Presented By: Dr. Maria Cristina Bautista - Gragasin

Event: Asia Pacific Sustainable Agriculture & Community Development Conference (07.02.2018)

Speaker Bio: Dr. Maria Cristina Bautista - Gragasin is the Supervising Science Research Specialist, Bioprocess Engineering Division of the Philippine Center for Postharvest Development and Mechanization (PhilMech). She is specialist in Pesticide Toxicology, Bio activities of Natural Products and Food Safety. She finished her Bachelor of Science in Chemistry at Far Eastern University, Manila, Philippines in 1983. She earned a Research Fellowship with Chiba University, Matsudo City, Chiba, Japan in 1994, and completed her PhD in Pesticide Toxicology at the same University in 2001. She has published several research papers and has received awards for her research work.

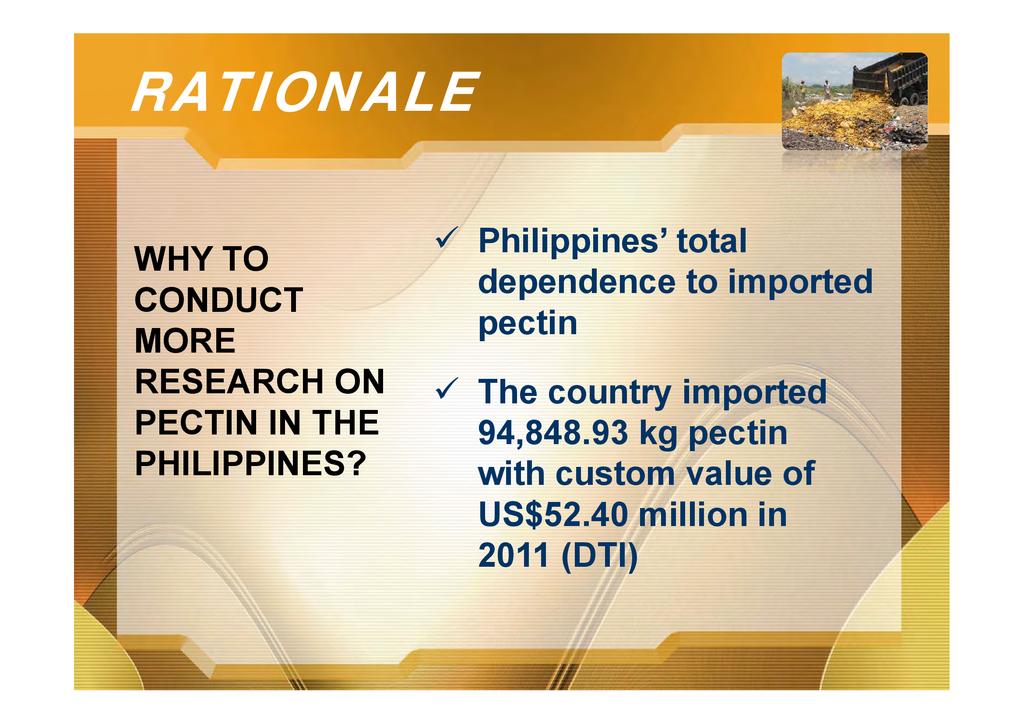

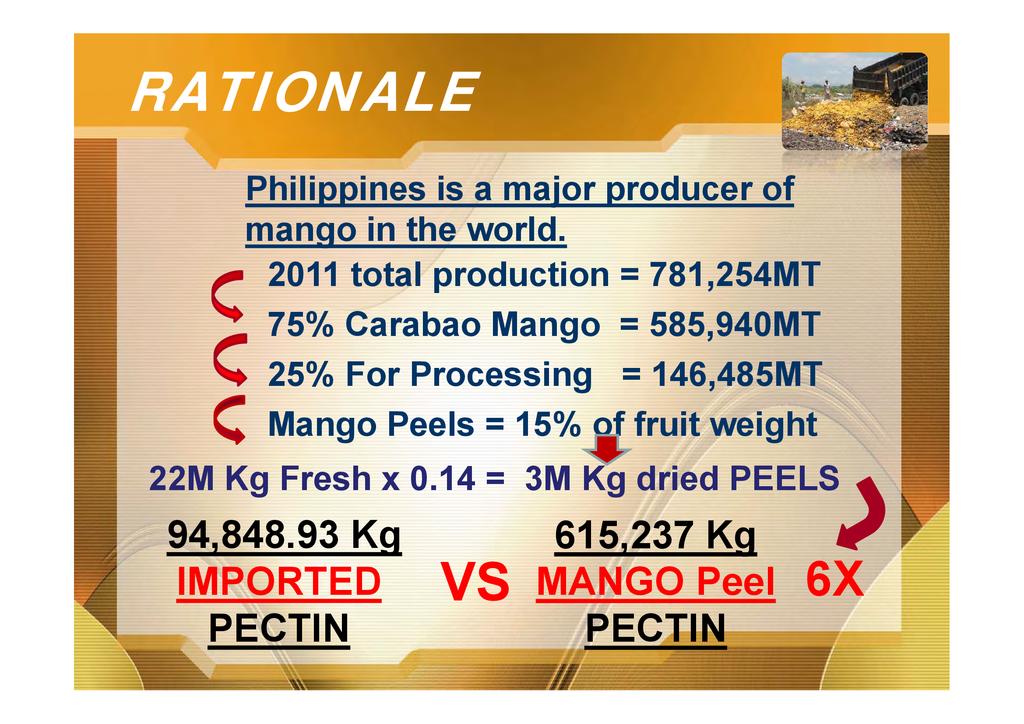

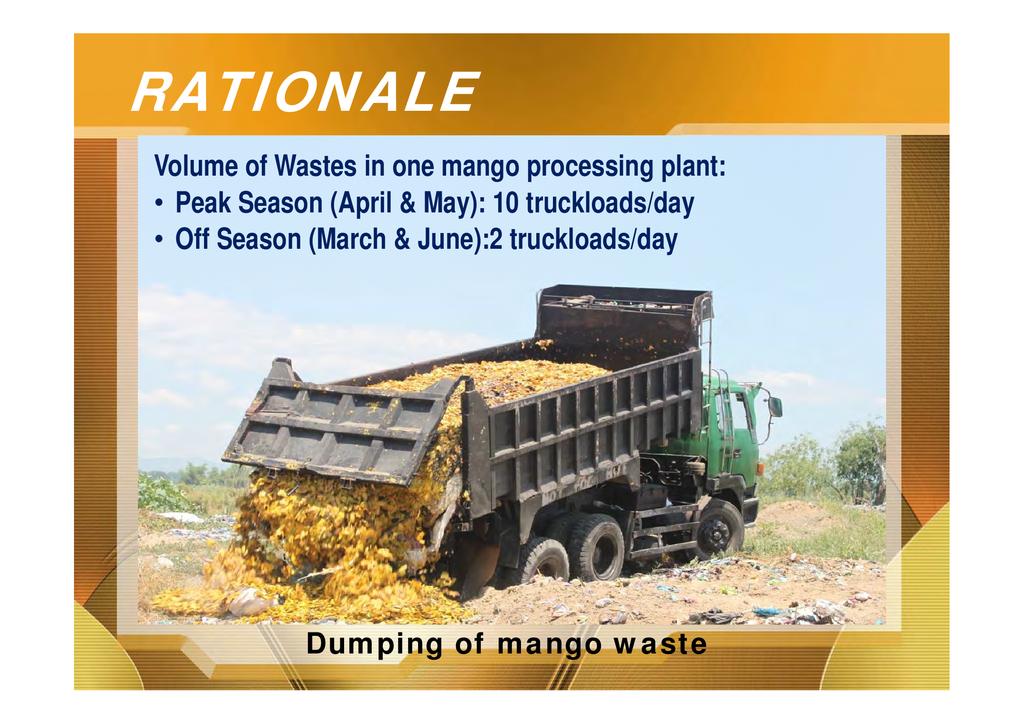

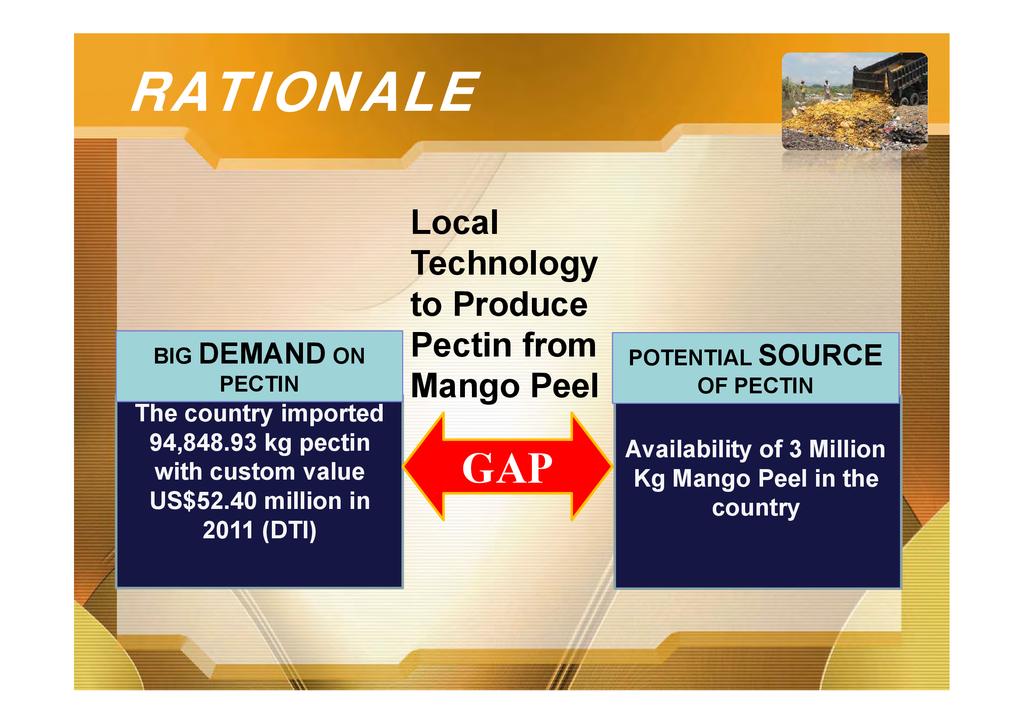

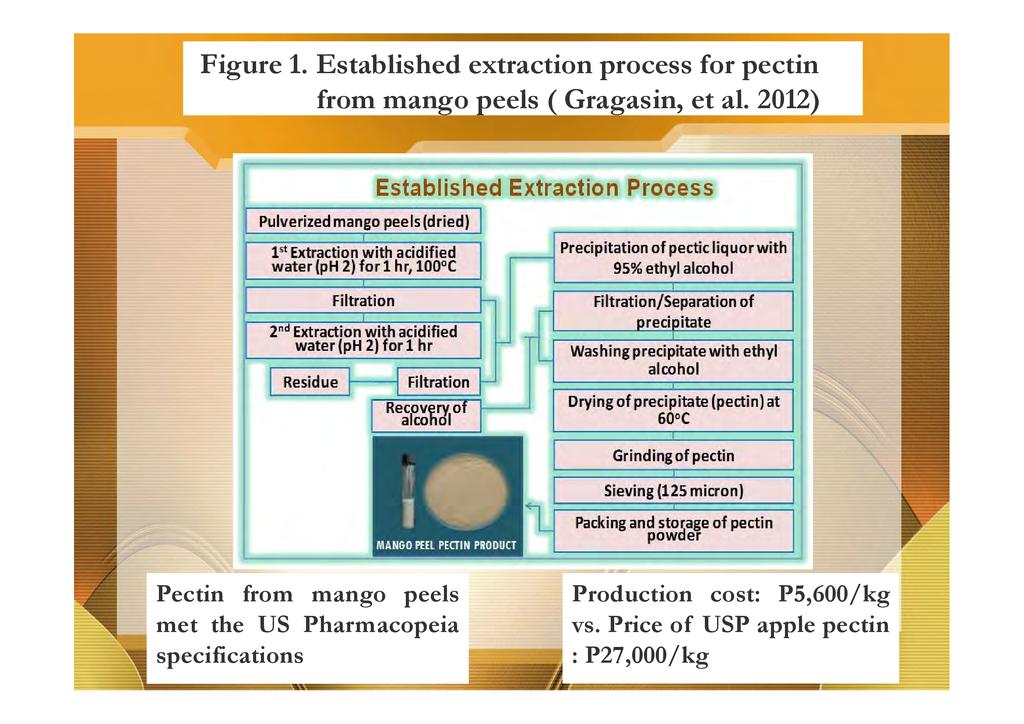

