A manual for drivers using pioneer roads and for novice mechanics who must depend upon their own resources in areas without extensive service facilities.

Volunteers in Technical Assistance 1600 Wilson Bloulevard, Suite 500 Arlington, Virginia 22209-8438 USA

Copyright [C] E. Christopher Cone, 1992

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechnical, including photocopy, recording, or any information storage and retrieval system without written permission of the publisher.

Published by Volunteers in Technical Assistance (VITA) 1600 Wilson Bloulevard, Suite 500 Arlington, Virginia 22209-8438 USA

Manufactured in the United States of America.

Library of Congress Cataloging-in-Publication Data

Cone, E. Christopher. Automotive operation and maintenance/ by E. Christopher Cone. [Revised Edition] Includes index. ISBN 0-86619-310-3 1. Automobiles--Maintenance and repair. 2. Automobile driving. I. Title. TL 152.C58 1992 926.28'72-dc20 90-49886 CIP

First printing, May 1973 Second printing, November 1973 Third printing, April 1974 Revisions and fourth printing, April 1975 Revisions and fifth printing, July 1992

DEDICATION

This book is dedicated to the memory of Fr. Joseph Bessom, OHC, a modern-day Christian saint whose love of Africa and its people sent me to live in its jungles and resulted in the writing of this book for VITA.

ACKNOWLEDGEMENTS

It would be fruitless to attempt to list all of the men and women who have contributed to the preparation of this book. They range from unlettered Africans with an inborn feeling for the capacity of a log bridge to engineers with the some of the largest corporations in the world. Special thanks should be made to my African instructors, James Tamba Kila, Stephen Boakai, Jaka Masambolahun, James Nyuma Dah, Moses Sivili Gelego, Andrew Kpehe Woiwor, and others. Appreciation is extended to the Order of the Holy Cross, which provided the "test track" for most of the material discussed in this book. Acknowledgement is also made of the assistance of several people at VITA, notably Terry Ladd and Gerri Forlenza, who worked on the first edition, and Patricia Mantey and Margaret Crouch, who prepared the current, revised version.

Special thanks go to VITA Volunteer John N. Amon of the Rochester Institute of Technology, who produced all new technical drawings for the fifth printing using Intergraphic MicroStation software, and Celia Jenkins and Jill Smith McClain, who assisted with the photographs.

The technical assistance of many vehicle manufacturers and their sales agents has contributed to the production of this book. Their aid has been invaluable in providing shop references concerning specific vehicles in the maintenance portion of this manual. E.C.C.

INTRODUCTION

This book is intended to fill a need found by the author at the start of his 30 years as a mechanic for a church mission in Liberia, West Africa. At that time the author could perhaps charitably be termed a mechanically inclined novice. Despite his lack of experience he found himself in charge of a substantial number of vehicles and a fair-sized electric generating station. It was largely through experiment and occasional disaster that much of the material for this book was assembled. It is presented here in the hope that it may save the reader from many of the same problems.

The intent is to offer suggestions to drivers or mechanics who operate in an area where service facilities and technical assistance are not readily available and they must be their own advisers on every problem that may arise. In the event that readers happen to have some service facilities at hand, they will find that they can skip over some sections of the manual.

This manual for the most part deals with four-wheel drive vehicles, since it can generally be expected that an area where no service facilities exist will be one with pioneer roads, which require the added traction of four-wheel drive. However, since FWD is the name of a manufacturer of heavy-duty, four-wheel drive trucks, it is inappropriate to use this abbreviation to indicate "four-wheel drive." The abbreviation FWD is also used to describe the growing number of cars with front-wheel drive and no power in the rear wheels. To avoid confusion, the term 4WD will be used here. Also, as a matter of convenience, the word "car" is taken as it is used in West Africa: to mean any sort of small or moderate size vehicle whether it be a sedan automobile, Jeep-type vehicle, or pickup truck.

On another matter of nomenclature, it should be noted that petroleum products are identified here by their U.S. names. Readers in other areas will have to translate according to local custom. This is a matter of some confusion; what the British call paraffin, for example, is known as kerosene in the United States, and paraffin to a U.S. reader means a translucent white wax.

The book is organized into several sections. An understanding of the organization should make it possible to find needed material quickly. The first section concerns operation of a car in an area served by pioneer roads. This section is intended to assist drivers with temporary repairs to the vehicle so that they can get home in the event of mechanical trouble.

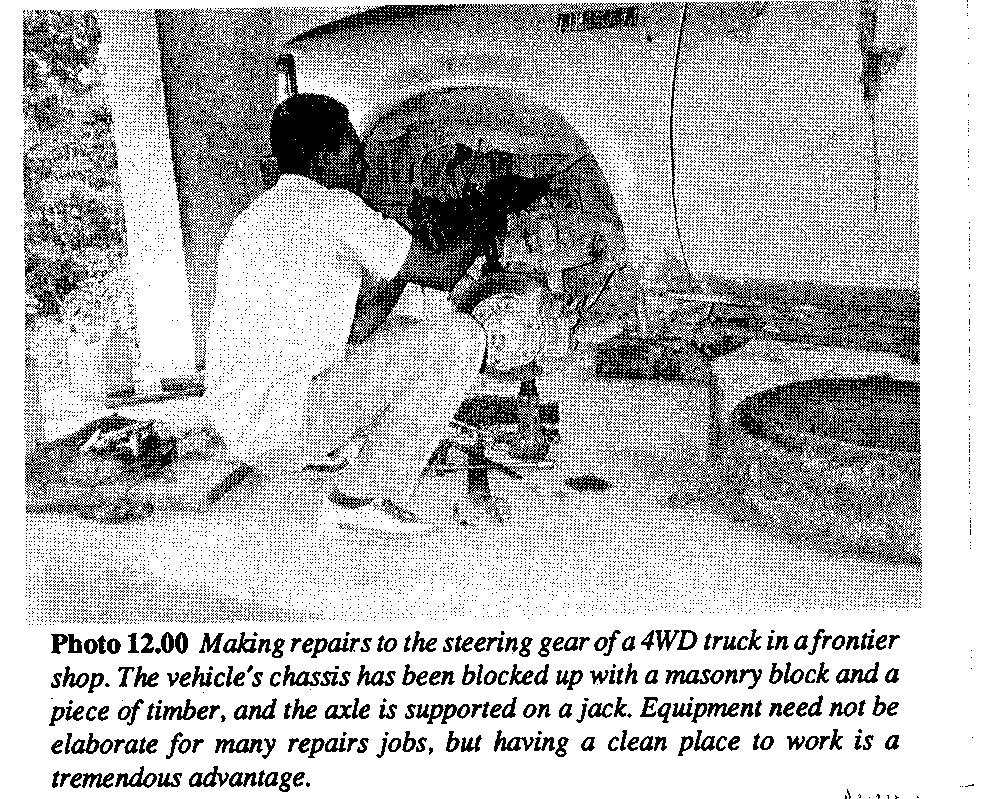

The second section of the book is devoted to maintenance suggestions, which are intended for use in a frontier shop or repair center, no matter how ill-equipped it may be. This book should be used as a supplement to the vehicle's shop manual. For example, this book will help indicate when brakes need to be relined, but the shop manual will tell how to do it. Since a book of this type is worthless if material cannot be located when it is needed, a special effort has been made to prepare as complete an index as possible. Cross references will also be found throughout the text.

NOTE regarding metric and English measurements: For convenience both systems of measurement are used in this book. Where an equivalent is given as a "rule of thumb," however, it is not intended as an exact equivalent. For example, 35 miles per hour is shown as being equivalent to 55 kilometers per hour. A more exact figure would be 56.35 kilometers per hour, but this is cumbersome and not readily remembered.

A complete table of English and metric equivalents is included in Section 20.00.

TABLE OF CONTENTS

Major sections of this book are divided by section numbers. Section 6.00, for example, covers the entire range of "Winching and Towing." Within this large chapter are smaller sections; 6.01 concerns wire rope, and the following sections cover methods of splicing wire rope, storage of wire rope, etc.

In addition to arranging the book in this "outline" fashion, a complete index can be found in Section 21.00.

Acknowledgements

Introduction

1.00 Mechanical Emergencies While Driving

Loss of oil pressure; tire blowout; broken axle or drive shaft; boiling radiator; broken steering linkage; steering bent and ineffective; headlight failure at night; accelerator pedal stuck down; brake failure.

2.00 Operating on Pioneer Roads

Examining the vehicle; loading the vehicle; introduction to the cab; mechanical operation.

3.00 Avoiding Road Hazards

Four-wheel drive; traveling in convoy; tire chains; loss of traction; piled-up mud or solid obstacles; log bridges; capsizing; fording and wading; submerging.

4.00 Extricating the Vehicle

Stuck in mud or snow; hung up in mud or snow; hung up on a solid obstacle; log bridges; stuck while fording.

5.00 Procedures when Stranded

Leaving the vehicle; water supply; seeking help; vehicle submerged.

