This article is from ECHO Asia Note # 31.

Introduction and Background

Saving your own seeds can be a cost-effective way to access crop seed for future planting and to help maintain the planet’s plant biodiversity. Whether you plant your own saved seeds, give them away to friends and neighbors, or distribute them through your organization, the ability to effectively harvest, clean, prepare, dry, and store seeds is important to help maintain seed germination and viability. This note will focus on the importance of drying seeds to proper seed moisture content, and will provide details about two low-cost seed dryers that we have built and use at the ECHO Asia Impact Center Seed Bank.

Definitions

- Orthodox seeds are tolerant to desiccation and are storable in

this condition. - Recalcitrant seeds lose germination capacity rapidly when exposed to dry air, in most cases within ten days of harvest.

- Seed moisture content is the amount of water in a seed; usually expressed as a percentage (%).

- Seed moisture content determination is done using either equilibrium moisture content predictions (see next term), or by the use of a seed moisture meter, or through destructive sampling (i.e. using an oven to burn off all water in the seed). See Rao et al. 2006 for more information.

- Equilibrium moisture content refers to the way seeds left in ambient environmental conditions will equilibrate with the relative humidity in the environment, changing their seed moisture content (expressed as a %).

- Seed drying is the reduction of seed moisture content to recommended levels for seed storage, using non-destructive methods. Seeds dry at an exponential rate until the equilibrium moisture content is reached.

- Seed viability is a measure of the percentage of seeds that will germinate after storage. The greater the viability of your seeds, the fewer seeds will be needed to establish a desired number of plants in the field or nursery.

Optimum Drying Conditions

Orthodox seeds that are sufficiently dried will retain their viability for longer periods of storage in seed banks. In general, orthodox seeds should be dried to between 3% and 7% moisture content for long-term storage, although some seeds (such as soybeans) may experience reduced viability at moisture contents below 8%. Realistically, we at the ECHO Asia Impact Center Seed Bank are rarely able to dry seeds below 10% moisture content during the rainy season, owing to relative humidity levels of 70-80%.

Recalcitrant seeds, which include a large number of tropical tree and fruit species, should not be dried or exposed to dry air, and therefore, are beyond the scope of this note. Determining seed moisture contents for orthodox seeds is also beyond the scope of this note, but many good online resources exist to help ascertain targeted seed moisture content for a particular species, as well as how to scientifically calculate the actual seed moisture contents. See FAO’s excellent Manual of Seed Handling in Genebanks, Chapters III and IV, for more information (Rao et al. 2006).

Please note that seeds can become damaged during drying if they are dried too quickly or at too high a temperature. In general, ensure that the drying temperature does not exceed 41⁰C (105⁰F) for tree or high-oil seeds, and 54⁰C (130⁰F) for most other orthodox seeds. Pre-drying in a slightly shaded environment that is protected from wind and rain can help reduce the time seeds need to spend in a seed dryer. Figures 1 and 2 show ECHO Asia’s pre-drying areas, under opaque plastic and in a custom-built screened pre-drying cabinet.

ECHO Asia’s Experience with Seed Banking Best Practices

ECHO Asia began experimenting with seed storage best practices for the tropics when our seed bank was established in 2009. Little work had been done on appropriate, low-cost techniques for the tropics and sub-tropics, so we began to conduct our own research. After several peer-reviewed articles and lots of staff input and observations, we have established best practices that are relevant for NGOs and organizations with seed banks that are an intermediate step between community-level seed banks and international seed or gene banks. Many of these best practices are summarized in ECHO’s Technical Note #63 (Motis 2010). We recommend that you:

- Start with healthy soils and healthy plants, which are better able to resist insect pests and diseases and are more likely to produce healthy seeds for future generations

- Ensure that seeds are mature and fully developed before harvesting

- Harvest seeds continuously when they reach full development, to avoid pests, shattering, disease incidences, or loss due to other unforeseen events

- Clean all seeds thoroughly to remove chaff, insects, pods, etc. which can harbor insects and diseases