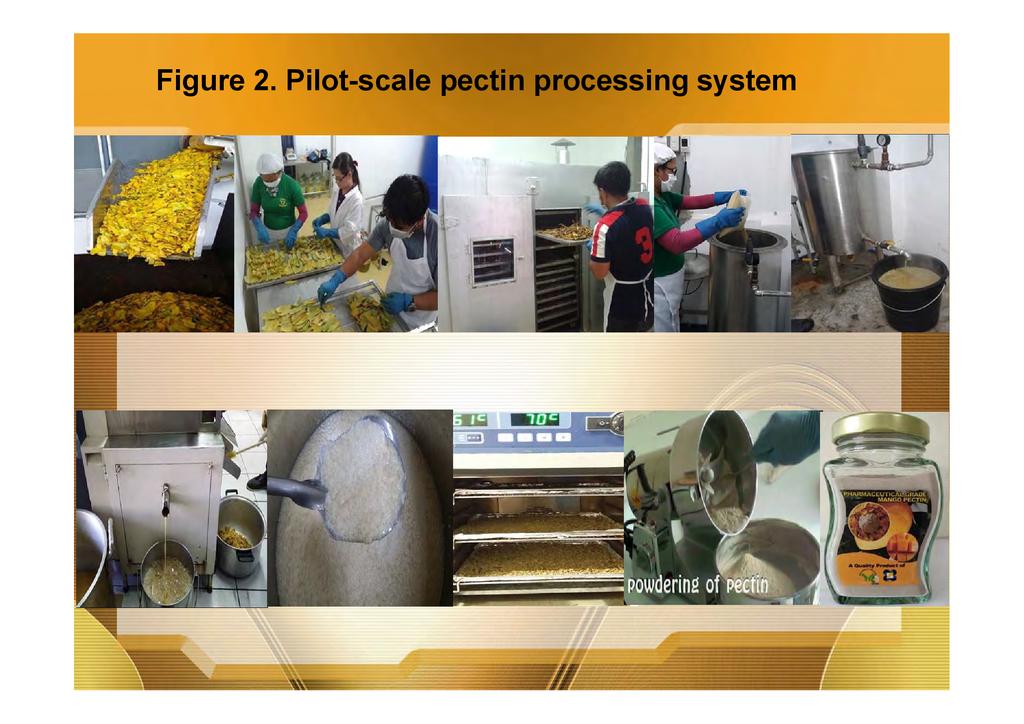

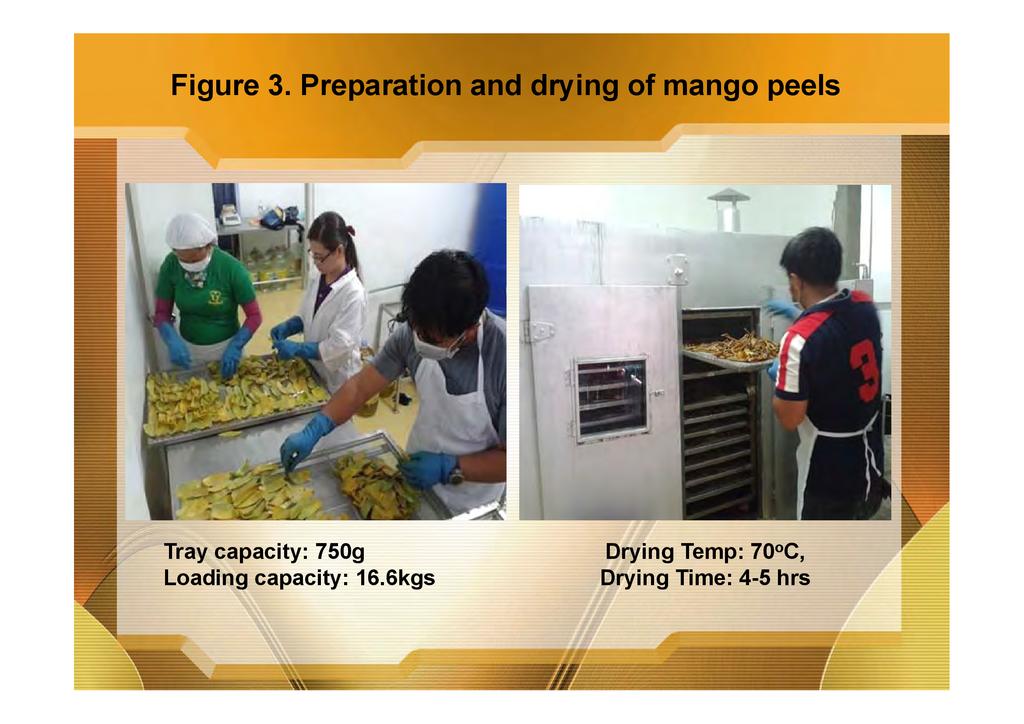

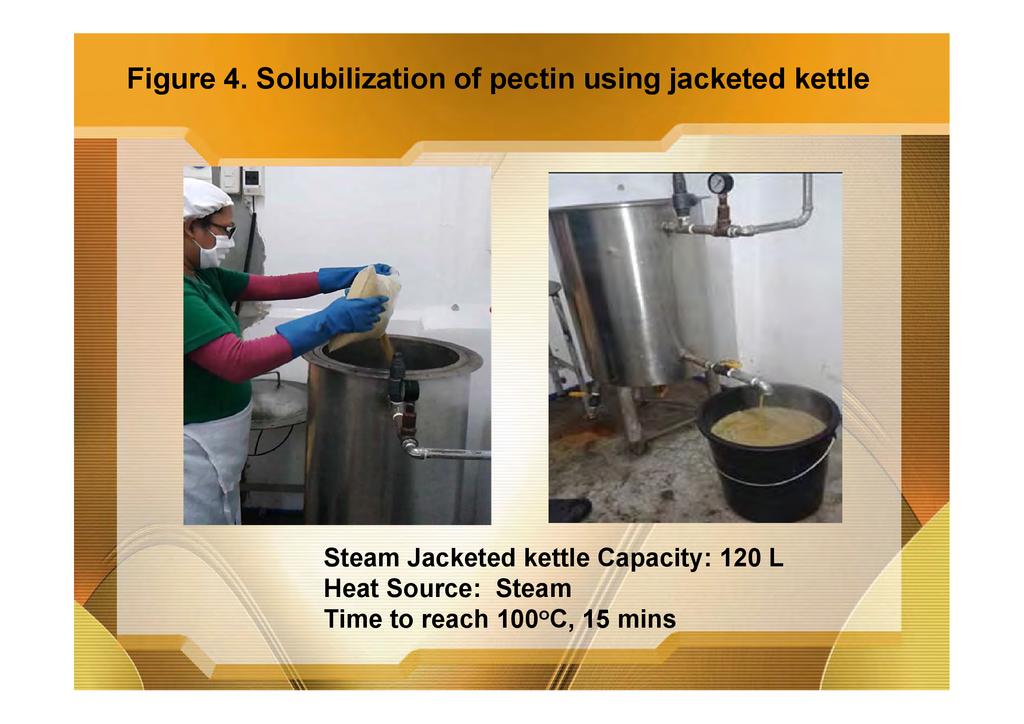

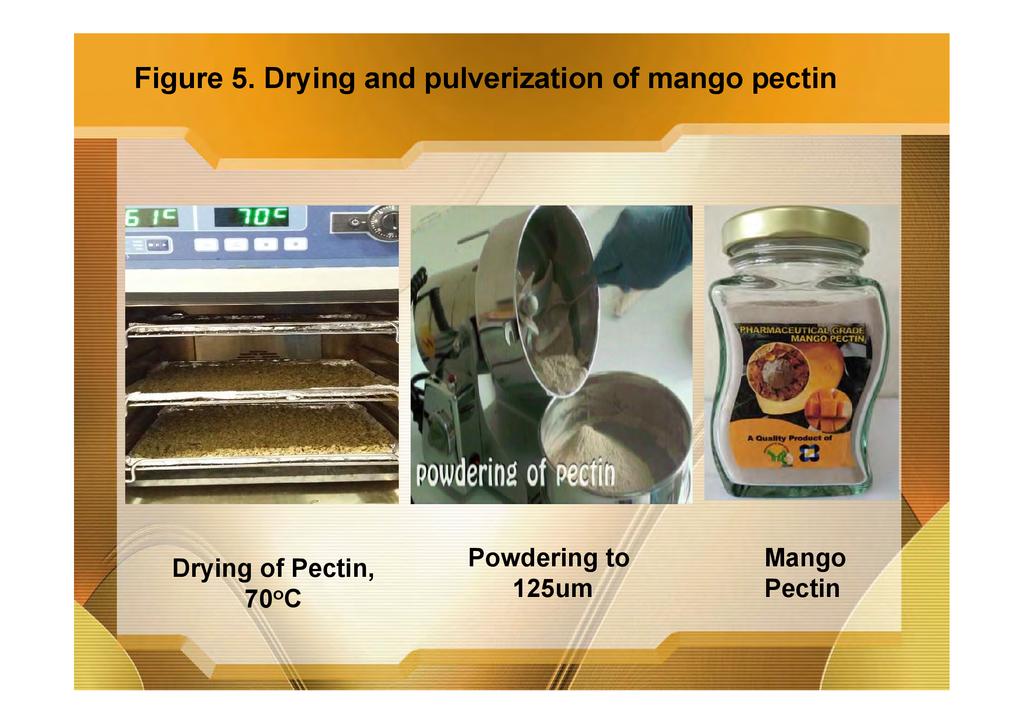

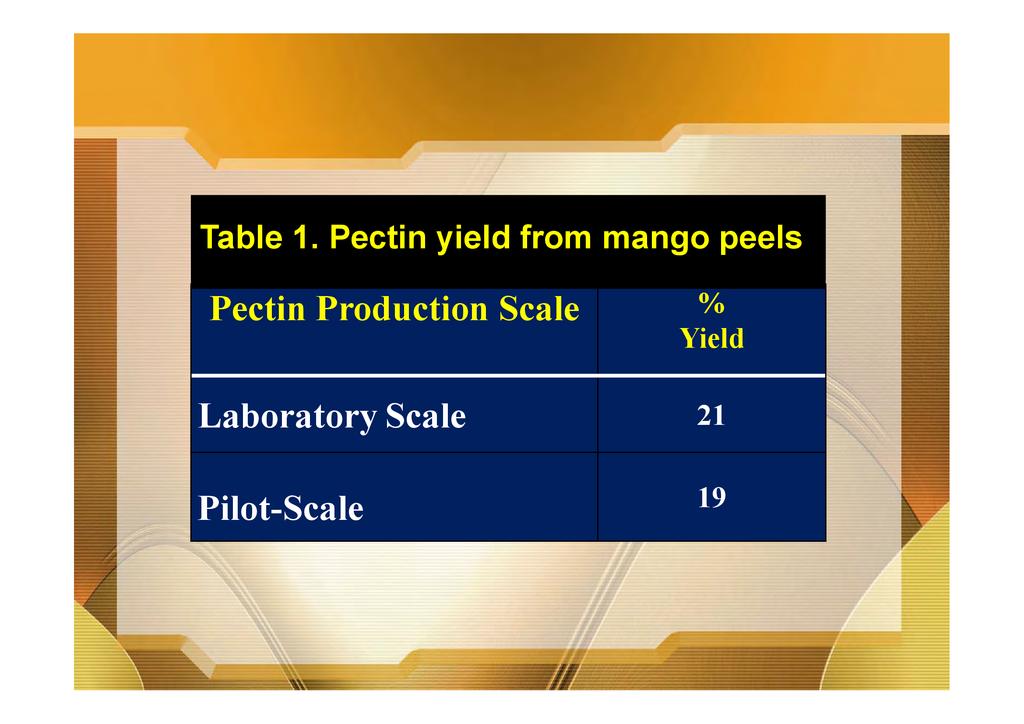

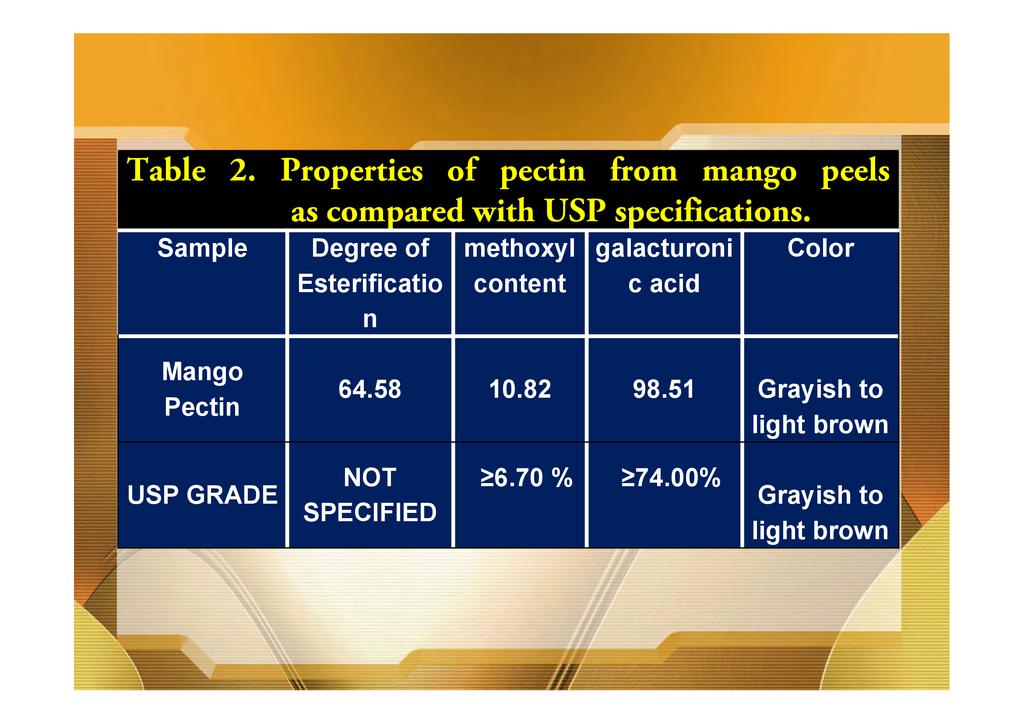

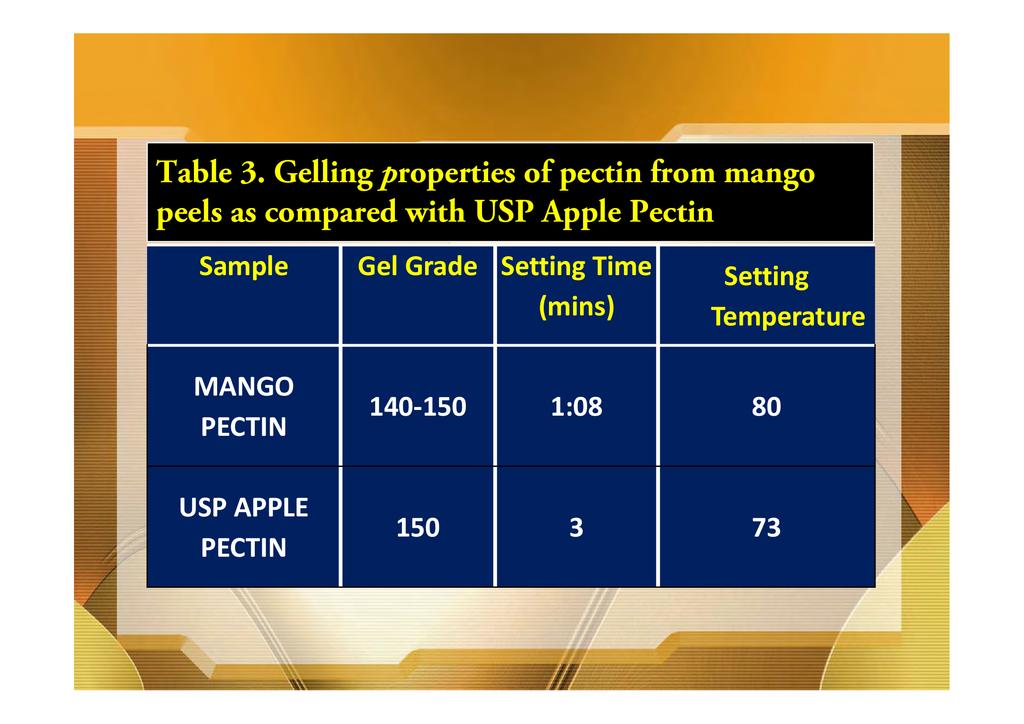

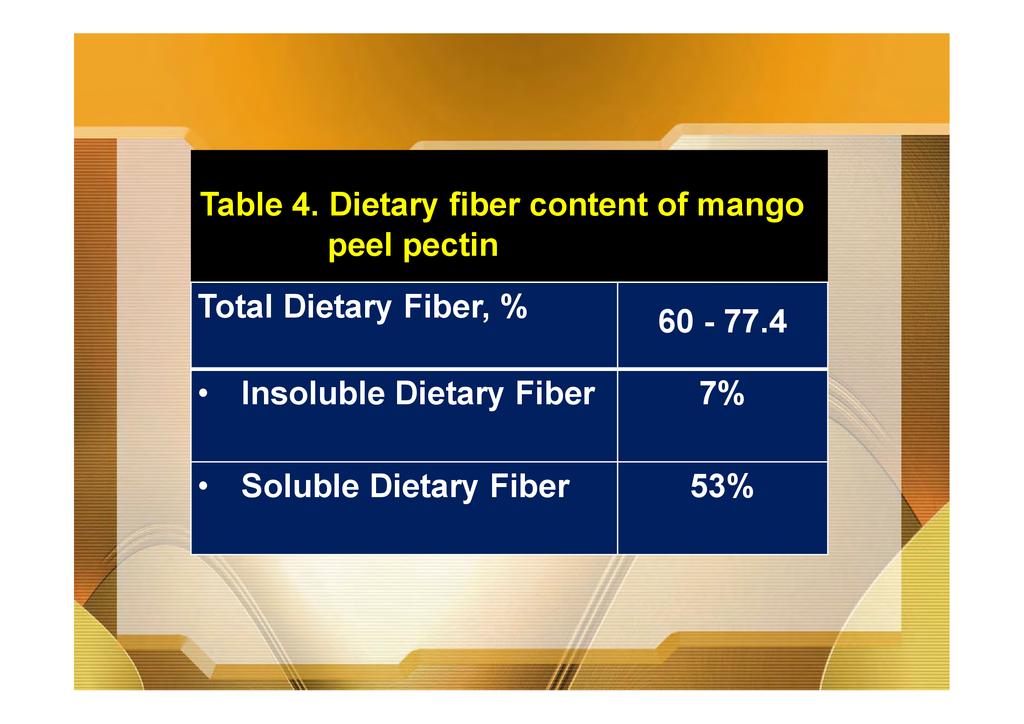

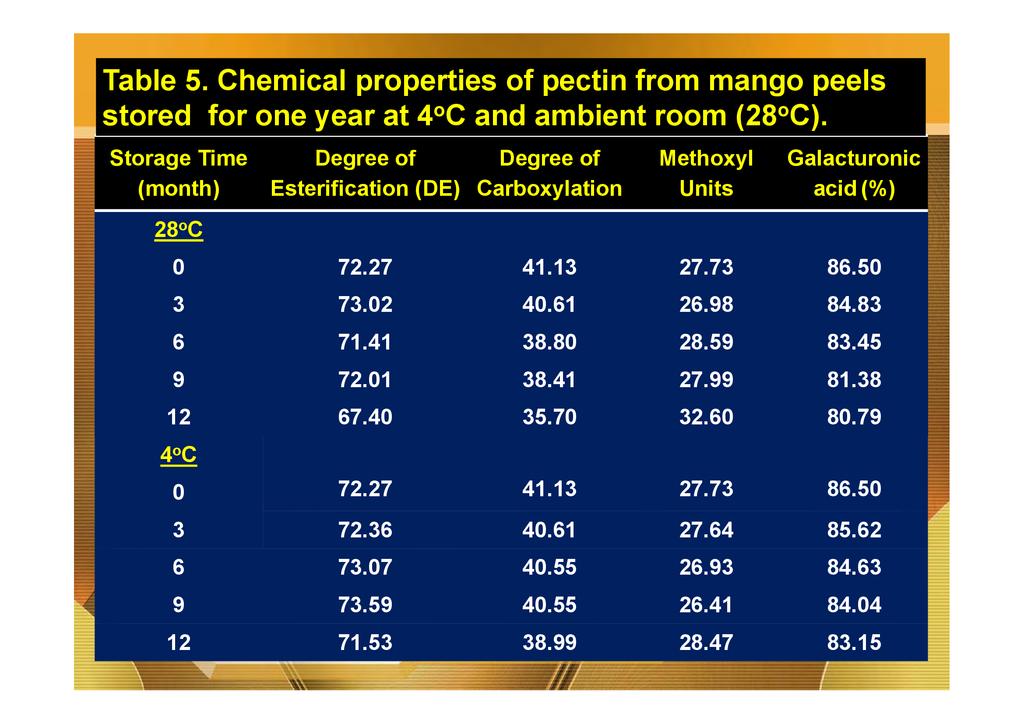

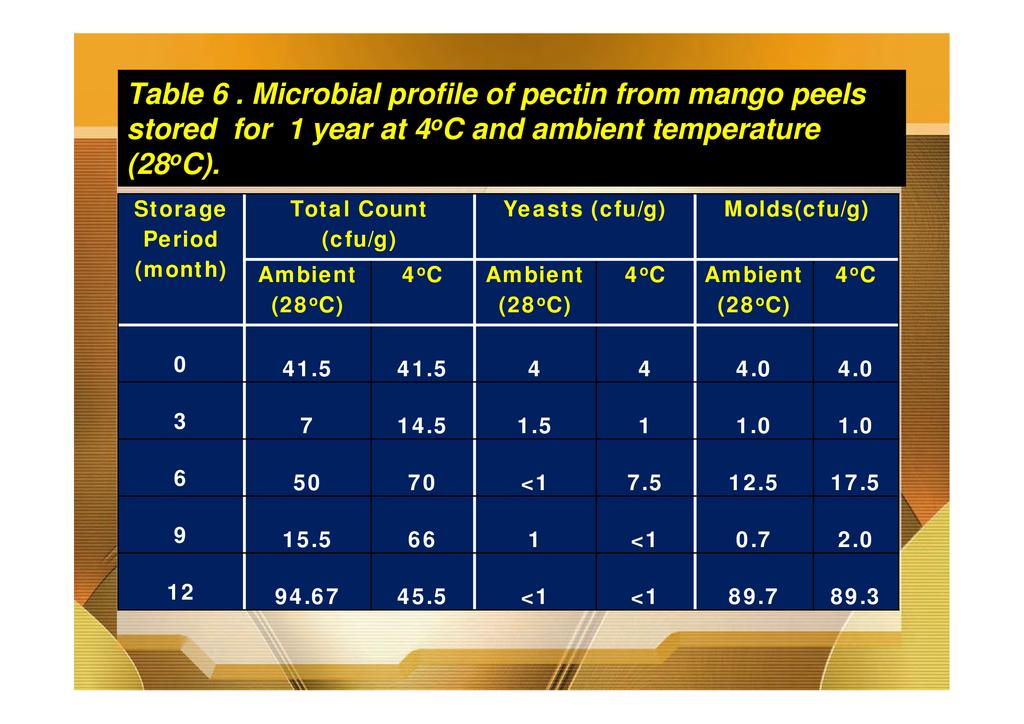

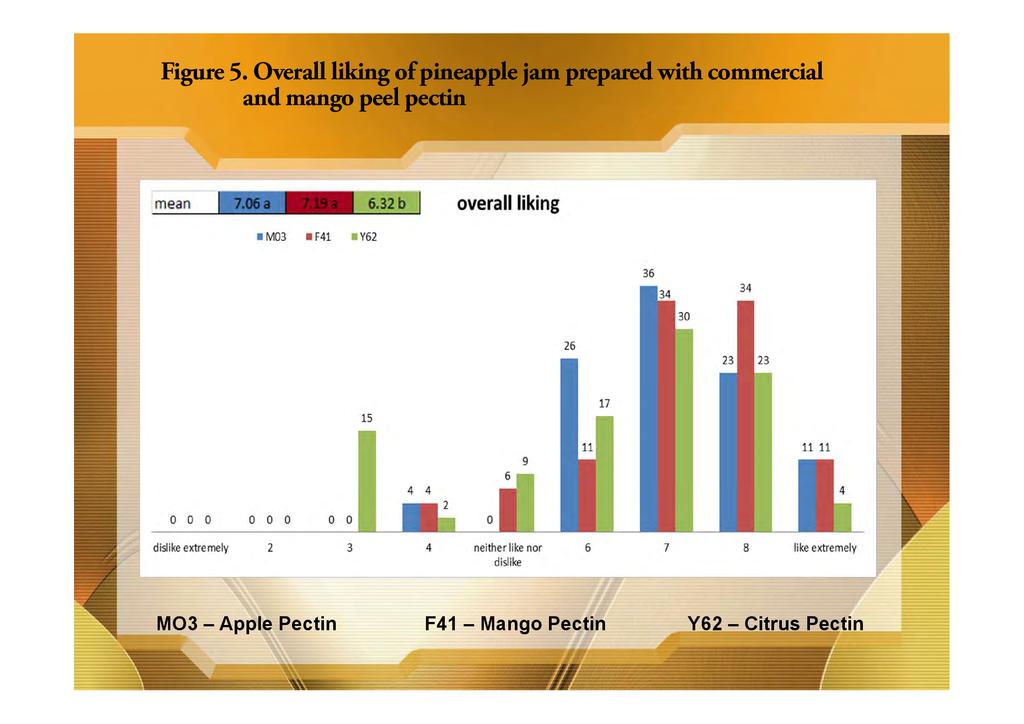

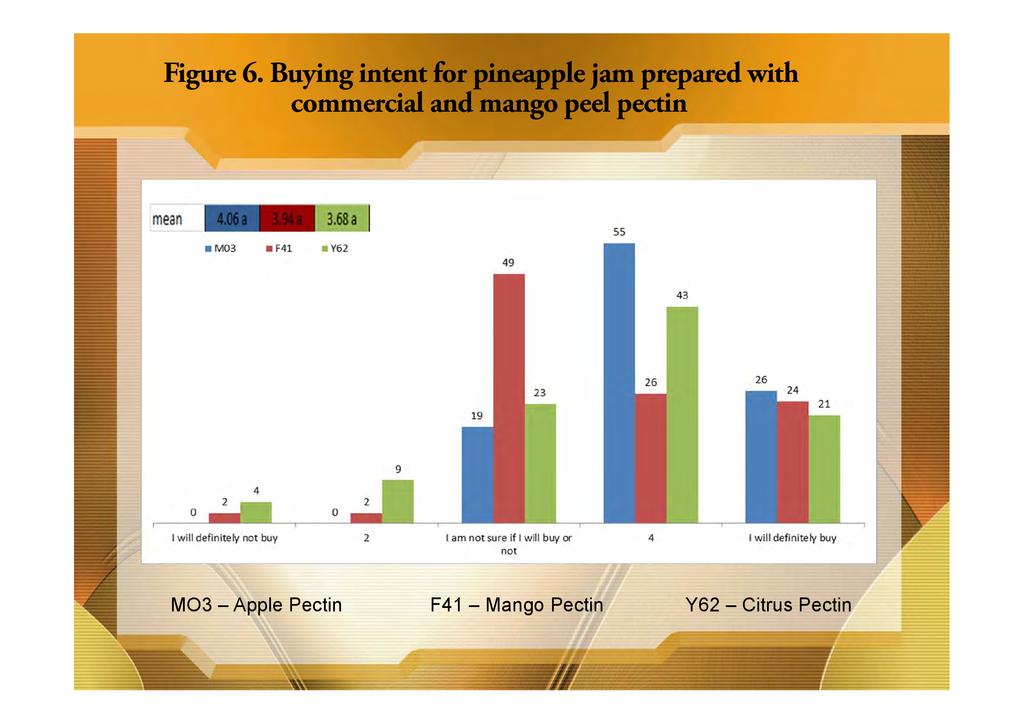

