VITA

Wilson Boulevard, Suite 500, Arlington, Virginia 22209 USA Telephone: (703) 276-1800, Fax: (703) 243-1865 Telex 440192 VITAUI, Cable: VITAINC Internet: vita@gmuvax.gmu.edu, Bitnet vita@gmuvax

Men's Dress Shirts ISBN: 0-86619-290-5 [C]1987, Volunteers in Technical Assistance

INDUSTRY PROFILES

Introduction

This Industry Profile is one of a series briefly describing small or medium-sized industries. The Profiles provide basic information for starting manufacturing plants in developing nations. Specifically, they provide general plant descriptions, financial, and technical factors for their operation, and sources of information and expertise. The series is intended to be useful in determining whether the industries described warrant further inquiry either to rule out or to decide upon investment. The underlying assumption of these Profiles is that the individual making use of them already has some knowledge and experience in industrial development.

Dollar values are listed only for machinery and equipment costs, and are primarily based on equipment in the United States. The price does not include shipping costs or import-export taxes, which must be considered and will vary greatly from country to country. No other investment costs are included (such as land value, building rental, labor, etc. as those prices also vary. These items are mentioned to provide the investor with a general checklist of considerations for setting up a business.

IMPORTANT

These profiles should not be substituted for feasibility studies. Before an investment is made in a plant, a feasibility study should be conducted. This may require skilled economic and engineering expertise. The following illustrates the range of questions to which answers must be obtained:

* What is the extent of the present demand for the product, and how is it now being satisfied?

* Will the estimated price and quality of the product make it competitive?

* What is the marketing and distribution plan and to whom will the product be sold?

* How will the plant be financed?

* Has a realistic time schedule for construction, equipment, delivery, obtaining materials and supplies, training of personnel, and the start-up time for the plant been developed?

* How are needed materials and supplies to be procured and machinery and equipment to be maintained and repaired?

* Are trained personnel available?

* Do adequate transportation, storage, power, communication, fuel, water, and other facilities exist?

* What management controls for design, production, quality control, and other factors have been included?

* Will the industry complement or interfere with development plans for the area?

* What social, cultural, environmental, and technological considerations must be addressed regarding manufacture and use of this product?

Fully documented information responding to these and many other questions should be determined before proceeding with implementation of an industrial project.

Equipment Suppliers, Engineering Companies

The services of professional engineers are desirable in the design of industrial plants even though the proposed plant may be small. A correct design is one that provides the greatest economy in the investment of funds and establishes the basis of operation that will be most profitable in the beginning and will also be capable of expansion without expensive alteration.

Professional engineers who specialize in industrial design can be found be referring to the published cards in various engineering magazines. They may also be reached through their national organizations.

Manufacturers of industrial equipment employ engineers familiar with the design and installation of their specialized products. These manufacturers are usually willing to give prospective customers the benefit of technical advice by those engineers in determining the suitability of their equipment in any proposed project.

VITA

Volunteers in Technical Assistance (VITA) is a private, non-profit, volunteer organization engaged in international development. Through its varied activities and services, VITA fosters self-sufficiency by promoting increased economic productivity. Supported by a volunteer foster of over 5,000 experts in a wide variety of fields, VITA is able to provide high quality technical information to requesters. This information is increasingly conveyed through low-cost advanced communication technologies, including terrestrial packet radio and low-earth-orbiting satellite. VITA also implements both long- and short-term projects to promote enterprise development and transfer technology.

PRODUCT DESCRIPTION

The Product

Men's dress shirts are made from white broadcloth. They come in a variety of styles and are made to be worn with suits and ties. They can be either long or short sleeved.

The Facility

This Profile describes one small plant operating with one shift and manufacturing 15,000 dozen men's dress shirts a year. It also describes a larger plant running a single shift and manufacturing 22,000 dozen shirts a year.

The proposed plant should not be confined to the production of just men's dress shirts. It should be able to adapt to many other similar products. For example, the same facility can be used to cut and sew plaids, checks, oxford, other shirts, school uniforms, and women's blouses. If proper supervision is maintained, there should be no loss of production capability. In fact, making a variety of styles should make it easier for the factory to sustain itself.

