Published by: VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pr-info@vita.org

ISBN #0-86619-220-4

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Giannuzzi and Leslie Gottschalk as editors, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

C.J. Swet, the author of this paper, has a background in engineering, and is a consultant in solar and other "gentle" technologies, with special emphasis on energy storage. He has 20 years experience in the field of solar energy, and has consulted on solar energy and other appropriate technology projects in developing countries. He has published several papers on solar energy and other energy related topics. Reviewers Paul E. Dorvel, John D. Furber, and Daniel Ingold are also experts in the field of solar energy. Paul E. Dorvel is currently Associate Principal Engineer in the Power Systems Division of the International Engineering Company. He has over seven years experience in Africa doing market research and field engineering for solar micropump irrigation systems. John D. Furber is President of Pleasant Valley Software Corporation and Starlight Energy Technology. He frequently lectures and consults overseas on solar energy technologies. Daniel Ingold is a biophysicist by training and a research engineer at Appropriate Technology Corporation.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers. For more information about VITA services in general, or the technology presented in this paper, contact VITA at 1815 North Lynn Street, Suite 200, Arlington, Virginia 22209 USA.

I. INTRODUCTION

This paper examines water pumping systems that use solar radiation as a direct source of energy. We look primarily at small-scale rural applications in the Third World, where the potential benefits are greatest and the near-term economics seem most favorable. Two generic technical approaches for solar water pumping systems will be examined: (1) thermodynamic (in which the radiant energy is first converted to heat); and (2) photovoltaic (in which it is first converted to electricity). Since photovoltaic technology is more mature, it is used for economic comparisons with other methods of pumping water. Our treatment of this complex subject is necessarily cursory; the aim is to provide prospective users with sufficient insight to determine whether solar water pumping is a plausible option for their specific situation, and to furnish a guide for further investigation.()

HISTORY

The history of thermodynamic solar water pumping technology goes back nearly four hundred years, when Solomon deCaux in France raised water for a fountain by the expansion of solar-heated air. By the beginning of this century, many of the currently competing design concepts had already been explored, and several promising attempts at commercialization were under way when activity subsided due to the advent of the internal combustion engine and cheap commercial fuels. Much of this development had been aimed at relatively large-scale applications. It was not until the resurgence of interest in solar energy caused by the 1973-1974 oil embargo that greater attention began to be directed at small-scale rural applications in developing countries.

() Of particular interest to the serious reader in this field is the the definitive and comprehensive work done in conjunction with the United Nations Development Programme/World Bank Small-Scale Solar-powered Irrigation Pumping Systems Project by Sir William Halcrow & Partners and the Intermediate Technology Development Group, Ltd. The most important reference for the prospective solar pump user is Handbook on Solar Water Pumping (see bibliography).

In contrast, the development of photovoltaic water pumps has heavily emphasized small-scale rural applications since the 1960s. While both of these technical approaches continue to mature, neither can yet be judged inherently superior. Most of the recent efforts, however, have concentrated on photovoltaic systems and a majority of solar pump field operating experience has been with photovoltaic installations.

NEEDS SERVED BY THE TECHNOLOGY

Solar water pumps may be used for irrigation, community water supply, livestock watering, and in various industrial processes. In principle they may be used virtually anywhere, but the most compelling needs and opportunities are found in the fuel-poor but sun-rich rural areas of the Third World. Solar pumps may also be almost any size, but most small farms, villages, and animal herds in developing countries require hydraulic output power of less than a kilowatt. Many of these potential users are too far from an electrical grid to economically tap that source of power, and engine-driven pumping tends to be prohibitevely expensive as well as unreliable due to the high cost of purchased fuel and insufficient maintenance and repair capabilities.

Developing countries increasingly require less costly and more reliable methods of pumping water that do not rely on commercial energy supplies. Solar water pumping is one of several potentially satisfactory alternatives, which also include wind, water, biomass, animal, and human power.

Greater use of irrigation is clearly needed to increase the yield from existing cultivated land and to permit cultivation of presently marginal or unusable land. Nearly all this additional irrigation will have to use pumped water, since most of the available sources of gravity-fed water are already fully exploited. In Third World countries, most irrigated land is in family plots of less than four hectares, a large proportion of these being under one hectare. This practice can be expected to extend to lands not yet under cultivation, since small plots have been found to be more productive than large farming units in terms of yield per hectare although more demanding in terms of labor input.

Daily demand for pumped irrigation water varies widely depending on the season, crop, stage of growth, region, method of water distribution, and water management effectiveness, with maximum values ranging from about 20 to 120 cubic meters per hectare per day. Water sources include ground water from open (dug) wells or boreholes that are surface water from rivers, ponds, or canals, and typically at depths of two to 10 meters below ground level. Irrigation water is seldom extracted from depths greater than 10 meters because the value of its benefits is seldom high enough to justify the extra cost of deeper wells and additional pumping energy. To be economically feasible for agricultural applications, the cost of water delivered must be less than the value of the benefits obtained through use of the irrigation water, either through improved yields or by enabling more crops to be grown per year. In 1982 a global norm for the cost ceiling for water delivered to the field (not to the crop) was approximately US$0.06 per cubic meter, although clearly the actual figure in a particular situation will depend on the crops grown, the field application efficiency, and market prices. If 60 percent of the pumped water is used by the crop itself (a fairly typical condition for earth furrows), the cost ceiling for that water would be US$0.10 per cubic meter.