- Remove all damaged or diseased seeds

- Dry seeds to the recommended seed moisture content

- Immediately store seeds in vacuum-sealed containers (see ECHO Asia Note #14- Croft et al. 2012; Croft et al. 2013; and Lawrence et al. 2017)

- Store vacuum-sealed seeds in low-temperature conditions (See ECHO Asia Note #14- Croft et al. 2012)

This note describes how to create a low-cost seed dryer to remove seed moisture content and thereby increase stored seed viability. However, if you are going to invest the time and money to dry seeds, once they are dried you must immediately store them in vacuum-sealed or hermetic containers. If left out, dry seeds will again pick up moisture from the outside air. Seed viability and germination remain highest when seeds with low moisture content are stored in vacuum-sealed containers at low temperatures.

Building a Seed Dryer

An effective seed dryer will include a heating source, a way to moderate the heating source, a container or box for maintaining the heat, screens on which to place seeds, a fan to circulate air (optional), and a vent for releasing moist air (optional). Basically, heated air from a heating element flows upward due to convection or is circulated around an enclosed space using a fan; this heating element is set to a specific temperature so as not to damage seeds. As the warm air moves through the chamber, seeds release moisture because warm air holds more moisture than cold air. If the chamber is very air-tight, your seed dryer will be more efficient with a vent to give off the warm, moisture-laden air, since seeds will equilibrate to the ambient relative humidity.

Drying times and ability to reduce seed moisture content will vary depending on the efficiency of your dryer, the heating source, the quantity of seed being dried, the types of seed being dried, and the ambient conditions. During the rainy season in northern Thailand, we find it difficult to dry seeds even with a seed dryer, but during very dry periods of the hot season, a seed dryer is hardly necessary. Learning how to dry seeds properly requires trial and error, and is both an art and a science. With time and experience, the ECHO Asia Seed Bank Staff have developed a keen finesse for drying seeds and approximating seed moisture content.

Depending on the type, seed dryers can play additional important roles on a Small Farm Resource Center or in a seed bank. When a thermostat is used along with a sealed, insulated chamber, the dryer can become a seed germination cabinet. Seed dryers with sufficient airflow and heat can be used to dry other biomass for research or commercial purposes (e.g. our Seed Dryer #3, which is a modified seed germination cabinet, can also be used to dry moringa and other plant materials for research purposes or to powder for nutrient supplements). With a little creativity, a seed dryer can be built from commonly available materials and can serve many concurrent purposes!

ECHO Asia has built three seed dryers over the past eight years. Below we look at each one of them in depth. In general, a seed dryer requires five or six main components. 1. A heating source, can either be a heating element or light bulbs. Incandescent light bulbs give off the most heat, but fluorescent bulbs can be used. Electricity will be needed to power the bulbs. 2. The way to moderate the heating source can either be with a thermostat or with a simple electric timer. The thermostat is the preferred method, as it can accurately regulate temperatures; however, a timer can be used, assuming that you spend the necessary time and effort to measure temperature inside the seed dryer and to adjust the bulbs’ heating/cooling cycle through the on/off function of the timer and pay attention to changing ambient temperature conditions. 3. A container or box that will store the seeds and will contain the heat is essential to ensure that seeds are not re-equilibrating to ambient air moisture and that the heating elements are being used efficiently. 4. Screens work well to hold the seeds inside the container. Any material that allows for airflow can work; we have successfully made removable screens out of screen door material. The screens should be arranged to allow for maximum airflow through the chamber. Stacking screens in layers like shelves has worked well for us. Spread seeds no more than one layer thick on the screen material, to allow for good air circulation and to maximize drying. 5. A small fan that circulates the warm air can help to speed up drying times, maximize efficiency, and ensure more uniform drying; you might use an AC fan connected directly to a mains power source, or a DC computer fan connected to a DC converter. Although helpful, a fan is not absolutely necessary if the heating element is below the screens and convection can carry the warm air up through the successive layers of screen shelves. 6. A vent that can be opened and closed is not absolutely necessary (especially if your cabinet or box is not too air-tight), but it can be helpful if your seeds have a very high moisture content. As warm air picks up moisture from the seeds, it loses its ability to hold more moisture, and makes the inside of the chamber moist. Opening a vent periodically allows moist air to escape and replaces it with fresh air. If you don’t have a vent, this can also be accomplished by opening the chamber door or shelves every so often.

