water supply and sanitation, housing and construction, and small business development. VITA's activities are facilitated by the active involvement of VITA Volunteer technical experts from around the world and by its documentation center containing specialized technical material of interest to people in developing countries.