Most villages in developing countries have fewer than 1,500 inhabitants, and in many of those villages the per capita water consumption is far less than the 40 or more liters per day deemed desirable from a health standpoint. A common reason for this low consumption is that all the water is drawn from a single well, resulting in lines, and in larger villages, the need to carry water considerable distances. Although multiple dispersed wells will alleviate these problems, polluted sources become more difficult to avoid. Ground water is usually extracted from depths of 30 meters or more because its value for human consumption is much greater than that for irrigation; water sellers in developing countries often command a price equivalent to more than US$3.00 per cubic meter for 10 to 30 liters per day. For this application, the economic feasibility of solar water pumping is much less a factor than its competitive position relative to other methods of mechanized pumping.

For livestock-watering in remote areas, daily demand per head varies widely depending on breed and type of forage; about 40 liters is fairly representative for dairy cattle. In recent years many engine-driven borehole pumps have been installed for this purpose, pumping from depths as low as 30 meters. Thus, a herd of cattle and a village of the same population may have comparable pumping power requirements. However, for this application it is often desirable to have multiple dispersed pumps in order to minimize overgrazing near each watering place. These considerations accent the need for pumps that can operate reliably when unattended for long periods of time, and that do not require secure fuel stores at each watering place.

II. OPERATING PRINCIPLES

Although thermodynamic and photovoltaic solar water pumping systems are conceptually similar in that both are powered directly by solar radiation, their operating principles are quite different. The following discussion highlights the distinctive features of these systems.()

THERMODYNAMIC SYSTEMS

All thermodynamic systems use a solar collector to convert solar radiation to heat and a heat engine to convert the heat to mechanical power for pumping. In heat engines a fluid or gas absorbs heat at a higher temperature, which causes it to expand; it then contracts upon removal of the heat at a lower temperature. This expansion and contraction is harnessed to move a reciprocating piston in a cylinder, or it can expand against a turbine wheel.

