Published By VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info[at]vita.org

Understanding Energy Storage Methods ISBN: 0-86619-222-0 [C]1985, Volunteers in Technical Assistance

PREFACE

This paper in one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technological assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Giannuzzi as editor Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

The author of this paper, Clyde S. Brooks, has been a VITA Volunteer for many years. He holds a B.S. in chemistry and has done graduate work at Duke University and Carnegie-Mellon University. Currently, Brooks performs independent research consultancies in applied physical chemistry. His experience includes coal chemical processing, chemical stimulation of oil recovery, and energy conversion processes. The reviewers of this paper are also VITA Volunteers. Paul J. Hauck has been a mechanical engineer for Westinghouse for the past 20 years. He designs piping systems and pressure vessels and operates and maintains pumps, motors, heat exchangers, valves, etc. LeGrand Merriman is an electrical engineer who worked for Westinghouse for 31 years. His duties included directing the installation, start-up and servicing of electrical equipment. Lester H. Smith, Jr., an electrical engineer, is a founding partner of an electrical consulting firm responsible for various medical, institutional, commercial, and residential projects in the United States.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Energy storage capability is essential if the maximum economic advantage is to be gained from small power plants. Unless the power plant is operated at full load on a continual basis, there will be periods when there is a lower load demand upon the plant. As a result of this lower demand, excess energy will be generated by the plant. The use of an energy storage system will allow for the recapture of this surplus energy and its later use during periods of high demand.

This paper presents a critical review of the technical features, state of development, and economics of various energy storage systems and their compatibility with small power plants. The small power plants examined here have generation capacities within a range of 1 to 50 kilowatts (kW) and consist of systems such as windmills and small-scale hydropower.

Energy storage systems potentially compatible with small power plants include batteries, flywheels, pumped water, and compressed air.(*) In selecting an energy storage system for small power plants in developing countries, the most important factors to consider are storage capacity required; capital costs; operating costs; nature of storage/generation duty cycles; system complexity in terms of how easily the system can be built, operated, and maintained; hardware availability; form of energy recoverable from storage; conversion efficiency; and the country's current state of technical development in related fields.

In this examination of energy storage systems, emphasis will be placed on the overall technical features of the systems and their comparative performance and efficiency. The characteristics of the various energy storage technologies are considered below individually and then compared with each other. Based on this comparison, recommendations as to the most promising storage systems for use in combination with small-scale hydropower and wind energy generators are made. It should be noted that the discussion of economic factors (e.g., operating costs) is based on data obtained for the most part from large power plants in highly industrialized countries such as the United States.

*Other more advanced energy storage technologies are beyond the scope of this paper

One word of caution: It is beyond the scope of this paper to provide a detailed engineering or economic analysis of energy storage systems. A feasibility study will have to be performed for any given site. Nevertheless, this paper will aid in the selection of promising energy storage system that merit more detailed study.

II. SYSTEM ALTERNATIVE

Several energy storage systems will be examined in this section: batteries, compressed air, pumped water, and flywheels.

BATTERIES

Batteries are commonly used to store the electricity generated by wind machines and small-scale hydropower plants. A typical system couples the drive shaft of the power source to a direct current (DC) generator. The rotating shaft produces mechanical energy, which is converted to electricity by the generator. Excess electricity can then be stored in banks of batteries.

Before choosing any generating and storage system, you must determine how much power you will need. Tables 1 through 3 show average annual power usage for electric home heating and appliances in the range of 5,000-8,000 kilowatt-hours per year (kWh/yr). A small wind power system of 5 kW, such as one currently marketed by an American company, is estimated by the manufacturer to provide about 1,0000 kWh/yr under average wind conditions. Such a system would be more than adequate to meet the energy requirements of an individual household in a highly industrialized country such as the United States. (No attempt is made here to specify the wind conditions essential for the economic operation of windmills. But it is fairly well established that if the wind velocity does not achieve or exceed 12 miles per hour for most of the year, the siting of even a small wind machine would be economically impractical.) Based on this estimate, even a household with many appliances could generate sufficient excess power to justify the cost of battery storage.

