Published By VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Mini-Hydroelectric Generation ISBN: 0-86619-218-2 [C]1985, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries.

The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Giannuzzi and Leslie Gottschalk as editors, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

The author of this paper, Christopher S. Weaver, P.E., is a senior engineer with Energy and Resource Consultants, an interdisciplinary consulting firm in Boulder, Colorado. He is a registered Professional Engineer, and has worked in the areas of electric-utility planning, solar energy, cogeneration, and air-pollution control as well as in small hydroelectric systems as a consultant. Weaver is the author of another VITA technical paper, Understanding Micro-Hydroelectric Generation. The reviewers of this paper are also technical experts in hydroelectricity. Theodore Alt, P.E., is a mechanical engineer who has been in the energy field since 1942. He has worked with the energy research and development group of the Arizona Public Service Company and the Government of Mexico's electric commission. Paul N. Garay, an associate engineer with F.M.C. Associates, has written many papers on various aspects of water transportation and energy uses of water.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

GENERAL BACKGROUND

Electricity can be generated from the power of flowing water. This is called hydroelectric generation, and it can be done anywhere that there is water and a hill or drop for it to run down--in an irrigation canal, where a river runs through rapids or over a waterfall, or where a dam has backed up water above the level of the river. Hydroelectric generating plants come in many sizes --from huge plants that produce more electricity than most countries can use, to very small plants that supply electricity for a single house. Hydroelectric plants which supply electric power in the range from about 15 kilowatts to 15,000 kilowatts are called mini-hydroelectric or mini-hydro. Other phrases that mean the same thing are "small-scale hydro" and "small hydro."(*)

Fifteen kilowatts is about the amount of power used by seven or eight houses in the industrial countries, or by a very small manufacturing plant, or it can provide lighting and other basic services for a village of 50-80 houses. Fifteen-thousand kilowatts is enough for a medium-sized town. Hydro plants which are larger than 15,000 kilowatts are usually called "large hydro" or "conventional hydro" plants, but there is no sharp line dividing "mini-hydro" from "large hydro." All mini-hydro and large hydroelectric plants use similar machinery, and work in the same way. Plants of either type need specially manufactured machinery, and must be designed by trained engineers. Both types of plants are also fairly expensive. Because of this, mini-hydro plants are not well-suited to village-level development in most cases--a larger organization such as a town, a collection of villages, or an industrial plant is usually needed.

Another type of hydro plant, called "micro-hydro," is better suited to village level development and local self-help projects. These plants are usually smaller than 15 kilowatts, and can be built by people without much special training, using mostly local materials and skills. Micro-hydro plants are usually very low in cost, but they are less efficient, and the quality of the electricity is not as good. Micro-hydro plants are suited to running lights, small motors, and electric cookers in isolated

*These definitions are not universally agreed on. Different authors may use mini, micro, or small to refer to the same project. houses and villages, but are not usually good for larger towns or industrial plants, and they cannot be interconnected with other generating plants in an electric system the way mini-hydro and large hydro plants can. Micro-hydro plants are described in another VITA technical paper, Understanding Micro-Hydroelectric Generation.

HISTORY OF MINI-HYDRO GENERATION

Water wheels have been used since ancient times to supply power for grinding grain and other laborious tasks. The first modern hydraulic turbines were developed in the first part of the 19th century by Fourneyron in France. These were further developed by a number of researchers during the middle of the century, so that by 1890 most of the types of turbines now in use had been invented. Edison's invention of the electric light and of ways to distribute electricity occurred at about the same time, leading to a great boom in hydroelectric development in Europe and North America. Until about the 1920s, most hydroelectric developments were quite small--in the size range which is now called mini-hydro. This was for two reasons: people didn't know how to build really large dams and turbines, and the small electric transmission systems of the time made it difficult to sell large amounts of electricity.

During the era of the 1950s and 1960s, advancing technology and cheap oil--combined with improved long-distance electric transmission--made it possible to sell electricity cheaper than the earlier small hydro plants could make it. Hundreds of small hydroelectric facilities were abandoned or dismantled during this period. With the oil embargo of 1973, which has led to enormous increases in the cost of oil, small hydro once again appears competitive. Many of the early plants which were abandoned in the 1950s and 1960s are now being refurbished, and many new ones are being planned. Small hydro is also well suited for developing countries, and is being actively encouraged by many governments and development organizations to reduce oil imports and encourage development.

II. HYDROPOWER FUNDAMENTALS

This section presents a few basic facts and principles about electric power and hydroelectric generation. Reading it will not make you into a hydroelectric engineer, but it will help you understand how hydroelectric systems work, and what makes a good or a bad hydroelectric site. It will also help you to understand your hydroelectric engineer if you decide to hire one.

BASIC PRINCIPLES

Electric Power

Power is defined as an amount of energy divided by the time it takes to supply the energy, or in other words as the rate at which energy is delivered. Power is measured in units called watts, or (for large amounts of power) in units of kilowatts. One kilowatt is equal to 1,000 watts. Power is also measured in horsepower. one horsepower equals 746 watts.

Two other quantities that are important in talking about electric power are the electric current and the voltage. Electric current can be thought of as the amount of electricity flowing through a wire (like the amount of water flowing through a pipe), while voltage can be thought of as a measure of how much force is needed to push the current. Current is measured in amperes, or amps for short, while voltage is measured in volts. The electric power (in watts) is equal to the product of the current and the voltage, so that a current of 1 amp with a voltage of 100 volts would give a power of (1 x 100) = 100 watts.

Two types of electricity are commonly used. Alternating current (AC) electricity is generated in a way that makes it change directions (alternate) many times each second. The number of times it changes direction is called the frequency. Direct current (DC) electricity does not change directions; it always flows the same way.

Large electric power systems and many small ones use alternating current, in order to be able to use transformers to change voltages up and down. Transformers will not work with direct current. On the other hand, batteries can produce only DC, so small electric systems which use batteries generally use DC current. AC can be converted into DC using a device called a rectifier, while DC can be changed into AC using an inverter.

Almost all mini-hydroelectric systems produce alternating current, in the same way as large electric power systems located in cities. In these systems, the voltage and frequency of the electricity produced are carefully controlled to keep them constant. Adding more load to an operating power system (such as by turning on more lights) tends to slow the generators down, which causes the voltage and the frequency to drop. Conversely, shutting off lights will reduce the load, permitting the generator to run faster. These systems must have some kind of an automatic control which detects when the speed changes, and takes action (such as letting more water into a turbine) to bring the generators back up to the right speed. These controls are expensive, and most micro-hydro systems don't have them.

