VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org

Preface

The purpose of this manual is to outline, in as simple a manner as possible, the details of making and burning clay brick suitable for domestic building. The scope of the manual is confined to "cottage industries"; it does not cover large commercial production such as is known in the United States. The author has had personal contact with such brickmaking plants in both Central Mexico and Honduras. It is hoped that by publishing some of the observations and experiences made at these two locations, I can help community development leaders to offer advice and assistance in developing areas where brickmaking plants are needed.

INTRODUCTION

The Materials: Clay and Fuel

The two principal materials needed to carry out even elementary brickmaking are (1) a source of clay, and (2) a reliable source of fuel. We will expand on the clay requirements first.

Clay

Clay is a hydrous aluminum silicate formed by the deterioration of a number of minerals over a long period of time. When glue-like organic material is associated with it, the clay becomes plastic or hand moldable and pliable. It is found throughout the world and has been treated, since time began, with far less respect than it deserves. It is from this ordinary clay that man can make the brick to house him, the tiles to cover his home, pipe to carry water to his living area, pipe to divert sewage, clay pots to store and cook his food, and tiles to pave his walk and driveways. Certainly, any material which in itself can provide all these features should not be slighted. How, then, does one select the proper clay and what, actually, IS the proper clay?

There are four characteristics of clay to consider when we are thinking of using it as an ingredient in brick or tiles:

- It must be easily available and must be able to be won from the earth with a minimum of physical effort.

- It must be plastic. This means that when the clay is mixed with small amounts of water, it will become pliable and will respond to the human hand by taking different shapes.

- It must develop strength upon drying.

- It must develop hard and durable "use" strength when fired or burned in a kiln.

Clays are found, for the most part, when topsoil is removed by stream action or as a result of a road cut. If a pond or water-collection area is above the normal level for flowing water, this can mean that a clay mass is present. Thus, a pond found in the countryside which is some 200 feet above the level of a nearby stream would indicate that there is a very fine material underlaying the pond and thus the normal outflow of rainfall has been restricted. Digging near the banks of such an area of captured water will generally reveal the presence of a "lens" of fine grained and plastic clay.

If community development leaders have samples of clay and are wondering if the material will, in fact, make good brick, these samples can be sent to ceramic laboratories in your country or in the United States where simple, but conclusive tests can be made to find out if the clay is a possible ingredient for brick forming. One such laboratory willing to make elementary tests of clay, and to comment on it, is the

Ceramic Laboratory International Minerals & Chemical Corp. Post Office Box 437 Mulberry, Florida U. S. A.

Community development leaders wishing to have local clays evaluated for their possible use in brick can contact this laboratory directly. You should get detailed packing and shipping instructions from the laboratory before shipping any material.

Starting and Operating a Brickmaking Plant

This manual continues now with the assumption that a suitable clay has been found and that it is within easy access of the proposed user. We will further assume that firing or heat-treating facilities do not presently exist and that there are only very limited sources of steel or metals. The fuels will be limited to materials such as wood scraps and other burnable materials as are locally available. In brief, we will now explore the establishment and operation of a building-brick plant wherein nothing but "on hand" materials and labor will be utilized.

Clay brick is made in the following steps:

- Clay winning and clay preparation.

- Brick forming.

- Brick drying.

- Kiln construction and brick firing.

- Finished product quality selection.

Clay Winning and Clay Preparation

It is common, in small one and two-family brick operations, to combine clay winning and clay preparation. In general practice, the operator desiring to make the clay plastic will use a simple hoe or adze to chip away small amounts of the clay bank. If the material is available as a flat lens, he will probably dig a hole about three feet deep under the level of the earth. The hole would be about 10 feet in diameter. Then, with short chopping strokes with his adze, the operator will "shave" the clay from the bank face. The flakes of clay so removed will be about 1/4" thick. In all probability, they will curl up as they are removed from the clay bank face. In those cases where the clay appears as an out-cropping on the side of the hill, the process is very similar, but the operator would move his "shavings" to a small pit or hole nearby. The function of the hole to receive the shavings is simply to provide a location wherein the clay, newly cut from the bank, can be mixed with water. The clay "shavings" are quite light and are not as dense as the clay remaining in the bank face. Small amounts of water are worked into the clay by use of the human foot. A dancing and hopping movement is characteristic of people accustomed to mixing water and clay in this manner. It is common to have one man chipping the clay face and another person doing the water mix operation. When the clay-water mixture reaches the consistency of pourable concrete, it is placed in a pail or bucket and removed to the brick-forming area. An ordinary wheelbarrow at this point would be considered a most welcome labor-saving device.