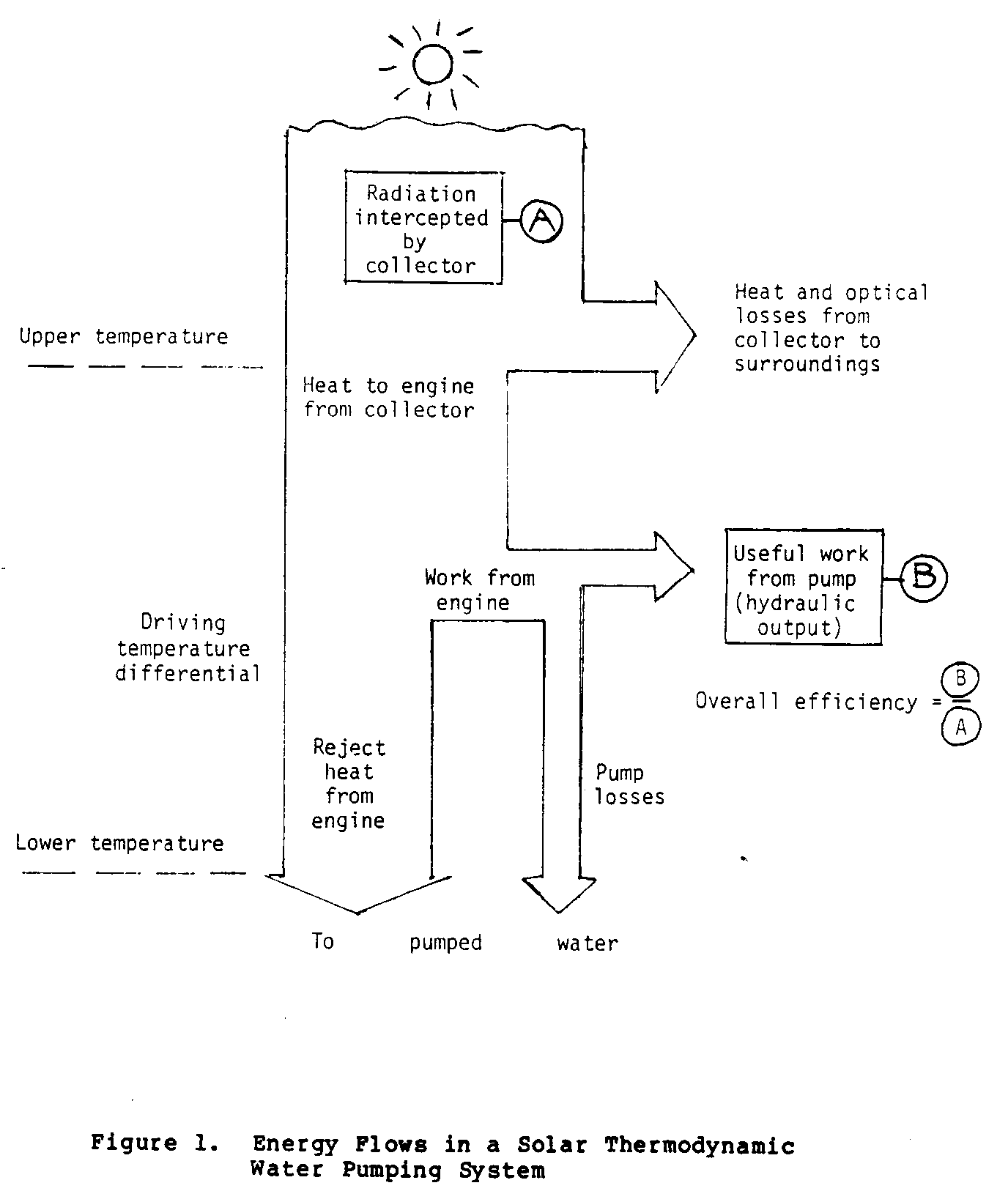

Figure 1 illustrates the basic energy flows, showing qualitatively

the necessary temperature differential across the heat engine and the unavoidable losses associated with each stage of the process. Of the two indicated temperatures, the lower one cannot be lower than that of the pumped water to which the unusable degraded heat is typically rejected, while the upper one is largely controlled by the type of collector. Increasing the upper temperature (within practical limits) raises the overall system efficiency and reduces the required collector size, but usually at the cost of greater complexity or more expensive materials. This broadly characterized conceptual approach can have many different embodiments, with various types and combinations of collectors, working fluids, heat engine cycles, engines, and pumps, as discussed in Section III.

PHOTOVOLTAIC SYSTEMS

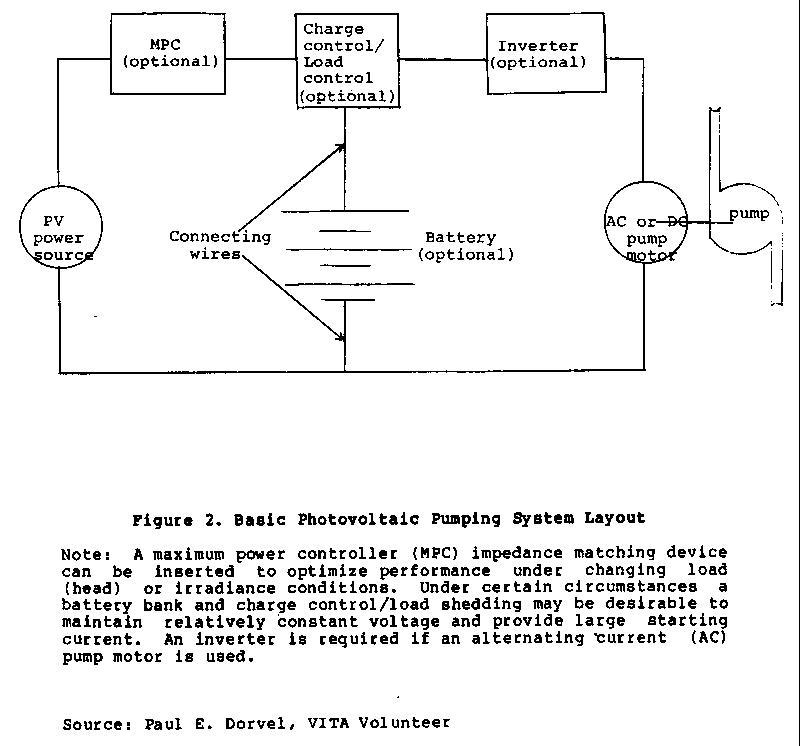

These systems exploit the photovoltaic effect to convert solar radiation to direct current electricity, which powers a motor-driven pump. A basic photovoltaic system layout is shown in Figure 2. Photovoltaic conversion occurs when light falls upon a

thin, flat material called a solar cell. One side of the cell becomes electrically positive, and the other electrically negative. This is a solid-state, electronic effect. Like a transistor, the solar cell has no moving parts except electrons.

() Detailed explanations of these operating principles can be found in the publications listed in the bibliography. As long as light falls on the cell, the electrons flow as an electrical current through an external circuit containing the motor. Individual solar cells are connected in series strings to obtain the desired output voltage. Series strings can be connected in parallel to obtain the desired output current of a module. Several modules are then interconnected and mounted. Photovoltaic array output current and power--to the extent voltage is constant--vary linearly with solar irradiance. Efficiency and power output decrease with increasing cell temperature on the order of 0.5 percent per [degrees] C above 28 [degrees] C.

