In many areas of developing countries paper is scarce. Rural schools may not have enough paper for their students and market goods may be wrapped in old newspapers if at all. Often this is because resources are not available to invest in modern papermaking factories, which require large amounts of energy and raw materials if they are to be economical.

But paper can be made in small shops in small quantities. Access to electricity makes some of the steps easier, but is not absolutely necessary. (Indeed, paper was made this way for many years before electricity was discovered.) In a situation where paper is scarce and expensive, it may be worthwhile to consider small-scale papermaking as a source of school supplies or as a small business. Such a business might produce heavy coarse paper for packaging or even thick paper egg cartons, plant pots, and so on.

PAPERMAKING PROCESSES

Whether paper is made in a home or school workshop or a small factory, the production processes for making paper by hand are quite similar. The scale of the equipment changes with the volume of production and the raw materials vary with what is available and the quality of paper to be produced.

Pre-processing

Cotton or other rags and waste paper to be recycled are sorted thoroughly to remove all non-fibrous materials such as staples, paper clips, cellophane, nails, buttons, zippers, etc. Both rags and paper are cut or shredded into small pieces.

Pulping

The cleaned and shredded raw materials are brought to the boiling point and cooked for two to six hours. They are rinsed thoroughly to remove impurities that might have separated out during the cooking process.

The beater--this can range from a kitchen blender to a specially made tank--is filled with the required quantity of water, and the cooked, chopped rags or paper are added gradually with high speed agitation. Bleaching powder or liquid bleach (1 percent) is then added. The pulp is washed thoroughly, a process that may take another six to eight hours. Additives used may include titanium dioxide or other fillers, dyes (for colored paper), or optical bleaching agents (for white paper). Rosin soap and alum are added later.

Lifting, Couching, and Stacking

When the pulp process is complete, the pulp is transferred to storage containiers or vats. Depending on the scale of the operation, the pulp is then mixed with a sufficient quantity of water to dilute it to form a uniform suspension, free of lumps. In the home workshop, the pulp is mixed in quantities to make one sheet at a time. In the small factory, a larger quantity may be mixed at one time. The diluted pulp is then lifted from the water on wire screens, and the resulting sheets are covered by felt or other absorbent cloth. With the cloth is place, the still wet pulp layer is carefully lifted from the screen. This process is called couching (pronounced cooching). The couching cloth, paper side down, is placed on a felt covered board and smoothed to remove wrinkles or air bubbles. Each succeeding sheet is placed in a stack over the first.

Pressing and Drying

When a sufficient number of sheets have been formed, they are put under a press to remove the water. The sheets are then separated and, to avoid shrinkage, placed under absorbent boards and pressed again. The sheets are hung to dry in bunches of three to six, according to thickness, or dried in a warm oven.

Sizing

Sizing gives paper a harder finish so that water based paints and inks will not bleed or run. Paper may be sized internally, by adding the sizing agents to the pulp, or externally, by painting or dipping the dried sheets. For internal sizing, alum, rosin, gelatin, cornstarch, or linseed oil may be added in very small quantities at the end of the pulping stage. For external sizing, the dried sheets are dipped in a dilute glue or starch solution, pressed to remove the excess, and hung up to dry again. In the home workshop, the individual sheets may be painted with the dilute solution.

Blotting paper, filter paper, toilet tissue, grey board, and some art papers may be require very little, if any, sizing.

Calendering

The dried sheets are placed alternately between metal plates into a stack or "post." The stack is passed between calender rollers to obtain the desired smoothness. This can be done in the home workshop by pressing the paper sheets between sheets of aluminum foil with a hot iron.

Sorting and Cutting

After calendering, the sheets are carefully sorted and cut to size for packing, storage, and/or shipment.

MAKING PAPER IN THE SMALL WORKSHOP

Papermaking at this scale can be done as hobby, for gifts, or to supply schools. The necessary equipment may already be available in some kitchens, but the markets should be considered carefully before any investment is made.

This process assumes that waste paper or cotton cloth will be used to make the paper. Approximately 50 sheets of 21.5cm x 28cm (8 1/2" x 11") paper can be made from a half kilo (about a pound) of waste paper. Household bleach, alum, gelatin, cornstarch, and animal glue may also be needed. And ordinary fabric dyes can be used to produce tinted or colored papers. As described here, the availability of adequate water and electrical or other power supplies is also assumed.