Electrical equipment is rated in terms of the voltage and the type of current it is designed for, and the nominal amount of power it can produce (for a generator) or use (for things that consume electricity, such as motors and light bulbs). A generator with a rating of 5 kilowatts (KW) at 100 volts is designed to produce 50 amperes at 100 volts at full load, which is 5,000 watts or 5 KW. The same generator could also produce smaller amounts of power. The amount of power put out by the generator must be equal to the amount of power being used by the electrical equipment connected to it. The voltage ratings and type of electricity (DC or AC) used for the electrical equipment should always be the same as the voltage and type of electricity being supplied. If you connect a device rated for one voltage to a wire at another voltage, it almost certainly will not work, and the device is very likely to be damaged. The same is true of connecting AC devices to DC. However, many DC devices such as light bulbs and motors can also be used with AC, if the voltage ratings are the same.

The amount of energy produced in a generator or used by an electrical machine can be calculated by multiplying the amount of power used by the length of time that it is used. Energy is measured in units of joules--one joule is equal to one watt times one second. One joule is a very small amount of energy, so we commonly use units like megajoules (one megajoule is one million joules) or kilowatt-hours (abbreviated KWH). A kilowatt hour is equal to one kilowatt provided for one hour, which is 3.6 million joules. As an example, a 50-KW generator, if it ran at full load for one hour, would produce produce 50 KWH of electric energy. If it ran for two hours, it would produce 100 KWH.

Mechanical Power

Mechanical power is the force that causes machinery and other things to move. The engine of a car produces mechanical power, and so does an electric motor. Mechanical power can easily be converted into electrical power (this is what a generator does), and electrical power can be converted back to mechanical power (this is done by an electric motor). Mechanical and electrical power are measured in the same units--watts and kilowatts.

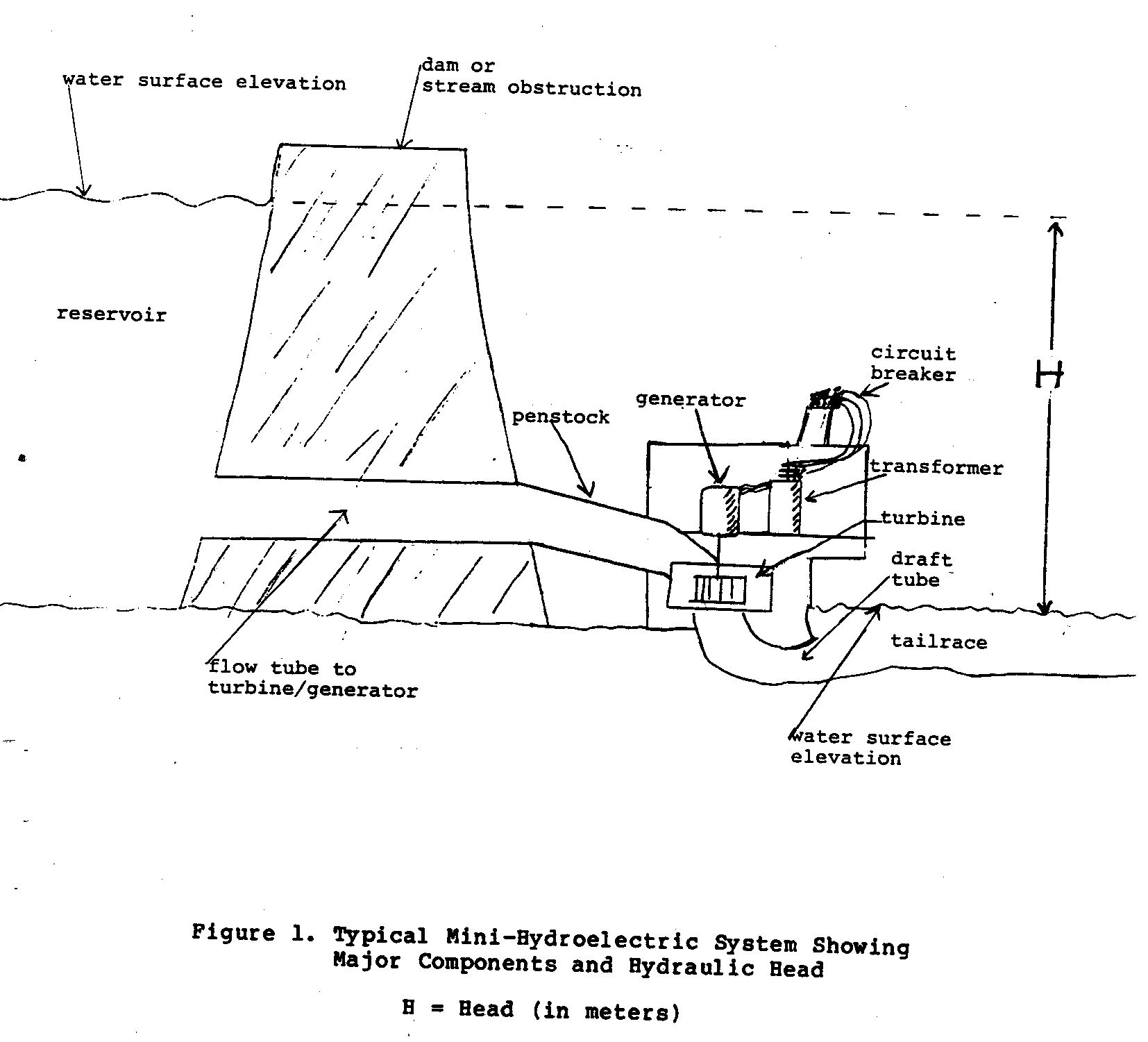

Head, Flow Rate, and Power Output

Water at the top of a hill or drop has energy, called potential energy, because of where it is situated. This potential energy is measured in terms of the "head," which is the vertical distance from the water level at the top of the drop to the water level at the bottom. Figure 1 shows how head is measured.

In natural streams, the potential energy or head of the water is dissipated by friction against the stream bed as the water flows downhill, or by turbulence at the bottom. However, if we put in a smooth pipe from the top to the bottom to reduce friction, and then put in a water turbine at the bottom, we can use the head in the water to turn the turbine and produce mechanical power. The amount of power we can theoretically get is given by:

[P.sub.th] = F x H x 9.807 (Equation 1)

where [P.sub.th] is the theoretical power output in watts, F is the rate of flow of water through the pipe in liters per second, H is the head in meters, and 9.807 is the conversion factor that accounts for the force of gravity on the water.