ECHO Asia Models of Seed Dryers

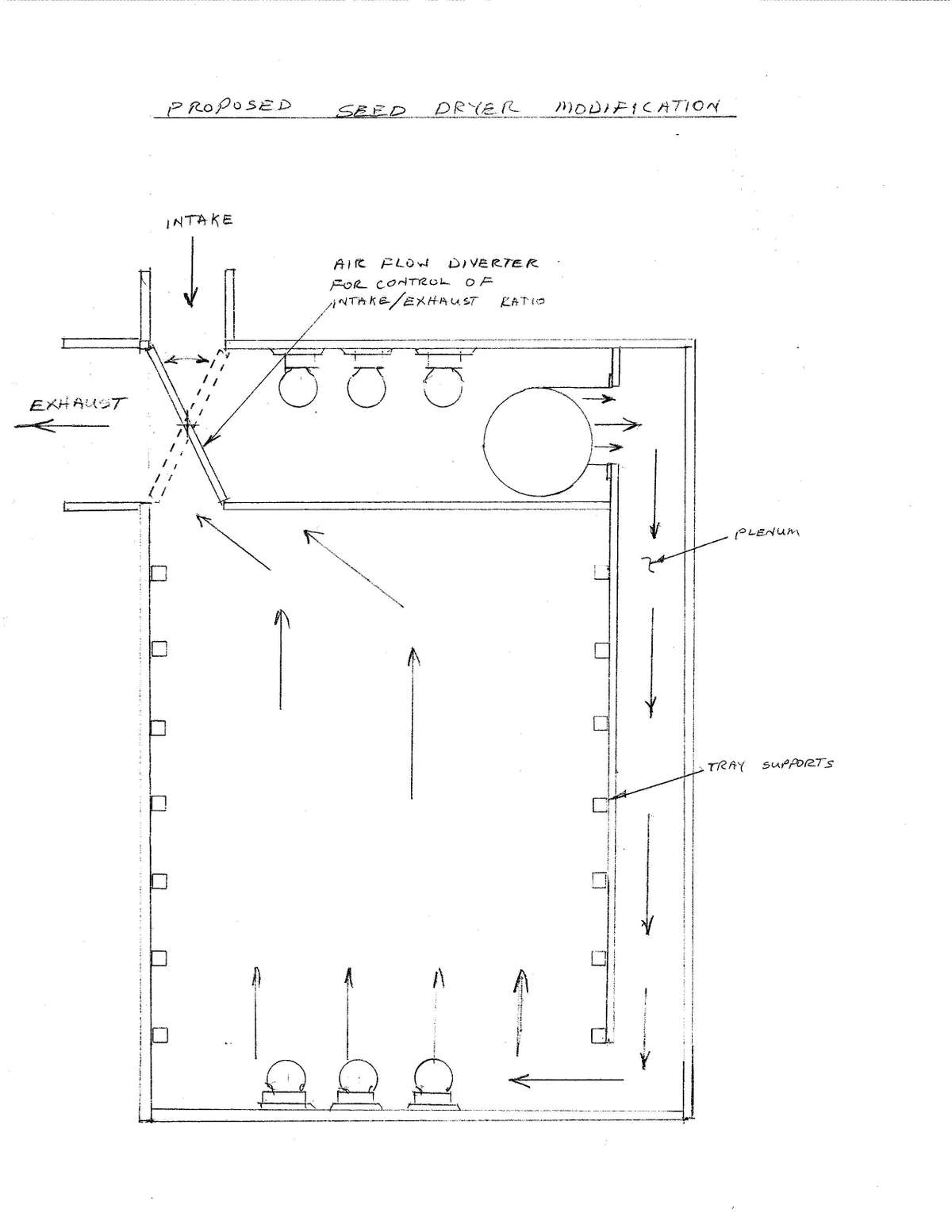

The first ECHO Asia Seed Bank dryer (we’ll call it Seed Dryer #1) is a very large, custom-built wooden box with shelves spaced about 8 inches (17 cm) apart (Figures 3, 4, and 5 on pages 11 and 12). It uses incandescent light bulbs in the bottom and at the top to heat the air (Figure 3). The dryer is quite rugged, but heavy, and has developed cracks in the walls over time, due to the use of local lumber that was not kiln-dried. We later modified it to include a ventilation system (which we rarely use), a thermostat to better control temperatures, and a squirrel fan, along with more incandescent light bulbs to try to circulate more air (Figure 4) from the upper part of the chamber down into the lower part of the chamber. This design also incorporates a separate heating area at the top to heat and exchange air (Figures 6 and 7 on Page 12).