In order to determine the cost of a combination generation and battery storage system, the capacity and number of wind or hydropower generators would have to be established, as well as an appropriate bank of storage batteries.

Proper design of battery storage capacity must be based on anticipated excess power for storage and recommended battery charge and discharge rates.

Table 1. Average Annual Energy Requirements of 110 Volt Electrical Appliances

Average Power Estimated Required per Annual Energy Appliance Consumption (Watts) (kwh) * Food Preparation Blender 385 15 Broiler 1,436 100 Carving Knife 92 8 Coffee Maker 894 106 Deep Fryer 1,448 83 Dishwasher 1,201 383 Egg Cooker 516 14 Frying Pan 1,196 185 Hot Plate 1,257 90 Mixer 127 13 Oven (microwave) 1,450 190 Range with oven 12,200 1,175 self-cleaning oven 12,200 1,205 Roaster 1,333 205 Sandwich Grill 1,161 33 Toaster 1,146 39 Trash Compactor 400 50 Waffle Iron 1,116 22 Waste Disposer 445 30

- Food Preservation Freezer (15 cu ft) 341 1,195 Freezer (2 cu ft frostless) 440 1,761 Refrigerator (12 cu ft) 241 728 Refrigerator (12 cu ft frostless) 321 1,217 Refrigerator/freezer (14 cu ft) 326 1,137 (14 cu ft frostless) 615 1,829 Low Energy Model 1973, 21 cu ft frostless starting 2,480 running 320 1,200

- Health & Beauty Germicidal lamp 20 141 Hair Dryer 381 14 Heat Lamp (infrared) 250 13 Shaver 14 18 Sun Lamp 279 16 Tooth Brush 7 0.5 Vibrator 40 2

- Home Entertainment Radio 71 86 Radio/Record Player 109 109 Television black & white tube type 160 350 solid state 55 120 color tube type 300 660 solid state 200 440

- Housewares Clock 2 17 Floor Polisher 305 15 Sewing Machine 75 11 Vacuum Cleaner 630 46

- Lights 75 Watt bulbs (8 each) 600 864

- Laundry Clothes Dryer 4,856 993 Iron (hand) 1,008 144 Washing Machine (automatic) 512 103 Washing Machine (non-automatic) 286 75 Water Heater 2,475 4,219 (quick recovery) 4,474 4,811

- Comfort Conditioning Air Cleaner 50 216 Air Conditioner (room) 1,565 1,889 Bed Covering 177 147 Dehumidifier 257 377 Fan (attic) 370 281 Fan (circulating) 83 43 Fan (rollaway) 171 138 Fan (window) 200 170 Heater (portable) 1,322 178 Heating Pad 65 10 Humidifier 177 163

- Tools 1/4" drill 250 2 Sabre Saw 325 1 Skill Saw 1,000 5 Typewriter 40 7 Water Pump (1/3 HP) 420 150 3" Sander, Belt 770 10

- Electric Home Heating [a] Measured Living Area 1,000 Sq. Ft. 17,000 16,300 1,500 Sq. Ft. 21,500 20,800 2,000 Sq. Ft. 26,000 25,500

Sources: Electric Energy Association, 90 Park Avenue, New York, New York; Henry Clews, "Electric Power from the Wind," Business Week, March 24, 1973.

Note: The estimated annual kilowatt-hour consumption of the electric appliances listed in this table are based on normal usage. When using these figures for projections, such factors as the size of the specific appliance, the geographical area of use, and individual usage should be taken into consideration. Please note that the wattages are not additive since all units are normally not in operation at the same time.

[a] Based on figures published by local utilities for electrically heated homes.

