VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Briquetting ISBN: 0-86619-233-6 [C]1985, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Gianuzzi as editor, Suzanne Brooks handling typesetting and layout, and Margaret Crouch as project manager.

The author of this paper, VITA Volunteer Mac Cosgrove-Davies, is a mechanical engineer currently working for the Carl T. Jones Corporation in Springfield, Virginia. He has traveled in Central and South America and has a keen interest in appropriate energy technology. The reviewer is also a VITA Volunteer. Dr. Ben Bryant is the professor of wood and fiber utilization technology at the College of Forest Resources, University of Washington, Seattle, and president of AFPITA, a non-profit technology transfer company. In addition to teaching and research in the forest products field, he has invented structural building panels made of wood and fiber, consulted extensively in the forest products industries, and performed studies in 22 developing countries in the area of approporiate technology transfer. His group developed the compound lever briquetting press.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

In many parts of the world, the primary source of energy for such vital activities as cooking and space heating is burning wood and other agricultural products. An increasing population using a dwindling resource of combustible biomass materials will eventually result in a shortage of those materials unless steps are taken to reverse the trend.

One means of making more efficient use of existing resources is through the use of briquetting. Briquetting involves collecting combustible materials that are not usable due to a lack of density, and compressing them into a solid fuel of a convenient shape that can be burned like wood or charcoal. Materials such as sawdust, wood bark, rice husks, and straw have been successfully briquetted.

During the first and second World Wars, households in several European countries employed a simple lever-operated briquetting press that used soaked waste paper and other combustible domestic waste as a feed stock. Today's industrial briquetting machines, although much larger and more complex, operate on the same general principles.

Although briquetting has been widely used in the metallurgical industry to recover metal filings, shavings, and scraps that would otherwise be of little value, this paper is concerned solely with the briquetting of combustible materials for fuel. The focus is on simple technologies that can be employed on a small to intermediate scale.

II. OPERATING PRINCIPLES

Briquetting is one of several compaction technologies in the general category of densification. In densification, a material is compressed to form a product of higher bulk density, lower moisture content, and uniform size, shape, and material properties. There are two ways that compaction can be accomplished: with and without a binder.

One must have something to make the material stick together during compression. Otherwise, when the briquette is removed from the mold, it will crumble to pieces. This fastening agent is known as a binder. In some cases, most commonly under high temperature and/or pressure, a material can act as its own binder. Wood, for example, becomes plastic and can be briquetted without a binder under such conditions. Many of the processes considered here, however, will require the addition of a binder.

In most cases, the process of briquetting will consist of a series of steps:

- Collecting material to be densified

- Preparing material

- Compacting

- Removing, drying or cooling, and storing

COLLECTION OF MATERIALS TO BE DENSIFIED

As mentioned above, there is a wide variety of materials that can be densified. Some can be bundled, <see figure 3> or tied together, rather than briquetted. A partial list is included below.

- jute + rice husks o coffee husks + coal dust + alfalfa + some nut shells + sisal + bagasse + dung + wood wastes + straw + vines - shavings o paper waste + municipal waste - sawdust o peat + sunflower husks - bark + olive residue + fish waste - twigs + hemp o coconut dust + coconut fiber + peat + cotton sowing (coir) + food processing + leather waste waste o charcoal fines

It should be noted that the use of industrial or automotive waste oils should be avoided since in many cases such oils contain additives that can give off toxic fumes when burned. If such oil waste is to be used, it should be thoroughly checked by a competent laboratory first.

In general, any material that will burn but is not in a convenient size, shape, or form to be readily usable as fuel is a good candidate for briquetting. It may be necessary or desirable to make briquettes of more than one material.

PREPARATION OF THE RAW MATERIAL

Once the raw material is collected, it must be assembled in a central location for processing. The method of preparation depends somewhat on the particular material being briquetted, but the procedure generally includes some or all of the following steps.

SIZE REDUCTION

The raw material is first reduced in size by chopping, crushing, breaking, rolling, hammering, milling, grinding, cutting, etc., until it can pass through a screen or reaches a suitably small and uniform size. Since this process consumes a good deal of energy, this size reduction step should be as short as possible. Indeed, with some materials this step may not even be necessary.