However, turbines and generators are not perfectly efficient, so the amount of electric power we can actually get from a micro-hydro plant with a given head and flow rate is less than [P.sub.th]. This amount is given by:

[P.sub.act] = [P.sub.th] x [E.sub.t] x [E.sub.g] x [E.sub.s] (Equation 2)

where [P.sub.act] is the actual useful power output from the plant, [E.sub.t] is the efficiency of the turbine, [E.sub.g] is the efficiency of the generator, and [E.sub.s] is the efficiency of the rest of the electrical system.

Efficiencies are always less than 1.0. Typically, [E.sub.t] is about 0.85 for turbines from a specialized manufacturer, 0.6 to 0.8 for pumps used as turbines, and 0.5 to 0.7 for locally-built cross-flow turbines: [E.sub.g] is usually 0.9 or more, for most kinds of generators. [E.sub.s]will be about 0.95, unless you are transmitting power a great distance.

Thus, a flow of 1,000 liters per second, with a head of 10 meters, could theoretically produce 1,000 x 10 x 9.807 = 9,8070 watts, or 98.07 KW. With a turbine efficiency of 0.85, a generator efficiency of 0.9, and a system efficiency of 0.95, we would actually get 98,070 x 0.85 x 0.9 x 0.95 = 71,270 watts of useful power, or 71.27 KW. The rest would be lost due to inefficiencies in the system.

III. MINI-HYDROELECTRIC SYSTEMS

SYSTEM COMPONENTS

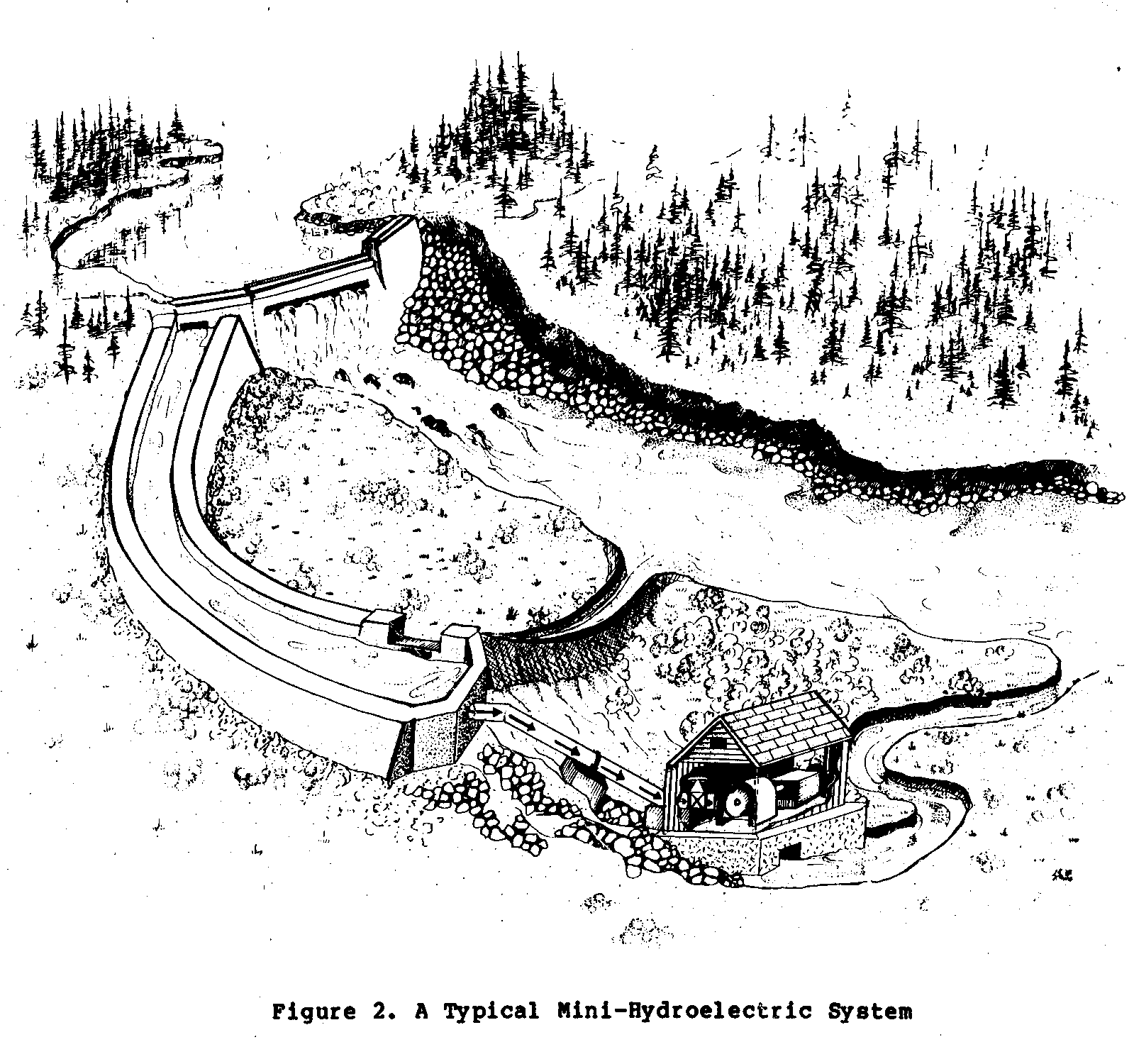

Figure 2 is a sketch of a typical mini-hydroelectric system,

showing the major components.

The water is backed up behind a dam (as shown) or some diversion structure, where it enters the penstock (the pipe leading to the turbine). It passes through the turbine, forcing the turbine to turn, and the turbine then turns the electric generator. The water then passes out through the draft tube into the tailrace, and then back into the river. Electricity from the generator goes to the transformer, where it is raised in voltage, and then out through a circuit breaker to the power line.

The structural parts of the hydro plant--the dam, penstock, draft tube, tailrace, power house, and so forth are called the civil works. The generator, transformer, and circuit breaker are often referred to collectively as the electrical gear. The electrical gear also includes many controls, switches, and safety devices which are not shown in Figure 2.

Civil Works

The civil works needed for a given mini-hydro plant will depend very strongly on the exact circumstances at the site. In the worst case, generating power at a completely undeveloped site might require building an access road to the site, a dam, spillways, penstock, powerhouse, draft tube, tailrace, and various other items, at a cost of several million U.S. dollars. On the other hand, a mini-hydro plant to go into an existing irrigation system might require only a power house, a short penstock, and a draft tube, with a correspondingly lower cost.

