This article is from ECHO Asia Note # 33.

Editors’ Note: Dr. Tapani Haapala is an adjunct professor, agriculturist, horticulturist, and researcher. During these experiments, he was working as a global food security advisor and regional development manager for FELM (the Finnish Evangelical Lutheran Mission) in Cambodia. Markku Lyytinen is a Finnish engineer, who lives in Cambodia. For more information about cultivating mushrooms, see Keith Mikkelson’s presentation on the Aloha House mushroom cultivation.

Key Words: Solar heater, pasteurization, mushroom production

Key Ideas:

- Mushrooms are often grown in plastic bags filled with organic material that needs to be sterilized or pasteurized to prevent contamination by bacteria or foreign fungi.

- High heat is used to sterilize / pasteurize.

- Heating requires a lot of energy, which often is not renewable.

- New energy-saving and environmentally friendly methods of mushroom media pasteurization need to be developed.

- The method presented in this article uses sunlight, which is free of charge and does not pollute the environment.

Summary

Mushrooms such as oyster mushrooms (Pleurotus ostreatus) are usually grown in plastic bags filled with organic material that may include organic farm wastes. That material must be sterilized (heated to temperatures above 100°C) or pasteurized (heated to a lower temperature, 60°C or higher) to prevent contamination by germs, viruses and fungal spores. However, sterilization and pasteurization are challenging for small-scale farmers because of the energy requirements. Normally, small-scale farmers use a drum sterilization method, during which water is heated until it boils. Farmers must buy or collect the firewood to heat water (an expensive and/or labor-intensive task). Charcoal is even more costly to buy or to make. Also, results of drum sterilization can be inconsistent, depending on the device used and quality of the fire wood.

The new, easy-to-build piece of pasteurization equipment introduced in this article is inexpensive, long-lasting, easy to prepare, and does not need fossil fuel energy. The pasteurization process does not need monitoring, so it requires less labor.

The aim of this article is to encourage other development workers and local farmers to continue these early experimentations to improve the device or other similar ones so that they become useable in their own different environments, with an aim of helping small-scale farmers save energy and money when growing mushrooms.

Introduction

Mushroom production is a good way of turning organic farm waste into nutritious food for human consumption. Mushrooms contain minerals, amino acids, and vitamins that are important for all human beings, but especially for growing children. According to the FAO: “The consumption of mushrooms can make a valuable addition to the often unbalanced diets of people in developing countries. Mushrooms are a good source of vitamin B, C, and D, including niacin, riboflavin, thiamine, and folate, and various minerals including potassium, phosphorus, calcium, magnesium, iron, and copper. They provide carbohydrates, but are low in fat and fiber, and contain no starch.

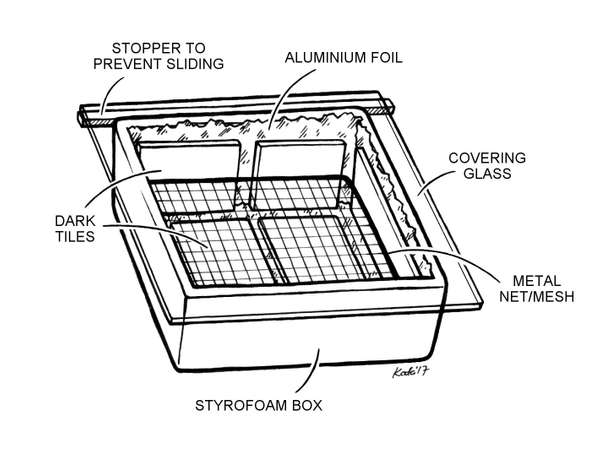

Figure 2: The pasteurization box made from an easily available Styrofoam storage box.

Furthermore, edible mushrooms are an excellent source of high quality protein (reportedly between 19 percent and 35 percent), and white button mushrooms contain more protein than kidney beans. In addition to all the essential amino acids, some mushrooms have medicinal benefits of certain polysaccharides, which are known to boost the immune system” (Marshall & Nair 2009).

Mushroom production can also be an excellent way of improving livelihoods in rural and semi-urban areas, especially for those who don’t have access to enough land for farming (FAO & Earthscan 2011; Marshall & Nair 2009).

When organic wastes are used for mushroom production, the medium must be sterilized or pasteurized (Sánchez 2010) to kill harmful microorganisms, such as the spores of molds, fungi, yeasts, bacteria, or viruses. This is an energy-intensive and expensive process that is particularly burdensome for small-scale farmers. New, environmentally-friendly solutions are needed.

Materials and Methods

Our solar pasteurizer is made from a Styrofoam box lined with aluminium

Figure 3: Plastic bags tightly filled with rice straw were used for the testing the device and serve as a good medium for mushroom cultivation.

foil (Figure 1). Dark-colored ceramic tiles are placed on the bottom and sides of the box to store the sun’s heat (Figure 1 and 2). A piece of metal mesh is placed on the bottom, to enable good air circulation within the box. Glass on the top (different kinds of glass materials were not systematically tested, and in fact, one glass material was not durable enough and was broken by rapid change due to the heat of the sun) allows the sun’s rays to enter the box and traps much of the heat inside. A stopper, such as a length of wood, must be attached to the bottom of the glass plate, to prevent the glass from sliding off the box while the box is angled to capture more of the sun’s heat (Figure 1). The box cost about $10 USD to build in Phnom Penh.