DRYING

Although the feed stock fed to the briquetting press is often wet, it may still be necessary to dry the stock before mixing it with the binder. Drying can be done in the sun, with a heater, or by using heated air and a rotating drum. You can dry the material before or after size reduction.

PREPARATION OF FEED STOCK

The method of mixing the raw material with the binder to produce a feed stock can vary widely. Anything from a simple trough and hoe to a modified commercial cement mixer can be used. A ribbon mixer for small-scale production is shown in Figure 1.

You must determine the correct propportion of raw material to binder before starting full-scale production. This is best accomplished by a trial and error method of making several briquettes with different mixtures of binder material, then testing each for mechanical strength and burning properties.

The cost of the binding material can be critical to the economic success of the project, so the smallest amount of binder necessary for an acceptable briquette should be used. Although a combustible binder is desirable, it is possible to use a noncombustible binder with good results. Alternative uses of the binder must be weighed against the value of the final product as an energy source. The following is a partial list of binding materials:

Combustible Binders Non-combustible binders

- natural or synthetic + slime resins + clay + tar + mud + animal manure o cement + sewage mud + fish waste + algae + starch

CARBONIZATION

In carbonization, a biomass material (usually wood) is heated to very high temperatures but is not given enough oxygen for the material to burn. This processs produces charcoal.

The briquetting process can be used with carbonization to produce briquettes made wholly or partially of charcoal. The briquettes can be made using charcoal fines or ash as part of the feed stock, or the briquettes can be compacted with any of the raw materials listed above and then carbonized. The first method wil probably produce a more consistent product. The second method may result in briquettes that are too fragile to handle without creating excessive dust.

COMPACTION

The next step, compaction, can be done in many ways. The following section on design variations will describe several possibilities. A basic overview is given below.

In general, a supply of prepared feed stock is loaded into a chamber, the chamber is covered with a close-fitting top, and pressure is applied to compress the feed stock. The pressure applied can be anywhere from 0.5 to 1,200 kilograms per square centimeter (kg/sq cm) depending on the process employed. In some cases, the feed stock is heated to aid in the binding.

Another method of compaction, employed by some of the more sophisticated briquetting machines, is to heat the feed stock and then extrude it. Extrusion is a process whereby the feed stock is forced through a small opening at high pressure. The result is a continuous log that can be cut to any length. The advantage of extrusion is that it is a continuous process that can produce briquettes in many shapes and sizes. Disadvantages include the need for high pressure, temperature, and energy consumption, as well as the relatively complex machinery involved (see Figure 2).

A handful of soaked paper or other feed stock is taken from the mixing vat and hand-molded into spherical briquettes. In some areas, dung is shaped by hand for use as fuel. Formed briquettes are sun dried before use. These briquettes will burn longer if wood ash containing some charcoal is added to the feed stock.

WROUGHT IRON BRIQUETTING PRESS I

This is the first of the briquetting presses. It utilizes a mechanical lever to apply greater pressure than is possible with hand molding. This press also utilizes waste paper. Soaked paper, preferably with wood ash added, is put in the mold and pressed. Briquettes are then removed and sun dried. Finished briquettes are spherical, about 5 cm in diameter and weigh about 30 grams.

WROUGHT IRON BRIQUETTING PRESS II

This press provides greater compaction than the Wrought Iron Press I because the compression face is pressed deeper into the mold form. The basic press is again easy to make, taking approximately four to five hours and five to eight kg of iron. The length of the lever arm will determine the briquetting pressure. The mold should be sturdy enough to handle the pressure created by the lever. Any of the briquetting materials given above can be used in this press. Modifications can also be made to yield different shapes depending on the skill of the manufacturer.

Briquetting feed stock is poured into the mold and the lever is pushed down, compressing the briquette. The lever is then lifted, the base plate removed, and the finished briquette is pushed through and then placed in the sun to dry.