Civil works are the most variable portion of a hydro plant's cost --they can account for anywhere from about 15 to more than 75 percent of the total. Be careful not to underestimate their cost --many of the things that are needed may not be obvious to people without experience in the area. The construction of dams and similar structures can be astonishingly expensive.

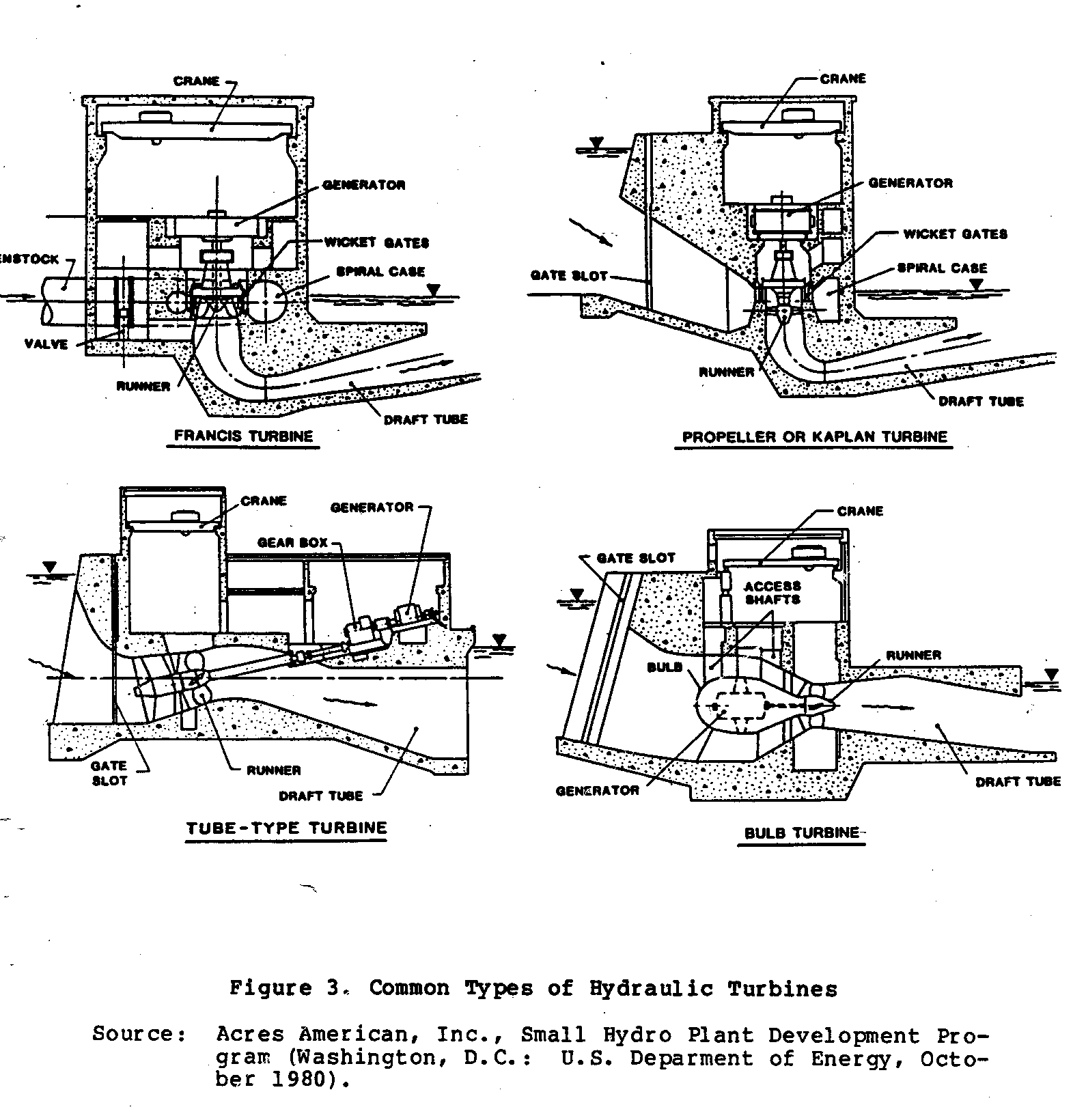

Hydraulic Turbines

A hydraulic turbine is a machine that converts the head or potential energy in water into mechanical energy (also called work), which is used to turn a shaft. There are a number of different kinds of hydraulic turbines--some of the more common types are shown in Figure 3. Except for the crossflow (also called the

Michell or Banki turbine), all hydraulic turbines for mini- or large hydro generation are high-technology items which must be built by a specialized manufacturer.

In response to the increasing interest in small hydro, a number of manufacturers have recently begun to come out with standardized turbines for small hydroelectric plants. Since each turbine does not need to be individually designed and built, this reduces the turbine's cost significantly. It is also possible to use rotating water pumps as hydraulic turbines. Since these pumps are mass-produced in great quantities, their cost can be less than a third of that of a specially-made turbine. However, this lower cost must be balanced against a lower efficiency, which can reduce the total power output and increase the cost per kilowatt from the plant.

Selecting the right turbine is one of the most important parts of designing a hydroelectic facility, and should be done by a qualified engineer in consultation with the turbine manufacturer. The choice of turbine is affected by many considerations, including the available head and flow, whether the plant will need to operate at part-load, whether it will be necessary for the plant to regulate the voltage and frequency in the electric system, the type of generator to be used, and the cost of the turbine, the generator, and other parts of the plant.

Electrical Gear

The electrical gear for a mini-hydro plant consists of the generator and the machinery to connect the generator to a powerline. In most cases, this machinery includes a transformer, a circuit breaker, and a number of protective relays, whose function is to trip the circuit breaker (and thus disconnect the generator from the power line) if anything goes wrong with either the plant or the electrical system it's connected to.

There are two main types of generators for use with mini-hydro plants. The first type is the synchronous generator, while the second is called the induction generator. An induction generator is the same thing as an induction motor (the most common kind of three-phase electric motor). They are simple, reliable, more efficient, and much less expensive than synchronous generators of similar size, but they need to be connected to a larger power system containing one or more synchronous generators in order to work. This is because the induction motor gets the power it needs to energize its magnets from the power system itself.

Synchronous generators are more expensive and are harder to interface to the power system, but they can operate independently of the system when necessary. This is because synchronous generators provide the power to energize their magnets themselves, rather than depending on the system. By controlling the timing and degree of energization, and their own rotation rate, these generators can also control the system frequency, voltage, and power factor. (Don't worry if you don't understand these technical terms, just take it for granted that these are things that need to be controlled). All generators in large hydro plants and other large electric generating plants are synchronous generators for this reason, and at least one generator in any isolated electrical system must be of the synchronous type.