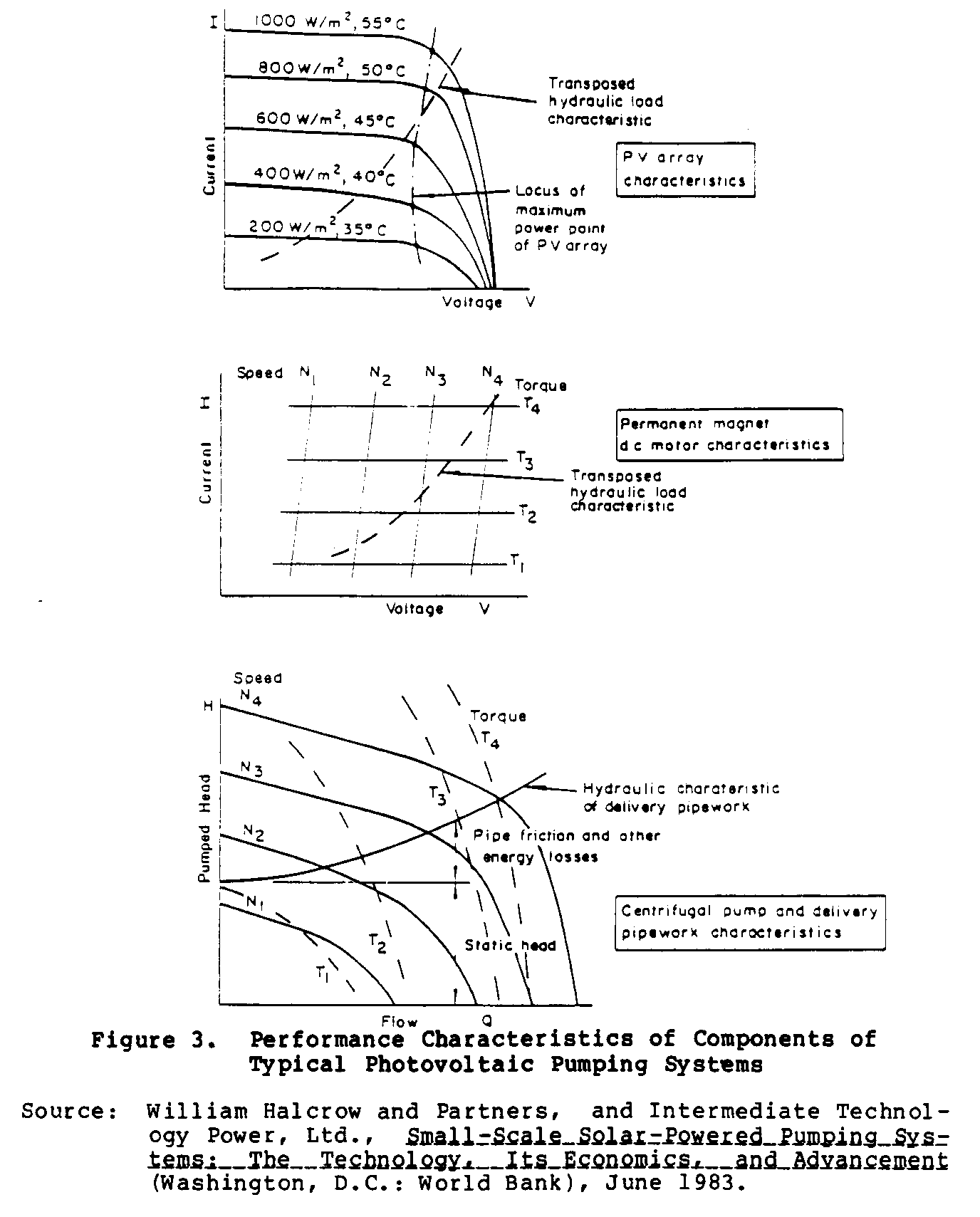

Figure 3 shows the performance characteristics of the components

of a typical photovoltaic pumping system, illustrating the importance of proper matching of the electical source and the hydraulic load over a range of operating conditions. Some optional components and configurations of these systems are discussed in Section III.