Table 2. Typical Home Power Usage

Average Power Daily Energy Required per Consumption Type of Appliance Appliance (Watts) (kWh) [a]

Refrigerator: 14 cu. ft. frostless 615 5.00 1/2 HP oil burner 400 3.21 Lights (100-watt bulb) 100 x number of lights 5.60 TV color tube 300 1.80 Coffee maker 900 0.60 Toaster 1,146 0.40 Frying pan 1,196 0.60 Clocks (3) 2 0.14 Hot plate 1,257 0.42 Vacuum cleaner 630 0.63 Dishwasher 1,201 0.80 Clothes washer 512 0.25 Clothes dryer 4,856 2.41

Total 21.86

Source: Grumman Aerospace Corporation, Living with Wind Power (Bethpage, New York, 1975), p. 4.

[a] 21.86 x 30 = 655.80 kWh per month; 655.80 x 12 = 7,869 kWh per year.

Table 3. Planned Home Usage

Average Power Daily Energy Required per Consumption Type of Appliance Appliance (Watts) (kWh) [a]

Refrigerator: 21 cu. ft. frostless Philco Ford 320 2.56 1/2 HP oil burner 400 3.21 Lights (40-watt bulb) 40 x number of lights 2.24 TV color solid state 200 1.20 Coffee maker 900 0.60 Toaster 1,146 0.40 Frying pan 1,196 0.60 Clocks (3) 2 0.14 Hot plate 1,257 0.42 Vacuum cleaner 630 0.63 Dishwasher 1,201 0.80 Clothes washer 512 0.25 Clothes dryer 4,856 2.41

Total 15.46

Source: Grumman Aerospace Corporation, Living with Wind Power (Bethpage, New York, 1975), p. 4.

[a] 15.46 x 30 = 463.80 kWh per month; 463.80 x 12 = 5,565.5 kWh per year.

Specific questions that must be considered in designing such a system are:

- The types of electrical loads to be served by the system. Whether direct current (DC) power only is required or whether inverters must be included to complete the conversion of stored DC electricity to alternating current (AC). If the loads to be served are largely incandescent lighting and heating, the output of the battery system may remain direct current since incandescent lamps and most heat producing equipment (space heaters, toasters, irons) operate successfully on DC or AC. If the loads are motors (pump drives, fans) of 1/2 horsepower and larger or are communication equipment (radio and television transmitters), inverters will be required as a part of the storage system.

- Whether a multiple power generation and multiple user system is required. In most applications, a single prime mover (windmill, turbine) will be required. However, if multiple generators are employed, additional equipment must be added to the system to enable paralleling of electrical output. Multiple battery installations accompany multiple generators as a general rule. For most applications, a single prime mover, generator, and battery bank will be preferred due to the simplicity of installation, operation, and maintenance. Where extended systems to serve more loads are desired, an increase in capacity of the single system is the preferred approach.

- Whether commercial hardware with established performance characteristics is available. While it is possible to assemble and fabricate a system from unrelated components, the chances for successful operation will be enhanced by using factory-assembled systems that have been designed to match one another. A compromise in development of the system would be to purchase and match groups of commercial equipment. For example, a prime mover and generator could be purchased and matched to a battery bank, charger, and inverter.

- Energy source characteristics, by day and by season. If wind is the source of energy, its availability must be determined, on average, for each day of each season. Its velocity must also be estimated. If water is the source, the same determinations must be made. Whether the energy source is wind or water, these determinations must be made in advance of designing the storage system. For example, winds usually vary in velocity throughout the day; during periods of low or no wind, the battery system must be capable of making up the electrical energy the generator cannot produce during those periods. Similarly, knowing the length and time of occurrence of strong wind velocity will enable a designer to estimate how large a battery bank can be recharged.

- Electrical load demand characteristics, by day and by season. The daily, weekly, and seasonal characteristics of the electrical load demand must be determined in advance of design of the system. To make electrical energy available at the moment it is needed requires an accurate estimate of how much is needed at what hours of which days during the year. For example, if water is to be pumped for irrigation, it will likely be a continuous load throughout certain seasons. Lighting loads will appear only in the early morning, evenings, and early hours of the night, but these loads will appear every day of the year even though the number of hours will vary each day. If space heating will be provided, it will likely appear as a load on the system only during a specific season.