GENERAL EVALUATION

The shirts described here are worn mostly on prestige occasions by white collar workers, government officials, and business executives. As such, the market for them may be greater among the white collar members of any society, including less industrialized nations.

1. Outlook

A. Economic

Will depend on the society and existing conditions.

B. Technical

Much of the machinery listed in this profile is expensive; if purchased new. In order to cut costs, it can be substituted with reconditioned used sewing machines.

2. Manufacturing Equipment Flexibility

The machinery and equipment required are much the same as those used to manufacture other clothing. As a result, fixed capital expenditure may be identical, but the fabric used is somewhat more expensive. The degree of skill needed may also be greater, and the total labor force somewhat larger. But it is possible to produce both men's dress shirts and men's work shirts in the same factory at different times, depending upon the demand.

3. Knowledge Base

A good business plan is necessary. A two-to three-year projection should be prepared carefully to avoid exaggeration.

Management should have:

a) Business experience b) Knowledge of field c) Sources of capital d) Capability of finding government support e) Knowledge of market and sales f) Knowledge of procurement of material and equipment g) Knowledge of export capabilities

4. Quality Control

Quality control is very important, and specifications vary from company to company and garment to garment. For example, an entire order can be rejected for as little an error as the number of stitches per inch or the tension of the thread.

5. Constraints and Limitations

In developing countries there is usually an ample labor pool easily adaptable to this industry. However, there is some possibility that a shortage of designers, pattern-makers, and possibly cutters and mechanics may occur. Other considerations include:

--No special transportation requirements. --Manager and supervisors should be fully experienced. --Some operators will work on more than one machine. --After break-in period, production workers should go on piece work rates. --Plant should be near a source of labor and a reliable electric power system.

MARKET ASPECTS

Users

White collar workers, officials and executives.

Suppliers

With a specific investment size in mid, management should plan a trip to New York or other garment centers for fabric sources and equipment dealers. There are usually sales representatives, of equipment and fabric in most urban centers, but there is much more diversity in the United States.

Sales Channels and Methods

This plant may sell directly to large stores and to wholesalers for resale to small retailers and dry goods stores.

Geographic Extent of market

Domestically, the market may be nationwide. The limiting factor in this case may be size of plant and outside competition rather than transportation. The product is easy to ship, and transport costs are normally low in relation to product value.

Export - Large investments in plant and equipment for textile export at this time is not a good idea, unless there is a written firm commitment from a textile outlet for the garments.

Competition

In the domestic market, more expensive materials may compete for prestige wear. Large-scale foreign manufacturers, with a large, low-wage labor force available, may constitute serious competition.

Export Market - The plant is relatively small and might have great difficulty in competing with large-scale plants or with exports from areas where labor is plentiful and cheap. There is a possibility of entering this field as contractors for U.S. manufacturers.

Market Capacity

The rate of consumption of dress shirts will depend primarily upon the level of income, and the availability of other prestige wears. Where such shirts are worn for more formal occasions and at all times by officials, higher white collar workers and professional people in a population between two and three million should be sufficient to support the output of this plant.

PRODUCTION AND PLANT REQUIREMENTS

Requirements Annual Output: 15,000 dozen 22,000 dozen 1. Infrastructure, Utilities Small Plant Medium Plant

Land 1/3 acre 1/2 acre Building one story 6,000 s.f. to 10,000 s.f. Power connected load 100 hp to 120 hp Fuel __________ ___________

Water __________ ___________ Other __________ ___________

- Major Equipment & Machinery Small Plant Medium Plant Units Units Tools & Machines cloth unwinder (1) (1) cloth spreader (1) (1) cutting table (360sf & 225sf) (2) (1) cutting machine (3) (4) cloth drill (1) (1) buttonhole machine (2) (2) buttonsewer machine (2) (2) sewing machines single needle (20) (26) shirt front (2) (2) safety stitch (2) (2) *1 lap seam (2) (2) trimmaster (portable) (2) (3) collar & pocket shapers (1) (2)