III. DESIGN VARIATIONS

THERMODYNAMIC SYSTEMS

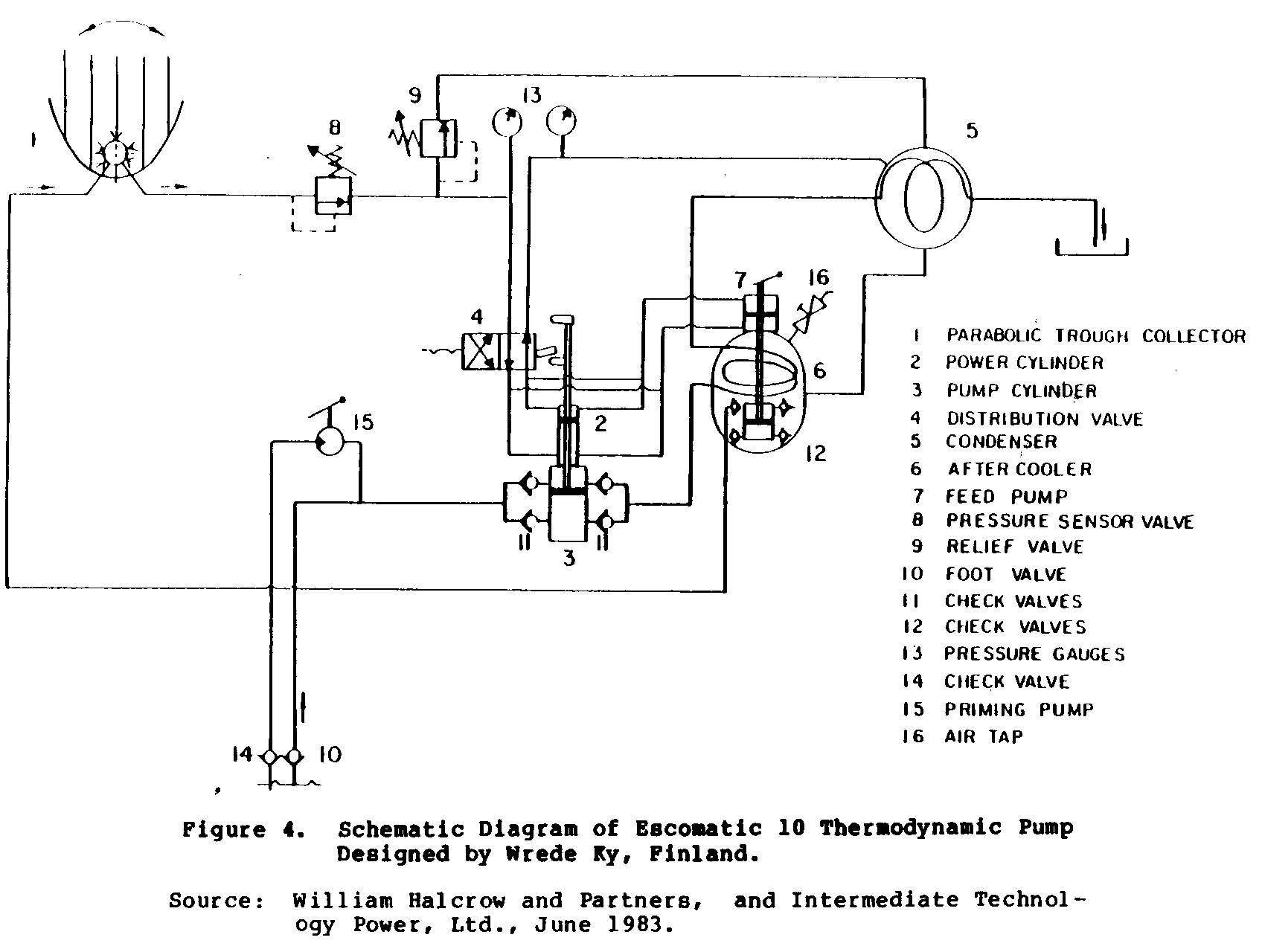

Most of the small-scale systems that have been developed beyond the prototype stage use Rankine cycles similar to the one shown schematically in Figure 4, with organic working fluids such as

Freon 11 and slow-speed reciprocating engines that directly drive piston pumps. Many developing regions are familiar with Rankine systems because of experience with steam engines. Organic working fluids can produce higher heat-to-work conversion efficiencies than steam at temperatures up to their stability limit of about 150 [degrees] C, but extreme care must be taken to ensure zero leakage since very small amounts incapacitate the system and recharging is difficult in the field. A reciprocating engine is virtually the only choice, since turbines and rotary expanders are excessively expensive in the small sizes of interest. Slow-speed reciprocating (piston) pumps tend to be more efficient than conventional high-speed centrifugal pumps at heads greater than about 10 meters, although single stage centrifugal pumps (which are easy to make) are well suited for very low-head irrigation.

The system depicted in Figure 4, which was designed by a Finnish company, has a trough-type concentrating solar collector that follows the sun by rotating about a horizontal north-south axis. Sun following is automatic, powered by the shifting weight of solar-heated Freon and controlled by a sun shade mounted on the collector, but the orientation must be reset manually each day. The collector has a 12 square meter aperture, occupies 16.5 square meters of ground space, and weighs 170 kilograms. All of the other above-ground components occupy a 0.4 cubic meter volume and weigh about 50 kilograms. Aluminum is used extensively for both weight reduction and corrosion resistance. At a Freon temperature of 107 [degrees] C the reported delivery rate is about two liters per second (roughly equivalent to 40 cubic meters per day if the pump operates eight hours) against a total pumping head of 14 meters. The reported rate is nearly five liters per second (100 cubic meters per day) against a head of three meters. The above-ground pump location limits the use of this system to shallow wells or surface water sources involving suction lifts no greater than about eight meters.

A somewhat similar system from West Germany has about 40 square meters of stationary flat plate collectors that can heat the Freon 11 working fluid to about 90 [degrees] C. Its pump can be located below grade and is adaptable to wells up to 60 meters deep. Preliminary testing in India indicates a delivery rate of 40 cubic meters per day against total pumping heads of 15 to 20 meters. The pump is sized to permit greater output when larger collectors are used.

Water (steam) has some important advantages as a Rankine cycle working fluid. It can be used at higher temperatures than are possible with organic fluids, to achieve higher efficiencies. Also, the consequences of leakage are far less severe. An Indian firm has developed a 2-kilowatt uniflow reciprocating steam engine powered by a glass strip reflector trough collector. However, higher temperatures require greater optical and tracking precision, which increases the cost per unit collector area and tends to offset the size reduction made possible by improved efficiency. The economic competitiveness of high-temperature Rankine cycle solar pumps is still a under contention.

Stirling cycle heat engines offer perhaps the most promising means of exploiting the very high temperatures (over 500 [degrees] C) that can be obtained with point focusing collectors, such as parabolic dish reflectors. Sunpower Inc. in the United States has developed a free piston Stirling engine with an integral diaphram pump, using helium as the working fluid. In tests by the manufacturer with a simulated solar thermal input of 1 kilowatt (corresponding to the output of a dish approximately 1.4 meters in diameter), the Stirling engine delivered 2 liters per second at 560 [degrees] C against a head of four meters. At its present stage of development, however, it is easily damaged, and test results have been disappointing. Another promising Stirling engine pump is the "Fluidyne" liquid piston system being developed by another Indian company, but no solar version has yet been demonstrated.

Many other technically intriguing and potentially useful systems have been or are being developed, including:

1. smaller organic Rankine systems; 2. very small (about 25 watts) steam Rankine systems;

3. an organic vapor liquid piston pump;

4. a heated air liquid piston pump;

5. a fluid overbalancing rocking beam engine pump; and

6. various solid state systems based on "memory metals," polymers, and the differential expansion of bimetal strips.

Some of these systems have become commercially available, but it must be emphasized that none of them (or of the other concepts described above) is known to have successfully undergone the extensive testing under field conditions that characterize a mature product.

Ability to manufacture and repair such technology often depends on the region. The several systems presently being developed in India presumably would be manufactured there, and an Indian affiliate of the West German company is evaluating the possibility of locally producing all or part of the German system. This does not mean, though, that these systems of Indian design could or would be manufactured elsewhere in the Third World. Supporting frames, conventional heat exchangers, and some types of collectors could be made and repaired in many developing countries, but reciprocating engines and piston pumps of high efficiency call for close tolerances that may not be readily achievable with available skills and equipment.