6.00 Winches and Towing

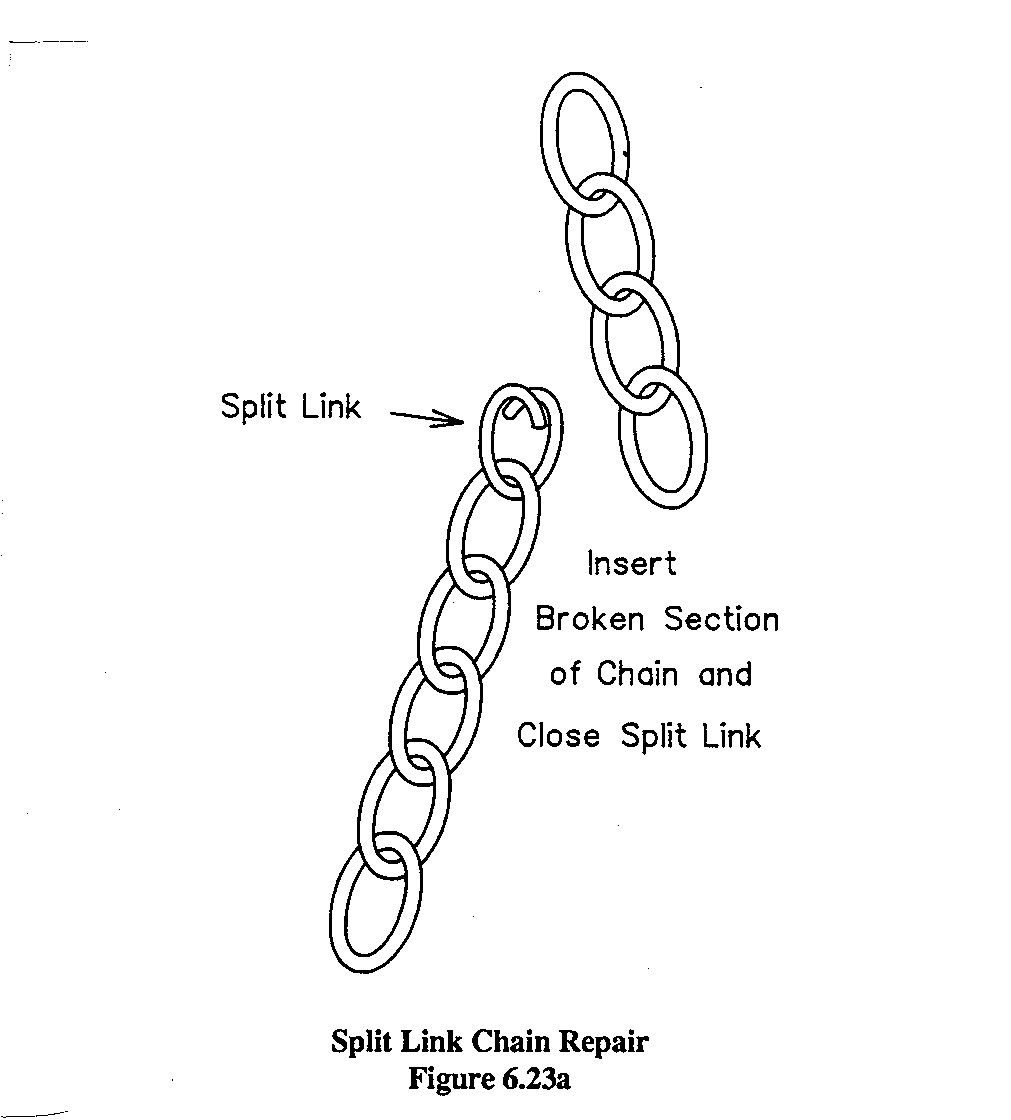

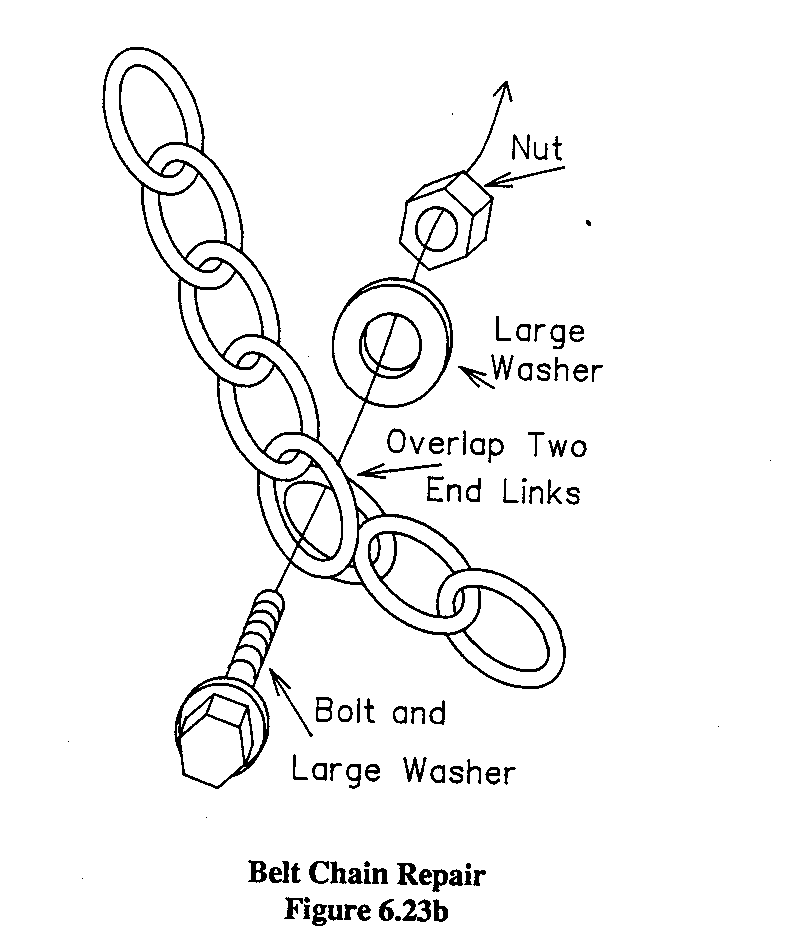

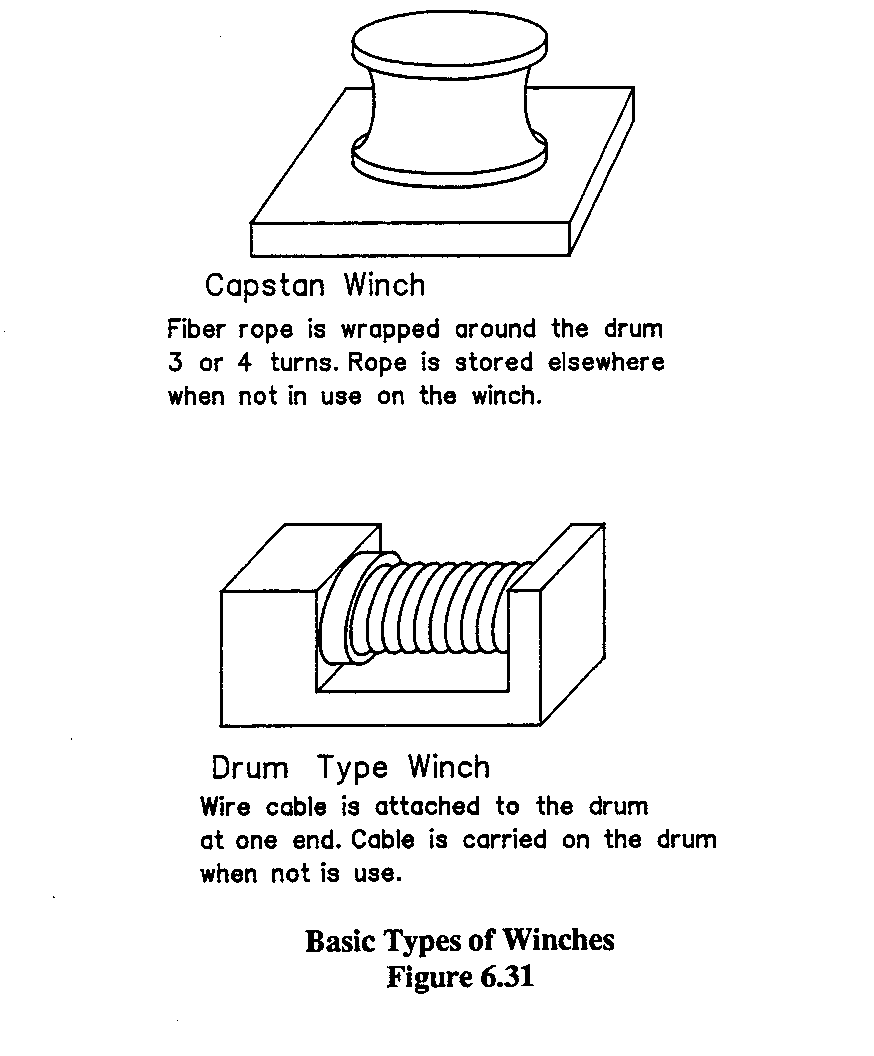

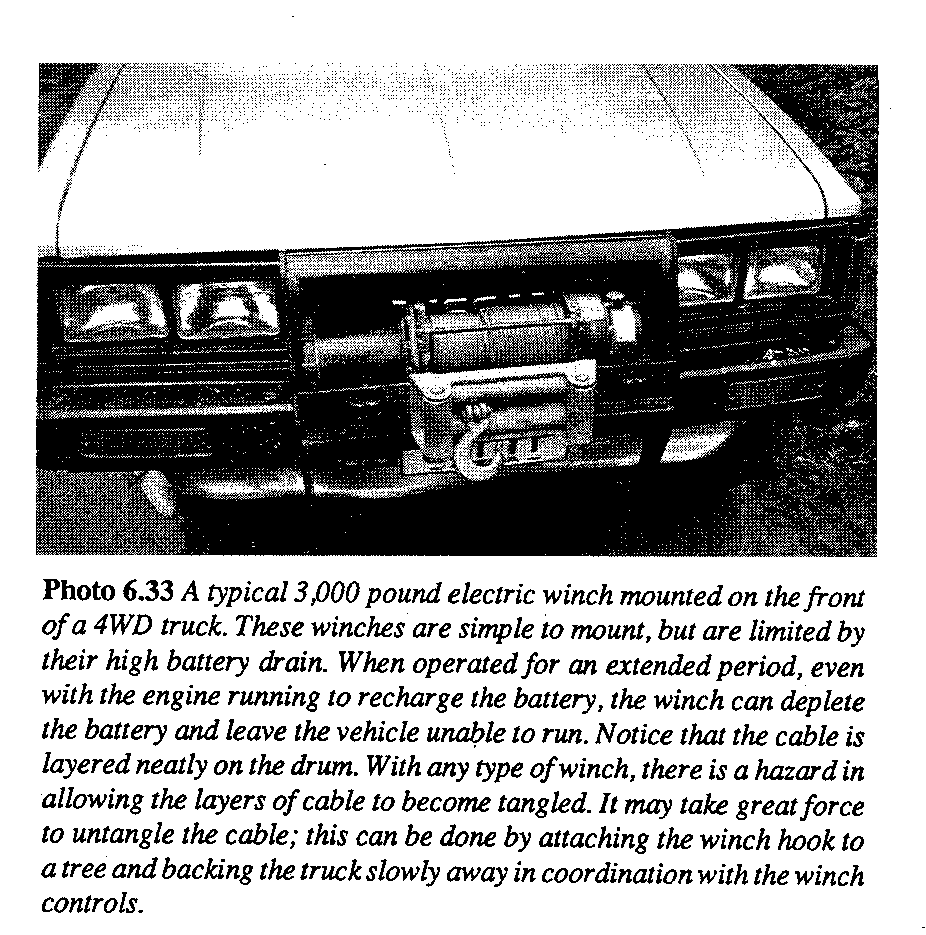

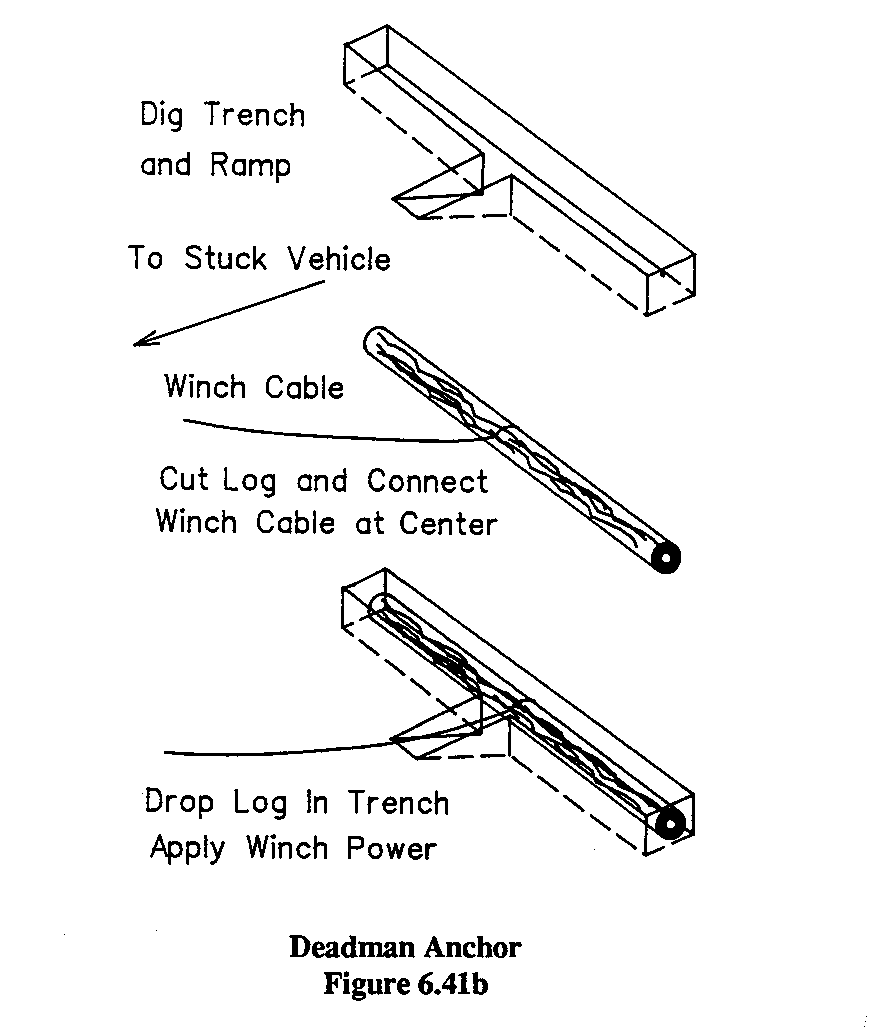

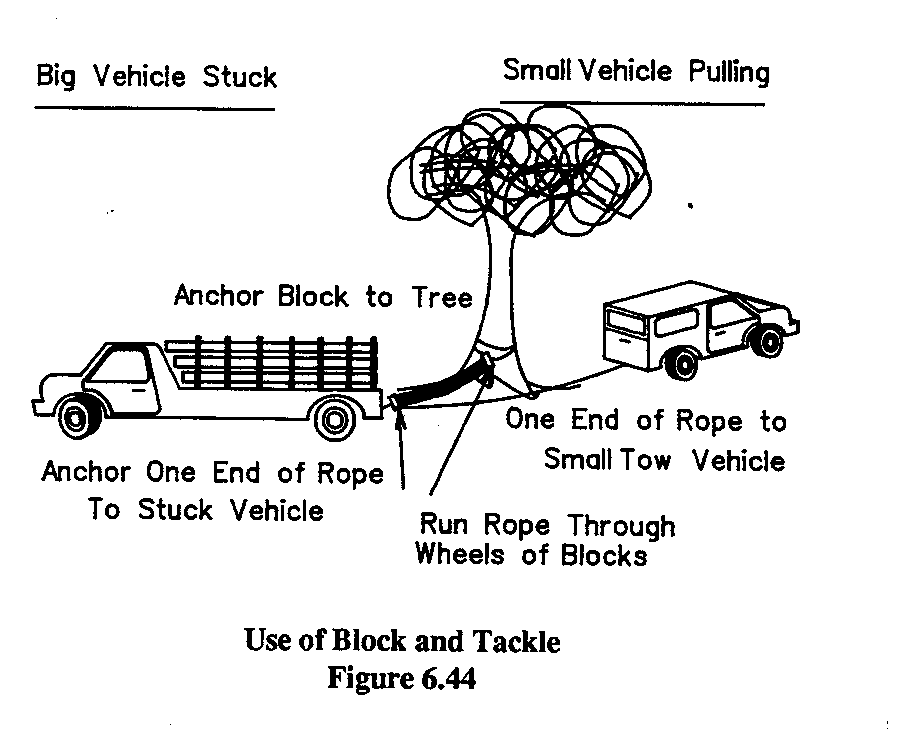

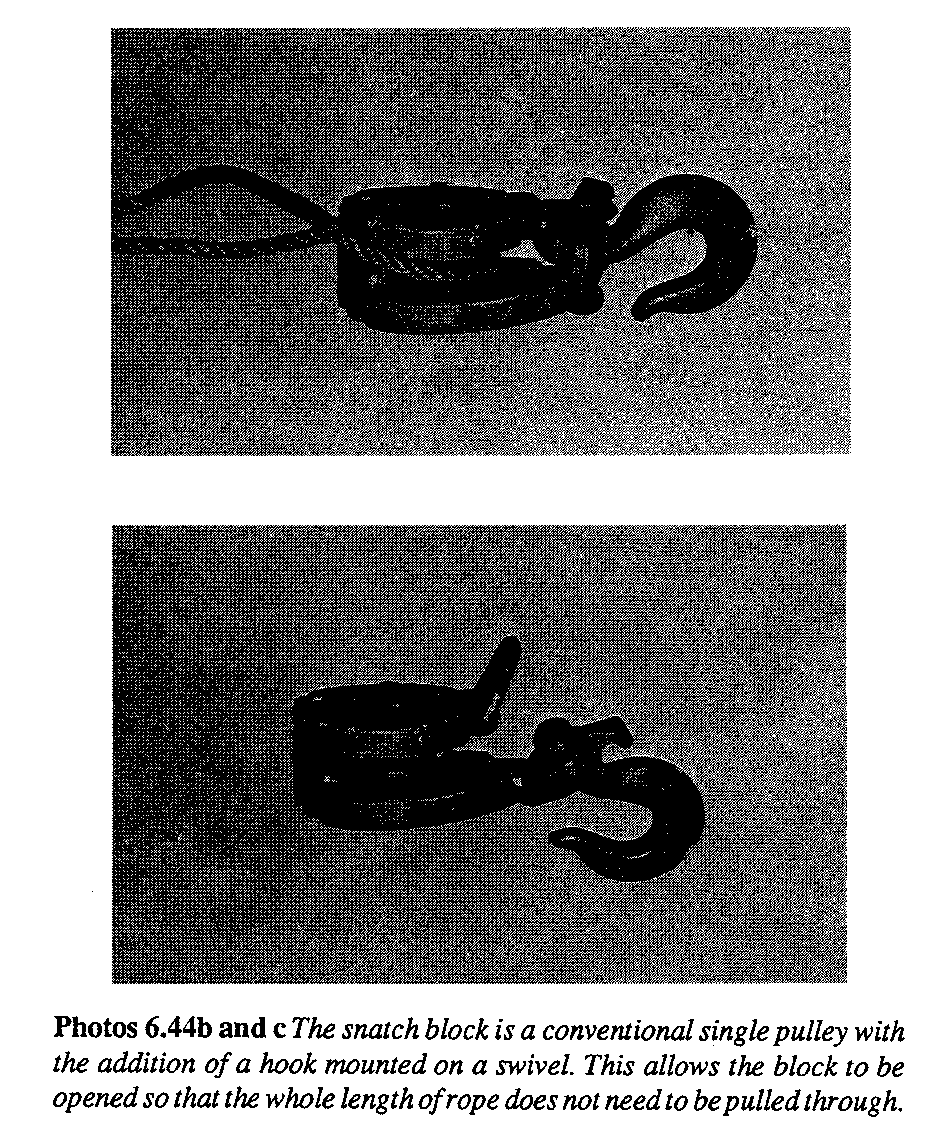

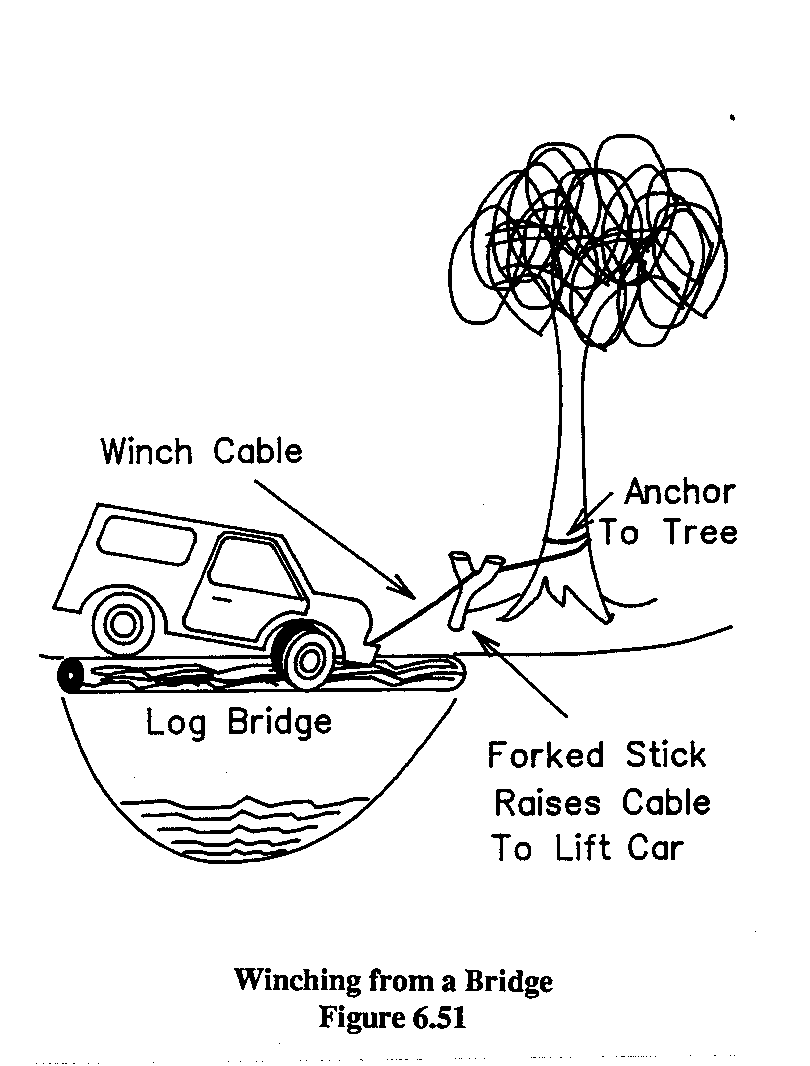

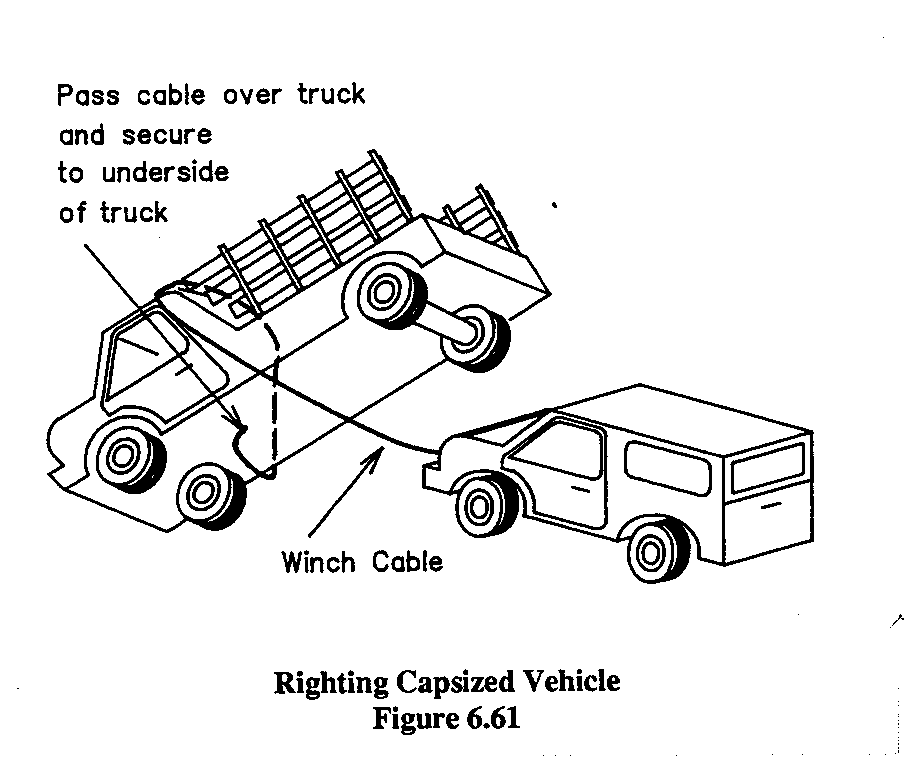

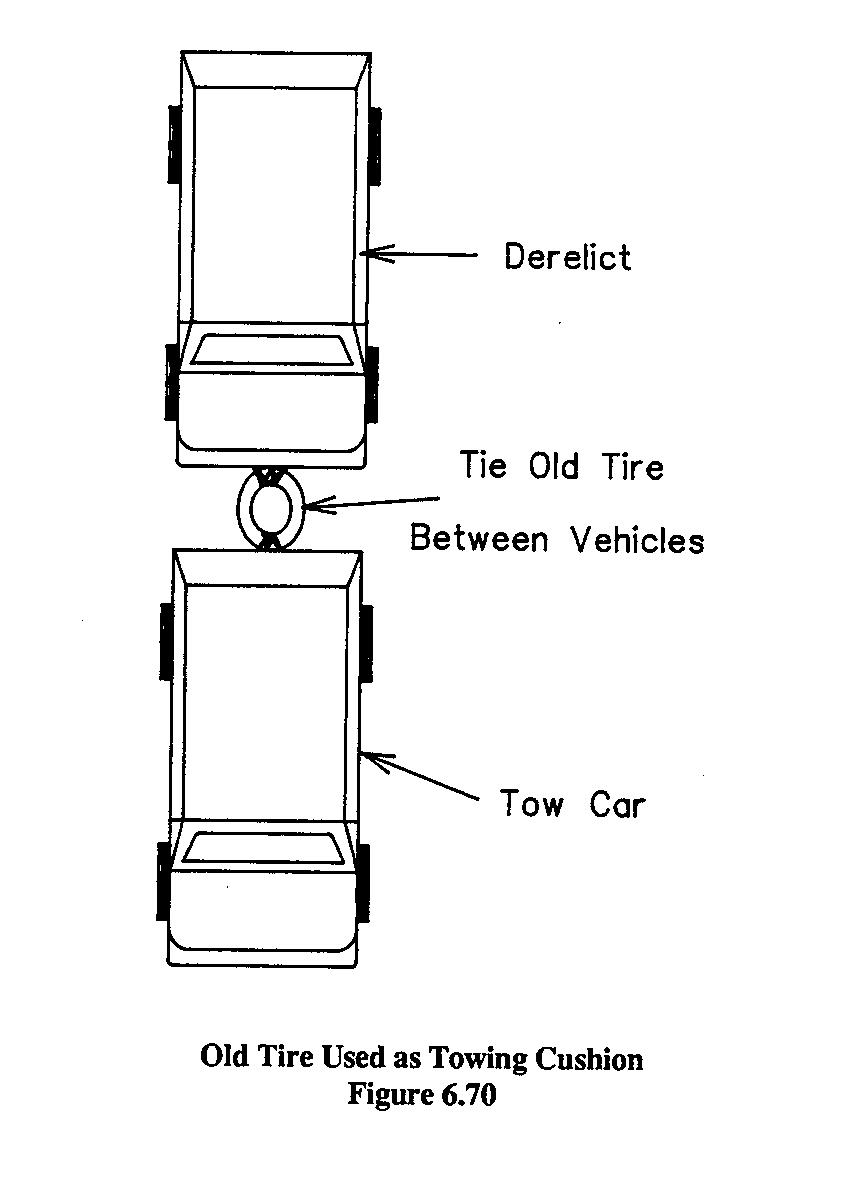

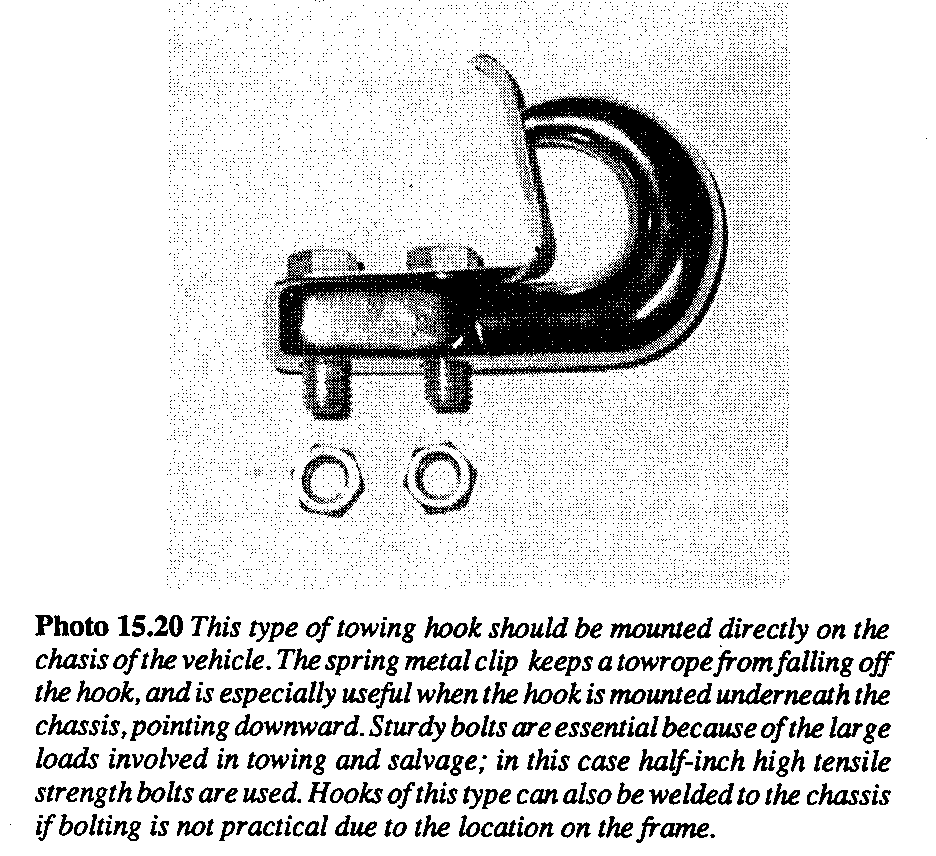

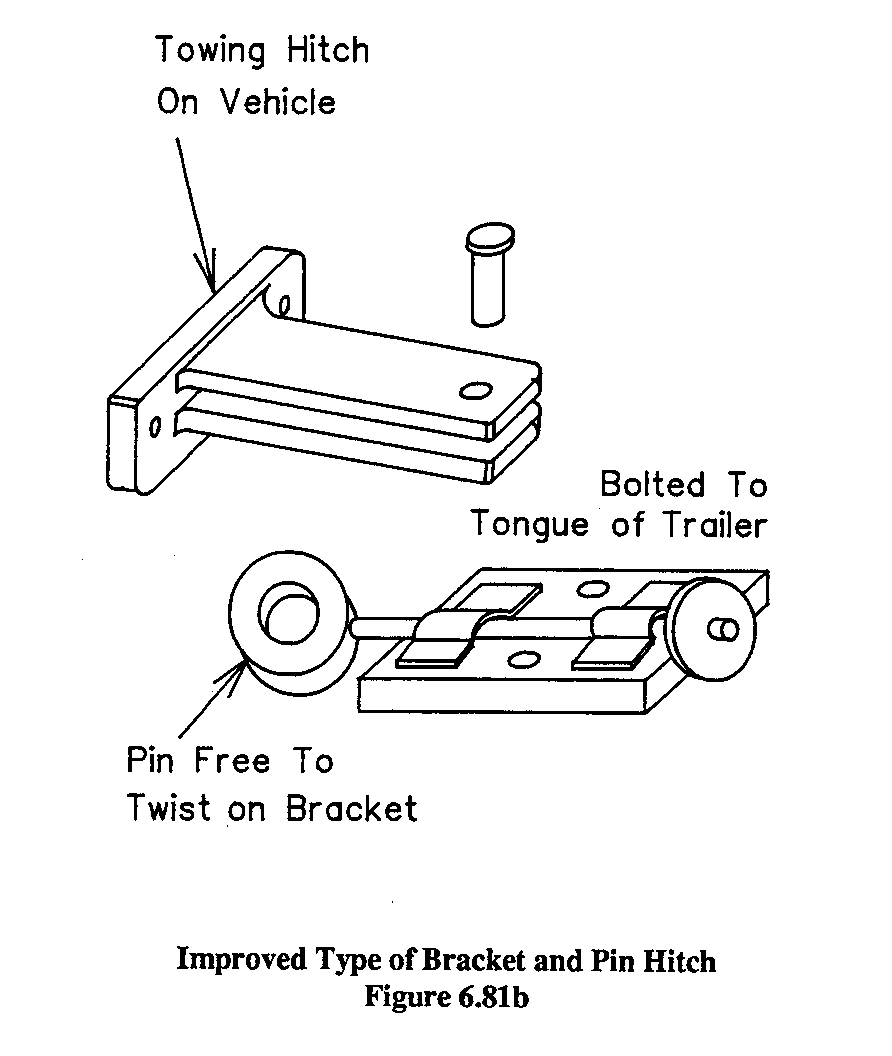

Wire rope; joining wire cable; storage of wire rope; types of rope; synthetic fiber ropes; knots for fiber rope; nylon towing straps; chain; joining chain; storage of chain; chain repairs; the winch; selecting a winch; installing a winch; winch drive systems; winch cable; use of the winch; anchoring the winch cable; winching safety; winding in the winch cable; block and tackle; recovery with a winch; winching from a bridge; removing a log under the car; lowering with the winch; using the winch for salvage; salvaging a capsized vehicle; salvaging a car from water; towing a derelict; attaching the tow cable; overcoming mechanical drag; towing a trailer; trailer hitches; extricating a stuck trailer.

7.00 Field Expedients

Capsizing and submerging accidents; drive train expedients; steering system expedients; brake system expedients; fuel system expedients; tire expedients; cooling system expedients; electrical expedients; problems in the primary circuit; ignition system expedients; engine expedients.

8.00 Check Lists

Cranking and starting trouble; engine will not crank; engine cranks, will not start; engine starts, then quits; low charge, dead battery; poor spark; low oil pressure; engine uses too much oil; steering problems; front tires worn; uneven tire wear; vibration in drive train; wheel bearings hot; steering troubles; brake trouble; brake pedal sinks to floor; brakes do not hold; brake pedal rises and brakes drag; brakes drag; car pulls to one side when braking; brakes grabbing; brake pedal does not return; clutch and gearshift problems; gearbox trouble; clutch trouble; rough running or conking out; engine short of power; engine conks out and will not restart; engine overheats, radiator boils; funny noises.

9.00 Tests and Testing Equipment

Cooling system tests; engine tests; clutch tests; drive train and steering tests; fuel system checks; brake tests; primary electrical tests; ignition tests; exhaust tests.