Brick Forming

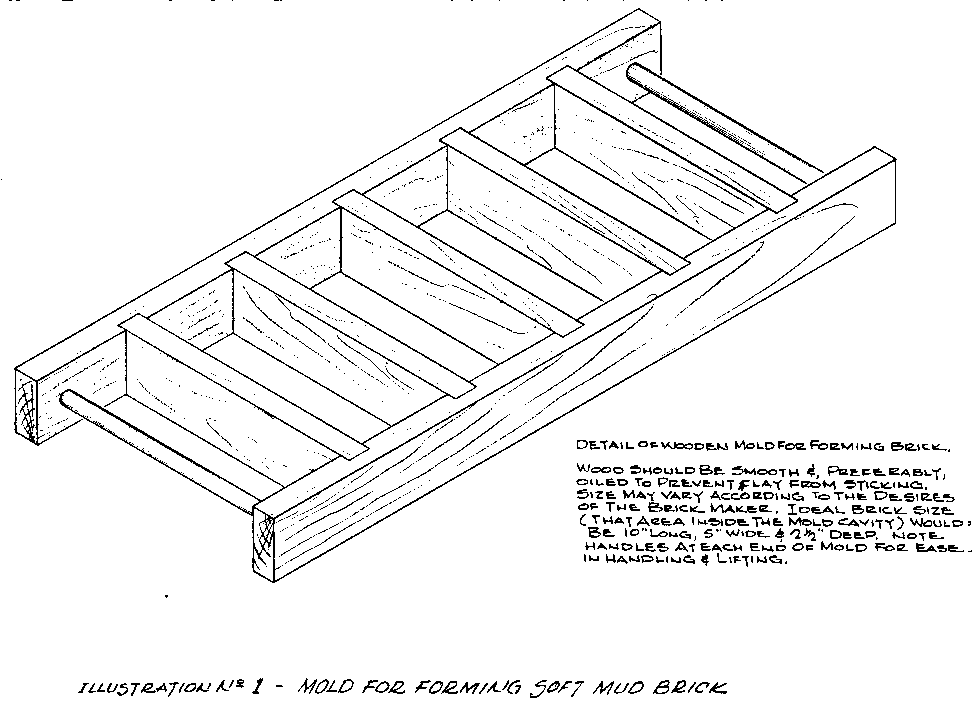

The actual brick-forming operation is one of merely pouring or dumping the clay-water mixture into a multiple-cavity brick die. This die is generally made of wood and is open on both faces. See Illustration No. 1 for

details of a typical wooden brick mold. There may be as many as four cavities in the die so that each casting will yield four brick. The brick themselves are roughly ten inches long, 2 1/2 inches high, and 5 inches wide. Actual dimensions will vary from country to country, depending on local taste and previous performance. The above brick, 10 x 2 1/2 x 5 inches may be too heavy or cumbersome for some female workers. If this is so, smaller units can be made. It should be noted at this point that the final brick will be smaller than the actual die or mold with which it was originally formed. This firing shrinkage will be dealt with in a later portion of this manual.

The molds are coated with sand to make it easier to remove the clay from the wooden sides of the mold. This can be done by sprinkling sand the size of grains of salt on the mold surfaces after the mold has been immersed in water. Oil, at a premium in most places, will also act as a parting agent. In those cases where oil can be used, it has a dual advantage in that it will be absorbed by the brick and consumed by the heat of the kiln and will actually provide part of the fuel requirements. The molds are filled on level ground. Usually, two operators are needed in the casting or pouring of the brick. After the bucket of clay-water mix has been poured into the open mold cavity, the mold is vibrated slightly by the heel of the hand. This causes the material to settle and level off at the top. Some water is absorbed by the ground; some comes to the top and is pushed off. Excess material laying on top of the mold is then struck from the mold by a deft movement of the heel of the hand. The excess material captured in this manner is placed in another mold and will be used in another brick.

The consistency of the brick mix is a very important and critical point. Clay-water mixtures which are too watery will have a tendency to flow or cause the brick to slump when the restraining mold is lifted free of the mix. Clay-water mixtures which are too stiff or lacking sufficient mobility will not fill the corners of the brick mold and the resultant product will then be irregular and jagged. Once the proper consistency or waterclay ratio is determined experimentally, the pit operator should exercise all possible care to see that this consistency is maintained throughout the working day.

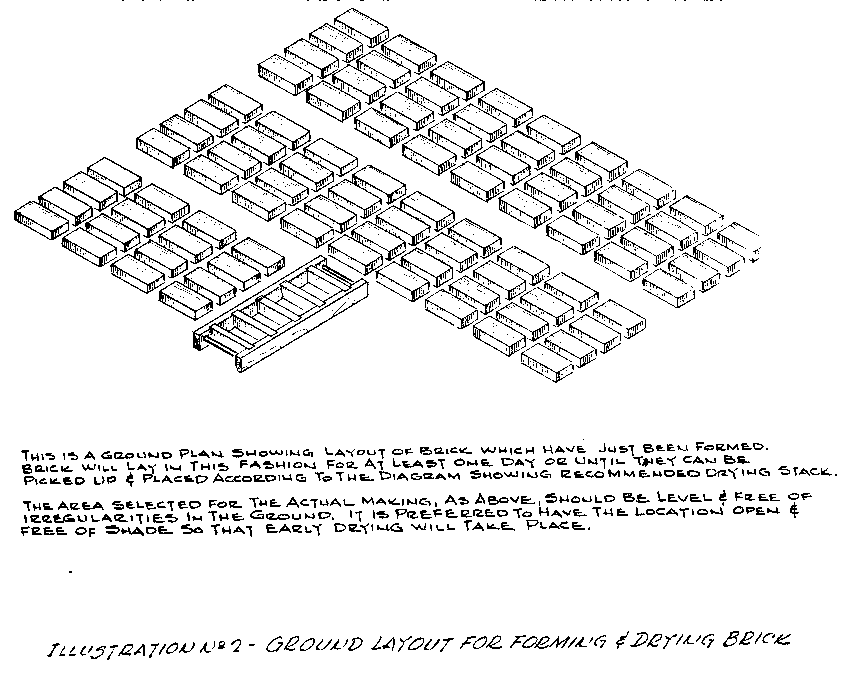

After excess clay is removed, the mold may be lifted up and free of the brick castings. In order to get a straight up draw of the mold, it is necessary to have two men perform the operation. Once free of the brick, the mold is again wetted with water and sand is sprinkled on the inner surfaces. It is then placed on the ground in front of the brick just released from the mold. Thus, the brickmaking process becomes a continuous operation with the mold moving progressively to make row after row of brick. See Illustration No. 2.