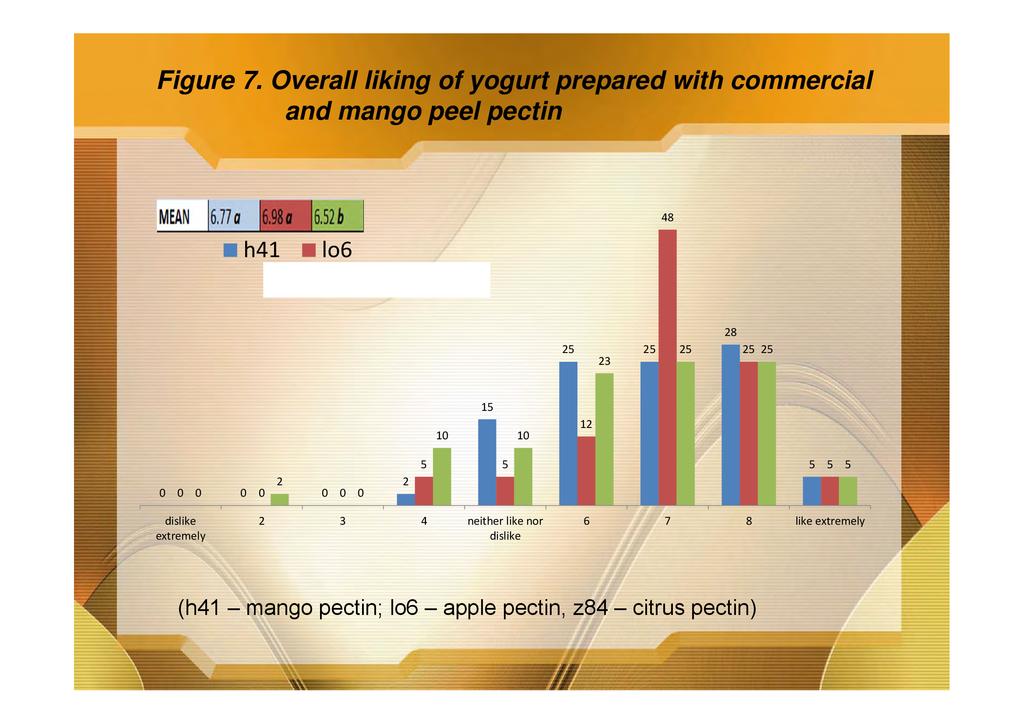

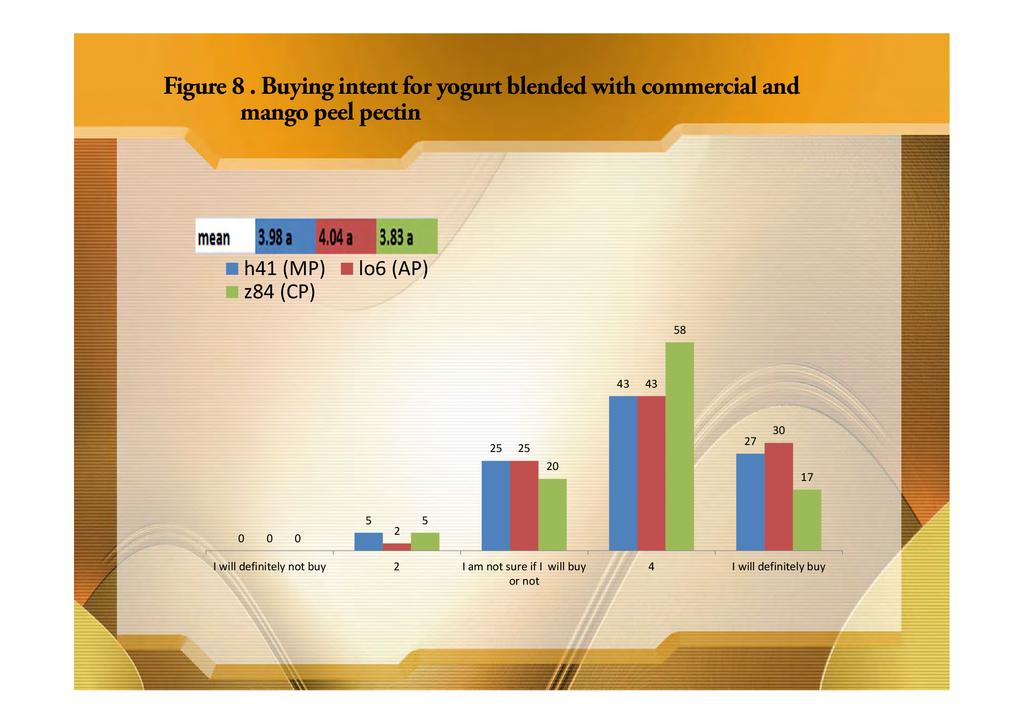

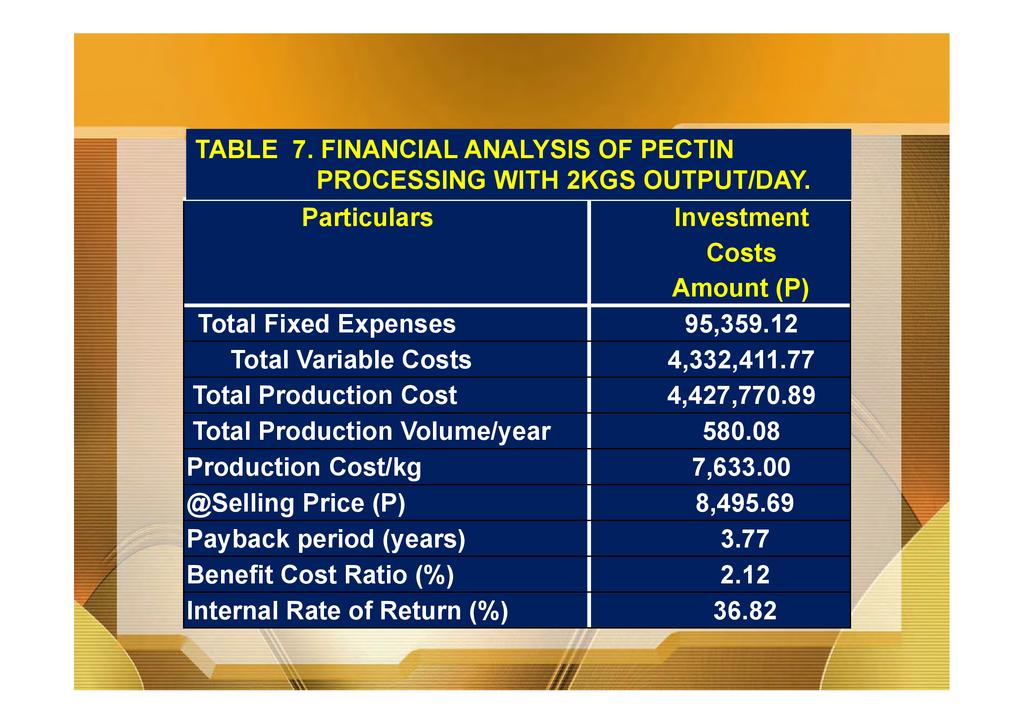

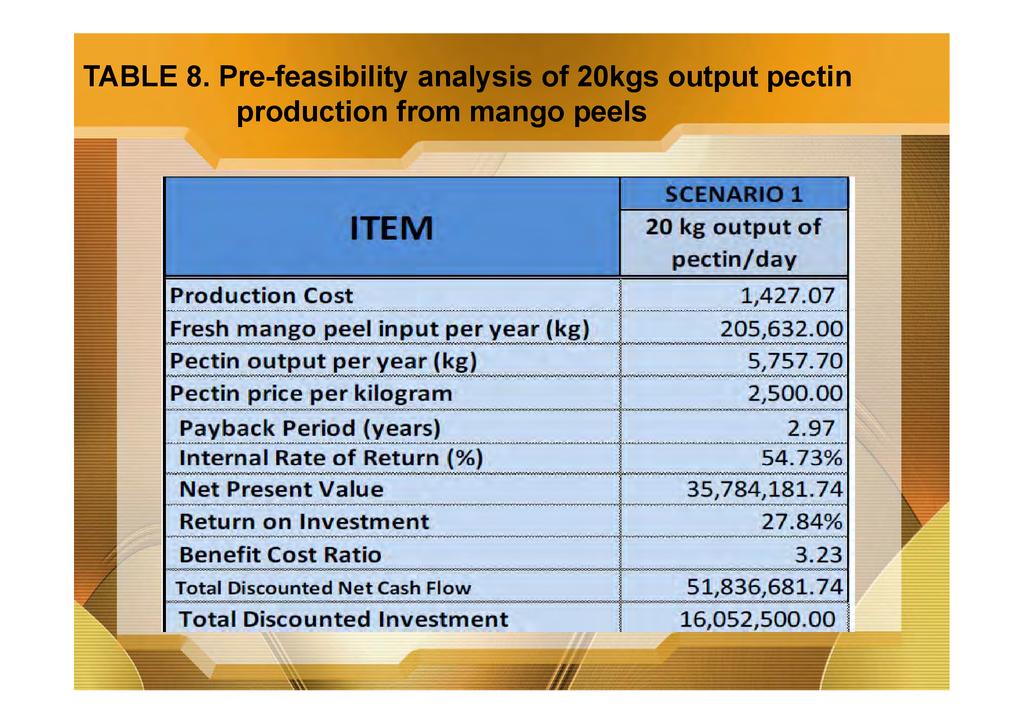

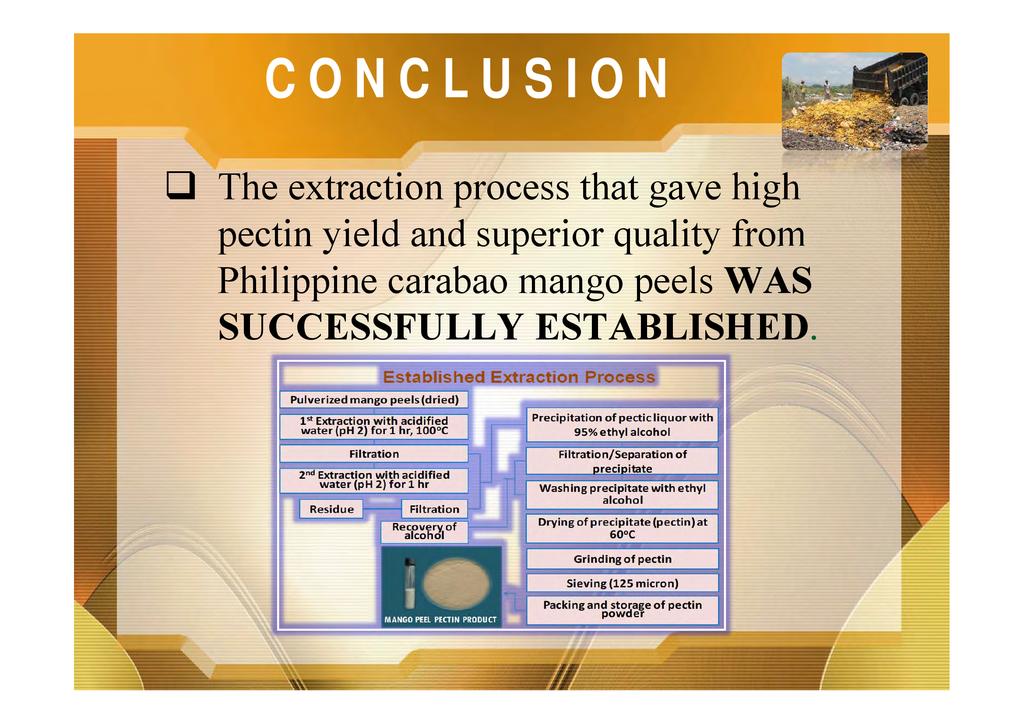

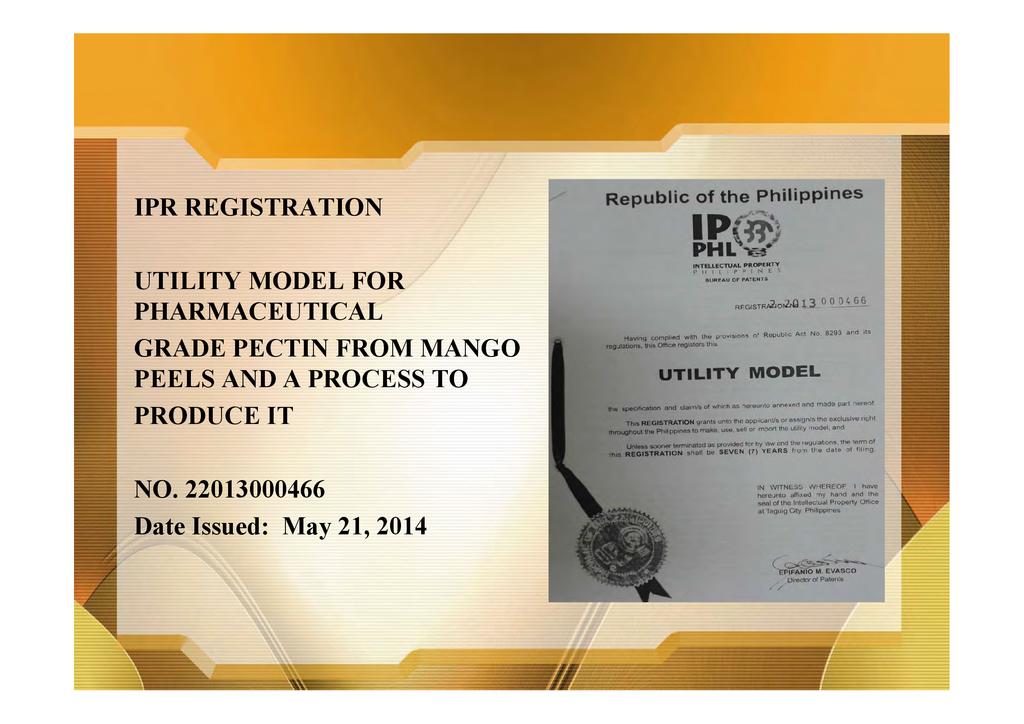

Abstract: The Philippines is totally dependent on imported pectin for applications in foods, cosmetics, and pharmaceuticals valued at P52M annually. In 2012, PHilMech and ITDI-DOST developed a laboratory-scale pectin processing system from mango peels with UM