10.00 Shop Techniques

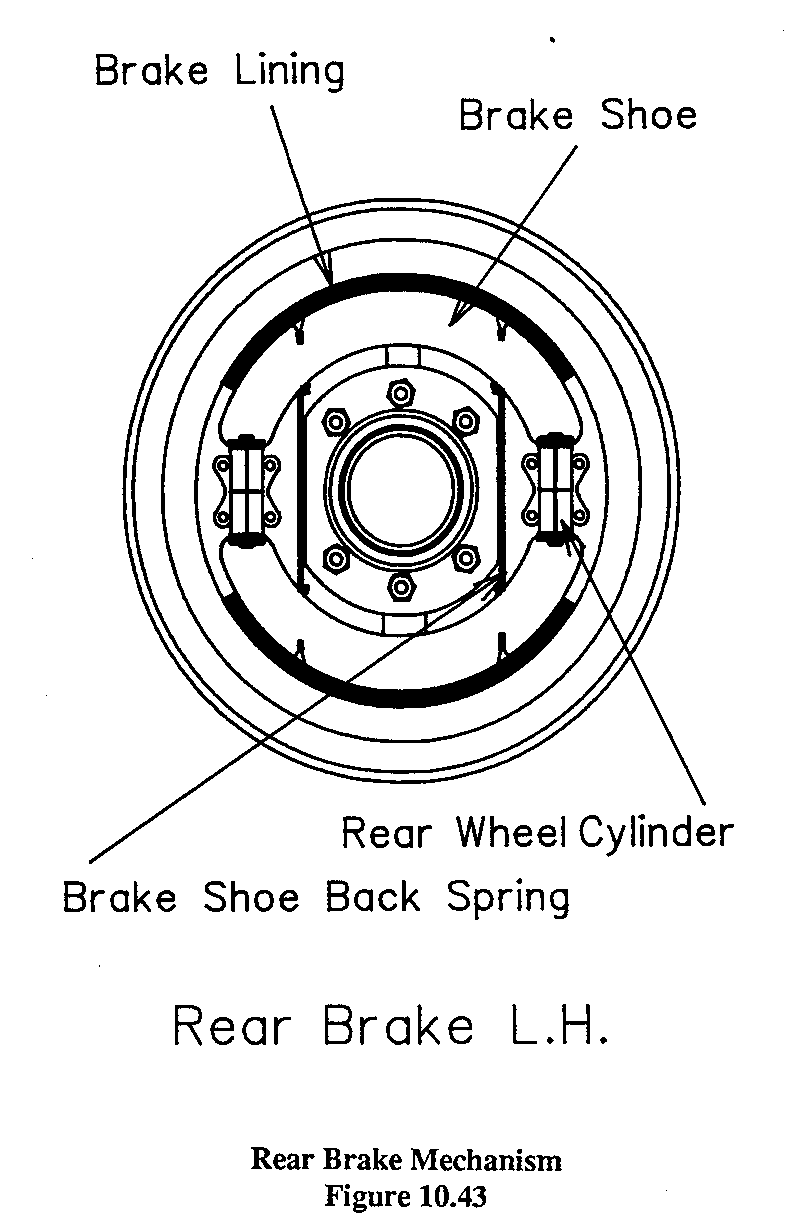

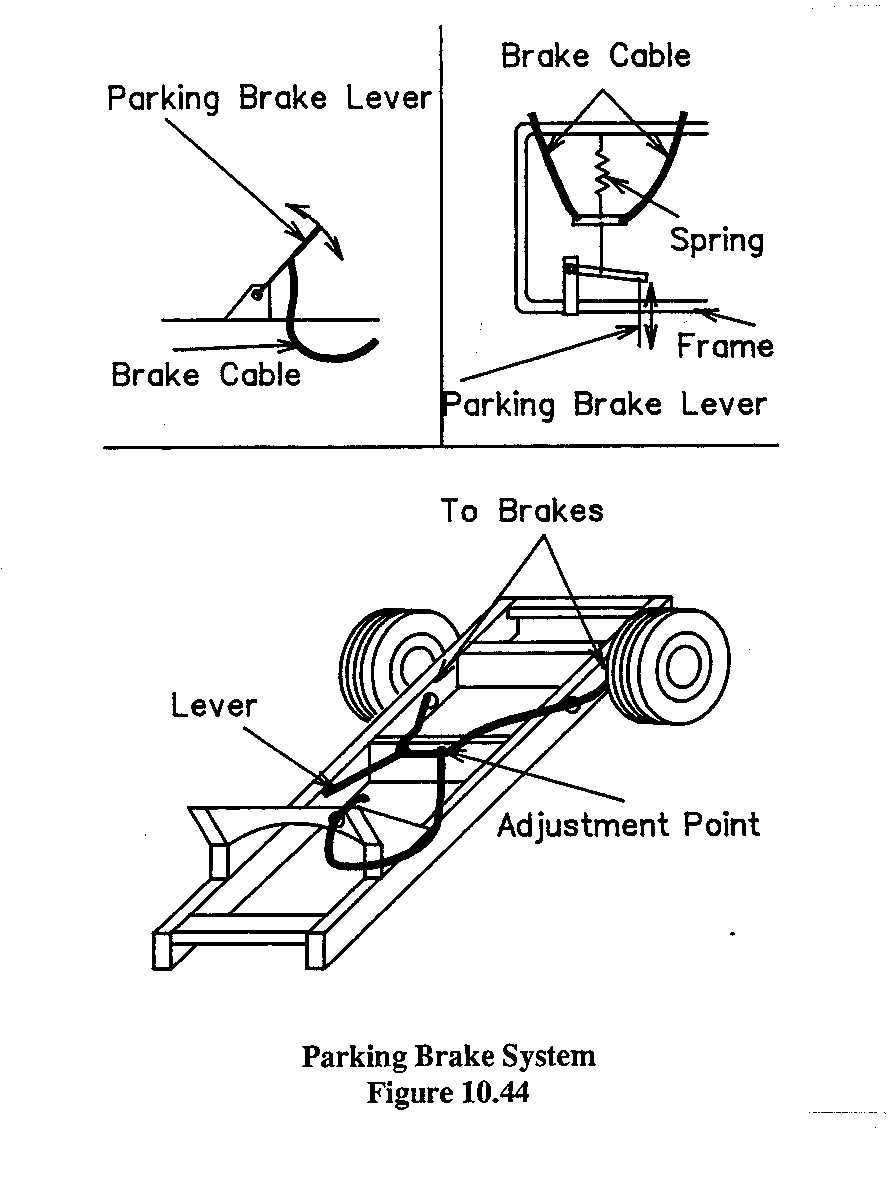

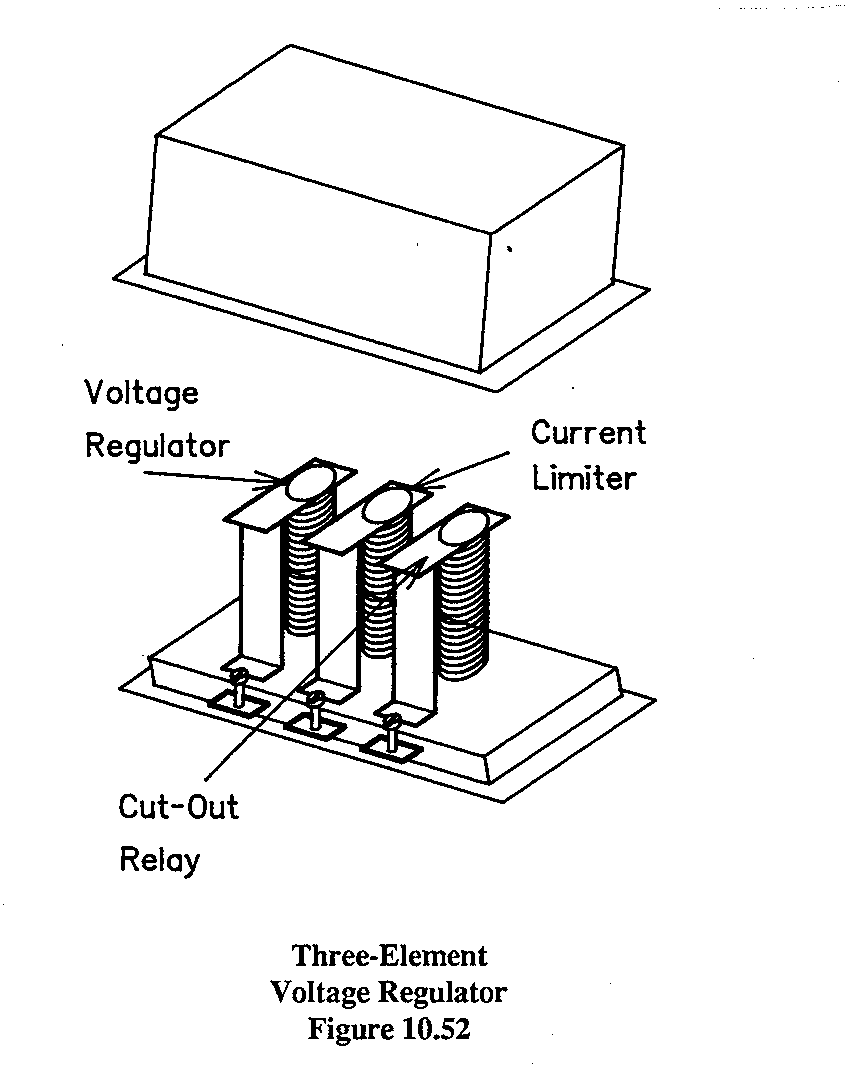

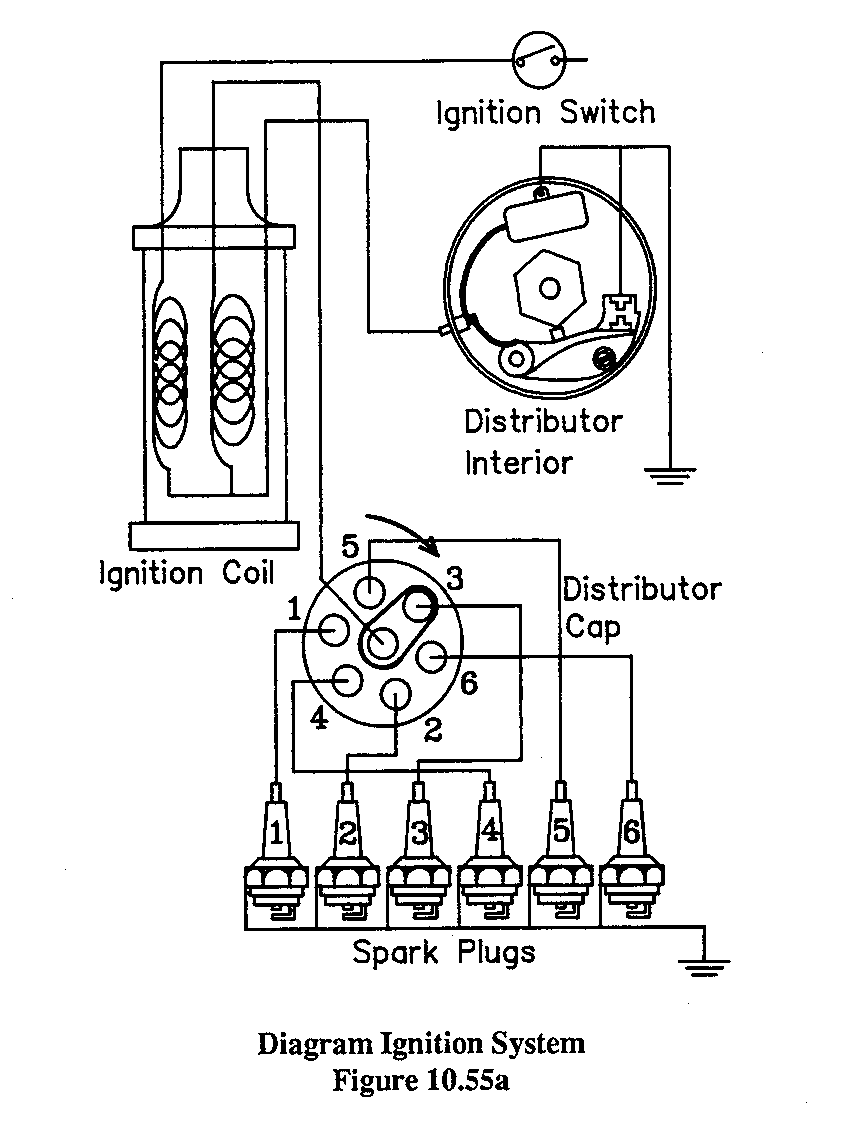

General shop hints; axles; differentials; wheel bearings; universal joints; fuel system; brakes; adjusting the brakes; bleeding the brakes; relining the brakes; the hand brake; electrical repairs; battery; voltage regulator; generator repairs; light system repairs; ignition repairs; steering repairs; tire and wheels; repairs to springs; repairs to shock absorbers; cooling system repairs; exhaust system repairs; engine repairs; valves; engine removal; miscellaneous engine repairs.

11.00 Body Repairs

Window glass; roof dents; chassis repairs.

12.00 A Shop Building

13.00 Diesel Engines

Diesel check list; diesel engine tests; diesel repairs.

14.00 Tools and Equipment

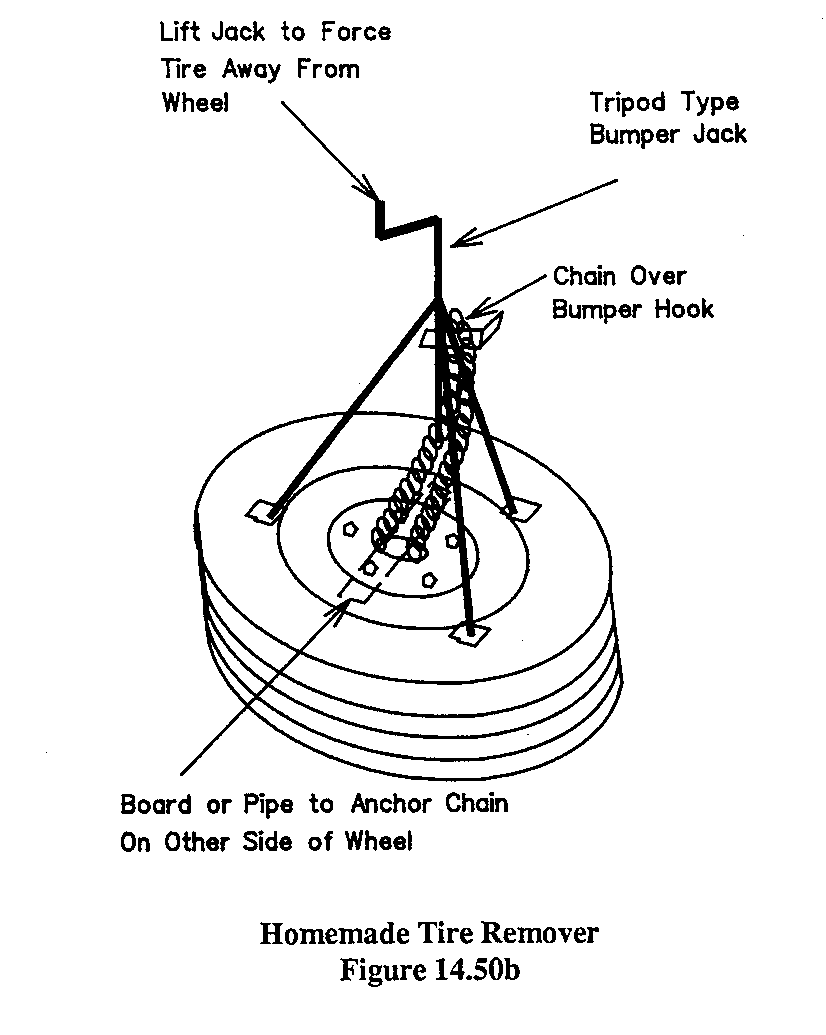

Tools for the car; shop tools; luxury tools and equipment; a generator; compressed air in the shop; welders; gas welders; electric arc welders; tools to make; homemade test equipment.

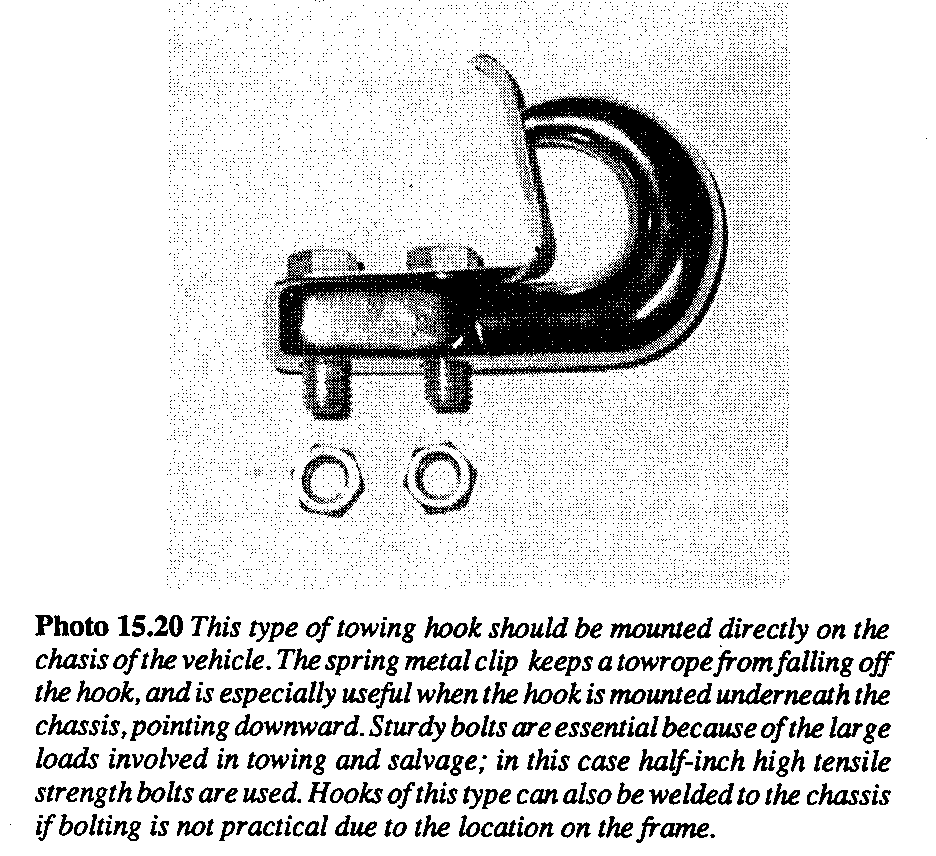

15.00 Vehicle Modifications

Storage facilities; body modifications.

16.00 Parts and Supplies

Supplies in the vehicle; supplies in the shop.

17.00 Storage Facilities

Fuel Storage.

18.00 Preventive Maintenance

Greasing; lubrication; tune-up procedure; radiator flush; miscellaneous maintenance; cold weather operation; periodic checks; check points; daily checks.

19.00 Selecting a Vehicle

Vehicle types and sizes; vehicle modifications; vehicle comparisons.

20.00 Miscellaneous Formulas

Engine displacement; weight on rear axles; pulley ratios; charts and measurements; water measurements; metric equivalents; torque values for nuts and bolts; battery electrolyte specific gravity; metric equivalents.

21.00 Definitions and Index

1.00 MECHANICAL EMERGENCIES WHILE DRIVING

While a discussion of the disasters that await the novice driver on a pioneer road may be a discouraging way to start a manual of this type, it is intended that readers examine this section before they must face any of these problems, so they can be fully prepared. This section is not concerned with such roadside problems as flat tires, dead batteries, or running out of fuel. By "mechanical emergencies" is meant the sort of trouble with the car that places its riders in danger through lack of control of the vehicle or the threat of major damage to the machinery. Many of the mechanical problems related here can be avoided through attention to the items summarized in Section 18.00 on preventive maintenance. Repairs to correct the problems listed here are described in Section 7.00: Field Expedients.