USES FOR MINI-HYDRO PLANTS

Almost all mini-hydro plants supply electric power as their only product. In the past, hydro turbines were sometimes used directly to drive large machinery, but except for micro-hydro, this is now very rare. Where the plants differ is in what kind of system they supply electricity to, what the alternative sources of generation are, and how reliable and well-controlled the power from the plant needs to be.

Hydro plants are used in three major ways. The simplest way is for the plant to be used to save fuel for an electric system that has other thermal electric generators. In this arrangement, the hydro plant is turned on and generates power whenever there is enough water to run it. The power generated by the hydro plant does not have to be generated by some other (usually oil-burning) generating station, so the utility saves on fuel and money. This type of plant is usually cheap and simple to build, since no water storage is needed, and elaborate controls are not necessary. Plants of this kind are sometimes called "run-of-river" plants. This is usually the only kind of generation that is acceptable for plants in irrigation systems and municipal water supply systems, since the water flows in these systems are needed for other purposes, and cannot be changed to match the generating needs.

A second way of using a mini-hydro plant is to provide firm capacity to a large electric system. In this case, the hydro plant is still used to generate power and to save fuel, but in addition, the system is able to count on the plant to help it meet the peak electric demand. Unless the water supply is very reliable, this will require that the plant have a reservoir for storing water, in order to make sure that it will be available when it is needed. Since this type of plant will always be connected to a large system with other generators, however, the plant itself can have simple controls.

The most demanding role for a mini-hydro plant is when it is the only generator on the system, or where it accounts for a large fraction of the system's generating capacity. This will usually be the case in small, isolated power systems which are not connected to a national or regional electric transmission network. Obviously, power from such a plant needs to be very reliable, which will require either a very reliable water source or a dam and reservoir. In addition, this kind of plant will need to be able to adjust the amount of power it produces to match the load on the system, and will need to be able to regulate the system voltage, frequency, and power factor. This will require complicated and expensive controls, and may require a more complicated kind of turbine as well.

The type of generation a plant is to do is determined mostly by how reliable its water supply is and what kind of system it is connected to. As discussed above, this can have major effects on the design of the plant, and on its cost. The type of generation also affects the value of the power produced by the plant. In an isolated system, for instance, the cost per KWH from a hydro plant might be high (due to the extra controls and so forth), but the cost of the alternative--diesel-electric generation--is likely to be even higher. Even in a large utility system, firm capacity is almost always more valuable than fuel-saving generation, since the utility will not have to maintain its other generators to fill in for the hydro plant if it is unable to generate.

SKILLS REQUIRED TO DESIGN, BUILD, OPERATE, AND MAINTAIN A MINI-HYDRO PLANT

Designing and building a mini-hydro plant is a complex operation, and most aspects of it are best left to experts in the area. The skills and expertise required to design the plant include civil and hydraulic engineering, mechanical engineering, electric power system engineering, hydrological expertise, map-making, and drafting skills. In addition, some knowledge of planning and financing for energy projects will be needed in designing an mini-hydro plant.

During the construction stage, the major skills required are those related to construction of the civil works: construction engineering, heavy-equipment operation, concrete construction, masonry construction, and so forth. Skills in electrical construction and power-system installation will also be needed. The installation of the turbine-generator and its control systems will also require highly-skilled mechanical and electrical workers.

The operation and maintenance of a mini-hydro system are much less demanding than its design and construction. Operating the plant requires only an understanding of how the plant operates, what is normal, and what requires special action to correct. This requires a basic understanding of mechanics and electricity, along with specific training in the operation of the particular system installed at the plant. This training is normally supplied by the same organization that oversees the building of the plant.

Maintaining a hydro plant requires the same skills needed for operating it, along with a general familiarity with machinery, and skill in using ordinary tools such as wrenches and hoists. The level of basic skill required is about the same as is needed by an auto mechanic. In addition, the plant maintenance person will need specialized training in maintenance procedures for the particular plant being maintained. This training is also usually supplied by the organization that oversees the building of the plant.

COST OF MINI-HYDRO GENERATION

The cost of building a mini-hydro power plant is highly dependent on the specific circumstances--whether there is already a dam at the site, how much civil work will be needed, the ease or difficulty of access, the level of sophistication of the controls needed, and so forth. A recent study of small-hydro potential at existing structures in the U.S. came up with cost estimates of $1,500 to $4,000 per kilowatt (in 1984 U.S $) for mini-hydro plants over about 500 KW, and from $2,000 to $6,000 per KW for those under 500 KW. Allowing for lower costs of local construction, and the fact that most of the best hydro sites in the U.S. have already been used, the comparable costs in a developing country might be from $1,000 to $4,000 per KW for units above 500 KW and from $1,500 to $6,000 per KW for units below that. This would result in costs of $500,000 to $2,000,000 for a 500 KW plant, and of $75,000 to $300,000 for one of 50 KW. Simple projects with moderately high head, so that extensive civil works would not be needed, would fall toward the lower end of this range, while complicated or very low-head projects would approach the upper end.

IV. COMPARING THE ALTERNATIVES

Before deciding to build a mini-hydro plant (or any other kind of electric generating plant), it is wise to carefully evaluate all of the alternatives. The alternatives that are available will depend on your situation, and on why you are interested in a mini-hydro plant. In general, people who are interested in building a mini-hydro plant fall into one of four categories.

1. The person may want to provide electric power to an area where there is no electric service at present. 2. The person may want to generate his or her own power (or power for a town, employer, cooperative, etc.), instead of buying power from a national or regional electric utility.

3. The person may have a good hydro site and want to develop it in order to sell the power to an electric utility. 4. The person is an employee of an electric utility and wants to develop a hydro site to provide additional capacity or to save on fuel for generation.

In cases two and three, the major alternative to building a mini-hydro plant is usually to do nothing at all--in case 2, to continue buying power from the utility, and in both cases, to invest the money in some other profitable investment. These cases are easy to analyze--if you know the price you will have to pay for power or the price the utility will pay you for your power, and the approximate cost of the hydro plant, you can compare the rate of return on your investment with the rate of return you can get elsewhere. The section below on "Choosing the Right Technology" gives some pointers on how to do this. In the first and the fourth cases, the major alternative to building a mini-hydro plant will usually be to build some other kind of generating plant. Depending on the situation, there may be a large number of different kinds of generating plants that look attractive. The decision as to which technology to use should be based on many factors, including: (1) the long-term cost of generating electricity using each technology; (2) appropriate consideration of the social and environmental costs and benefits created by each technology; (3) the risk of delays or cost overruns and (4) the amount and timing of power demand. Some of the important kinds of electric generating plants for both large utilities and isolated electric systems are listed in the next subsection. The following subsection describes some of the special advantages of mini-hydro technology as compared with the others. The points discussed in Section V, "Choosing the Right Technology" are also applicable to these cases.