The costs of a given system will have to be estimated, based on discussions with specific hardware suppliers regarding:

* performance specifications for the system; * capital costs; * shipping costs; * power consumption and efficiency of operation; * labor commitment required for system operation; and * anticipated life of hardware components.

Having stated these requirements for initial system design and pricing, it is clear that an experienced electrical engineer should be selected to plan and oversee system installation. Once a system has been assembled, semi-skilled laborers could become operators, but there should be supervision by someone sufficiently trained in the component hardware to conduct all necessary routine maintenance.

No attempt is made here to specify hardware, which must be done by the electrical engineer selected for system design, in collaboration with specific hardware suppliers.

There are many types of storage batteries. Many of these, in various stages of development, have performance characteristics superior to the lead-acid battery. However, in terms of overall demonstrated performance, cost, useful life, and commercial availability, the lead-acid battery is the most conservative and economical choice (see Table 4). Industrial lead-acid batteries with power ratings to 225 ampere-hours and regeneration life cycles to about 1,800 are available commercially.

Table 4. Comparison of Today's Storage Batteries

Battery Density By: [b]

Cost [a] Weight Volume Life[c] Battery Type (Dollars/kWh) (Wh/kg) (kWh/cu.meter) (Cycles)

Silver-Zinc 900 120 310.8 100/300 Nickel-cadmium 600 40 127.1 300/2,000 Nickel-iron 400 33 49.4 3,000 Load-acid: 50 22 91.8 1,500/2,000

Source: D.L. Douglas, "Batteries for Energy Storage," Symposium on Energy Storage, 168th National Meeting, American Chemical Society, Preprint Fuel Division, Vol. 19, no. 4 (Washington, D.C.: ACS, 1974), pp. 135-154.

[al Cost to the user. [b] Battery capacity is inversely related to rate of discharge. The values shown are for the 6-hour rate. [c] Cycle life depends on a number of factors, including depth of discharge, rate of charge and discharge, temperature, and amount of overcharge. Range shown is from most severe to modest duty.

COMPRESSED AIR

The drive shafts of wind power systems or small-scale hydropower plants can be linked to conventional gas compressors and used to store air at pressures on the order of 600 pounds square inch (psi). The compressed air can be depressurized subsequently through conventional turbines to generate electricity, or it can be linked through gearing for use of the stored energy to power any mechanical machinery driven by a rotating shaft or drive belt. Efficiencies of 75 percent can be attained for utilization of the stored energy. The compressed gas can either be air or fuel gases (e.g., natural gas or hydrogen). However, for purposes of this paper, the discussion will relate to compressed air only.

The economics of storage will be most favorable if existing underground storage capacity such as depleted oil fields, coal mines, or aquifers can be used. Underground storage of natural gas is a widely used and economical technology. If underground storage containers are used, costs are minimized, but a certain amount of unrecoverable residual gas loss (20 percent or more) will have to be accepted as a penalty. High pressure gas can also be stored in steel containers. However, if new containers must be purchased, the capital costs for a large power plant may be greatly increased. For small plants, steel tanks are a practical alternative.

PUMPED WATER

Pumped water, stored above ground or underground, can also be used as an energy storage device in combination with either small-scale hydro or wind energy generators. Pumped water as an aid in peak leveling for electric hydropower generation has been used in the United States since the early 1930s. The options for energy retrieval are quite similar to compressed air with perhaps 5-15 percent' less overall efficiency than that obtained from compressed air. Underground storage in various types of depleted mines or aquifers offers some cost advantages over surface storage, since the costs of reservoir construction can greatly increase the total cost of power plant construction.

Pumped water storage in a special reservoir can be provided during high river flow periods. During spring thaws or rainy seasons the river flow may be able to develop more power than the electrical system can consume. The stored water may then be released for power generation during future peak load periods or dry seasons. Extensive areas of land must be flooded to provide sufficient storage or pondage for a hydroplant. Losses due to evaporation, irrigation, and infiltration into the soil are difficult to estimate and may vary from time to time. When evaporation rates are high, a shallow pond with a large surface area is disadvantageous.