PHOTOVOLTAIC SYSTEMS

A number of types and sizes of photovoltaic systems are available commercially, in various stages of product development, that meet the range of pumping needs outlined in Section I. The significant design variations of these systems are fewer and more easily presented than those of the relatively immature thermodynamic approach. These variations center mainly on:

1. the choice of solar cell material;

2. the choice between stationary and sun-following solar arrays;

3. the choice between planar and concentrating solar arrays;

4. the type of electric motor;

5. the type of pump; and

6. the method of source/load matching.

All commercially available systems use crystalline silicon solar cells, of either the single crystal or polycrystal type. Other types of solar cells, which may be less expensive, are under development. These use thin films of semiconductor materials, such as amorphous silicon or cadmium sulfide. Currently available solar arrays produce roughly 100 watts per square meter under the most favorable conditions. Specific pumping needs do not influence the choice among these competing designs.

In most systems the solar arrays have a fixed orientation; they are tilted permanently toward the equator at an angle that maximizes energy collection during the season of maximum demand (or for the year if demand is fairly constant). This is the simplest and most affordable configuration, but not necessarily the least-expensive in terms of cost per unit of delivered water. At slightly greater first cost and complexity, the orientation may be manually adjusted several times during the day, thereby increasing the daily output by up to 30 percent. This tends to be cost effective provided that manual labor is available and is inexpensive for highly seasonal irrigation applications. If the system is used over most of the year, a fully automatic tracking device may be justified. Although such systems have not yet demonstrated sufficient reliability under field conditions, some recent field operating experience with gravity-driven Freon trackers on pumping systems has been encouraging.(*)

As long as solar cells remain the dominant cost item there is an incentive to reduce the required area not only through sun following but also through concentrating the intercepted solar radiation. The cost decrease due to further cell area reduction tends to be offset by the added cost of concentrating optics and the need for better cooling of the cells and more precise tracking. If solar cell prices diminish as predicted, the incentive will become much less compelling.

Permanent magnet direct current motors are the most commonly used pump drivers for small-scale systems. Alternating current motors cost less but are much less efficient in the sizes of interest. Linear actuators have been used to drive piston pumps, but the concept requires considerably more development. Many of the direct current motors in current use are of the conventional brush type, which is efficient but poorly suited for submerged operation and needs brush replacement after every few thousand hours of use. Electronically-commutated brushless direct current motors are finding favor because they require less maintenance and are more readily adapted to submerged operation, although they are slightly less efficient.

* See for example Dankoff, W., "Pumping Water," Solar Age, February 1984, pp. 29-35.

Single-stage centrifugal pumps are frequently used when the total pumping head is less than 10 meters, and are either self-priming or (if the suction lift is too great) submerged. With open wells or surface water sources, these pumps and the motors can float, thereby minimizing the suction lift. For higher heads, either multistage centrifugal or positive displacement (piston or progressive cavity) types are most efficient. If the pump is above ground or floating, it usually is closely coupled to the motor; if submerged, the pump may either be closely coupled to a submersible motor or driven by a vertical shaft. Positive displacement pumps ordinarily are submerged except in cases where the lift is small but the total pumping head is high.

Single-stage centrifugal pumps can be made with head-capacity characteristics that fairly closely the solar array current-voltage characteristics, so that the array can operate at near-peak efficiency over a wide range of operating conditions. This matching cannot take place with multistage centrifugal or positive displacement pumps. For systems that are not inherently compatible in this respect, it is possible to install an electronic impedance matching device between the array and the motor that will automatically optimize the load on the array. These devices, called maximum power point trackers or maximum power controllers (MPCs), will increase daily pumped output and will allow pumping to start under low moring irradiance. Maximum power controllers add to the complexity and cost of a system, in addition to creating an approximate five percent power drain on the array. Indications are that MPCs are most cost-effective in systems over about one kilowatt peak capacity. Below this level, it may be more cost-effective to substitute extra array capacity for an MPC.

Local production of nearly all components except the solar cells appears possible in many developing countries.(*) India and Brazil have begun cell manufacture and some other countries are considering the assembly of modules from imported cells. Since solar cell technology is advancing so rapidly, and crucial choices among the candidate semiconducting materials have yet to be made, it may be prudent for most of the Third World to await the emergence of clearly superior design approaches before investing in production facilities. Other than solar cells, the most doubtful items for potential local manufacture appear to be piston pumps, because of their close machining tolerances.

(*) For an in-depth discussion of the potential for local production, see Small-Scale Solar-Powered Pumping Systems: The Technology Its Economics and Advancement, by William Halcrow and Partners, and Intermediate Technology Power, Ltd., and its supporting documents concerning manufacture of solar water pumps in the less developed countries (June 1983).

IV. COMPARING THE ALTERNATIVES

To gain widespread acceptance, small-scale water pumps must not only deliver water at a cost below the value of that water; they must also do so at a lower cost than alternative methods of pumping water. Most prominent among the currently available alternatives are diesel or kerosene engines, wind power, animals, and humans. A good basis for comparing them with solar is the cost per unit volume of water delivered under like conditions over a like number of years. This takes into account costs of purchasing, financing, delivery, installation and start-up, fuel, operating and maintenance labor, repairs, and replacements. In United Nations Development Programme studies, comparative costs of delivered water have been estimated for irrigation, village water supply, and livestock watering in Kenya, Bangladesh, and Thailand (see bibliography).