Figure 4: The temperature inside the mushroom bags was recorded using a food thermometer.

There are many different kinds of organic materials that can be used for mushroom cultivation, such as straw, sawdust, cotton waste, or even coffee pulp (Aguilar-Rivera et al. 2012). In this study, we used rice straw (Figure 3), which is easily available and free of charge or very cheap to use in Cambodia.

Results and Discussion

The Styrofoam solar pasteurizer was built in Phnom Penh and tested during several sunny days at the end of November, 2015. Results show that the temperature inside the bags rose higher than 60°C, which is the temperature at which the most harmful microorganisms in the bags would be killed (Figure 4; Tajudeen et al. 2012). Although it took 1.5 hours for the box to reach a temperature above 60°C, once heated, the box was able to remain at or above the desired temperature for up to four hours (Figure 5), an example of average results of a sunny day. [Eds’ Note: As is the case with many new innovations, ECHO Asia encourages you, as a community change agent, to first try out any emerging technologies yourself, before extending these new ideas to a community. Not only can the extension of untested ideas in your particular environmental and social context be deleterious to your legitimacy and reputation, it can also be deleterious to peoples’ lives and livelihoods. In the case of this pasteurizer box, it would be wise to first test it yourself during different lighting and temperature scenarios to ensure that the mushroom media is thoroughly pasteurized.]

Conclusions

The box was inexpensive to build ($10 in Phnom Penh); although the cost and availability of materials will vary from place to place, we believe that most places in SE Asia should be able to procure the needed materials rather inexpensively. All parts of the device are easily replaceable and inexpensive. For the glass cover, be sure to use a type of glass that can withstand temperature fluctuations without breaking.

The relatively small size of the box limits the amount of media that can be sterilized. However, several boxes could be used in tandem. Alternatively, the box could be used multiple days in a row; each day, a set of bags could be pasteurized, so that in one week, seven sets of bags would be ready for use. In places where charcoal and/or firewood (for traditional water or steam pasteurization) are expensive, this technology could quickly pay for itself while conserving forests and reducing exposure to smoke.

Figure 5: The measured temperatures in one mushroom bag (Figure 3) inside the pasteurization box during different times of the day in Phnom Penh, Cambodia.

The solar pasteurizer was tested on sunny days at one time of the year (near the end of November). The amount of heat from the sun would vary depending on cloud cover and possibly also on the time of year; if you build a similar solar pasteurizer, we recommend that you test the temperature inside the box before or (preferably) during use, to ensure that the target temperature of 60oC or higher is reached inside your media.

The dark ceramic tiles inside the pasteurizer absorb heat. They can help to balance changes in temperature, providing temperature stability when, for example, a cloud passes in front of the sun.

This solar pasteurizer is inexpensive to build, easy to use, and saves fossil fuel or biomass energy by using direct sunlight. It is also very user-friendly, especially when compared to water heating methods that require constant tending. We ask development workers in different countries in the field of mushroom production to join us in testing these novel kinds of devices in their particular environments and climates and continue to help develop the device further. We would appreciate feedback to continue this early innovative work.

REFERENCES

Aguilar-Rivera, N., A. C. Moran, D. A. Rodríguez Lagunes, and J. M. Gonzalez. 2012. Production of Pleurotus ostreatus (Oyster mushroom) grown on sugar cane biomass (trash, bagasse, and pith). In: Mushrooms: Types, Properties, and Nutrition (Sophie Andres and Niko Baumann, Eds.). London: Nova Science Publishers, Inc.

FAO & Earthscan. 2011. The State of the World´s Land and Water Resources for Food and Agriculture.

Guardia, M. L., G. Venturella, and F. Venturella. 2005. On the chemical composition and nutritional value of Pleurotus taxa growing on Umbelliferous plants (Apiaceae). Journal of Agricultural and Food Chemistry 53: 5997-6002.

Marshall, E., and N. G. (Tan) Nair. 2009. Diversification Booklet Number 7: Make Money by Growing Mushrooms. Rome: FAO. Rural Infrastructure and Agro-Industries.

Mattila, P., P. Salo-Vaananen, K. Konko, H. Aro, and T. Jalava. 2002. Basic composition and amino acid contents of mushrooms cultivated in Finland. Journal of Agricultural and Food Chemistry 50: 6419-6422.

Mattila, P., K. Konko, M. Eurola, J. Pihlava, J. Astola, L. Vahteristo, V. Hietaniemi, J. Kumpulainen, M. Valtonen, and V. Piironen. 2001. Contents of vitamins, mineral elements, and some phenolic compounds in cultivated mushrooms. Journal of Agricultural and Food Chemistry 49: 2343-2348.

Sánchez, C. 2010. Cultivation of Pleurotus ostreatus and other edible mushrooms. Applied Microbiology and Biotechnology 85(5): 1321–1337.

Tajudeen, O. O., O. D. Sikhumbuzo, D. M. Earnshaw, and M. T. Masarirambi. 2012. Effect of substrate pre-treatment methods on Oyster Mushroom (Pleurotus ostreatus) production. International Journal of Agriculture and Biology 14(2).

Yang, J. H., H. C. Lin, and J. L. Mau. 2001. Non-volatile taste components of several commercial mushrooms. Food Chemistry 72: 465-471.