The available data on costs for pumped water storage systems are derived entirely from megawatt size power plants. For small power plants, applicable cost data will have to be calculated for any given site considered.

FLYWHEELS

The flywheel is a device that permits storage of energy in the form of a rotating wheel. Mechanical energy such as that from the rotating shaft of a wind energy or hydropower system can be converted to the kinetic energy of a low-friction flywheel for storage. Surplus energy from a wind or hydropower system stored in the rotating flywheel can be subsequently recovered as rotating shaft mechanical energy or possibly converted to electrical energy via a generator to satisfy peak demands.

The energy stored in the flywheel is given by the formula W = 1/2 [Iw.sup.2] where "W" is the stored energy, "I" is the moment of inertia of the flywheel, and "w" is the angular velocity in radians per second of the flywheel. One of the attractive features of the flywheel is its adaptability to a wide range of energy requirements for small power plants in the 1-50 kW range. The mass of the flywheel and its angular velocity can be varied to obtain this range of storage capacities. Efficiencies are potentially high and energy densities of 66 watts/kilogram can be attained for power peaking rotation speeds of 1,800 to 3,600 revolutions per minute (rpm) by gearing to the rotating shaft of small power generators, whether wind or hydro.

Successful performance requires careful design and high-strength materials. Steel has been used for years, but modern composites, such as metal alloys, glass fiber, and polymer/carbon fiber, provide the strength required for coherence during extended duty cycles to prevent catastrophic failure of the flywheel at high rotation speeds. Actually, wood and bamboo are low-cost, high-strength flywheel materials that are economically competitive with the synthetic composite materials cited above.