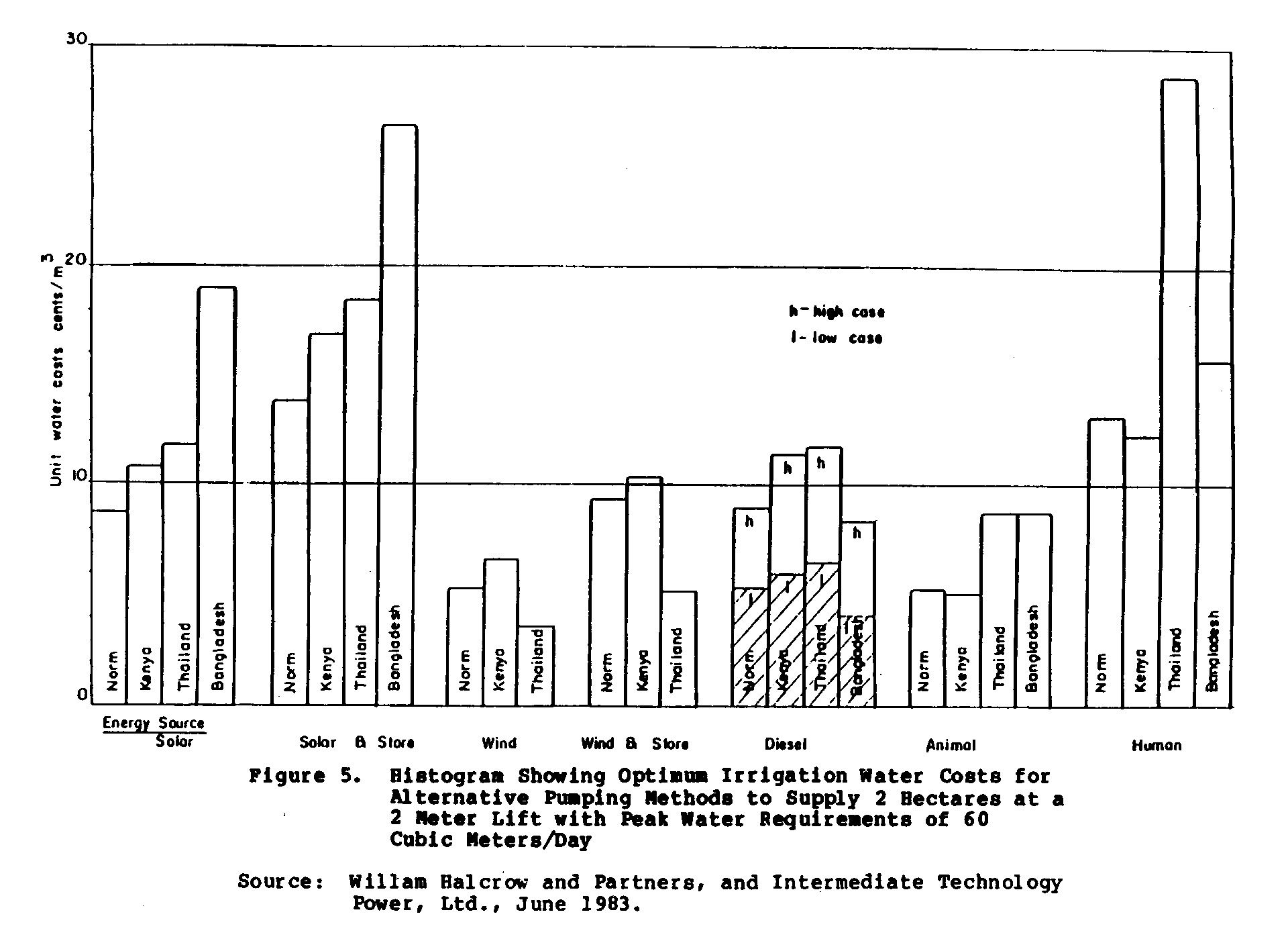

Based on 1982 prices, some typical results are shown in Figures 5, 6, 7, and 8.

There are many qualifications to these results, too numerous and complex for exposition here. It must be pointed out, though, that the solar costs are based on photovoltaic systems in which the dominant cost item is the solar module at its 1982 price of about US$8/ peak watt. That price is likely to become much lower within a few years, making the solar option more competitive. It should also be noted that the attractively low wind power costs are based on average mean wind velocities for each country; within those countries there are regions with totally inadequate wind. The costs for animal power are somewhat optimistic because they do not include the cost of diverting animals from other activities, and the "low case" diesel costs are based on unrealistically optimistic values for fuel cost and consumption. With these points in mind it seems fairly clear that within a few years solar will be quite competitive in most sunny regions that have little wind. GLOSSARY OF TERMS

Aperature: The Solar Collection Area.

Dish Collector

One in which the reflecting surface is a paraboloid of revolution that concentrates direct solar radiation onto an absorber at its focal point. Usually for temperatures above 250 [degrees] C, with two-axis tracking.

Drawdown

The distance the water level in a well is temporarily lowered by pumping.

Flat plate solar collector. One in which the aperture is essentially identical to the area of the absorber surface, the absorbing surface is essentially planar, and no concentration is employed. Usually for temperatures below 100 [degrees] C.

Hydraulic output power. The power imparted by the pump to the water, proportional to the product of the flow rate and the total pumping head. In watts, roughly equal to liters per second times meters times ten.

Irradiance (radiation intensity). The energy flux density in the solar radiation, usually expressed in watts per square meter.

Static Head

The vertical distance between the water source level at no flow and the point of discharge.

Suction Lift

The height that water must be lifted from the source level to the pump.