ELECTRIC GENERATION TECHNOLOGIES

Table 1 contains a list of the major types of conventional and alternative electric generation technologies, along with some comments on the applicability and cost of each. Costs for electric generating plants vary greatly from year to year, country to country, and plant to plant. For this reason, no specific cost figures are given. In order to compare the cost of mini-hydro with other alternative sources of generation, you should use recent cost estimates for similar plants in your country, or in a country with similar economic conditions and topography.

Table 1. A Comparison of Electric Generation Technologies

Type of Technology Comments

For Isolated Systems Conventional Systems Diesel generator Most commonly used approach.

Gas-turbine generator Cheaper to buy than diesel or (oil-fired) hydro but uses more fuel/KWH than diesel.

Mini-hydro plant More expensive to build, but requires no fuel and less maintenance. Unconventional Wind-turbine generator Requires strong, steady wind.

Photovoltaics Very expensive, except in small units.

For Large Interconnected Utilities (grid) Conventional Large hydroelectric plant Usually the lowest-cost choice if an appropriate site is available.

Steam-electric plant Expensive fuel makes this (oil or natural gas-fired) very expensive to run.

Steam-electric plant Less costly to run than oil (coal-fired) or gas-fired plants due to cheaper fuel, but more expensive to build, plus there are environmental concerns.

Simple gas-turbine plant Very cheap to buy, but expensive (oil or natural gas-fired) to run due to low efficiency and high fuel cost.

Nuclear reactor Feasible only in very large plants, and frequently very expensive. Unconventional Wind-turbine generator Not suitable for base-load power.

Mini-hydro plants Feasibility depends on site and other conditions, but often good feasibility.

Steam electric plant, Requires a large, dependable biomass-fired supply of biomass. May have engineering and/or environmental problems.

ADVANTAGES OF MINI-HYDROELECTRIC GENERATION

If properly used in a good site, small-scale hydroelectric generation has many advantages over most of the conventional means of electrical generation listed in Table 1. Some of the most important advantages for developing countries are listed below.

Cost--Hydro plants usually cost more to build than plants that make electricity by burning coal, oil, or natural gas; but once they are built, the energy to run them is free, while thermal generating plants must pay for their fuel. The hydro plant is also inflation-proof, while the cost of fuel for other plants has increased enormously. Hydro plants also last longer than most other kinds of generating plants.

Rapid Construction--Smaller projects such as mini-hydro plants can be built more quickly, and can thus be built and providing electricity long before large hydro plant or most kinds of fuel-burning generators. This means faster development, less interest paid on construction loans, and quicker benefits to the country. There is also much less risk of long delays in construction with cost overruns, and a reduced risk of ordering an expensive plant far in advance, then finding out that it isn't needed after all.

Local Self-Sufficiency--as a renewable resource, hydropower does not depend on imported oil, coal, or uranium; and it is much less dependent on foreign experts and technology than other kinds of electric generation. Mini-hydro plants can promote self-sufficiency within a country--if necessary, a town, a cooperative, or an industry can build its own electric plant, without waiting for a national electrification project, and without depending on fuel supplies which may be unreliable and expensive to get.

Appropriate Technology--Compared to other means of generating electricity, mini-hydro is labor-intensive and suited to operation by local people. Although the initial cost of the plant can be quite high, a good part of this cost comes from on-site construction, which can provide jobs and training to local residents. Most other kinds of generating plants require much more skilled labor, which must be imported at great expense from the industrial countries.

Beneficial Side-Effects--Small-hydroelectric development is often accompanied by other beneficial developments such as irrigation, water-supply and sanitation, fishing, and fish-farming. The value of the electric power generated can often make the difference between a practical, profitable project and one which is too expensive.

Environmental and Social Impact--Since small-hydro development occurs on a much smaller scale, most of the bad environmental and social effects of large energy-development projects are eliminated or greatly reduced. In many cases, the social consequences of small hydro (such as jobs, training, community cooperation, opportunity for small manufacturing development) are highly beneficial, and well-designed small-hydro projects should not have any serious environmental problems. However, some plants using storage reservoirs may flood a large amount of farm land or other valuable land.

V. CHOOSING THE RIGHT TECHNOLOGY

A choice between mini-hydro and some other generating technology, or some other source of electricity, should be based mainly on economics--which option will cost less in the long run? The best way to calculate this is to calculate the discounted present value of the life-cycle cost for each alternative. Present value is a way of measuring how much something (such as an amount of money) which will be received in the future, is worth right now. For instance, if someone promised to give you $100 in one year, that would be worth less than if he were to give it to you right away. This is because, if you had the $100 now, you could put it in the bank or loan it out at interest for a year, and have the $100 plus the interest on the $100 at the end of the year. If the interest rate were 10 percent, you could loan $90.91 for a year and get back $100. Thus, the present value of $100 one year from now is $90.91. The interest rate used in computing the present value is called the discount rate, and $90.91 is the present value of $100 one year from now, discounted at 10 percent per year.

The present value of any amount of money to be received at any future time can be calculated from the following formula:

P = M - [(1 + i).sup.n]

where P is the present value M is the amount of money to be received in the future i is the discount rate, expressed as a decimal fraction per unit of time (for instance, 0.10 per year) n is the number of units of time in the future the money is to be received.

The discount rate you should use will depend on your situation. In general, it should be the same as the best rate that you could earn in some other equally risky investment. If you would need to borrow the money for the plant, then the discount rate should be at least as great as the interest rate on the borrowed money, and probably higher, since there is some risk involved. It is also important that the units of time be consistent. If n is expressed in years, then i must be in fractions per year; if n is in months, then i must be in fractions per month.

To calculate the discounted present value of the life-cycle cost, you simply add up the discounted present values of the costs in each year that the system would last, and subtract out the present value of any payments you would receive during the life of the system. If you are not sure how to do this, any accountant, or any good book on accounting should be able to help you.