Support Equipment & Parts furniture & fixtures turning stands hand trucks (2) (2) steam irons (with generators) (6) (8) chairs & workbenches (36) (45) work tables storage shelves spare parts * tools work baskets truck/van (1) (1)

*TOTAL ESTIMATED COST of equipment & machinery only $84,000 $96,000 Duty & shipping not included *Based on $US 1987 prices. The costs provided are estimates and are given only to provide a general idea f or machinery costs; they are not intended to be used as absolute prices. Costs still need to be determined on a case by case basis. *1 Assemblers could use lap seam or safety stitch.

*3. Materials & Supplies Small Plant Medium Plant

Raw Materials broadcloth 400,000 yards 600,000 yards lining 8,000 yards 10,000 yards buttons 15,000 gross 22,000 gross tags and labels 1,800 gross 2,400 gross thread 3,000 cones 4,000 cones

Supplies lubricants office & factory supplies Packaging shirt boards & paper 15,000 dozen 22,000 dozen pins 10,000 gross 10,000 gross boxes (6 shirts/box) 2,500 dozen 3,750 dozen shipping cartons (3 doz./carton) 5,000 dozen 7,500 dozen

- Labor Small Plant Medium Plant

Skilled cutters 2 3 operators 26 36 pressers 6 8 floor help 6 8

Semiskilled

Unskilled bundling/cleaning 4 6

Indirect manager 1 1 office 1 2 supervisor 2 3

- Distribution/Supply flow Small Plant Medium Plant

Amount in per day Amount out per day 60 dozen 75-85 dozen

- Market Requirements Small Plant Medium Plant population 2-3 million

- Other Requirements Small Plant Medium Plant

*This includes an approximate amount of materials used over a period of a year. It does not mean that a year's supply must be stored on the premises.