1.01 Loss of Oil Pressure

Since oil, under pressure, is required to lubricate the many moving parts of an engine, loss of this pressure is a major mechanical emergency. Stop the engine immediately, or it will in all likelihood be permanently damaged. Once the engine is safely stopped, look for the cause of the difficulty. Section 8.00 on check lists may be of assistance in this search.

1.02 Tire Blowout

At the slow speeds that are common on pioneer roads, tire failure may not be a serious problem. You will only hear a flopping noise and notice that the steering seems unresponsive. At high speeds, however, a blowout can spin the car out of control. The correct response to a blowout is to keep the foot off the brake pedal or accelerator and try to steer the car to a safe stop. If a front tire blows, the car will swerve toward the same side as the blown tire. Using the brake will often cause a spin. With the transmission in gear the engine will slow the car gradually, making it more likely that you will be able to hold the wheel and steer to a halt.

1.03 Broken Axle or Drive Shaft

A two-wheel drive car propelled by only one pair of wheels will stop if an axle or propeller shaft breaks; going up a hill it will roll back. In such a vehicle it is necessary to make repairs before the car can proceed.

A 4WD car can continue as long as either the front or rear wheels are functioning. If an axle shaft is broken in the rear end, for example, shift to 4WD and attempt to proceed using only front-wheel drive. If a propeller shaft is broken it should be removed before proceeding, or the stub end will flop around and may damage the underframe of the car.

1.04 Boiling Radiator

A boiling radiator is indicative of an overheated engine, which may be caused by any of a number of things as listed in Section 8.70 on check lists.

Do not shut off the engine if the radiator is boiling, for then all circulation of water, even though the water is overheated, will be cut off. Put the transmission in neutral and leave the engine idling. Very carefully open the radiator cap; live steam is likely to be forced out under pressure, so it is advisable to cover the cap with a thick rag for protection. With the engine still idling, slowly add enough water to fill the radiator. Allow the engine to continue idling until the temperature indicator returns to normal.

If opening the radiator cap reveals that the radiator is already full and additional water is not needed, the engine is probably being overworked and slower speeds and lower gears should be used. Alternatively, the thermostat may be blocked, preventing the flow of coolant through the engine.

1.05 Broken Steering Linkage

In the event of breakage of any part of the steering system, it will probably become impossible to steer the car, At low speed this may not be a crisis, but at high speed it may not be possible to avoid a crash. Stop the car as quickly as possible under such circumstances. The critical nature of the steering system makes frequent examination a prime safety consideration.

1.06 Steering Bent and Ineffective

If a car strikes a tree stump, rock, or other obstacle in such a way as to bend part of the steering linkage under the front end, the steering may become ineffective. The two front wheels may point toward each other, for example. You will usually be able to maintain enough control to stop safely.

1.07 Headlight Failure at Night

The obvious move in the event of headlight failure is to stop immediately. The well- prepared driver will have a flashlight with which to seek the difficulty.

1.08 Accelerator Pedal Stuck Down

Mechanical failure sometimes results in leaving the accelerator pedal down, rather than returning it when you release your foot. In this event the car will continue to move. If you cannot lift the pedal with the toe of the foot, shut off the ignition and brake to a stop.

1.09 Brake Failure

Before giving brakes up for lost, try pumping the pedal vigorously several times. This may provide enough pressure to stop the car. If it does not, several courses of action are open:

If the parking brake works, it can be used to stop the car.

If the parking brake does not work and if there is no steering lock incorporated in the ignition lock, you can shut off the ignition switch, leaving the transmission in gear. Engine friction will then slow the vehicle.

Alternatively, downshift to the car's lowest gear. This will bring the car gradually to a slow speed. When the ignition is then shut off, the car will stop.

There are also occasions when terrain may aid in stopping the car. A swampy section of road, for example, will serve this purpose, as will sand, deep snow, or an uphill grade.

2.00 OPERATING ON PIoNEER ROADS

Experience indicates that a number of factors contribute to successful operation on pioneer roads. Among these are a knowledge of the individual vehicle, the ability to load the car properly, and familiarity with the mechanical operation of the car. These various factors will be considered before any discussion of driving techniques.

2.01 Examining the Vehicle

Although it eventually becomes second nature, it is important to become familiar with your vehicle and to examine it carefully before starting on a trip.

Know which side the differentials are on, since they are usually not centered. The differential is the lowest point of the undercarriage on most cars. The driver can gain a few extra inches of clearance over a rock or stump by placing the car correctly over the obstacle, with the differential to the side. This allows the higher side of the axle to pass over the obstacle.

See whether there is a protective plate under the front end to guard the steering gear from obstacles. Such a plate is a good investment on a new vehicle. It usually extends from the underside of the radiator housing back to the crankcase, and on some cars covers the crankcase as well.

Know how wide the car is so that clearance between trees, rocks, or other obstacles can be accurately judged.

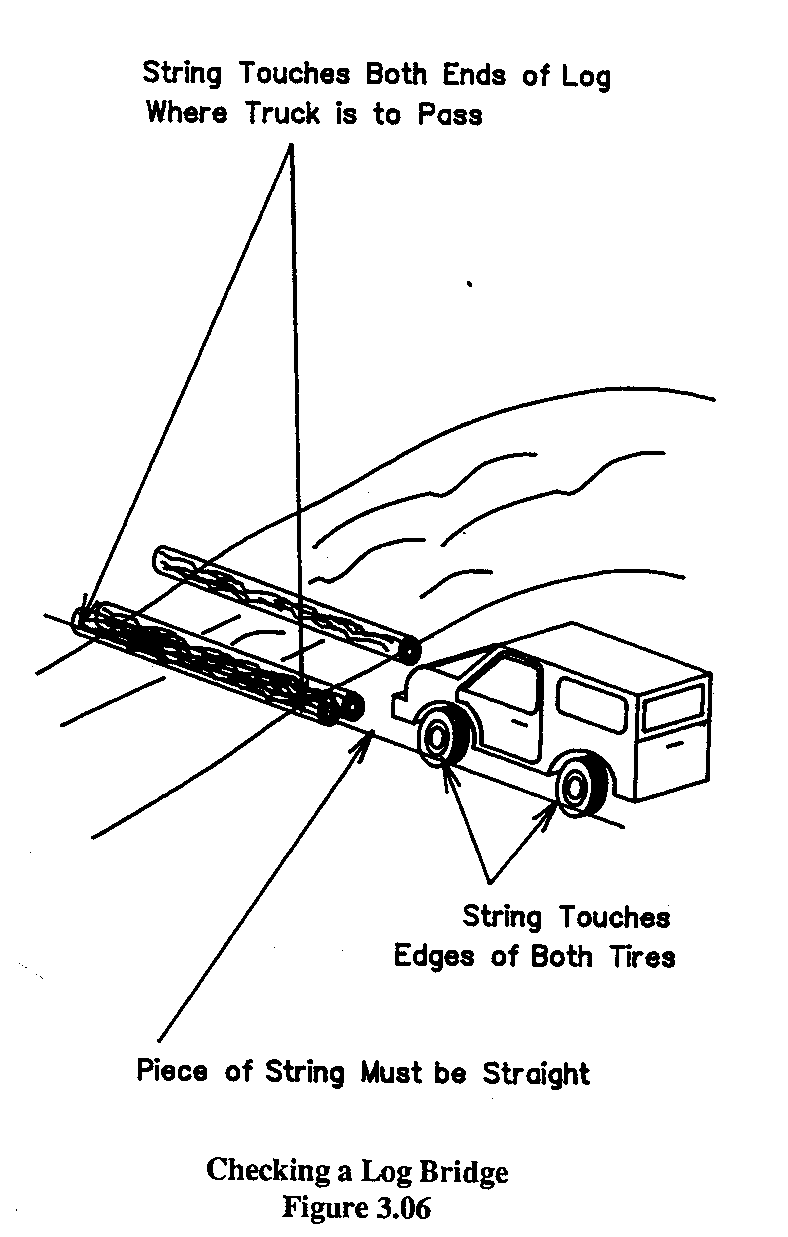

Know how far apart the tires are, especially in an area where log bridges are common. At first it is advisable to get out of the car when approaching a log bridge to be sure that you have estimated correctly before proceeding. (See Section 3.06.)

Know how high the top of the truck or the load is. This is important in relation to overhanging branches.

Beyond the dimensions of the vehicle, there are other mechanical details that should be examined before departing:

In areas with poor bridges, remove the cab doors if this is at all practical. The author and many of his friends have been saved from drowning by this simple expedient. If the cab has no roof, of course there is no need to remove the doors. On some vehicles it is possible to remove the top half of the door, leaving the lower half in place. Seat belts should be used to prevent the occupants from falling out of the car.

Be sure that the fuel tank is full before starting, even on a short journey. Even in familiar territory it is quite possible to get stuck and work all day to get free.

If there are racks for additional fuel or water cans, be sure that they are full before starting.

Check to see that oil, battery, radiator, power steering, and brake fluid reservoir are full.

See that the brake pedal does not feel spongy or sink to the floor, and that the hand brake will stop the car if necessary.

Be sure that there are enough spare tires to get where you are going, or have the tools and patches to make repairs on the road if necessary.

Examine the toolbox to see that it contains appropriate tools and spare parts.(See Section 14.10.)

2.02 Loading the Vehicle

The two most important factors in loading are the total weight of the load in relation to the capacity of the vehicle and the distribution of the load over the chassis.

The driver's manual for the vehicle will indicate the total load allowable. For a small car, the weight of the driver and any passengers may make up a large part of the total load. A full fuel tank may add 75 to 150 pounds (34 to 67 kilograms), and a spare five-gallon (19 liter) fuel can adds an additional 40 pounds (18 kilograms).

As a very rough rule of thumb for overloading, there should be some free movement between the axle and the chassis. The chassis should never rest upon the axle without any reserve in the springs.

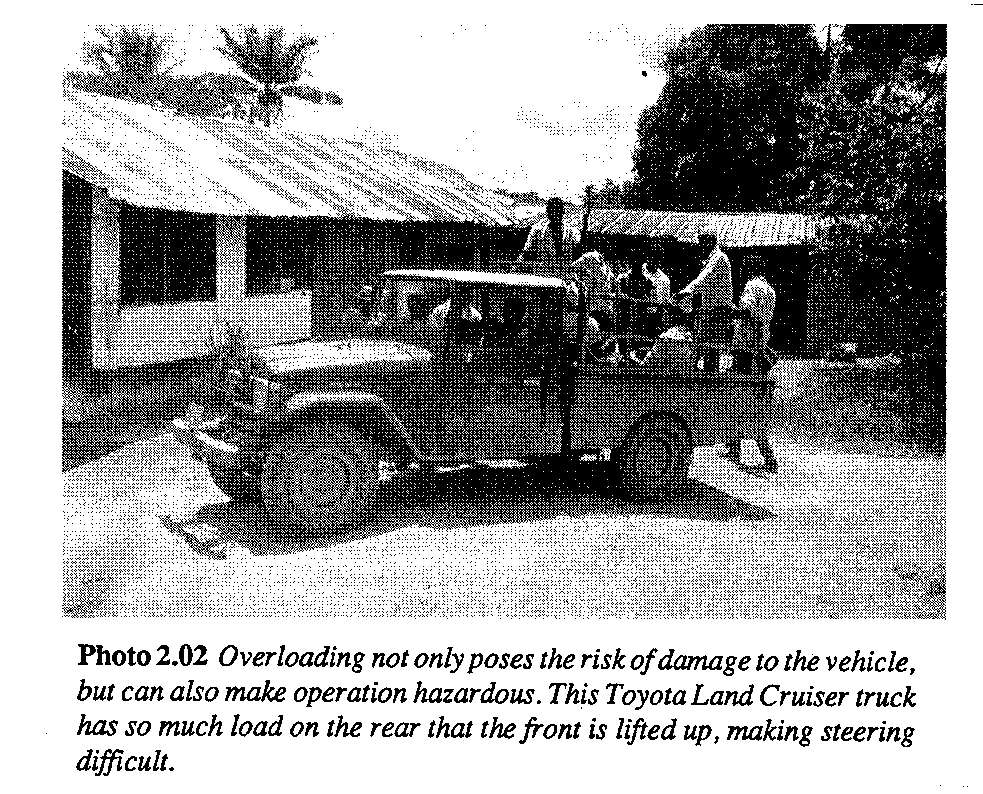

In balancing the load, spread the weight as evenly as possible between the front and rear axles. Concentrated weight on the front portion of the load box in a pickup truck, for example, may break the chassis even though the load does not exceed the maximum allowed in the driver's manual.

Weight placed halfway between the front and rear wheels will be supported equally by each axle. If all the weight is over the rear wheels, the rear springs and axle housing may be overloaded. If all the weight is concentrated behind the rear wheels, the front end will be lightened; it may even leave the ground, making steering impossible.

Formulas are presented in Section 20.00 for the mathematical calculation of the load on the rear wheels, although this is not necessary if common sense is used in load distribution.

If there is a choice of vehicles for a given load, use the one that will give the lowest center of gravity. That is, the one that will carry the load nearest to the ground. A pickup truck carries its load between the rear wheels, for example, while a stake body truck carries the load above the rear wheels. The result is that a pickup truck is more stable and less likely to capsize than a stake body truck of the same size.

Similarly, keep the heavy part of a load as low as possible in the truck. If the load is too high it will make the vehicle top-heavy. When a truck must of necessity be loaded so that it is top-heavy (for example, with a large machine), be very careful on roads with excessive crown or tilt to avoid capsizing the vehicle.

The load should not be allowed to hang out of the sides of the vehicle if this can possibly be avoided, since a hazard will be presented by trees, branches, buildings, and other vehicles.

After loading, be sure that the load is secure and cannot shift even if the car lurches severely. A load that shifts forward may injure the driver; if it shifts back it may fall out of the vehicle; if it shifts to the side the vehicle may be turned over. Tie the load to the car with ropes or ratchet straps with hooks on the ends, sold for this purpose. Tires that do not contain steel strands can be cut into long elastic straps with great strength for securing loads. Fastening the load tightly is especially important in the case of a small vehicle carrying a relatively large single unit such as a drum of fuel. A great deal of damage can be done by such a drum if it "gets loose" in the back of a pickup truck.

2.03 Introduction to the Cab

Before starting the engine, take a moment to familiarize yourself with the cab.

Many drivers believe that on pioneer roads speeds are so low that seat belts are not necessary. Experience will show, however, that they are a great asset. While there may be no danger of a collision in an area with very few cars, the seat belt can keep you from hitting your head on the cab roof on a rough road, or from falling out of the car if the doors have been removed.

One of the best safety rules for driving on rough roads is to keep the thumbs outside the rim of the steering wheel. Although unnatural at first, it soon becomes second nature, and if the steering wheel is wrenched away by striking an obstacle, the spokes cannot injure or dislocate your thumbs. This practice is not required on vehicles with power steering, but few true frontier vehicles are fitted with power steering, which adds to the complexity and cost and offers an unneeded opportunity for mechanical failure.

Hold the steering wheel with the hands in a position corresponding to the position of clock hands at ten minutes past ten. Two-handed steering is essential if roads are rough, and this position gives the best leverage for a turn in either direction.

In a snowy or rainy climate where the driver's feet will often be wet, remove the rubber pads from the pedals. The rubber will become very slippery when wet, making it hard to keep the feet on the pedals. (See Section 15.20.)

Although many cars advertise that three people can be accommodated in the front seat, it is much safer to carry only the driver and one passenger. This allows more room for the operation of the gear shift and the transfer case, and it is much easier for two people to get out of an endangered car in a hurry than it is for a third person sitting in the center of a bench seat.

2.04 Introduction to the Drive Train

Before starting off, a few words about the mechanics of the car are needed.

In an age where most sedans have automatic transmissions, many people are not familiar with the gear shift and clutch, or with their function. The gear shift is intended to allow the engine to operate at optimum speed regardless of the speed of the vehicle, since a gasoline engine develops very low power at low speeds. Thus in first gear the engine is turning rapidly but the wheels turn slowly; in top gear the engine and wheels are generally turning at the same speed.