The second ECHO Asia Seed Bank dryer (Seed Dryer #2) was built six years after the first. We used the same principles, but with modifications to make it more compact and efficient (Figure 8 on Page 12). While the first dryer was built using local lumber prone to splitting, this dryer was built using kiln-dried wood and plywood. We also used heavier-duty hardware and more closely-spaced shelves (to make the design more compact). Like the first dryer, this one has light bulbs for heating (Figure 9), a thermostat, and DC-computer fans to circulate the air (Figure 10). Whereas Seed Dryer #1 is unmovable, this dryer has caster wheels that allow us to move it where needed. Hardware is high quality (Figure 11) and provides for smooth operation, but is somewhat difficult to remove from the cabinet for cleaning (Figure 12).

We have built a third design (Seed Dryer #3), but have not yet used it widely. It is a modular design, based off of a seed germination cabinet (Figure 13) that ECHO Asia built and has been promoting (see EAN #8 (Bicksler 2011) as well as our YouTube video). This seed dryer is essentially a seed germination cabinet with a thermostat (Figure 14) to precisely control temperatures, a vent to allow for release of saturated air, DC-computer fans to circulate air within the cabinet (Figure 15), and a number of holes drilled into the pre-existing shelf in the chamber to aid in airflow (Figure 16). Advantages of this design are that: 1) it can double as a seed germination cabinet, and 2) with pre-existing insulation, is extremely heat efficient. A drawback is that it is limited in size to the pre-existing size of the kitchen cabinet that was used in its construction.

|

Staff Feedback About the Designs

ECHO Asia Seed Bank staff members provided the following feedback on the designs and operability of Seed Dryer #1 and Seed Dryer #2. They also shared their parameters for an ideal seed dryer (Table 1). We would like to combine some of the best features of both to create a new seed dryer in the future.

Conclusion

A high-quality and highly effective seed drying cabinet can be built from local materials with very low financial and labor inputs. Using such a seed dryer helps to reduce seed moisture content, improving the viability of seeds and the effectiveness of seed storage techniques. Improved seed storage and viability can reduce the need to purchase seed, improve the self-sufficiency and sustainability of farmers and communities, and help in the fight to protect the planet’s crop seed biodiversity.

References Cited

Bicksler, A. J. 2011. Build your own seed germination cabinet for testing seed viability. ECHO Asia Note #8. Chiang Mai, Thailand: ECHO Asia Impact Center.

Croft, M., A. Bicksler, J. Manson, and R. Burnette. 2013. Comparison of appropriate seed storage techniques for germplasm conservation in mountainous sub-tropical climates with resource constraints. Journal of Experimental Agriculture 49(2): 279-294).

Croft, M., A. Bicksler, J. Manson, and R. Burnette. 2012. Vacuum sealing vs. refrigeration: Which is the most effective way to store seeds? ECHO Asia Note #14. Chiang Mai, Thailand: ECHO Asia Impact Center.

Lawrence, B., A. J. Bicksler, and K. Duncan. 2017. Local treatments and vacuum sealing as novel control strategies for stored seed pests in the tropics. Agronomy for Sustainable Development 37(6).

Motis, T. 2010. Seed saving steps and technologies. ECHO Technical Note #63. N. Ft. Myers, FL: ECHO, Inc.

Rao, N. K., J. Hanson, M. E. Dulloo, K. Ghosh, D. Nowell, and M. Larinde. 2006. Manual of Seed Handling in Genebanks. Handbooks for Genebanks Number 8. Rome: FAO.