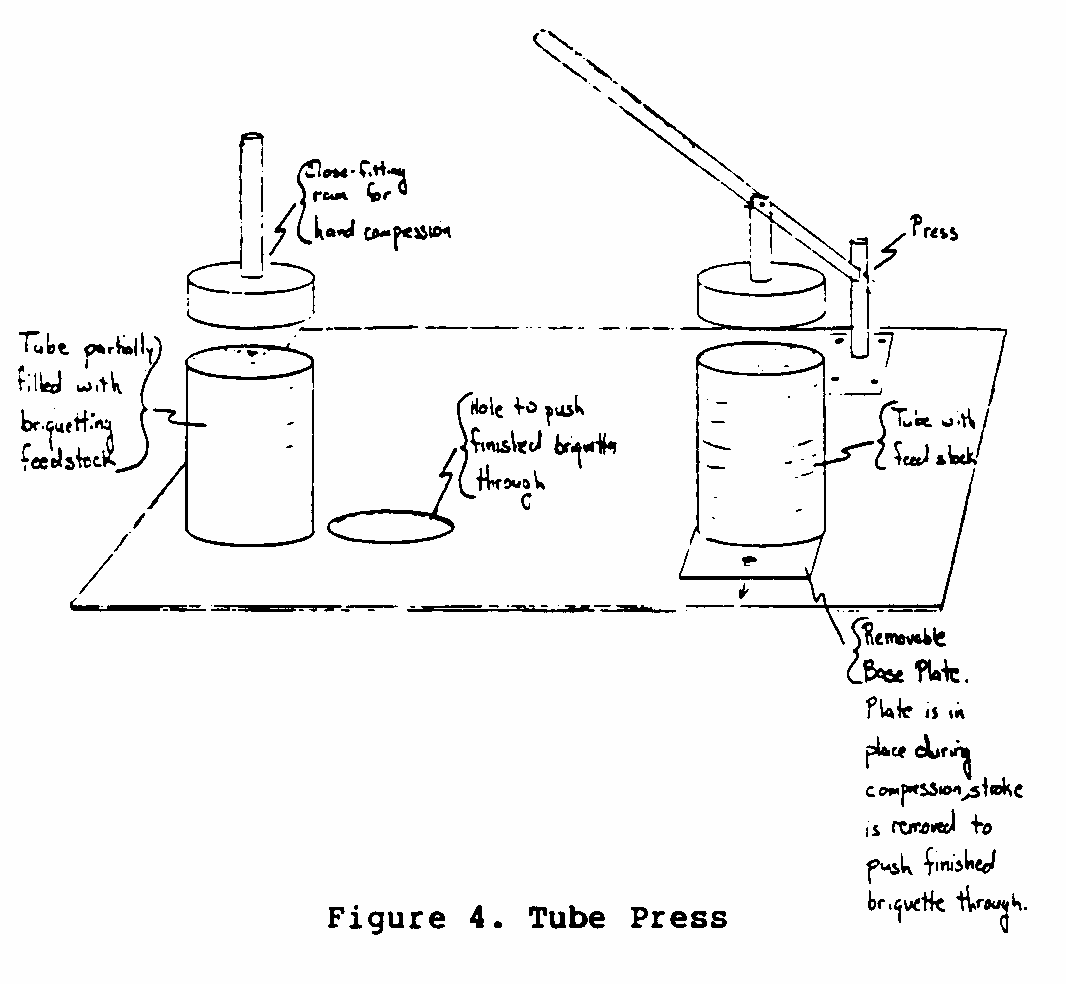

TUBE-PRESSES

Metal or plastic pipe provides a good briquetting mold since it produces cylindrical briquettes. The tube presses illustrated (see Figure 4) consist of a tube mounted vertically on a platform

and a close fitting ram used for compaction. The basic design can be varied considerably, as the figure indicates.

Feed stock is poured into the tube and compressed with the ram. The tube is then positioned over a hole (or a slide is removed) below the tube exposing a hole) and the briquette is pushed through. Briquettes are then dried in the sun before storage and use.