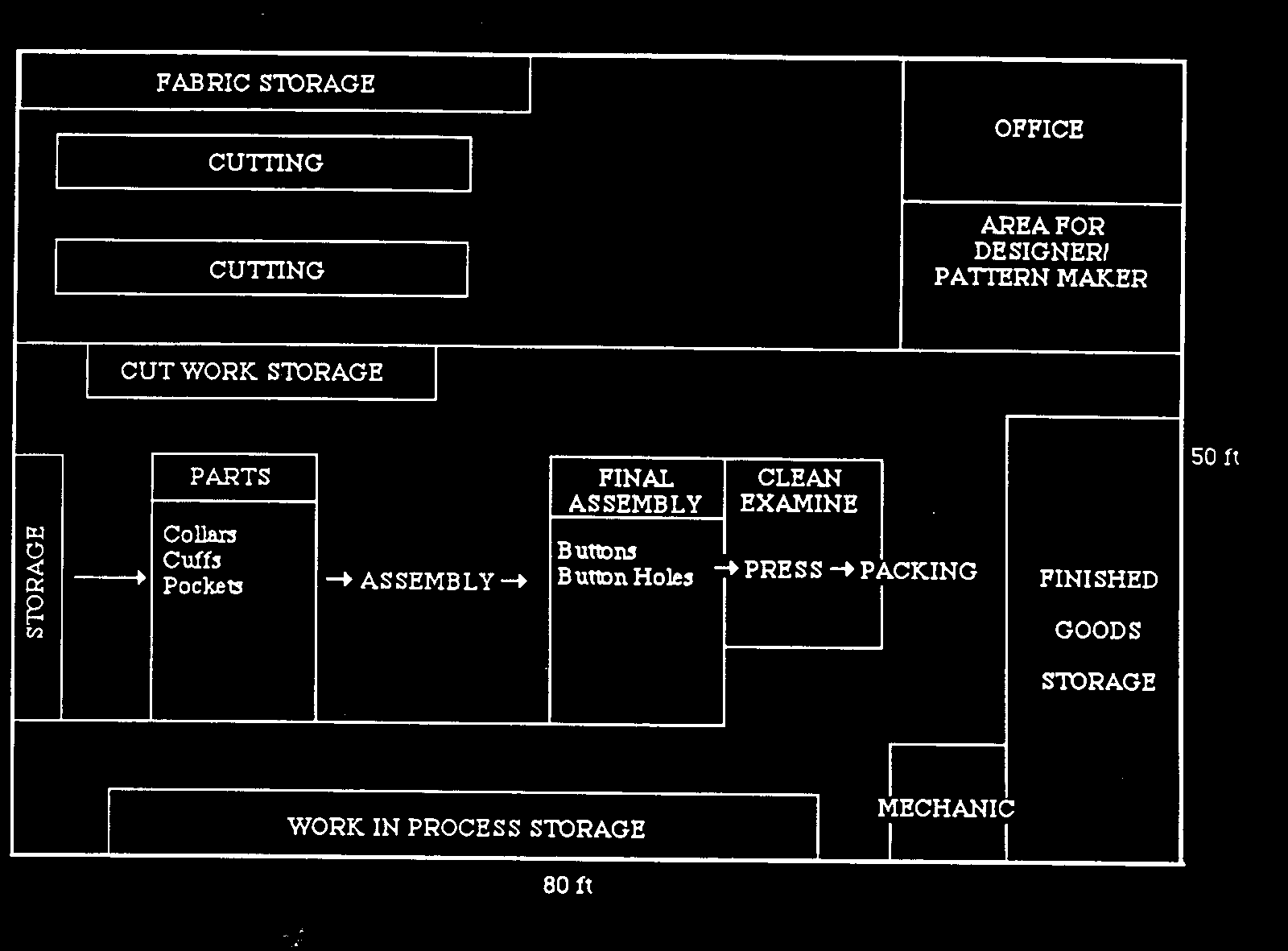

PROCESS DIAGRAM

The plant layout should be no problem as the equipment is easily moved about to

provide an efficient flow of work. Adequate work space needs to be allowed for ease of movement. Room should be allocated foa a designer/pattern maker.

REFERENCES

Unless otherwise stated, these addresses are in the United States.

Technical Manuals & Textbooks

Fashion Institute of Technology 7 Ave. & 27 St. New York, New York 10001 Library and bookstore with full listing of books on design and pattern-making, marketing, etc.

Model Garment and Factory for Men's Shirts and Trousers. United Nations Industrial Development Organization. 31 pp. December, 1974.

Periodicals

Women's Wear Daily & Daily News Record Fairchild Publications 7 E 12 St. New York, New York 10003

Apparel World 366 Park Ave., South New York, New York 10016

Bobbin Magazine Bobbin International, Inc. PO Box 1986 1110 Shop Road Columbia, South Carolina 29202

Apparel Industries Magazine 180 Allen Street Atlanta, Georgia 30328

Trade Associations

American Apparel Manufacturing Association 2500 Wilson Boulevard Arlington, Virginia 22201 (703) 524-1864

National Knitwear & Sportswear Association 366 Park Ave., South New York, New York 10016

Equipment Suppliers, Engineering Companies

Hudson Sewing Machine Co. 109 Johnston St. Newburgh, New York 12550 (dealer in all types of equipment)

The Singer Company 135 Raritan Center Parkway Edison, New Jersey 08837 (sewing room equipment, cutting room equipment)

Kurt Salmon Associates 350 Fifth Avenue New York, New York 10118 (management consultants, consulting services)

Directories

Buyers Guide: Sourcing Guide for the Apparel Industry produced by The Associate Membership Congress American Apparel Manufacturers Association 2500 Wilson Boulevard Arlington, Virginia 22201

VITA Resources

VITA has on file a number of documents related to the textile and clothing industry. For example: Selected Information Resources on Textiles. Compiled by J.A. Feulner. National Referral Center, Library of Congress. May, 1986. 17 pp. XII E-1, P.1, 022470, 12.

VITA Venture Services

VITA Venture Services, a subsidiary of VITA, provides commercial services for industrial development. This fee-for-service includes technology and financial information, technical assistance, marketing, and joint ventures. For further information, contact VITA.