Brick Drying

In arid countries, it is not generally necessary to cover the newly made brick. They are simply left in the position in which they were made and allowed to dry in the sun. In those areas where rainfall is a daily occurrence, it is best to provide a covering for the newly formed brick. The cover should have no sides so that the air can move freely around the brick. After about three days in the flat or "as made" position, the brick can be handled without deforming or crumbling. At this stage, they are placed in a special manner to speed up the final stages of drying.

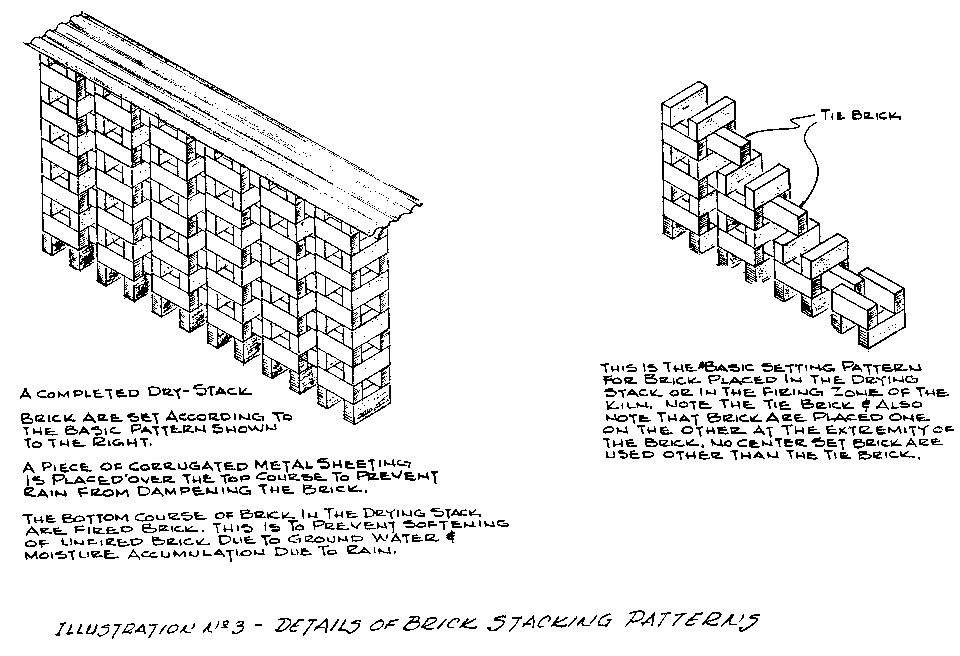

Perhaps the most important factor in drying is the "hack" or manner in which the brick shapes are stacked in the drying area. In Illustration No. 3, right hand

drawing, is shown a typical "hack" for drying brick. In this operation, two brick are first placed on the ground on the face or narrow dimension. They are placed as far apart as a brick is long. Then, at 90 [degrees] to the first two brick, two more brick are placed on the top of the first two. The second placed brick will cover the ends of the first pair. In order to establish some degree of stability in such an open setting of brick as the pile extends higher, it is recommended that a "tie" brick be used to keep the stacks of brick from toppling. The tie brick actually keys one vertical column of brick into the one adjoining it. The key, or tie, brick is placed so that it extends from the center of the first two brick mentioned above to the center of the pair of brick placed adjacent to it. The continued placing of pair on pair, 90 [degrees] reversal as the pile extends upward, and the alternate tie-brick placement continues until the drying stack is about five feet high and of any convenient length, generally about 10 feet.

Drying is accomplished by permitting prevailing winds to circulate through the open spaces of the "hack". Three important factors control the rate of drying: (1) the heat naturally available, (2) the humidity, and (3) the amount of fine particles in the clay. Obviously, ideal conditions would call for a locale wherein the heat of the day would stay quite high with the sun shining most of the time. Secondly, the lower the humidity, the more rapid the drying of the brick. The presence of extreme fines or very powdery clay will require more water in the clay-water mixture to form. As the same fines in the clay are more reluctant to give up the forming water, the drying time will thus be extended. A sandy clay is more apt to dry rapidly, without cracks, than a clay which is predominantly fines.

The brickmaker may find that the clay he is using has a preponderance of extremely fine particles which causes brick cracking. He can correct this fault by adding some sandy material to the clay mix. The particles of sand should be the size of grains of salt with a few as large as match heads.

In any event, it is necessary to provide at least one full week to insure complete drying. During this time, the possibility of rainfall must be taken into account. If the stack of brick, as described above, is standing in an unprotected area and is exposed to the rain, it is entirely possible that the brick will lose strength upon being wetted and will slake or crumble as a result of the newly combined water. Both the top of the brick stand and the base must be adequately protected. Top protection designed to shed ordinary rainfall is accomplished by placing a few cuts of lightweight corrugated metal on the top of the brick. This is demonstrated in Illustration No. 3, left hand drawing. During a rainfall, it is possible that run-off water or pools may develop around the bottom course of brick. In order to protect the stack from becoming weakened due to a water softening of this bottom course, it is recommended that the drying stack be built upon a first course of previously burned brick. These brick are resistant to water slaking and will remain rigid although wet from water run-off.