Registration No 22013000466. Her work has verified the technical requirements, performance, and financial viability of the technology at a bigger scale in Mandaue, Cebu. The technical performance was assessed based on the physico-chemical properties of the produced pectin, and acceptability of mango pectin-based food products in terms of sensory attributes and stability in terms of microbial safety. The produced pectin met the USP specifications indicating its superior quality. The physico-chemical properties remained stable for at least one year. Functional attributes are highly acceptable based on sensory evaluation of pectin-based food products. It contains 60-77% total dietary fiber, wherein 53% correspond to soluble dietary fiber, thus providing many health benefits. The mango pectin stored for one year contained low microbial populations, rendering it safe. A pilot-scale pectin production system was established at Profoods Corporation located in Mandaue, Cebu and verified to be technically feasible and financially viable. All the needed equipment for pectin processing are available commercially and locally. The produced pectin from the pilot pectin processing plant met the USP specifications for pharmaceutical grade pectin indicating the superior quality of the produced pectin. Overall acceptability of mango pectin-based food products (i.e. yogurt and jams) showed that the functional attributes of the produced pectin are highly acceptable. Financial indicators showed that an upscale pectin production from mango peels is profitable. A benefit-cost ratio of 2.12 and internal rate of return of 36.82 can be realized with a 2kgs output pectin processing facility. Once this technology is commercialized, it will create a new industry thus will help in alleviating poverty due to job generation. Also, the country’s dollar reserves can be saved through non or less pectin importation. Last but not the least, utilization of mango peels as source of pectin will help in saving the environment through solid wastes reduction.