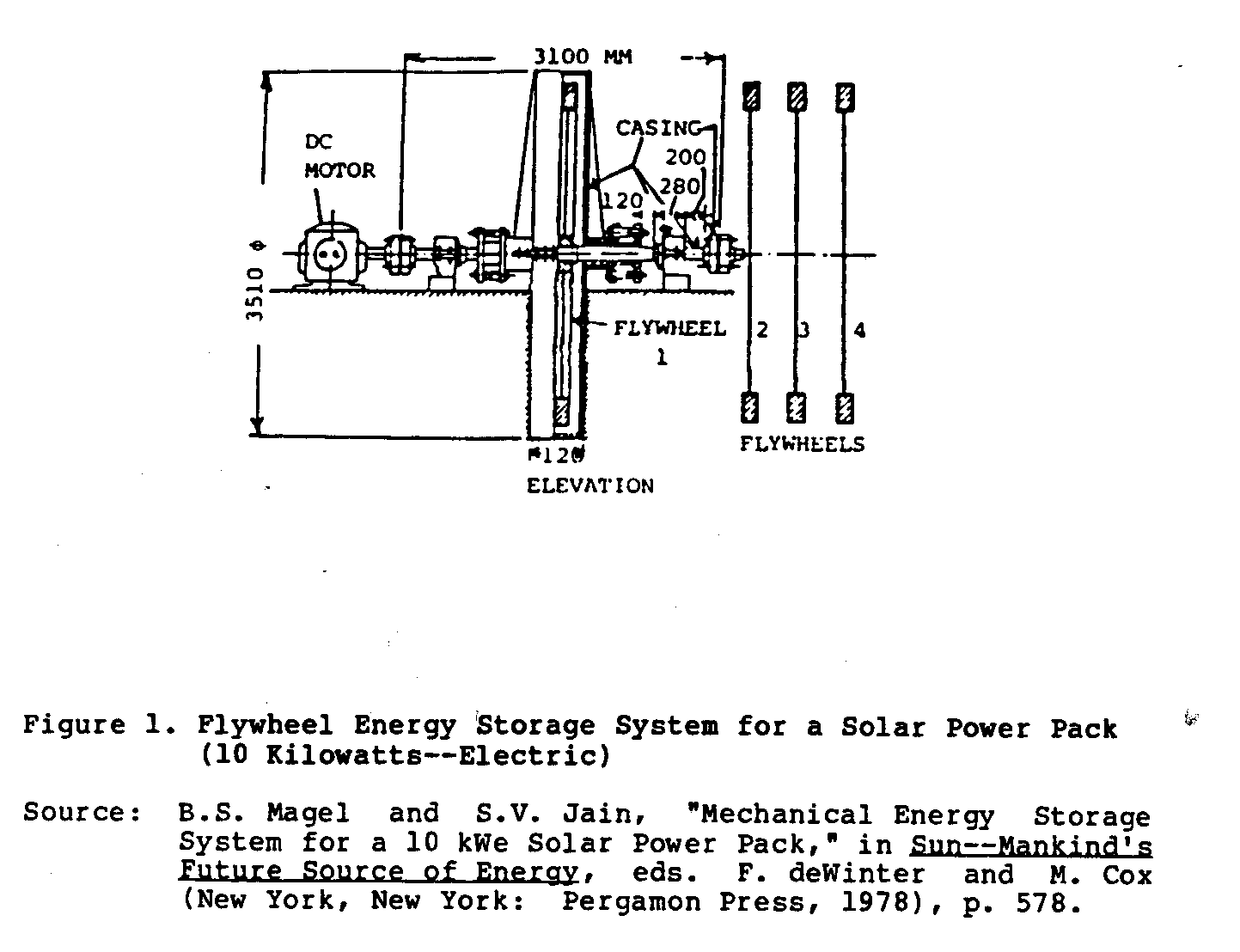

The flywheel is quite competitive with alternative energy storage systems for small power plants in terms of efficiency, storage energy density, and cost. Small flywheels that provide 30-1,000 watt-hours (Wh) of energy storage for around $50-100/kW have been developed (see Figure 1).

Flywheels are small, but are high technology devices requiring sophisticated engineering know-how on the part of those who will select the hardware and design the match to the wind or hydropower installation. Once installed, semi-skilled operators can maintain these installations under the supervision of an engineer.