Local conditions, including the humidity, the persistence of rain, the amount of solar exposure, the motion of hot air caused by wind, as well as the nature of the clay itself, will dictate, to a large degree, when the drying process is completed. In any event, it is imperative that the drying process be complete before the brick are taken to the final process: the firing or burning of the brick.

There are two simple tests to determine if the drying process is, indeed, complete. As clay dries, it changes color. Generally the color becomes lighter as the water leaves the clay mass. Thus, a thoroughly dried brick would show no color differential, upon being broken in half, from the outer skin area or the center section inside the brick. Another means of determining if all the drying is completed, is to weigh a brick taken from the drying hack. Then place it in an oven or near a source of heat. Weigh again. If the brick heated in the oven shows a loss of weight, this means that the brick in the drying pile also must contain water and thus the drying process is not complete.

Kiln Construction and Brick Firing

It is in the firing of the brick that it receives its strength. In the presence of high heat, the alkalies in the clay, together with small amounts of oxides of iron and other metals are joined, to a degree, in chemical union with the alumina and silica in the clay to form a dense and durable mass. A kiln is a furnace or oven in which brick are fired or heat treated to develop hardness. Where brickmaking is done on a large scale, the firing operation is performed in a continuous-process kiln referred to as a tunnel kiln. In making brick on a small scale, firing is a periodic operation wherein the brick are placed in the kiln, the fire started and heat developed, and then, after several days of firing, the fuel is cut off from the fire and the entire kiln and its load are allowed to cool down naturally. Where brickmaking is on a high production basis, the kiln is the largest single investment for the manufacturer. It can represent a cost of as much as a half million dollars. For our purposes, we will concern ourselves with the periodic-type kiln. We will limit our attention to kilns which can be built of locally available material and can be fired with fuels native to the land.

To reduce the kiln to its simplest parts, we will identify the different components as follows:

The Fire Box, The Flue System, The Permanent Side Walls and the Mudded End Walls

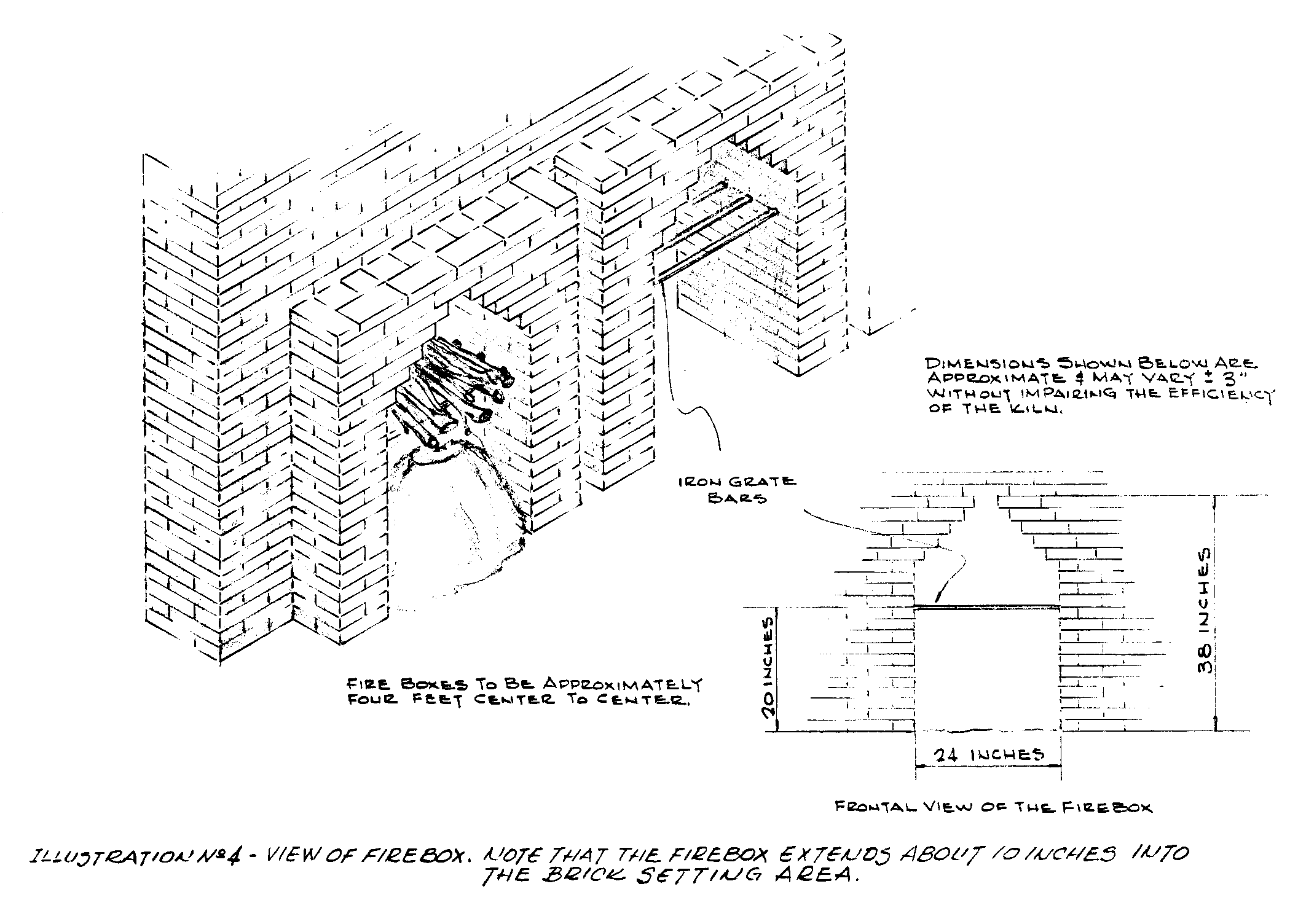

The fire box is an opening through which the operator feeds the fuel. It generally consists of an opening about 24 inches wide and 38 inches high and 30 inches deep. The top area can be arch-shaped, but this is a refinement which is not necessary. In the center of the 24-inch span, about 20 inches from the ground, iron rods or grid bars are placed. These bars, preferably 3/4 inches in diameter, are spaced about 3 inches apart and are to serve as a grate in the opening of the fire box. They are secured by embedding them in the brick work on either side of the opening. See detail in Illustration No. 4.

The flue system is the system of open spaces purposely made in stacking the brick to allow the movement of heat and gases. The flue system provides openings for the heat from the fire box to reach the brick in the kiln and to travel to the upper areas of the kiln in the same manner as smoke and heat will travel up a chimney. The flue system is, then, a chimney built in the kiln of the brick to be burned.