Total Pumping Head

The static head plus drawdown and flow pressure losses in piping.

Trough Collector

One with a cylindrical parabolic reflecting surface that concentrates direct solar radiation onto an absorber (usually a tube) at its focal line. Usually for temperatures from 100 [degrees] to 250 [degrees] C, tracking about one axis.

Overall System Efficiency

The fraction of intercepted solar radiation that imparts pumping energy to the water, i.e., pump hydraulic output power per unit aperture/irradiance.

BIBLIOGRAPHY/SUGGESTED READING LIST

Halcrow, William and Partners, and Intermediate Technology Power, Ltd. Small-Scale Solar-Powered Pumping Systems: The Technology, Its Economics and Advancement (United Nations Development Programme Project GLO/80/003). Washington, D.C.: World Bank, June 1983. Available through the World Bank, along with the following supporting documents:

1. Performance tests on improved photovoltaic pumping systems 2. Economic evaluation of solar water pumps 3. Potential for improvement of photovoltaic pumping systems 4. Review of solar thermodynamic pumping systems 5. Manufacture of solar water pumps in developing countries

Small-Scale Solar-Powered Irrigation Pumping Systems (United Nations Development Programme Project GLO/78/004, Phase I report). Washington, D.C.: World Bank, July 1981. See also Small-Scale Solar-Powered Irrigation Pumping System Technical and Economic Review (September 1981), amplifying this report.

Handbook on Solar Water Pumping (United Nations Development Programme Project GLO/80/003). Washington, D.C.: World Bank, February 1984. This handbook directly addresses the concrete issues and methods of selecting, evaluating, and specifying a solar water pumping system.

Kreider, J., and Kreith, F., eds. Solar Energy Handbook. New York: McGraw Hill, 1981. The reader is referred to the following chapters:

Chapter 1 for history of solar thermodynamic water pumping Chapter 7 for non-concentrating solar-thermal collectors Chapter 8 for intermediate concentration collectors Chapter 9 for high concentration collectors Chapter 22 for solar powered heat engines Chapter 24 for photovoltaics

McNelis, ed. United Kingdom Section of International Solar Energy Society. Proceedings of Conference on Solar Energy for Developing Countries, Volume on Refrigeration and Water Pumping. London: ISES, January 1982.

United Nations Development Programme; World Bank; and Philippines Ministry of Energy. Proceedings of Workshops on Solar Pumping in Developing Countries. Washington, D.C.: World Bank, June 1981.

PARTIAL LIST OF SUPPLIERS AND MANUFACTURERS OF SOLAR WATER PUMPING SYSTEMS

THERMODYNAMIC SYSTEMS (not necessarily mature products):

Dornier organic Rankine flat plate, Postfach 1360 approx. 500 watts output 7990 Friedrichshafen 1 FEDERAL REPUBLIC OF GERMANY

Grinakers fluid overbalancing beam engine, c/o A. de Beer flat plate, approx. 200 watts P.O. Box 349 Rosslyn 0200 REPUBLIC OF SOUTH AFRICA

Grinakers fluid overbalancing beam engine, c/o Pelegano Village Industries flat plate, approx. 200 watts P.O. Box 464 Gaborone BOTSWANA

Wrede-Ky organic Rankine trough P.O. Box 42 approx. 300 watts output SF-02701 Kaunianen FINLAND

PHOTOVOLTAIC SYSTEMS (commercially available and fairly mature):

AEG--Telefunken Raumfahrttechnik und Neue Technologien Industriestrasse 29 2000 Wedel, Holstein FEDERAL REPUBLIC OF GERMANY

Aerimpianti S.p.A. Via Bergano, 21 20135 Milano ITALY

ARCO Solar, Inc. 20554 Plummer Street Chatsworth, California 91311 USA

A.Y. McDonald Corp. P.O. Box 508 Dubuque, Iowa 52001 USA

Baker-Monitor 133 Enterprise St. Evansville, Wisconsin 53536 USA

Briau BP 43 37009 Tours FRANCE

Grundfos Pump Corp. 2555 Clovis Ave. Clovis, California 93612 USA

Heliodinamica Caixa Postal 8085 Sao Paulo 01000 BRAZIL

Intersol Power 11901 West Cedar Avenue Lakewood, Colorado 80228 USA

Jacuzzi Brothers 11511 New Benton Hwy. Little Rock, Arkansas 72201 USA

Mobil Solar Energy Corp. 16 Hickory Dr. Waltham, Massachusetts 02254 USA

Pompes Gitnard Etablissements 179, Boulevard Saint Denis 92402 Courbevoie FRANCE

Philips GmbH, Unternehmensbereich Licht und Anlagen-Energie-Systeme Monckebergstrasse 7 2000 Hamburg 1 FEDERAL REPUBLIC OF GERMANY

Solar Electric International 31 Queen Anne's Gate London, SW1H 9BU ENGLAND

Solar Usage Now Inc. Box 306 420 East Tiffin St. Bascom Ohio USA

Solarex Corp. 1335 Piccard Dr. Rockville, Maryland 20850 USA

Solavolt International 3646 E. Atlanta Ave. Phoenix, Arizona 85040 USA

Solec International 12533 Chadron Avenue Hawthorne, California 90250 USA

Tri-Solar Corp. 10 DeAngelo Dr. Bedford, Massachusetts 10730 USA

Virden Perma-Bilt 2821 Mays Ave. Amarillo, Texas 79109 USA

Windlight Workshop P.O. Box 6015 Santa Fe, New Mexico 87502 USA