III. COMPARISIONS AND RECOMMENDATIONS

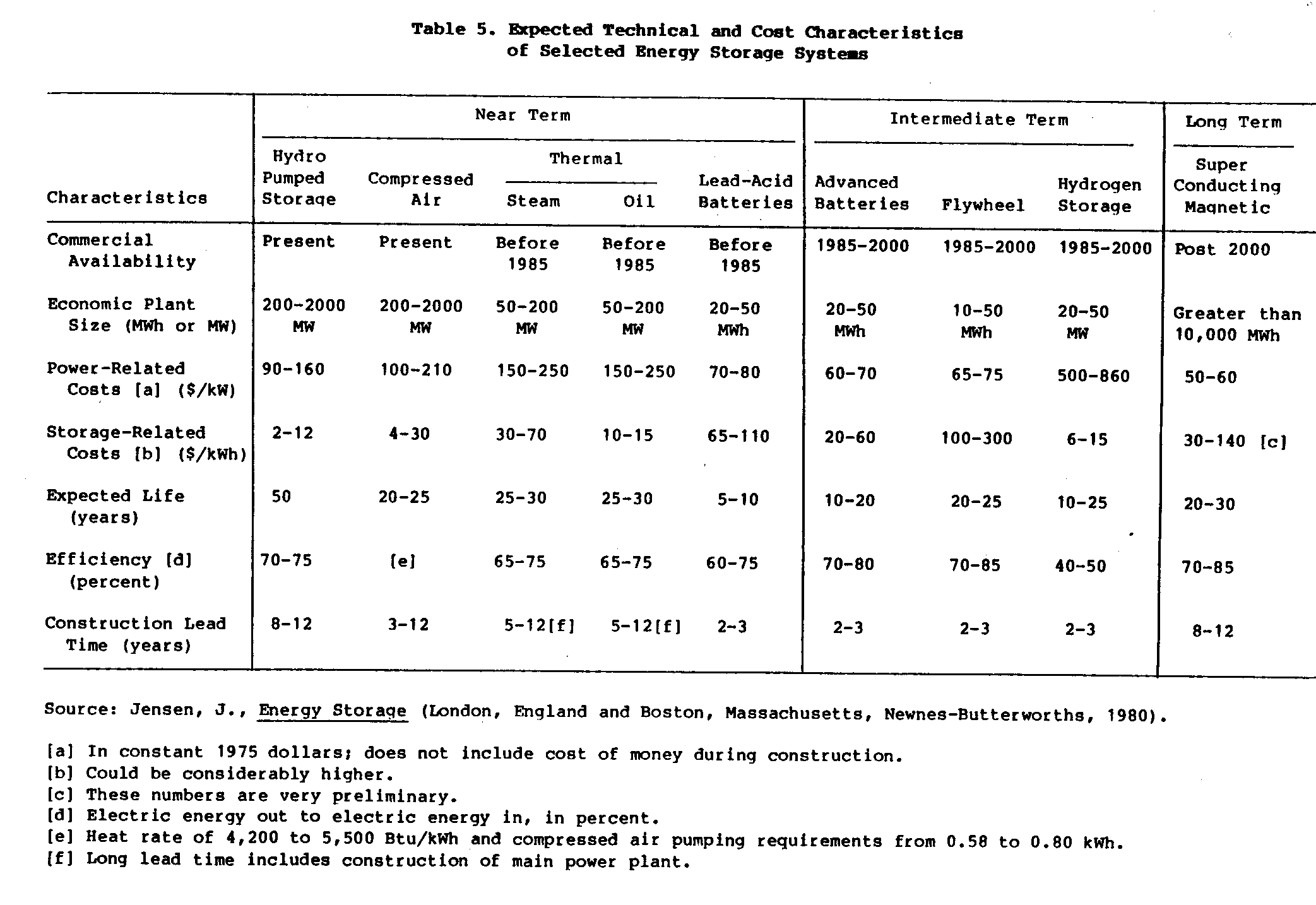

Tables 5 and 6 give comparisons of the energy densities, conversion

efficiencies, state of technical development, cost data, and potential applications of the various types of energy storage systems. These comparisons, however, were based on data obtained from large power plants, and therefore must be adjusted for small power plants.

The essential criteria for selecting an energy storage system are: (1) the technology should provide high conversion efficiency; (2) commercial hardware should be currently available; and (3) costs should be favorable compared to alternative options.

Based on the above criteria, the energy storage systems most likely to be both technically feasible and economical are:

1. Conversion to electricity via generators and storage in lead-acid batteries.

2. Storage as mechanical energy in a flywheel with recovery as mechanical energy.

3. Compressed air storage, combined with a turbogenerator for recovery of stored energy as electricity or as mechanical energy.

4. Pumped water combined with a turbogenerator for recovery of stored energy as electricity or as mechanical energy.

BIBLIOGRAPHY/SUGGESTED READING LIST

Abelson, P.H., ed. Energy: Use, Conservation and Supply. Special Science Compendium. Washington, D.C.: American Association for the Advancement of Science, 1974.

Adams, J.T. Electricity and Electrical Appliances Handbook. New York, New York: Arco Publishing Co., 1976.

Ayer, Franklin A. Symposium on Environment and Energy Conservation. EPA 600/2-76/212:PB-271 680. Washington, D.C.: U.S. Environmental Protection Agency, 1975.

Berkowitz, J.B. and Silverman, H.P. "Energy Storage." Proceedings of Symposium, October 6, 1975. P.O. Box 2071, Princeton, New Jersey 08540: New Technology Subcommittee and Electrothermics and Metallurgy Divisions, Electrochemical Society, 1976.

Bockris, J.O. Energy Options. New York, New York: John Wiley & Sons, 1980.

Brookhaven National Laboratory. Proceedings of the ERDA Contractors' Review Meeting on Chemical Energy Storage and Hydrogen Energy Systems. CONF-761134. Upton, New York: Brookhaven National Laboratory, 1976.