In calculating the costs of each option, you should be careful to allow for future increases in price, especially in the price of oil. Inflation will probably also increase the cost of electricity purchased from a utility, operation and maintenance, and most other recurring costs. You should also be sure to count any "hidden" costs--costs which do not result in an immediate outlay of money. These might include the lost production from farmland covered by a hydro reservoir, downtime and expense due to depending on an unreliable power source, lost profits from money invested in a power plant that could have been invested elsewhere, and other factors.

If you are planning to sell power to an electric utility, it will be necessary to determine how much the utility will be willing to pay (and whether it will even be willing to buy the power).

Similarly, if you are planning to substitute your own power for the utility's, you will need to know how much you will save on power over the life of the plant, which means that you must try to predict the utility's rates.

BUILDING A MINI-HYDRO PLANT

The major steps in planning, designing, and building a mini-hydro plant are listed below. In the sections that follow, a few tips are given on how to carry out those steps.

- Select a promising site.

- Gather as much information about the site as possible.

- Do a "pre-feasibility" study to determine whether the site is worth further investigation. If not, drop the project or go back to Step 1.

- Carry out a full-scale feasibility study. If the feasibility study is unfavorable, drop the project or go back to Step 1.

- Arrange financing for the project, and agree on any necessary arrangements with the electric utility.

- Have a consulting engineering firm draw up designs and specifications for the reservoir, dam, penstocks, power plant, and switch yard.

- Issue a request for proposals to build the plant, select a contractor, and draw up a contract for construction.

- Arrange for construction management.

- Have the plant built.

- Test the operation of the plant.

- Operate the plant.

Steps 1 and 2 in this process are ones you can do yourself, even with very little technical background. Step 3, the pre-feasibility study, requires some technical background, but not as much as you might think. Several books listed in the Suggested Reading List can help you with this. A few tips on how to carry out these steps are presented below.

Steps 4 through 10 are highly technical, and unless you have a strong background and experience in the area these are best left to the management of professional consultants. Such professional expertise is expensive, but it is usually much more expensive not to have professional help. If a consultant prevents just one serious mistake in the project, he will have paid for his fees ten times over! Step 11, operating the plant, will normally be done by you, or by someone you hire. You should be sure that adequate training on the plant's operation is included in the contract for its construction.

Site Selection--Before you can even begin to decide whether to build a mini-hydro plant, you will need to know where you want to build it. In other words, you must pick out a site. The site should have a steady supply of water, and a significant vertical drop--the more the better. The cost per kilowatt increases for low head plants, for low flow, and for plants where a great deal of civil works must be constructed. In a preexisting dam with reliable flow, a head of as little as one meter might be worth exploiting, since most of the civil works would already be built. On the other hand, a completely unimproved site might need a head of as much as 50 meters to be worth exploiting. Gathering Data--Once you have picked out a promising site, you should try to find out as much as possible about it. Exactly how much head is available? What are the minimum and maximum flow rate, and when do these occur? How much power can be generated with these flow rates? How much water would we need to store for the dry season? Can we store water at all? Who owns the land? Who must give permission to build a dam, or to install a power plant at an existing dam? Where are the nearest power lines? How long an extension to the power lines would be needed to reach the site? What arrangements must be made with the electric utility (if any) to sell them power, or to generate in parallel with them? What would the environmental effects of a mini-hydro plant be? Are there people who would be harmed by building a plant at that site (for instance, fishermen, or people who use the river for washing)? You should try to think of as many questions as possible, then try to find answers to them. In this way, you will be able to find out about any major problems before you invest a lot of time and money in the site. All of these questions will need to be answered during the feasibility study anyway, so you can save on consulting fees by answering them yourself.

Pre-feasibility Study--Before making a definite commitment to any but the very smallest mini-hydro projects, you will need to call in the help of professional hydro engineering consultants for a full-scale feasibility study, which will generally include the preliminary design and costing for the plant. This will be necessary both to ensure that there are no unsuspected problems with the site, and to obtain financing. Few banks or other sources of funding will provide money without a professionally done study of this kind. Such studies are quite expensive (from U.S.$5,000 to U.S.$50,000). For this reason, it is important to carry out a "pre-feasibility" study, in which you make a very rough estimate of the cost of the plant, the amount of power to be generated, and the value of that power. Only if this pre-feasibility study is favorable should you proceed with the full study.

If you are technically inclined, you can probably carry out this pre-feasibility study yourself, with the help of one of the guides listed at the end of this paper. Otherwise, you should try to find a local consultant, such as an practicing engineer, a university professor of engineering, or a professional consulting firm to assist you. In some cases, VITA or other development-promotion organizations may also be able to provide assistance for a pre-feasibility study. A reasonably detailed study should not take more than three to five days of a consultant's time, depending on the size of the site and the complexity of the issues. You should allow considerably longer if you are planning to carry it out yourself (unless you have considerable related experience).

FOR MORE INFORMATION

The Suggested Reading List at the back of this technical paper describes a number of useful books and reports that can provide more general information, as well as some that give specific directions for evaluating a potential hydro site. In addition, the manufacturers of small hydroelectric equipment, listed at the end of this paper, may be able to provide information and additional references. Before contacting manufacturers about a specific site, you should first find out (at least approximately) the head, and either the minimum and maximum flow rates or the amount of power you want to generate.

Many organizations may be able to provide information or assistance to you in evaluating a small hydroelectric site. The first places you should check with are the local electric utility and the local irrigation authority or other organization that is concerned with dams and canals. These organizations will probably employ engineers knowledgeable in the area, and may be able to refer you to consultants, government agencies, or others who may be able to help. If there is a government agency which is concerned with rivers, dams, navigation, or similar areas, it will probably be a good source of information, and you will need to contact it anyway to find out what legal restrictions there may be. Another good source may be in the departments of civil engineering, mechanical engineering, or agricultural engineering at a nearby university or technical institute. Finally, VITA and other international organizations may be able to provide information, technical assistance, or both in some cases.

SUGGESTED READING LIST

MAGAZINES

International Water Power and Dam Construction, Business Press International, Ltd. Oakfield House, Perrymount Road, Haywards Heath, Sussex RH16 3DH, Great Britain.

This is an excellent source of information on everything to do with all forms of hydropower. They run frequent articles on aspects of mini-hydro, and have devoted several special issues to the topic. Their advertisements also serve as a good directory to engineers, manufacturers, and consultants in the field.

Alternative Sources of Energy, Alternative Sources of Energy Inc., 107 S. Central Ave., Milaca, Minnesota 56353 USA.

Issue No. 68, July/August 1984, is a special issue on hydropower.