The clutch separates the engine from the wheels for a moment so that the gears can be shifted. A clutch resembles two flat discs, one of which is connected to the engine and the other through the gearbox to the wheels. When the discs are separated, no power is transmitted to the wheels. When they are pressed together, the engine power is sent through the two discs to the wheels.

In order to shift from one gear to another, it is necessary to first depress the clutch pedal. This will disconnect the engine from the wheels so that the car is coasting freely. The shift can then be made, and the clutch released to apply power again. This process of clutching, shifting, and unclutching should not be hurried; the result is rapid clutch wear or even broken axles.

DOUBLE CLUTCHING is needed to shift from a high gear to a lower one. While synchromesh transmissions have made double clutching less critical and even unnecessary in some circumstances, the technique is still a great wear-saver for any gearbox. Double clutching allows the engine and the gearbox to be matched in speed before the gears are engaged. If this were not done, the gears would "crash," or grind against each other until they were meshed by force.

Double clutching is not at all difficult, but it does require some practice. It cannot be taught from a book, although some suggestions will be presented here for you to try in practice sessions.

Suppose it is necessary to shift from second gear down to first gear in order to slow the car going down a hill. With the car moving across the top of the hill in second gear, press the clutch down. Put the gearshift in neutral and let the clutch up. The engine is now connected to the gearbox, although the gearbox is in neutral and not transmitting any power to the wheels. Accelerate the engine until its speed approximates the speed at which it would be running if the car were in first gear. Then quickly press the clutch down, shift gently into first gear, and let the clutch up. If the estimate of engine speed is accurate, the spinning gears in the gearbox will be going at the same speed as the wheels, and will mesh without crashing.

Double clutching should become the natural way to get into a low gear when descending a bill. Use of the brakes will cause overheating and failure, possibly at a crucial time. In addition, braking on a slope can start the car sliding out of control. THE TRANSFER CASE is actually another gearshift added to the main gearbox to obtain even lower gear ratios. At these lower ratios the engine turns at high speed, thus developing peak power, while the wheels turn very slowly. In most 4WD cars the transfer case approximately doubles the overall gear ratio, meaning that the car travels only half as fast in low range as in high range.

The regular gearshift is used in the normal way in low range. If the vehicle can be accelerated to top gear in low range and you want to go faster, it is necessary to shift both levers. First shift the transfer case to high range, then put the gearshift into the appropriate gear. It may also be necessary to engage the front-wheel drive after shifting the transfer case. The whole shift may take so long that momentum will be lost, and the regular gearshift will probably have to be put into the first gear even though it is a lower ratio than top gear in low range.

2.05 Introduction to the Engine

For those who are not familiar with the basic principles of automotive engines, the following basic introduction may be useful:

Energy to move the car is derived from fuel, usually gasoline, which must be mixed with air to make it burn, and then must be burned in a controlled way so that the energy can be used.

Gasoline is stored in the fuel tank. From there it goes through tubing to a small pump, which forces it into the carburetor. At the same time, air is sucked through the air cleaner where dust and solid particles are removed, and into the carburetor. In the carburetor the fuel and air are mixed to a combustible vapor. This vapor is then sucked through the intake manifold to the engine itself. At the engine, the fuel vapor passes through a valve at the top of each cylinder, where it is sucked into the cylinder when the piston within it moves down, creating a vacuum inside the engine.

Some gasoline engines have no carburetor. Air is drawn into the cylinders by the action of the piston, and fuel is sprayed into the cylinders by injectors similar to those in a diesel engine. This "fuel injection" system is not commonly found on frontier vehicles because of its complexity and intolerance of poor fuel quality.

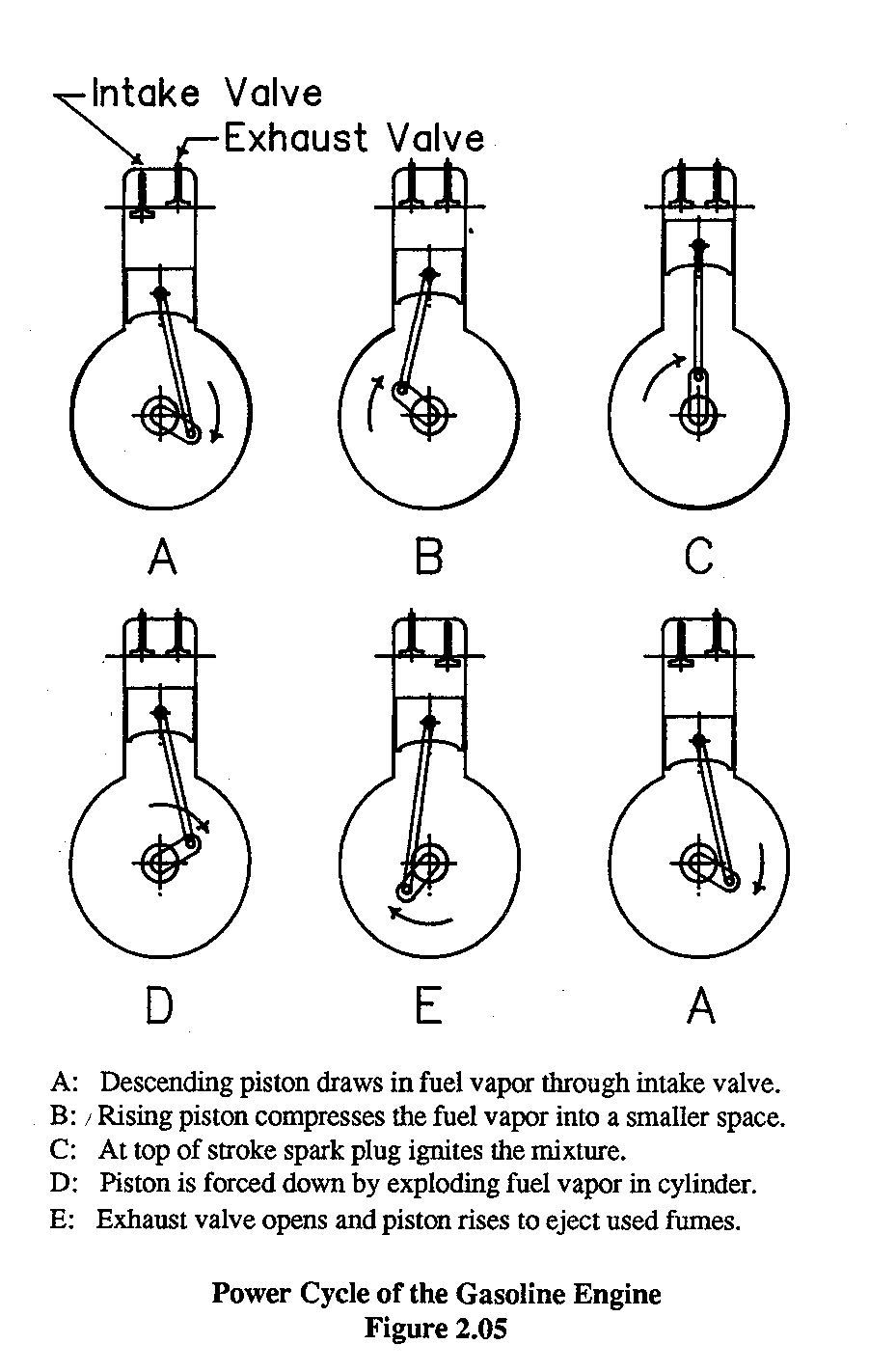

The engine operates on what is termed a four-stroke cycle. The four strokes are intake, compression, ignition (or power), and exhaust. On the intake stroke of a piston, the cylinder is filled with fuel vapor through the intake valve. As the piston reaches the bottom of the cylinder the intake valve closes, and the piston starts up again. The fuel vapor is thus compressed, cramming more energy into a smaller space. As the piston passes the top of its stroke, the space within the cylinder is smallest, and the fuel mixture is ignited by a spark from the spark plug. The fuel explodes violently, but since both valves are closed there is nowhere for the energy to go unless the piston is forced downward. This is the power stroke, and it is the energy of the explosion forcing the piston downward that turns the engine and makes the car go. The fourth stroke, exhaust, serves to force the used gases out the exhaust valve to clear the cylinder for the next cycle.

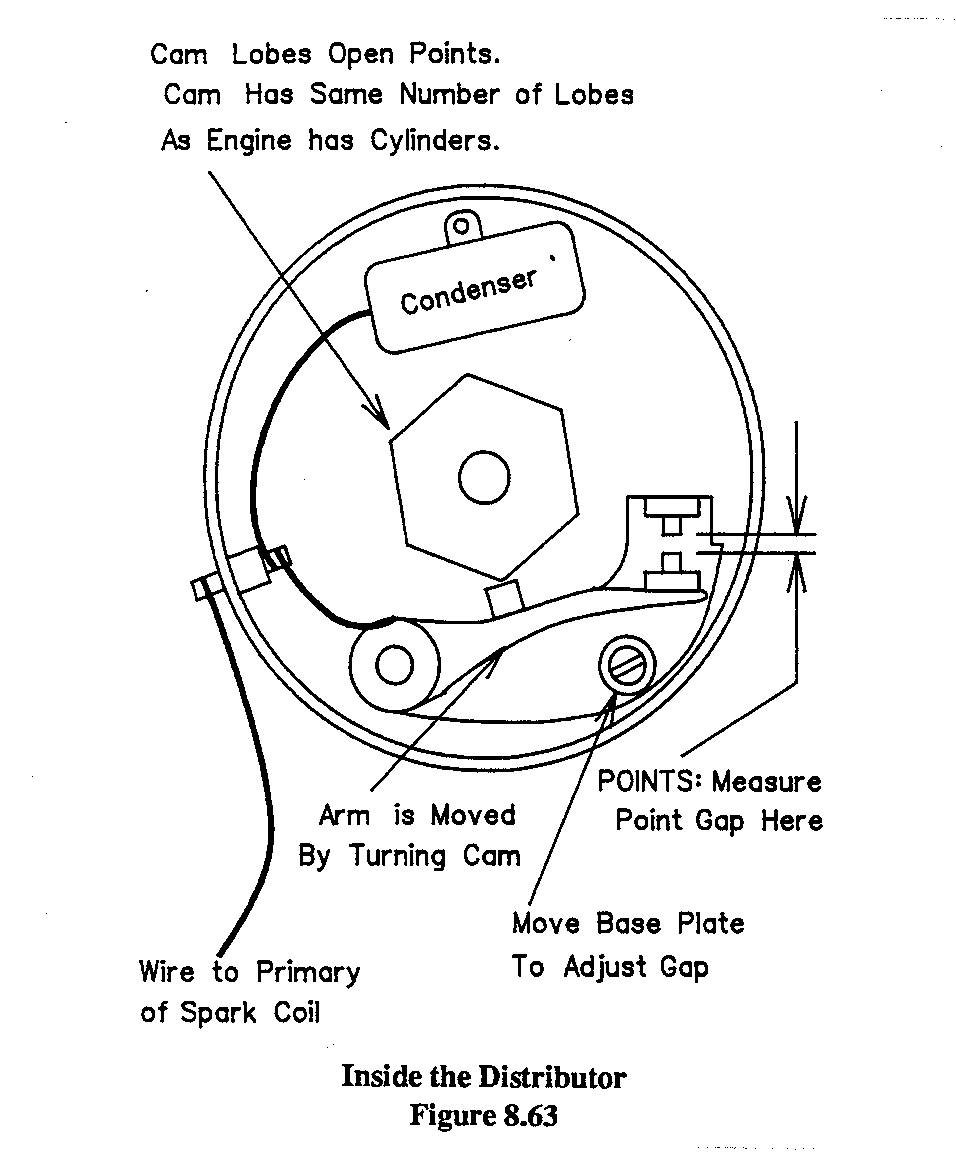

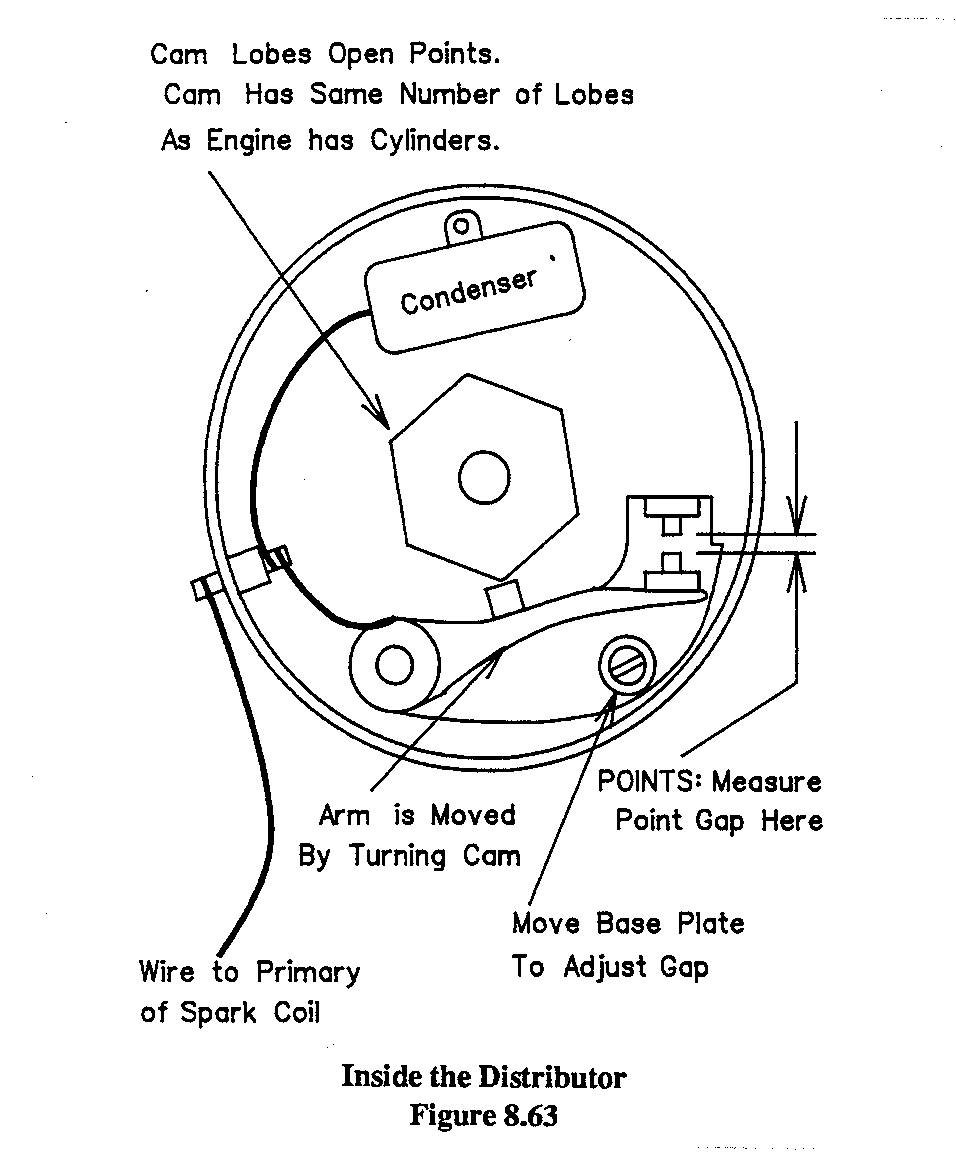

In order to keep this cycle moving, several extra parts are essential. The generator, which is turned by the engine, provides electric power to keep the battery charged for the operation of electric accessories such as headlights, windshield wipers, and the horn. The battery also provides power to the ignition system of the car; 12-volt power from the battery travels through the breaker points to the spark coil. There it is built up to a very high voltage, which is sent through the distributor to each spark plug at precisely the right time to ignite the fuel mixture at the top of the compression stoke.

The cooling system keeps the heat of the explosions inside the cylinders from damaging the engine. It consists of a radiator, fan, water pump, and a supply of cooling water which runs through little channels inside the engine block. The fan blows air through the radiator to keep it cool, and water flowing through the radiator is therefore also cooled as it circulates around its path through the engine, water pump and radiator.