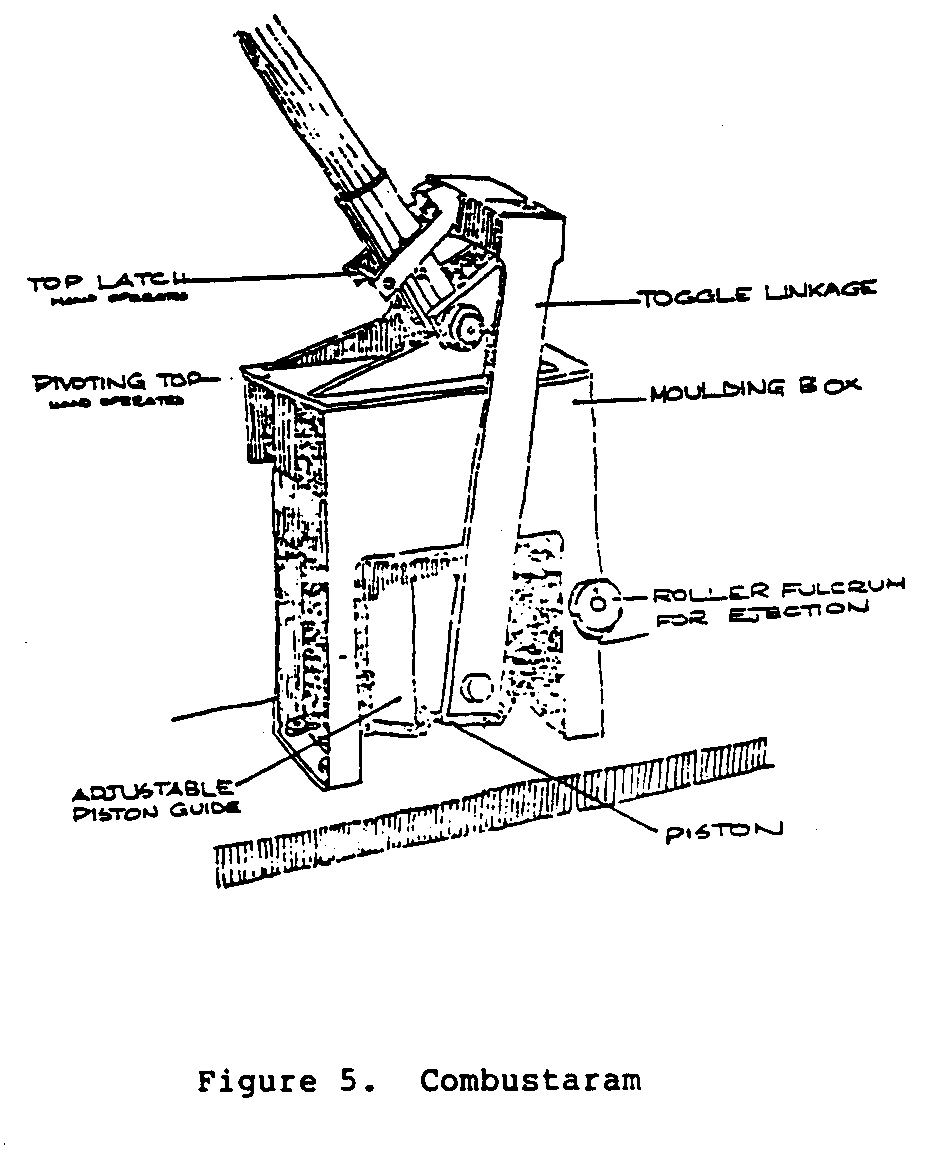

EARTH RAMS

Presses currently in use for making stabilized earth blocks might be modified to make briquettes from a mixture of a clay binder and charcoal dust or coal dust. The Combustaram, similar to the CINVA-Ram and Tersaram, is commercially available or can be manufactured locally (see Figure 5).

The lever arm is put in the open position, feed stock is poured into the molds and the lever is then quickly pushed up, over the top of the press, and down. This movement positions the top of the press and compresses the briquettes on the downward stroke. The lever is then moved back to the original position and again pushed down, thus forcing the briquettes out of the molds. Finished briquettes are set in the sun to dry. The process requires at least two workers.

COMPOUND LEVER PRESS

This press incorporates the principles of both the wrought iron briquetting press and the tube press. Made of wood, the compound lever multiplies the effectiveness of a simple lever. Enough pressure is generated when chopped, biodegraded, or finely divided fibrous material is used in the damp or wet state to eliminate the need for a binder.