Chubb, T.A. "Analysis of Gas Dissociation Solar Thermal Power System." Solar Energy 17. New York, New York: Pergamon Press, 1975, pp. 129-136.

Cohen, R.L. and Wernick, J.H. "Hydrogen Storage Materials: Properties and Possibilities." Science 214, 1981, pp. 1081-1095.

deWinter, F. and Cox, M., eds. "Mechanical Energy Storage System for a 10 kWe Solar Power Pack." Sun--Mankind's Future Source of Energy. New York, New York: Pergamon Press, 1978.

Douglas, D.L. "Batteries for Energy Storage." Symposium on Energy Storage. 168th National Meeting, American Chemical Society, Division of Fuel Chemistry. Preprints Vol. 19, No. 4, 135-154. Washington, D.C.: American Chemical Society, 1974.

Duffie, J.A. and Beckman, W.A. Solar Energy Thermal Processes. New York, New York: John Wiley & Sons, 1974.

Fickett, A.P. "Fuel-Cell Power Plants" Scientific American 293(6), 1978, pp. 70-76.

Gross, S., ed. Battery Design and Optimization. Proceedings of Symposium. Vol. 79. P.O. Box 2071, Princeton, New Jersey 08540: Battery Division, Electrochemical Society, 1979.

Grumman Aerospace Corporation, Living With Wind Power. Bethpage, New York: Grumman Aerospace Corporation, 1975.

Harboe, Henrik. The Use of Compressed Air for Energy Storage. 168th National Meeting, American Chemical Society, Division of Fuel Chemistry. Preprints Vol. 19, No. 4, 155-161. Washington, D.C.: American Chemical Society, 1974.

Jensen, J. Energy Storage. London, England and Boston, Massachusetts: Newnes-Butterworths, 1980.

Johnson, D.G.; Escher, W.J.D.; and Pangborn, J.B. New Energy from an Old Source: Hydrogen from Falling Water. Society of Automotive Engineers, No. 789135, Warrendale, Pennsylvania: Society of Automotive Engineers, 1978.

Marier, D. Wind Power for the Homeowner. Emmaus, Pennsylvania: Rodale Press, 1981.

Mathis, D.A.: Hydrogen Technology for Energy 1976. Energy Technology Review No. 9. 18901 Cranwood Parkway, Cleveland, Ohio 44128: CRC Press, 1976.

McMullan, J.T.; Morgan, R.; and Murray, R.B. Energy Resources and Supply. New York, New York: John Wiley & Sons, 1976.

McGown, L.B. and Bockris, J.O. How to Obtain Abundant Clean Energy. New York, New York and London, England: Plenum Press, 1980.

McGuigan, D. Harnessing the Wind for Home Energy. Charlotte, Vermont 05445: Garden Way Publishing Co., 1978.

McGuigan, D. Harnessing Water Power for Home Energy. Charlotte, Vermont 05445: Garden Way Publishing Co., 1978.

McIntyre, J.D.G.; Srinivasan, S. and Will, F.G., eds. Electrode Materials and Processes for Energy Storage. Proceedings of Symposium. Vol. 77-6. P.O. Box 2071, Princeton, New Jersey 08540: Battery and Physical Electrochemistry Divisions and Energy Technology Group, Electrochemical Society, 1977.

Portola Institute. Energy Primer--Solar, Water, Wind, and Biofuels. Fremont, California 94536: Fricks-Parks Press, Inc., 1974.

Scott, F.M. Hydropower From Underground Pumped Storage. 168th National Meeting, American Chemical Society, Division of Fuel Chemistry. Preprints Vol. 19, No. 4, 85-91. Washington, D.C.: American Chemical Society, 1974.

Silverman, J., ed. "Demonstration of a Low-Cost Flywheel in an Energy Storage System." Energy Storage. New York, New York: Pergamon Press, 1980.

Veziroglu, T.N. and Seifritz, W., eds. "Hydrogen Energy System." Proceedings of Second World Hydrogen Energy Conference, Zurich, Switzerland, 21-24 August 1978. New York, New York: Pergamon Press, 1978.