BOOKS AND REPORTS

Feasibility Studies For Small Scale Hydropower Additions: A Guide Manual from the U.S. Army Corps of Engineers. Available from the U.S. Army Corps of Engineers, Institute for Water Resources, Kingman Building, Fort Belvoir, Virginia 22060 USA.

This book is intended to help someone decide whether a hydro site is worth a full-scale feasibility study. The book would also be a big help in doing the full-scale study. It is much more detailed than the EPRI report below, and is somewhat harder to understand. The numerous pictures and drawings, and the glossary help somewhat to make the text more understandable, but it can be slow work going through it. Nonetheless, if you have the time and some technical background, this is the book to use. It has two major limitations--it is intended mostly for sites where the dam or other water works are already there, and it is aimed at conditions in the U.S. However, it can be adapted to local conditions.

Low-Cost Development of Small Water Power Sites by Hans Hamm. Available from VITA, c/o Publisher's Service Inc., 80 South Early Street, Alexandria, Virginia 22304 USA.

This book was written in 1967, so it is somewhat dated. It is aimed mainly at people interested in micro-hydro. However, it is still an excellent, understandable guide to assessing a hydro site, determining head and flow, etc., and includes a good discussion of low-technology hydro schemes. Reading this book is a good first step for the beginner.

Simplified Methodology For Economic Screening of Potential Low-Head Small-Capacity Hydroelectric Sites, prepared by Tudor Engineering Company. Available as report EPRI EM-1679 from the Electric Power Research Institute, Research Reports Center, P.O. Box 50490, Palo Alto, California 94303 USA.

This report is intended for people without experience in hydro, but with some technical background in electric generation. It shows you how to come up with reasonable estimates of the amount of power available, the value of the power, and the cost of a hydroelectric project at a given site, so that you can decide whether it is worthwhile to call in consultants to do a full-scale feasibility study. It concentrates on the larger mini-hydro sites (above 500 KW). It is aimed at people in the U.S., so you may need to adapt it somewhat to local conditions.

Small Hydroelectric Potential At Existing Hydraulic Structures in California. Available as Bulletin 211 from the state of California, Department of Water Resources, P.O. Box 388, Sacramento, California 95802 USA. Price is $15.00 for the report and its appendixes (be sure to specify that you want the appendixes).

California has a similar climate to many developing countries, a large agricultural sector, and extensive irrigation. The government is actively encouraging mini-hydro development. This report and its appendixes describe 70 possible mini-hydro projects, with a summary of the characteristics, advantages, disadvantages, estimated cost to construct, and cost of power produced at each site. The cost estimates and technology are up-to-date, so this is a very good source of numbers to compare with your estimates. The large number and variety of projects described may also help to suggest ideas. Like the Corps of Engineers' report, however, it deals only with adding hydro to present water works--projects which would require new dams are not covered.

MANUFACTURERS AND DISTRIBUTORS

UNITED STATES

Allis-Chalmers Fluid Products Co. Hydro Turbine Division Box 712 York, Pennsylvania 17405

Arbanas Industries 24 Hill St. Xenia, Ohio 45385

Axel Johnson Engineering 666 Howard Street San Francisco, California 94105

Bouvier Hydropower Inc. 12 Bayard Lane Suffern, New York 10901

BBC Brown Boveri Corp. 1460 Livingston Ave. North Brunswick, New Jersey 08902

Canyon Industries 5346 Moquito Lake Rd. Deming, Washington 98224

C-E/Neyrpic Hydro Power, Inc. 969 High Ridget Rd. Box 3834 Stamford, Connecticut 06905

Elektra Power Corp. 744 San Antonio Rd. Palo Alto, California 94303

Essex Development Associates 110 Tremont St. Boston, Massachusetts 02108

Fairbanks Mill Contracting North Danville Village RFD 2 St. Johnsbury, Vermont 05819

Flygt Corporation 129 Glover Ave. Norwalk, Connecticut 06856

General Electric Co. Small Hydroelectric Operation One River Rd. Bldg. 4, Rm. 305 Schenectady, New York 12345

Generation Unlimited 701 Placentia Ave. Costa Mesa, California 92627

Hayward Tyler Pump Co. P.O. Box 492 80 Industrial Pkwy Burlington, Vermont 05402

Hydro-Tech Systems, Inc. P.O. Box 82 Chattaroy, Washington 99003

Hydro Watt Systems, Inc. 146 Siglun Rd. Coos Bay, Oregon 97420

International Power Machinery Co. 833-835 Terminal Tower Cleveland, Ohio 44113

The James Leffel Company 426 East Street Springfield, Ohio 45501

Layne & Bowler, Inc. P.O. Box 8097 Memphis, Tennessee 38108

Mini Hydro Co. 110 East 9th St. Los Angeles, California 90079

Micro Hydro, Inc. P.O. Box 1016 Idaho Falls, Idaho 83401

New Found Power Co., Inc. P.O. Box 576 Hope Valley, Rhode Island 02832

Northwest Energy Systems P.O. Box 925 Malone, Washington 98559

Oriental Engineering and Supply Co. 251 High St. Palo Alto, California 94301

Philip C. Ellis RD 7, Box 125 Reading, Pennsylvania 19606

Real Goods Trading Company, Inc. 308 East Perkins Street Ukiah, California 95482 (This organization also sells wind generators and photovoltaic systems, and many low-voltage DC appliances. Their catalog is an excellent introduction to low-voltage power generation.)

Scantech 162 Battery St. Burlington, Vermont 05401

Small Hydro East Star Route 240 Bethel, Maine 04217

Sunny Brook Hydro P.O. Box 424 Lost Nation Rd. Lancaster, New Hampshire 03584

Ted Miller Associates 2140 S. Ivanhoe Denver, Colorado 80222

Worthington Group, McGraw-Edison Company Box 91 Tarrytown, Maryland 21787 (Worthington is a pump company that has done a lot of work on using its pumps as turbines.)

FOREIGN

Atlas Polar Company, Ltd. Hercules Hydrorake Division P.O. Box 160, Station O Toronto, Ontario Canada

Barber Hydraulic Turbine Division of Marsh Engineering Limited P.O. Box 340 Port Colborne, Ontario L3K 5W1 Canada

Canbar Products Ltd. P.O. Box 280 Waterloo, Ontario Canada

China National Machinery Company Beijing People's Republic of China (Contact the Chinese embassy in your country for information.)

Dependable Turbines Inc. #7, 3005 Murray St. Port Moody British Columbia Canada

Neyrpic Rue General Mangin, BP 75 38041, Grenoble Cedex France

Ossberger-Turbinenfabrik P.O. Box 425 D-8832 Weissenberg/Bavaria West Germany