The filled mold with the plunger inserted is initially placed toward the rear of the main lever to take advantage of the maximum stroke. After initial compaction, the mold is moved to the forward position for final pressure application. The mold is perforated to allow for escape of excess fluids, and a dowel in the face of the mold assembly places a center hole, improves combustion of the briquette.

RICE HUSK EXTRUDER

This device is designed specifically to make fuel logs from rice husks. The extruder, powered by a 20 HP electric motor, works best with husks that have been ground and/or dried to reduce moisture content. The device measures 1.5 x 2.75 x 1.1 meters, requires one or two workers, and produces 150 kgs of fuel logs per hour. The rice husk fuel log extruder is relatively new and has not yet been manufactured outside of Thailand.

Once the device is warmed up, the operator must keep the machine continuously supplied with prepared husks. The operator must also stack the finished logs and monitor the temperature of the device's heating unit. The machine is designed to operate 24 hours a day. Because of the large volume of rice husks required to keep the machine in continuous operation, this device may be best-suited to large rice processing centers.

INDUSTRIAL BRIQUETTING MACHINES

Industrial briquetting machines densify waste produced in an industrial setting. These machines produce a wide variety of products--briquettes, pellets, cubes, logs. Quite often, machines used for producing animal feed pellets can be modified for fuel pellets. Many do not require binding materials. In addition, several manufacturers offer a consulting service to determine which of their models is most appropriate for a particular application. Manufacturers should be contacted for more information on their products.

V. COMPARING THE ALTERNATIVES

Briquetting or densification is only one of several technologies that should be considered for the use of agricultural and biomass waste. Alternatives include:

- Fertilizer or Soil Conditioner: The use of biomass waste for energy production can deprive the soil of important conditioning agents, and the long-term impact of this deprivation must be carefully studied.

- Livestock Feed: In some cases, the potential briquetting material could be used as food for local livestock that could be used as a source of food or as work animals.

- Bacterial Fermentation for Alcohol Production: In aerobic fermentation, bacteria act to break down organic materials in the presence of oxygen. This process can produce alcohol, which is an attractive fuel because of its high energy content. It is also a liquid and therefore relatively easy to handle. Research into fermentation has progressed rapidly in the past several years. The economics of alcohol production favor large-scale facilities and this technology is not recommended on the village scale.

- Anaerobic Digestion for Methane Production: Anaerobic digestion differs from aerobic digestion in that in anaerobic digestion the bacteria acts in the absence of oxygen. The product of anaerobic digestion is methane, a high-heat, clean-burning flammable gas similar to natural gas. However, it requires a relatively large initial investment in equipment and special storage and handling, as well as a gas-burning stove. Several countries, notably China and India, have developed simple small-scale digesters.

- Gasification: When a combustible material is raised to a very high temperature without sufficient oxygen for combustion to take place, reactions occur that produce a combustible gas, liquid products, and charcoal or ash. These processes of thermal decomposition are known as gasification, pyrolysis, and carbonization respectively. Gasification can be performed on biomass waste, but in general it requires a large-scale operation to be economically feasible.

- Pyrolysis: As mentioned above, pyrolysis is the process of producing a liquid when a combustible solid is heated without enough oxygen for complete combustion. Large-scale plants exist, and pyrolysis can also be performed on a small scale in conjunction with a retort for making charcoal. The products of pyrolysis, such as oils, tars, and resins, are useful in various industrial, commercial, and household applications.

- Suspension Burners: These are burners in which ground combustible materials are mixed with air blowing up from the bottom of a combustion chamber and burned in suspension. They effectively supply a relatively clean, hot gas than can be used in dry kilns, power boilers, veneer dryers, and other processes. They are not recommended for household use, but may be appropriate in a light industrial setting.

- Fluidized Bed Combustors: In a fluidized bed combustor, air is blown up from the bottom of the combustion chamber, but in this case the combustion chamber is partially filled with a granular material such as sand. The air being forced up through the sand circulates the sand as it if were "boiling." When combustion takes place in this system, the sand acts as a bed on and in which the combustible material burns. This system is more flexible than the suspension burner because the feed stock need not be finely ground or even of a consistent size. Fluidized bed combustors also represent a proven technology and are appropriate in light industrial settings.