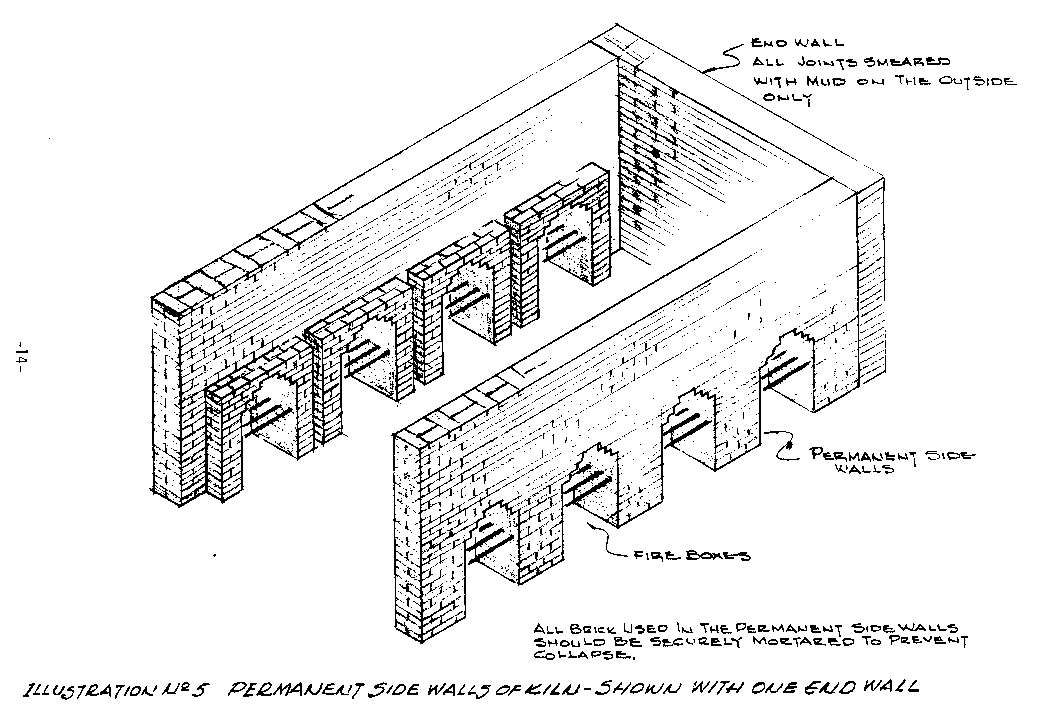

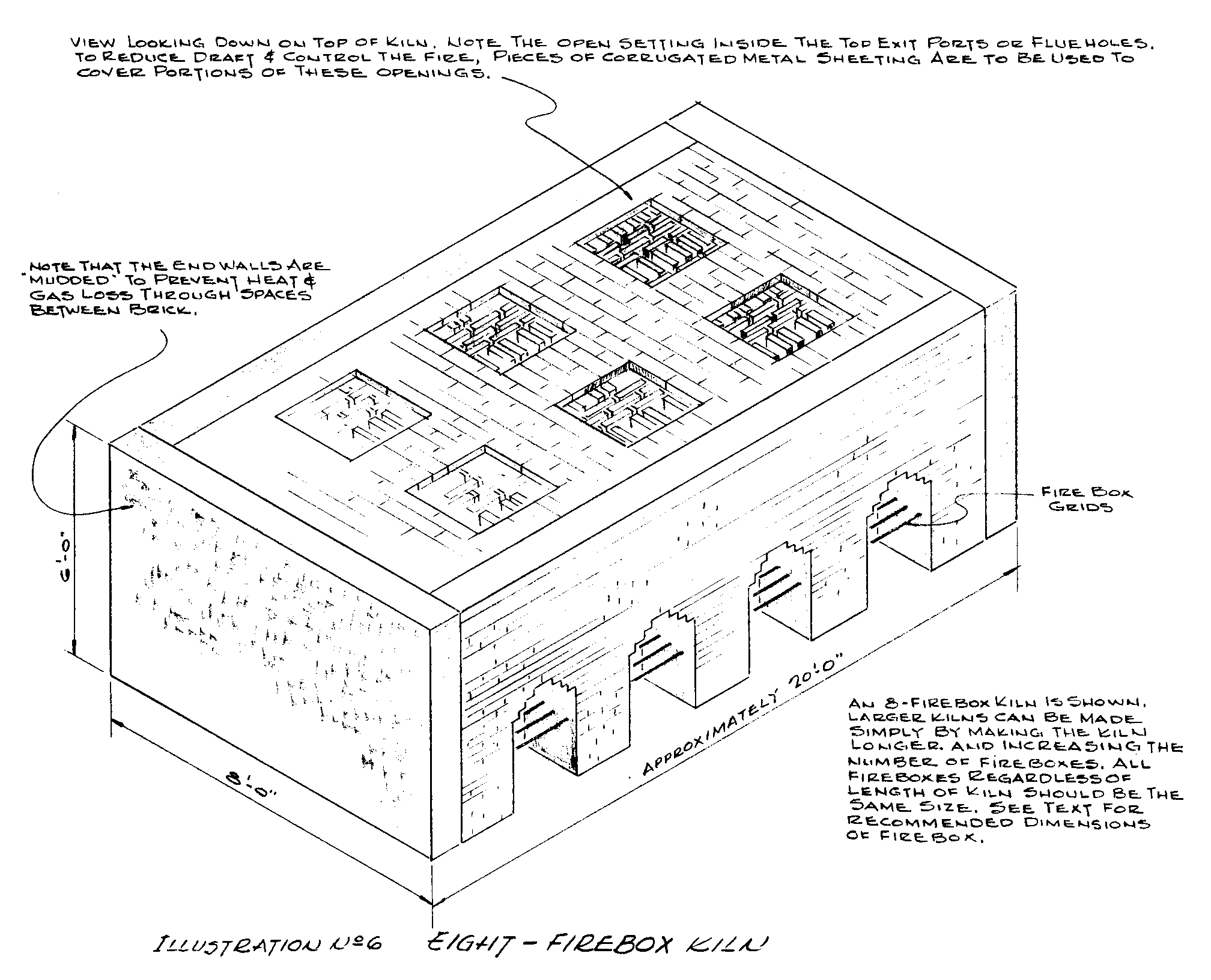

The permanent side walls are made of previously fired brick which form the two sides of the kiln. The fire boxes are located in the permanent side walls. Both side walls are identical. They are generally about 10 feet apart and are perfectly parallel. The brick to be fired are placed in the area between the permanent side walls. Permanent side walls are normally two brick lengths or 20 inches thick. See Illustration No. 5.

To those confronted with the task of building such a kiln, the thought may occur, "Just where do I get brick to make the side walls and the fire boxes?" The answer is simple. One would start with "green" or unfired brick and make the entire kiln, side walls and fire box. The first kiln would be greatly reduced from the size of the projected kiln. After the first firing, perhaps as many as 50% of the brick in the kiln will develop enough hardness to be used. These are set aside and continued firings with the small scale kiln are made until sufficient brick to make the two full-sized side walls are accumulated.

The Mudded End Walls are closures of brick which are constructed at the ends-of the permanent side walls. The mudded End Walls may be made of previously burned brick or they may be built up of unburned brick. It is through the openings closed by the Mudded End Walls that the brick are loaded into the kiln and removed from the kiln's mid-section. Illustrations 5 and 6 will serve to show the

layout and construction of the fire boxes, the permanent side walls and the mudded end walls. The mud for the end walls is a mixture of brick clay and water which is smeared on the outer areas of the brick placed between the permanent side walls. This mud is smeared on by hand in a fashion much like the modern day plasterer would spread plaster on a house wall. The purpose of the "plastering" mud is to prevent the development of flues or escaping heat from the kiln as it might travel through cracks between brick set in the ends of the kiln. Brick fired in this end area are seldom exposed to the heat necessary to develop desired hardness and, for this reason, they are set aside to be placed in the inner kiln areas on subsequent firings.