There are several other accessories that are not strictly essential to the operation of the engine, but are useful or even vital parts of the car. The lights, windshield wipers, dashboard gauges, and speedometer fall into this category. The drive train has been discussed in Section 2.04, together with the principles of its operation.

Also essential, although not closely related to the work of the engine, are such frame parts as the chassis, upon which the car parts are mounted. On the chassis are the springs, which support the weight of the vehicle on the axles; the shock absorbers, which smooth out some of the road bumps; and the brake system, which stops the car. The steering system, also mounted on the chassis, is another separate entity that is essential to the operation of the car.

Each of these parts and systems is discussed in some detail in other section of this book. Refer to the index at the back of the book for a complete list of the various parts, their functions, and how to test and repair them when necessary.

3.00 AVOIDING ROAD HAZARDS

Having devoted some time to checking the vehicle, you can safely start on your journey. The difficult process of pulling a car out of a swamp or broken bridge, or removing it from a projecting rock or stump, can be eliminated by avoiding road hazards of this type. Knowing what to do in advance can save a great deal of time and effort.

The most common road hazards involve loss of traction, being hung up on the chassis, log bridge failures, capsizing, fording, and to a lesser extent, submerging. The following sections will illustrate in some detail how to avoid each type of problem.

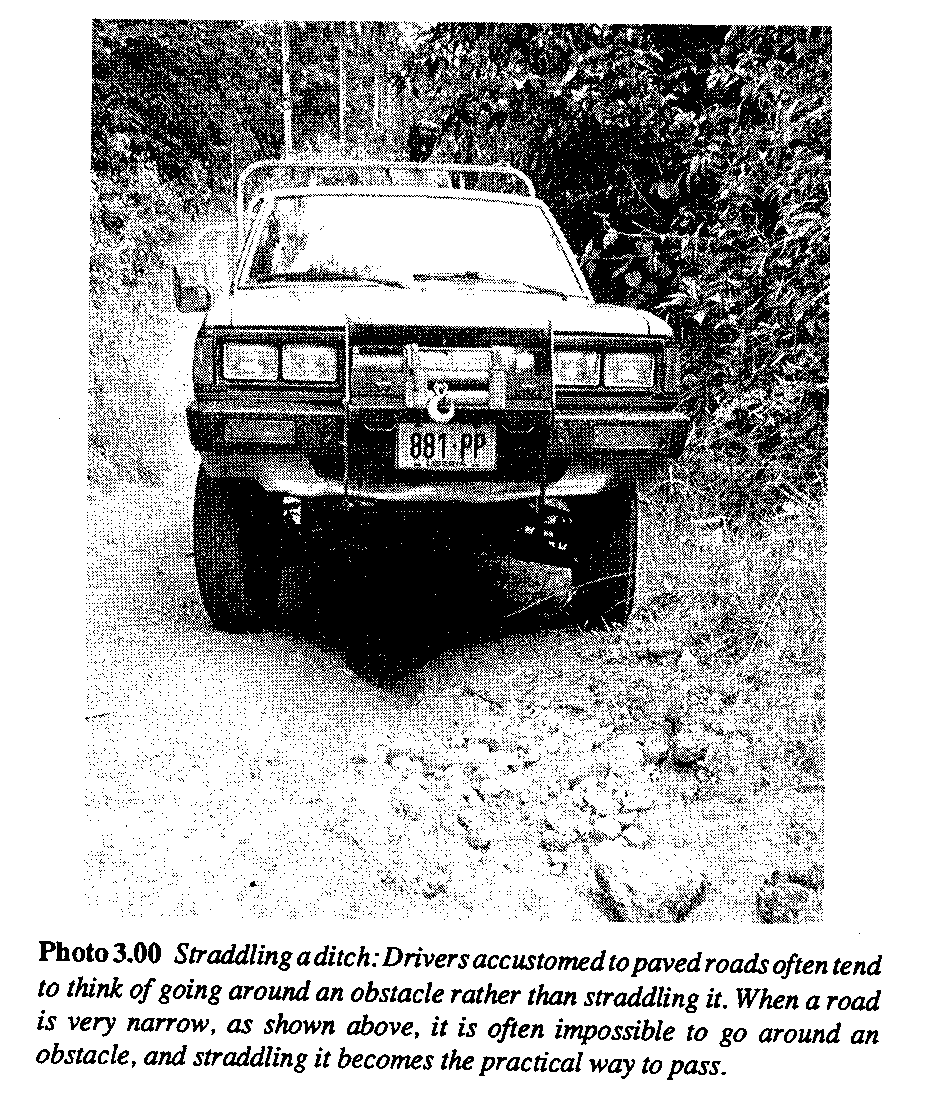

STRADDLING OBSTACLES such as potholes, rocks, and logs is a simple technique, and yet few drivers who are accustomed only to wide paved roads readily adapt to driving over an obstacle. All that is needed is a quick judgment of how large the obstacle is and whether the car will pass over it without falling in or getting hung up. If the car will pass, go over the obstacle rather than trying to pass around it. Going around an obstacle on a narrow pioneer road generally means going off the road, which is not usually a good practice.

RUTS AND GULLEYS can also be straddled in the same way. Often rain will wash a deep gully down the middle of the road or a hill, since that is the lowest part of the track. It is frequently safer to straddle this gulley than to go to one side of it and be forced off the road. Careful evaluation of a long gulley is necessary before starting over it, since it may widen farther along its course, trapping the car.

GRAVEL ROADS pose their own special problems. Although they are usually more passable in poor weather than dirt roads, the loose gravel is a hazard. Speed should be kept to 35 miles (55 kilometers) per hour or less because of the damage that can be done by flying gravel. When passing another car speed should be further reduced. In many areas it is common practice to cover the glass lenses of headlights with cardboard or heavy screening for daylight driving.

TAKING A HELPER is always good practice on a pioneer road. Even in a vehicle equipped with a winch, having another person with the driver makes it much easier to get the car out of trouble. A helper can make sure the car is lined up on a log bridge, can check to see that a suspicious rock will not hit the oil pan or steering gear, and perform similar duties. In many parts of the world it is possible to get such assistance in exchange for a ride.

DRIVING AT NIGHT should be avoided, especially in an unfamiliar area. When it is absolutely necessary, take a good flashlight in addition to any other necessary tools and supplies. If the car's lights seem very dim, check for mud or dust on the lenses. If allowed by law, it is often useful to add extra driving lights; they should be protected from branches and other obstacles.

A WORD ON BRAKES: Stopping the car with all four wheels locked up and not turning, although spectacular, is not the quickest way to stop. You also lose steering ability, since the front wheels can only be steered if they are turning. The best method, although it requires practice, is to use as much pressure on the brake pedal as the wheels can take without locking up. If they do skid, too much pressure is being applied.

When driving on mud or snow where traction is poor, continuous application of the brakes will send the car out of control. Under such conditions you can either steer or brake, and therefore must alternate between the two. Pumping the brakes is a good compromise: when the brakes are applied, the car slows but is unsteerable; when the brakes are released the car can be steered, but is not being slowed.

3.01 Four-Wheel Drive

The most common method of avoiding or overcoming road hazards is through the use of four-wheel drive. As the name indicates, this system provides power to all four wheels of the car, not just to the rear or front wheels as is generally the case with sedan-type automobiles. Any vehicle used for rugged driving is generally equipped with four-wheel drive.

When traction is a problem, such as driving on snow or mud, tire chains are commonly used. Tire chains, on the rear wheels or on all of the wheels, add significantly to tractive power on slippery roads. They are considered in Section 3.03. Improved traction can also be obtained with a limited-slip differential. This device is available on most cars as a factory option. It supplies power to the wheel with the best traction. While it does add to reliability, a limited-slip differential offers some special maintenance problems, and is therefore not a universally accepted device.

At least one vehicle, the German Unimog, provides differential locks that eliminate the slipping ability of the differential. As a result all power is transmitted to the tire with traction, even if only one tire has traction at the moment.

Four-wheel drive should be engaged only when it is needed. The practice of leaving a car in 4WD just because it might be necessary somewhere down the road greatly increases tire wear and may also damage the drive train. This is because all four tires are being moved under power, but the tires are not exactly the same size due to tire wear and differences in tread thickness and inflation pressure. The larger tire will go farther with a single revolution than the smaller one, and one of the two will have to be scuffed along to make up the difference between front and rear axle speeds. This scuffing wears away the tread, and if the road is hard and dry so that the tires cannot scuff, the drive train may be overworked and fail.

Experienced drivers will run in two-wheel drive until they see an obstacle ahead, then will shift to 4WD without stopping. Because the car is still moving at a good speed, the momentum may carry the car through the obstacle, with the help of the doubled traction that results from engaging the front wheel drive. Once past the obstacle, two-wheel drive can be resumed.

Some 4WD vehicles are equipped with constant four-wheel power supplied through a gearbox similar to a differential. This system allows for variations in tire size, eliminating dragging or scuffing and resulting tire damage. It also eliminates the need for a control lever to engage the front wheel drive. This system is more commonly found on luxury touring cars.

3.02 Traveling in Convoy

An excellent way to avoid getting stuck, or to simplify the process of extricating a stuck car, is to travel with two or more vehicles in a convoy. Each car can help the other, either pushing or pulling a stalled vehicle through difficult areas. If a car must travel on a poor road without a winch, having another car along with a winch is almost as good as having its own.

It is usually advisable to send the more experienced driver first when going in convoy in order to show the best way over or around obstacles. His chances of getting through a difficult area are improved by his experience, and if he passes and the following car does not, he can tow it through.

When different sizes of cars are traveling in the same group, the drivers should consider which one to send first. In deep snow, mud, or swamps, for example, the larger car should be sent through first. Its greater road clearance gives a better chance of getting through, and it can then tow the smaller car if it gets stuck. If the smaller car went first and got stuck, it would be necessary to pull it out backward (unless it had a winch) and then send the bigger car through.

On a bridge of questionable strength, send the small car first. A weak bridge may carry the smaller car where it would collapse under the larger one. The driver of the small car can evaluate the larger car's chances as he crosses.

3.03 Tire Chains

A great aid to getting through slippery areas is the use of tire chains. Chains are excellent in mud or snow, but provide a very rough ride on a smooth or hard road. They are a nuisance when they must be put on and taken off frequently to allow for alternating sections of good and poor road.

On very poor roads or where no roads exist, chains on all four wheels and the use of 4WD will provide a tremendous increase in tractive power. Tire chains should never be used on only two wheels if four-wheel drive is used. The difference in effective circumference of the tires with and without chains will cause tremendous strains to the car's drive train, which may damage the vehicle.

The best type of tire chains has V-shaped bars welded across the links that run around the driving surface of the tire. This bar gives both added strength and, more important, added traction.

The most important consideration for long life of tire chains is a good fit on the tire. The chain should be so tight that it cannot slip when the wheel turns. The springs or rubber circles used to pull the chains tight are not meant to hold loose chains in place. If necessary these spreaders can be supplemented with loops of inner tube rubber. To pull the chains tight, many drivers deflate the tire somewhat, fasten the chains as tight as they will go, and then inflate the tire to proper pressure. Another some what easier method is to put the chains on as tight as possible, then drive around a bit until they have "settled in." This should not take more than a few hundred feet (100 meters), then the chains can be pulled up again. It is surprising to see how much slack is left in the chains even though they were tight when applied. Similarly, it is good practice to stop periodically and check that the chains are tight while driving. They should never slap the fenders, exhaust pipe, or any other part of the car.

Driving with tire chains when they are not needed causes severe wear. If used on a hard-surfaced road, for example, the chains will soon be ruined by the friction and beating action.

3.04 Loss of Traction

Perhaps the most commonly faced hazard on pioneer roads is loss of traction. Slipping can be caused by mud, snow, ice, wet leaves, or similar surface conditions, or it can be related to another problem. For example, a car might be hung up on a rock and have the double problem of being anchored to the rock and having insufficient traction to pull off.

Driving on mud is very similar to driving on snow, except that mud offers much higher resistance to the passage of a wheel than snow does. In computing the rolling resistance, a measure of the retarding effect of a road surface to forward movement of a vehicle, the following formula is used:

(gross weight of vehicle, pounds or kgs) x (road factor) - 1,000 = rolling resistance (in lbs or kgs)

In this formula the following figures may be used for the "road factor":

good concrete road, 15 2 in (or 5 cm) of snow, 25 4 in (or 10 cm) of snow, 37 smooth dirt road, 25 sandy dirt road, 37 mud, 35 to 150, depending on type and depth soft sand, 60 to 150

Obviously in a practical situation a driver will not stop near a swamp and get our the calculator to figure what the rolling resistance will be. On a theoretical basis, however, from these figures it is evident that the resistance of mud is as much as six times as great as that of two inches (5 cm) of snow. To overcome the resistance, the driver will need to use lower gears or other tractive aids.

A little experience will indicate that different types of mud have different effects on the car. Some mud may be recognized by a distinctive color or appearance. The driver will learn to be prepared for deep, thick mud, a slippery hill, or some other difficulty solely by the appearance of the mud's surface.

To avoid getting stuck, a good basic rule is never to do anything suddenly while driving on a slippery surface. Brakes, accelerator, or steering, if suddenly applied, will usually result in a spin or slip. As a mental guide, it is often useful to pretend that there is a drinking cup sitting on the front of the car, full to the top with water. The goal is to drive the car without spilling a drop.

If the car does skid in mud or snow, keep off the brake pedal. It will only make the skid worse. Instead, gently press the accelerator and steer in the direction in which the car is sliding. This may not be the desired direction of travel, but as soon as the car is under control it can be slowed and turned.

In an area where loss of traction is a frequent problem, it is useful to carry a piece of burlap, canvas, or expanded metal to lay in front of a spinning tire. Planks are often used in the same way, but are less convenient to carry.

To avoid getting stuck in a swamp or mud hole it may be worth the effort required to cut leafy branches or sticks to throw in before attempting to cross. Branches, rocks, planks, sticks, sand, thick grass, or any other material that will increase traction may take less time to gather than would be required to pull the car out if it got stuck.

Inertia can be a great help in getting through a slippery area. If hills and swamps alternate, as is often the case, a driver can build up speed going downbill and drive into the swamp as fast as possible. The car will rapidly lose speed in the mud, but the inertia may carry it through. In any event, it will get farther than if the car had entered at slow speed. This method is rough on the car, and should never be used if a solid obstacle such as a rock or stump may be hidden in the mud, since it could rip the front end of the car apart. There is no way to get up any speed in an area where the hills are also slick, so under such circumstances this method is of no value.

STOPPING THE CAR can also be a problem where traction is low. Rather than use the brakes, which will generally cause the car to spin or slide, shift the transmission to a lower gear to slow down. If the car must be stopped, pump the brakes up and down.

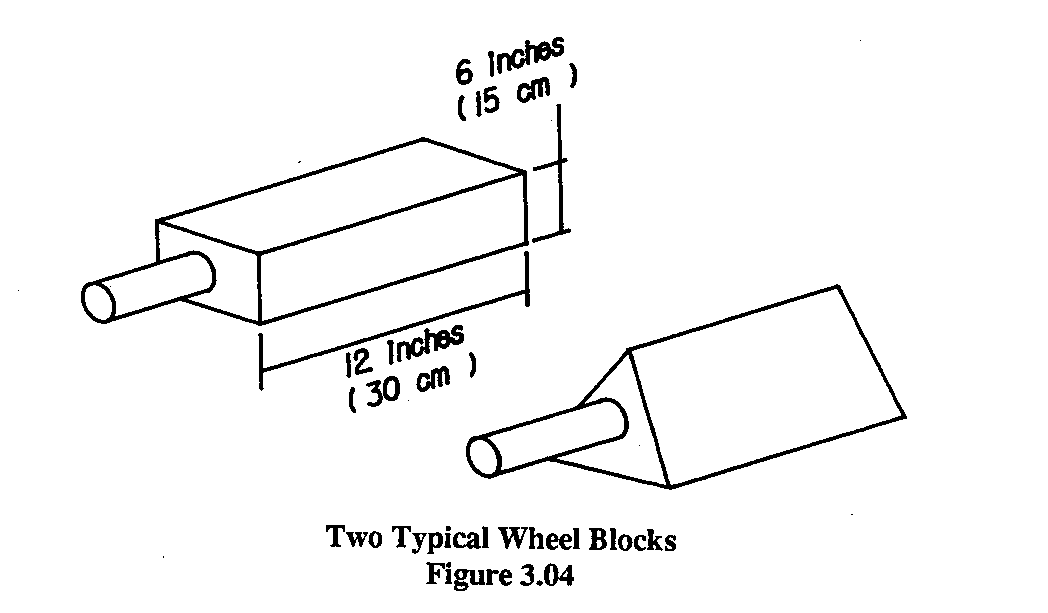

ON A STEEP HILL with poor traction a car may slip downward with all four wheels locked. This may be forward, sideways, or backward, or the car may spin slowly around as it goes down. The same aids that are useful for moving will also help to stop: tire chains, leaves and branches on the road surface, etc. Another great help in such a situation is the "Block," which increases the area exposed

to the slippery surface. The Block is nothing more than a large piece of timber, perhaps with a handle cut into one end, which seems to be a universal piece of equipment for driving on a poor road. It may be called a chock or wedge, or any of a hundred names in other languages, but it is found in any part of the world where pavement has not yet reached--and some where it has.