V. CHOOSING THE TECHNOLOGY RIGHT FOR YOU

Before embarking on a briquetting program, investigate the potential market to determine the viability of the project. Social, environmental, political, and economic factors should be researched along with technical matters. Many projects have failed because the non-technical factors in their involved were neglected.

For example, although in some cases the raw materials required for briquetting will be very low in cost, the market for briquettes itself will increase the value of the raw materials. This could have negative effects on the distribution of income.

In addition, some briquetting materials have competing uses. Dung, for example, is also used as a fertilizer. Thus the value of the fuel for its various uses must be weighed before any decision is made. Further, there are usually several ways of producing energy from the raw material.

A special note with respect to the stove that will be used: In general, the final briquetted product has a heating value comparable to wood. It may, however, burn in a different manner than traditional fuels and thus the stove (or the briquette) may have to be modified to be compatible. This issue should be taken quite seriously by the briquette manufacturer who plans to sell the product on the open market.

When analyzing the feasibility of a briquetting project and the market appeal of the product, some preliminary research is essential before proceeding with technical design. The most effective way of achieving success is to assess the situation from several viewpoints--forestry administration, farmers' cooperatives, women's associations, contractors, technicians, etc. These groups are a good source of information about the availability of combustible waste of all kinds, the social climate, the attitudes of local people to innovations, and economic and other relevant factors.

Environmental questions should also be taken into consideration, because using biomass waste as fuel eliminates an important element in the ecological chain. Normally, biomass waste is returned to the soil. If this balance is broken, the consequences may decrease productivity of the soil and, in extreme conditions, even lead to desertification.

The analysis should include information on:

1. Cultural habits pertinent to food preparation and cooking styles

2. Size of the market: number of people and amount of fuel used

3. Relevant social factors

4. The history of previous innovations in local society

5. The willingness and ability of people to pay for the new fuel product

6. Types and requirements of stoves in use in the market area

7. Availability and characteristics of biomass waste in the region

8. Environmental considerations

9. Transportation problems

10. Availability of credit or subsidy to get the enterprise started.

The briquetting of biomass waste that would otherwise be unavailable as fuel can be an effective, low-cost method of increasing the fuel supply. In addition, by providing an alternative to wood burning, briquetting can help slow the process of deforestation. A wide range of technologies makes briquetting accessible to nearly everyone. Finally, briquetting holds a unique place among the various alternative uses of biomass with its easily understandable technology and its simplicity of operation.

SUPPLIERS AND MANUFACTURERS

UNITED STATES

Agnew Environmental Products Box 1168 Grants Pass, Oregon 97526 Telephone: 503/479-3396

Bio-Solar Corp. P.O. Box 762 Eugene, Oregon 97401 503/686-0765

Bonnot 800 Lake St. Kent, Ohio 44240 216/676-5829

California Pellet Mill Co. 1800 Folsom St. San Francisco, California 94103 415/431-3800

Deere & Co. (formerly John Deere) John Deere Rd. Moline, Illinois 61265 309/752-8000

Ferro-Tech 467 Eureka Rd. Wyandotte, Michigan 48192

Fourply Inc. P.O. Box 890 Grants Pass, Oregon 97526 503/479-3301

Guaranty Performance Co. Inc. P.O. Box 748 Independence, Kansas 67301 316/331-0027

Hobbs (C.B.) Co. Elk Grove, California 95624 916/685-3925

Papakube Corp. 7185 Navajo Rd. Suite 1 San Diego, California 92119

Sprout Waldron 802 Logan St. Muncy, Pennsylvania 17756 717/546-8211

FOREIGN

Ferdinand Platbrood 12 Category des Rossignols 6070 Chatlet Belgium

Fred Hausmann Ltd. 4005 Basel Switzerland

Hawker Siddeley Canada Inc. (formerly Ltd.) 7 King St., East Toronto, Canada M5C1A3 416/362-2941

Mr. Sayan Panpinig 53 MOO. 6 A. Ladkrabang Bangkok, Thailand