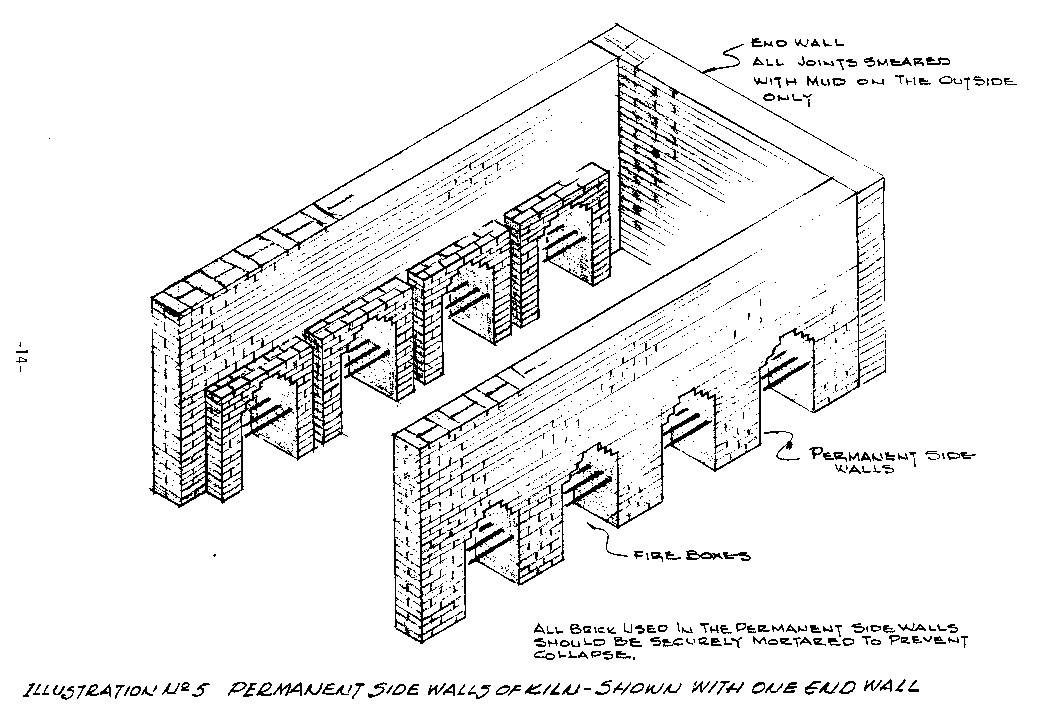

Let us assume that the brick to be processed as burned building units have been thoroughly dried and that the permanent side walls of the kiln, together with the archway fire boxes, have been prepared for loading and subsequent firing. The dried brick are first arranged in the area immediately in back of the fire box. The placing of brick is always BETWEEN the permanent side walls. Brick in the fire box area are placed one on top of the other in a cross hatch manner. Thus, two brick would be placed on the ground in back of the fire box and two more will be placed on top of these but turned 90 [degrees] so that they overlap the bottom two brick. This process continues until the entire area is filled. Bricks in the inner section of the kiln are never placed in close proximity one to the other. This is to permit the heat to make thorough penetration of the mass of brick and to permit gases generated during the firing process to escape. There are two exceptions to the rule about placing brick close to each other. In the case of the brick appearing in the end zones of the kiln, it is recommended that these units be placed close to each other. This is the area where the end wall mud is applied and it is not desirable to permit the development of a flue area through the end walls. The other area where brick are close-set is the last course of brick at the top of the kiln. In laying or placing the top-most row of brick, the operator will place the brick wide-spaced to form areas about 2 feet square in a number of places across the top of the kiln. Thus, when looking down on the top of a properly placed kiln, one would see the two permanent side walls and he would see a number of square areas in which the brick were open placed or separated. The number of these top openings depends on the size of the kiln. Illustration No. 6

shows a typical arrangement. As in the case of the end walls, the close-set top brick are mudded over to prevent the escape of gases and heat through cracks between brick. It is now obvious that we have established a flue system or draftway extending from the fire box, through the setting of brick and extending onward through the kiln setting to the top of the kiln itself. It is at this point that we apply one set of firing controls required on the kiln. Pieces of sheet metal should be provided to slide over the various openings to control the amount of hot air and gases as they pass out of the open set flue space. Thus, a piece of sheet metal about three feet square should be provided for each 2' x 2' opening in the top of the kiln. To create a greater draft and to get the fires burning more rapidly, the flue covers would be removed. To dampen the fires and to hold the heat as long as possible (known as fire soaking) the draft covers would be slid over the openings and thus retard the passage of gases and heat from the kiln.

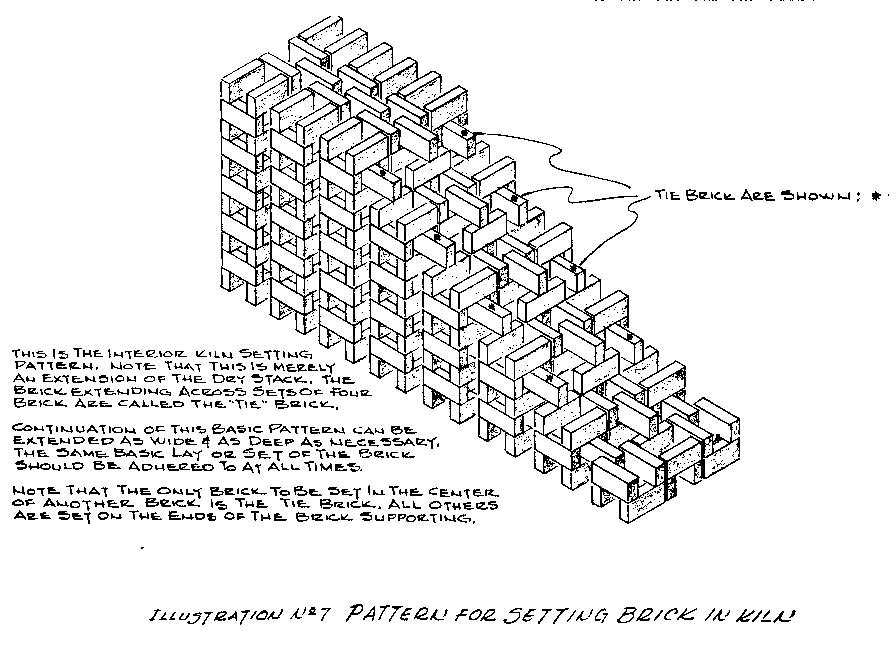

Special attention is drawn to the cross hatch manner in which brick are stacked, one on the other, to accomplish the flue system mentioned above. The basic structure is the same as that outlined for the drying stack earlier. The same tie or key system is adhered to. The keying technique, in the inner brick placing area is extended two directions. In order to prevent internal topple or insecure and unstable piling of brick, the rows are keyed, one to the other, by placing the second row of brick in close proximity (actually about one-half inch short of touching) the brick in the first column. The brick so placed are set so that a side of the brick in the second column will be placed against the ENDS of the brick in the first row. This setting is reversed in the case of the second stand of brick and so on until the entire kiln is loaded and thoroughly tied in, row with column, etc. See Illustration No. 7 for details of row and column placing.