Equipment and Materials

The following equipment is needed:

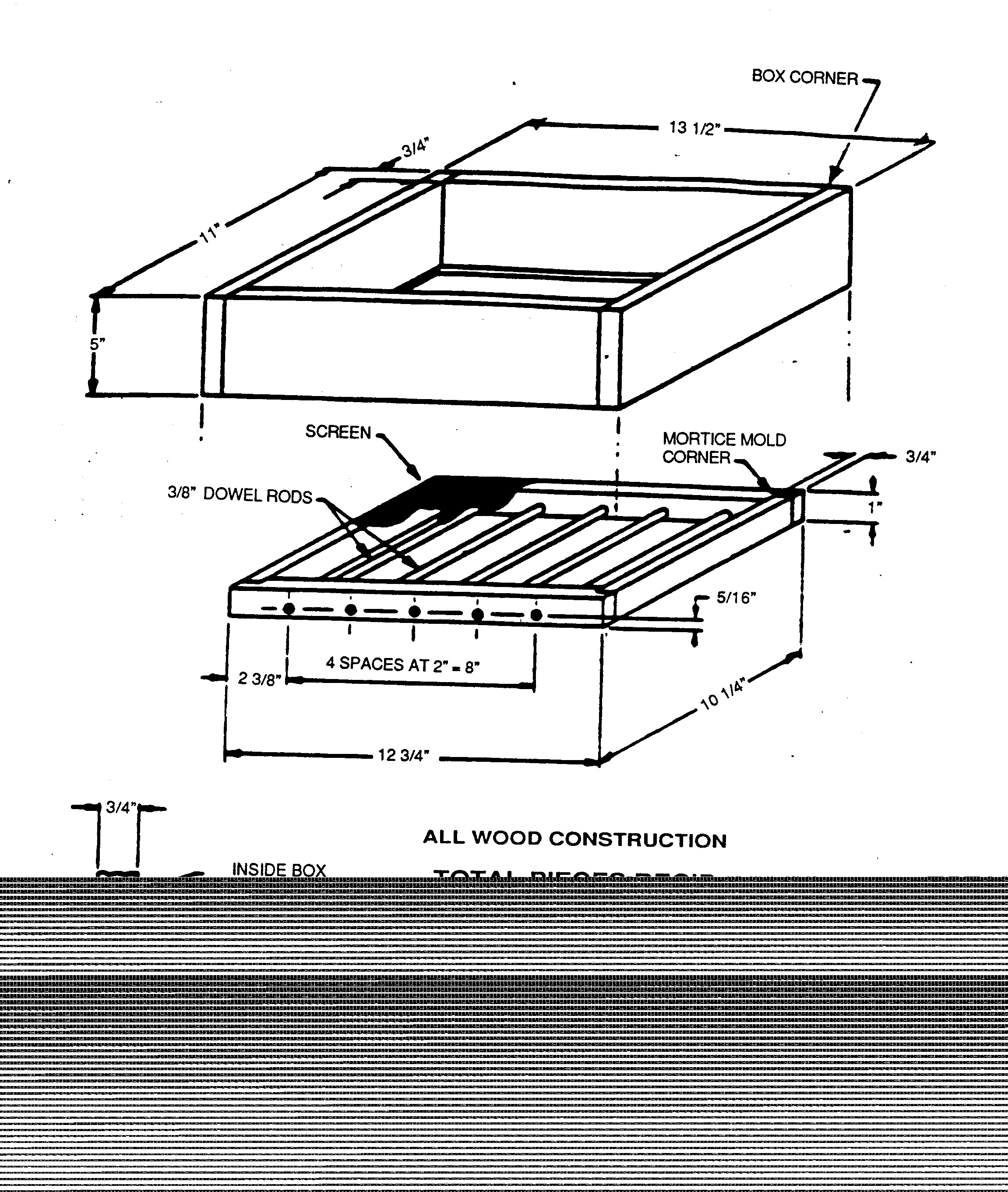

Deckle box and mold, made of oiled wood (figure 1)

Power food mixer or blender Stainless steel or enamel pot (not almuinum) Steam iron Stove with oven Sink, tub or wash basin Couching cloth (e.g., cotton sheeting), cut to size Felt or absorbent terry cloth, cut to size Thin metal sheet Flat "receiving" board, 1cm (1/4") plywood or other board

Pulping

Choose paper with minimal printing. Old envelopes are good for this reason; the glue on the flap won't matter. Colored paper is acceptable; the dye usually comes out when it is boiled. Avoid paper that has "wet strength" such as paper towels. Be careful how many brown paper bags you use. Unbleached kraft paper lowers the brightness or whiteness of the pulp, but it is strong and will give your paper toughness.

Newsprint alone makes a weak pulp, grey in color. It adds little but bulk. Cotton or other cloth or yarns may also be used. They must be cut or shredded into very small pieces to avoid jamming the mixer.

Cut or tear the paper into small pieces, about 5cm x 5cm (2" x 2"). Shred any cloth that may be used. Put the pieces in the pot, cover with water, and add a few tablespoonfuls of household bleach. Turn on the heat, cover the pot, and bring to a gentle boil. Stir occasionally for a couple of hours to ensure that the bleach is mixed and all the paper is wetted down well, then cool.

After the batch has cooled, try to break up the lumps and any remaining pieces of paper still holding together. The smaller the pieces in the beginning, the easier this step is now. (The pulp can then be drained and stored in plastic bags in a refrigerator, if you have one, until you are ready to make the sheets. It will keep for weeks without any change.)