The selection of fuel is frequently limited to just what burnable materials are on hand. Wood is the most likely fuel and is perfectly acceptable in creating the high heat necessary for complete burning of the kiln. The wood should be cut in lengths of about 6 feet. It is placed on top of the grate bars and extends into only the inner edge of the permanent side walls. The wood is pushed inward as the ends are consumed. Other than wood, fuels which have been used successfully to burn brick in various countries include coffee husks, coconut hulls, dung, olive pits, and even burnable fabric scraps. Sufficient fuel in a "ready-to-go" condition should be in good supply whenever the firing process is started. It would be conceivable that the operator short of fuel would lose his entire load of brick due to under firing if the fires were allowed to die down and go out simply because sufficient fuel was not on hand to complete the firing operation.

As mentioned above, when the firing is about to start, the operator places the wood or other fuel on top of the fire box grate bars. Then he starts a small fire directly under the grate so that the flames traveling upward will ignite the fuel on top of the grate bars. The flue covers on the top of the kiln would be left open to permit free access of air and to create a draft from the fire box, through the fire, and on upward to the roof of the kiln.

The principal part of the burning is done on top of the grate bars. The under area provides a point of entry for the air (oxygen) required to accomplish continued combustion. This under area can be closed off by placing excess fuel or ashes in the under area. This dampering by closing off the area under the grate is still another control feature. The early stages of firing, when the fires are just getting started and developing heat, would be conducted with the dampers on top open and the under grate area free of fuel or ash. After ten to twelve hours of continued burning and stoking, the inner portion of the kiln will begin to pick up heat. The operator may be able to discern a slight reddish glow as he observes the inner portion of the kiln by looking through the archway of the fire box. When the entire inner mass of the kiln has developed a cherry red glow, the kiln is at its prime heat for good firing. At this time, however, the hot areas may be confined to just those brick in or near the flue path. In order to complete the firing and to permit the inner portion of all the brick to attain proper heat, it is best to retard the draft movement by sliding the top covers over about half of the flue openings. At the same time, it is advisable to place fuel or ash in the bottom grate area. This retardation of draft reduces the heat loss through the stack and permits the heat to travel in the areas of the brick setting not reached via the normal draft or flue routes. This period of dampered fire box and upper flue tops is known as the "soaking" period. Soaking in the firing of brick is very important. Once the cherry red inner hue (corresponding to a temperature range of 1600 [degrees] F - 1750 [degrees] F., 875 [degrees] C - 900 [degrees] C.) is developed and the soak period started, it is necessary for the operator to hold this condition for at least 6 hours. During this six hour "hold", fuel will be consumed and should be applied to the fire. The combustion will, however, be retarded as the passage of air is reduced.

After the six hour "hold" period is completed, the fuel is cut off and the top plates are placed in position to cover the flue openings. Often the openings in the permanent side wall or the fire box will be filled with ashes from previous fires. The reason for this is to prevent any heat loss due to the open grate way and thus hold the heat in the kiln and on the brick as long as possible. This covering of flues and closing the fire box may be thought of as an extension to the soaking period. After about two days, the brick can be removed from the kiln. The end walls are torn down by removing the upper section first. The brick which formed the actual end wall and did not receive full benefits of the heat can be refired in subsequent firings. The mud used to close up the gaps between close set brick will knock off and will not impair the appearance of the brick. After all brick are removed from the area between the two permanent side walls, the entire kiln, with the fire boxes included, should be swept clean of refuse and bits of clay and broken brick. The kiln is now ready for another firing.

One final word concerning the firing operation should be included at this point. When clay products are processed through the firing or heat treating stage, they undergo an important transition: shrinkage. Normally the shrinkage of a fired clay product will amount to as much as ten percent of its original size. Thus, in firing a kiln loaded with brick, we should be aware of the shrinkage factor and expect the stacking of brick in the center of the kiln to be several inches lower after the firing process than it was at the beginning. Some kiln operators will be able to judge the degree of firing by noting the height to which the pile of brick has been reduced as a result of this normal function: shrinkage.

Building brick, as noted here, can be made with clay and locally available fuels. The labor required is hard, and by our terms, backbreaking. The rewards, on the other hand, are enormous. Durable housing which will resist the torments of the elements generates a feeling of purposefullness and security to those so sheltered. The comfort of living in a dry abode and one which will remain cool in the hot sun should be reward enough for the hard work involved.

For the PCV who strikes out on his own, and attempts to build and operate such a kiln and product as is described here, the author has one additional ingredient to suggest: patience!!

Haste in building the kiln can result in shoddy side walls, shoddy side walls and fire boxes means that constant and time consuming repairs are called for. Haste in placing the brick in the kiln can result in collapse of the entire mass. The net result here is dead loss in most cases. Perhaps the most critical area to exercise patience is in the drying process. Brick with even a trace of water should never be placed in the kiln.

Questions and comments will be welcomed by the author. Inquiries and related comments should be directed to:

D. W. THOMAS 39 WOODBRIDGE AVENUE UNIT 23 METUCHEN NJ 08840 USA