Making the Sheets

Take a lump of the semi-moist pulp you have prepared. Press as much moisture out of it as possible to leave a ball about the size of a pigeon egg (7g--1/4 oz--dry weight). This is enough pulp to make one 21.5cm x 28cm sheet. Make the sheets, one at a time, as follows:

- Blend and mix pulp in blender 3/4 full of water. Add additives.

- Put mold in box, screen side up and immerse in sink. Rap box to get rid of air bubbles.

- Pour pulp into box.

- Holding box down, agitate the water in the box with fingers so that the pulp spreads evenly over the mesh.

- Grasp box and mold firmly and lift quickly and evenly to surface (feel suction).

- Hold for 10 seconds or so to drain.

- Lift up out of water and hold vertically to drain. If sheet looks okay, proceed; if flawed, put box and mold back into sink. Repeat steps 4 to 7.

- Set box on flat surface and carefully remove box. Note: Water drops on wet web will make marks!

- Carefully lay cotton couching cloth over web and smooth gently.

- Place absorbent felt over couching cloth. Smooth and press down from center out.

- Remove felt and wring out water.

- Repeat 10 and 11 until no more water comes out.

- Couch off sheet, starting at corner and peeling back quickly.

- Place couched sheet, paper side up or down on flat absorbent surface. Smooth and press down to remove trapped air.

- Repeat for each sheet until a neat stack is built up.

Pressing and Drying

The sheets can be dried quickly by pressing them with a hot iron and an aluminum sheet or slowly (2-3 hours) by placing them in a 120[degrees]C (280[degrees]F) oven, with the couching sheets tacked down to the receiving board all along the edges of the paper sheets. The first method gives a smooth surface on one side, embossing with cloth marks on the other; the second gives embossing on both sides.

A very slick surface can be obtained by smoothing the couching cloth, paper side down, against an aluminum or oiled galvanized sheet. A squeegee can be used to get rid of all the air. Dry in air or in a 120[degrees]C (280[degrees]F) degree oven.

Sizing and Coating

A simple method of internal sizing uses a combination of pure gelatin and cornstarch (either laundry or cooking type). The gelatin is dissolved in boiling water and cornstarch is added to make a clear, thick mixture to add to the pulp. Use about one teaspoon of this per 21.5cm x 28cm sheet.

Another simple internal sizing procedure is to add about 1/4 teaspoon of linseed and/or a teaspoon of cornstarch solution while the pulp is being mixed at step 1. The oil is dispersed in the water and precipitates on the fiber. The starch will be caught on the fibers and during the drying stage will set to give a stiffer sheet. External sizing is done when the sheet is coated with a water based solution after the paper has been dried. With an ordinary 4cm (1 1/2") paint brush, coat each sheet with a 7 percent straight corn starch solution. one tablespoonful of cornstarch added to a cup of water will be enough for 20 to 25 sheets (both sides). Animal glue can be added to the starch to improve the water resistance. Modern glues can be added also.

When the coated sheets are nearly dry to the touch, place them in a neat stack. They should be somewhat limp but not wet. Put a metal sheet or smooth board on top. Allow the stack to dry overnight. The sheets can then be trimmed if necessary and packaged for sale.

MAKING PAPER IN THE MICRO FACTORY

On a somewhat larger scale, but still in an essentially hand process, paper can be made in a micro factory capable of producing about 240kg (1/4 ton) of paper per day. Such small factories are fairly common in India, and VITA has assisted at least one such operation in Tanzania. This process uses wastepaper or rags to make pulp, or pulp purchased from a pulp mill. It can produce good quality bond or drawing paper, card stock, school tablets, filter paper, toilet tissue, grey board, and album or blotting paper. It can also turn out such articles as egg cartons, flower pots, seed flats, hospital trays, and so on.

In addition to an identified, reliable market, the small factory requires a steady, reliable supply of raw materials, water, and power. Suggested facilities include a building of about 300 square meters for operations and a shed of about 185 square meters for collecting and sorting the materials. Six administrative staff and as many as 100 laborers working in two or three shifts are needed.

The U.N. Industrial Development Organization (UNIDO) estimates an investment of approximately US$26,000 (1984) for the total cost of installation. Production may be increased by installing one or two more beaters and operating the vats in three shifts. (Beyond this capacity, however, economies of scale decline, and production moves up to small-scale mechanized plants.)

Sources:

Vogler, Jon, and Sarjeant, Peter. Understanding Small-Scale Papermaking. Arlington, Virginia: Volunteers in Technical Assistance, 1986.

Appropriate Industrial Technology for Paper Products and Small Pulp Mills. Vienna Austria: United Nations Industrial Development Organization (UNIDO), 1979

Sheriff Dewji and Sons, Arusha, Tanzania

American Paper Institute, 260 Madison Avenue, New York, New York