3.05 Piled-Up Mud or Solid Obstacles

Another obstacle caused by mud is the retarding effect when the chassis of the car sinks deep enough to get hung up on the road surface. This is a special hazard for cars with small tires and, consequently, a low frame.

If there are no rocks or stumps in the mud, the inertia principle described in Section 3.04 can be used to carry the car though the deep mud, or at least well into it.

Asking the passengers to get out before a deep swamp will lighten the load, and may help to avoid getting stuck. There is much to be said for the universal driver's slogan, "Everybody get out and push!" Getting out decreases the load and raises the frame of the car; pushing increases the tractive effort. If the other vehicles using the road are of similar size to your own, it is usually best to stay in the ruts on a very muddy road. The mud in the ruts is likely to be packed somewhat by earlier passages.

To avoid getting hung up, especially in a small car, it may be better to get off the road altogether under some circumstances.

Avoiding getting stuck in deep snow may be somewhat different. Often the snow is piled higher than the hood of the car, so that the problem is not merely one of getting hung up on the chassis. It becomes necessary to push the car into the snow, and the traction may not be adequate. The snow must be removed in such a case. This is usually done with a plow or blower mounted on the front of the vehicle.

In snow less than two feet (1/2 meter) deep, the principles used for driving in mud apply.

Avoiding getting hung up on rocks, stumps, and other solid obstacles is more a matter of judgment than power. Usually such obstacles are large enough to prevent passage, and one cannot simply push through without damaging the car. Keeping the car moving, then, means going around such obstacles if the car cannot pass freely over them. If there is any doubt, always get out and check.

3.06 Log Bridges

Probably the most common type of bridge on a frontier road consists of parallel logs laid across the stream. Generally there are three logs. One is on one side of the bridge, and two are on the other side. Both large and small vehicles will use the single log on one side, the inner of the double logs is arranged to fit the smallest vehicle likely to use the road, and the outer log will accommodate larger vehicles.

Avoiding getting stuck on such a bridge is largely a matter of getting lined up straight before starting across. While experience may allow some drivers to charge across without slowing down, the novice will do better to stop and check first. By sighting along the line of the logs it will be possible to determine whether the tires are properly lined up. Some drivers carry a piece of string for lining up bridges. One end of the string is held at the far end of the bridge and the other end at the back tire of the car; it should line up with the entire length of the log and the front tire of the car as well. (See Figure 3.06),

When you are sure that the car is lined up, shift the car into 4WD, but not low range. Move across the bridge as quickly as possible, so that inertia may carry the front wheels across even if the rear ones slip off or the bridge collapses. In such an event, the front wheels will often be able to pull the car across if they have reached the other side.

Once practiced, the crossing of a bridge of this type becomes quite routine, and the driver will learn to judge from some distance a rotten log or one that may slip sideways. If the capacity of the bridge is in doubt, it is usually advisable to ask passengers to walk across, thus lightening the load on the bridge and perhaps sparing them a dunking.

When crossing a bridge while towing a trailer, bear in mind the added length of the combined vehicles and do not stop before the trailer is fully across the bridge. (See also Section 6.80 on driving with a trailer.)

One of the most common problems with log bridges, other than collapse due to rot or overloading, is the separation of the logs. This allows the tires to slip off of the logs, trapping the car. This can be prevented by proper bridge design, anchoring the logs with stakes or large rocks at the ends. A driver approaching a bridge that looks like its logs may separate can usually save time by fixing the bridge before trying to cross. If the logs do drop the car, the bridge will have to be repaired anyhow.

3.07 Capsizing

A driving trauma to which many drivers may be unaccustomed is tipping over. This may occur due to the road surface or the way in which the vehicle is loaded, or both.

A vehicle body style in which the load is carried high, such as a stake or platform body, is inherently less stable than one where the load is low, such as a pickup body. (See Section 2.02.) Luggage racks on the roof will add to the tendency to roll over.

Capsizing can also result from the angle of the road. On a slick hill with a drop at the edge, for example, try to keep the car away from the ditch. If two wheels on one side slip into the ditch, even though it may not be very deep, the car is likely to roll over. The inertia built up in sliding into the ditch will help to carry the car over onto its side.

Being unaccustomed to pioneer roads, some drivers feel insecure on them. If a car feels as though it is about to tip over, it is often helpful to get out and look at it from in front or behind. Generally it feels worse than it looks, and a quick check will reassure the driver.

Some drivers tie a length of string with a small weight on the end--a stone or washer, for example--to some convenient part of the dashboard where it can hang down freely. As the car starts to tip the driver becomes familiar with how great an angle between the string and the floor represents a danger point.

For the novice, it may even be worth tipping the car intentionally just to see how far it can go before capsizing. The learning experience may save a lot of grief and anxiety later. Fortunately speeds on pioneer roads are low, so that there is no great danger to life from capsizing. The most notable exception would be a mountain road, where a great drop may be involved.

Although this section has emphasized techniques to be used in avoiding capsizing, there is an important point to remember if capsizing is inevitable: Shut off the engine. As the car rolls over, oil will be drained away from the oil pump intake, the engine will get no lubrication, and it will risk freezing up. After capsizing, of course, the first concern is the physical safety of the occupants. After that, reference may be made to Section 7.00 on field expedients for advice on restoring the car.

3.08 Fording and Wading

Because of construction problems, many frontier roads may not have bridges over minor streams. Cars are expected to ford the water, which is not common practice in areas where paved roads are the norm. Getting stuck while fording presents extra problems, and extra care is warranted to avoid stalling.

If unfamiliar with a ford area, stop and get out for a check before driving through. Walk through the water if possible on the same route the car will follow. The bottom should be relatively firm and free of large rocks. There should be acceptable entrance and exit paths. The current must not be strong enough to carry the car off, and the water should not be too deep. The allowable depth will be governed by the size of the car. Knee deep or slightly more is usually the greatest depth that a small car such as a jeep or land rover will cross safely. A larger truck will be able to go proportionately deeper.

If the water will be deep enough to wet the fan blades, loosen the fan belt temporarily while crossing, so that the fan does not turn. This will keep the ignition system from getting sprayed and drowned. Of course, the fan belt must be tightened immediately after crossing the ford.

If the car has a clutch housing plug, as the Land Rover does, be sure it is in place before entering the water. This plug drains moisture from the clutch housing when it is removed, but the clutch would be "lubricated" by the water and the bearings would be corroded if the housing were full of water.

While fording, keep the left foot lightly on the brake pedal. This will keep water from getting between the brake shoes and the drums, which would lubricate the brakes and make them useless. Disc brakes, available on some 4WD cars, greatly reduce the problem of water lubrication.

Drive the car slowly through water, since high speed will result in water being thrown up by the wheels which will drown the ignition system and stall the car. A diesel-powered vehicle such as the Unimog or a diesel Land Rover offers the advantage of having no ignition system. It is consequently much more reliable for fording than a gasoline engine.

If current in the stream threatens to wash the car downstream, attach the winch cable to a tree on the other side before starting across. If there is no winch on the car, put a wire cable across the stream along the down-stream side of the ford area to act as a guide for the car. This cable should be securely anchored to trees or rocks on each side.

After completing the ford, check to see that the brakes are working. If they have become wet and are ineffective, hold the brake pedal down lightly while driving; the heat will dry the brake linings and restore stopping power.

If the fan belt gets wet while crossing it may slip and fail to cool the radiator or turn the generator. For a quick check, look at the ammeter. If it shows a discharge rather than a charge, the belt is probably slipping. Stop and dry the belt with a rag.

Fording with a trailer can be simplified by unhitching the trailer and sending the car across first, then towing the trailer across with a length of wire rope.

If the water is deep enough to cover the exhaust pipe, the pressure in the exhaust system may reduce engine power or stall the engine. Once the engine has stopped the water pressure will make it virtually impossible to restart, and the car will have to be towed out.

If a car is driven into water that is too deep, or where the bottom is unsatisfactory, it may stall or capsize or both. Stalling on land is of little consequence, but in water it may be a serious matter. Extra attention to fording is therefore worthwhile.

3.09 Submerging

Submerging accidents may result from a broken bridge, a ford that is too deep, or from slipping off an adjacent road into deep water. In all of these cases the accident can be avoided by the exercise of sufficient care.

As outlined in Section 2.01, it is well worth the trouble to remove the doors if a submerging accident is even a remote possibility. This simple expedient can be a real life-saver.

If submerging is inevitable, it is important to shut off the engine before it goes under water. This will prevent the pistons from drawing water into the cylinders and trying to compress it as they do the gas-air vapor. Water cannot be compressed, and the engine will be ruined in the attempt.

If there is time, it is advisable to shut off all electrical accessories that may be running: lights, radio, windshield wipers, electric fuel pump, etc.

See instruction in Sections 5.01 and 7.20 regarding recovery and restoration of a submerged vehicle.

Although most drivers would be reluctant to experiment, it is interesting to note that the classic Volkswagen "Beetle"--one of the most widely distributed vehicles on earth--will float in water for a short time if lightly loaded. Opening a door, however, lets the water in and sinks the car, so it is necessary to escape through a window.

4.00 EXTRICATING THE VEHICLE

No matter how carefully they may try to avoid hazards, even the best drivers will find that on some roads there are obstacles that cannot be passed by ordinary means and the car becomes stuck. This section presents a number of suggestions for getting out of difficulties involving mud, rocks, log bridges, and other hazards.

The first step when the vehicle is stuck is to consider what resources are available. The greatest asset is probably a winch. There are few problems that cannot be remedied with this all-purpose tool, since it can move the car without traction. The uses of the winch are so varied that an entire section (Section 6.00) has been devoted to its operation.

Even lacking a winch, however, there are many things that can be done to extricate a car before it is necessary to give up and send for help--if any is available.

A SHOVEL is a very basic tool, and should be a part of the equipment carried in the car if mud, sand, or snow must be crossed.

EXTRA JACKS provide tremendous power, although the travel they can provide is limited to a few inches in most cases.

PLANKS can be used as levers, hole fillers, mats to provide traction, etc. They make good platforms for jacks, which otherwise may slip and drop the car.

A BLOCK AND TACKLE can multiply a person's pulling power several times, and there are many types of ratchet hoists and similar devices that can be used to move a stuck vehicle in much the same way as a winch except that they are hand powered and do not have the speed of a winch.

ANIMALS are often overlooked as a source of rescue power. The kind of animals available will vary widely from one area to another, but any animal that can pull a plow should be capable of pulling a car if necessary. In areas where human labor is inexpensive and plentiful it is often possible to gather a group of people to haul on a towrope for a small fee, or even for no charge at all if motor vehicles are enough of a novelty.

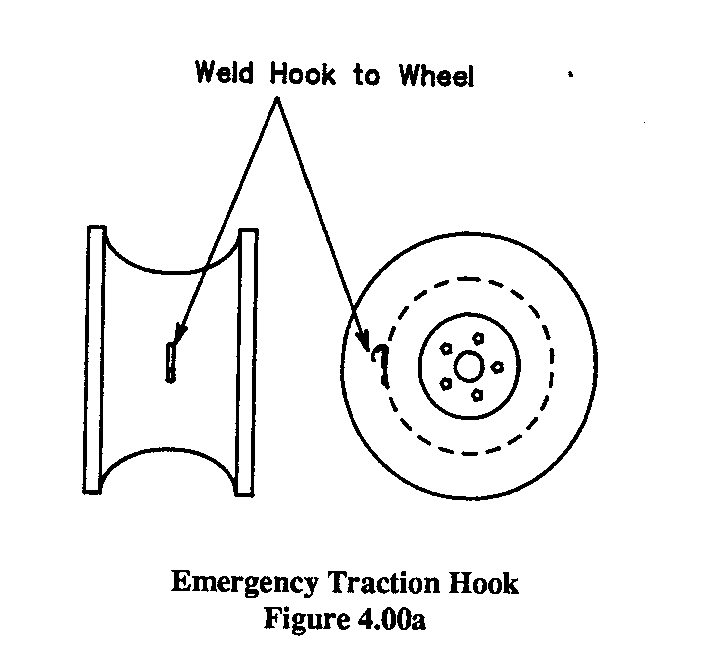

WELD A HOOK onto a wheel for use in an emergency as a replacement for natural traction. Weld the hook in such a way that it would be inside the tire if a tire were fitted to the wheel. When stuck, jack up and remove the slipping wheel and replace it with the prepared wheel. Attach a rope to the hook on the wheel and attach the other end to a solid anchor such as tree or rock, in front of the car. Drive the car forward, letting the hook hold the rope and wind it onto the wheel like a winch. (See Figure 4.00a)

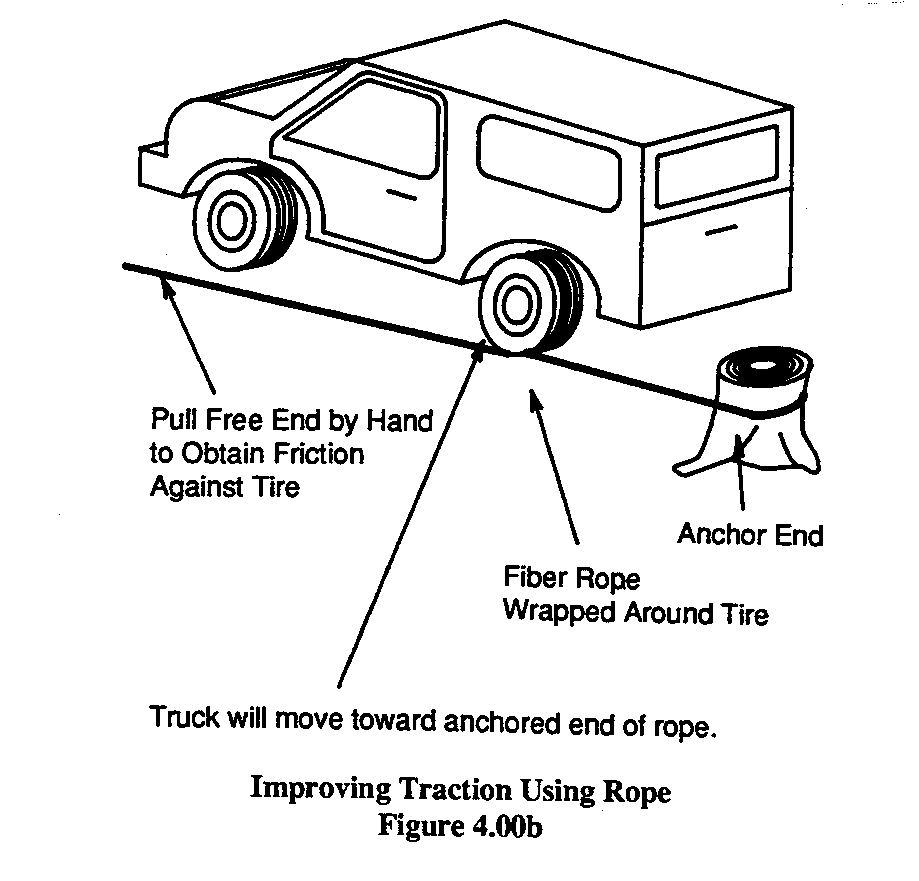

FIBER ROPE can often be wrapped around a tire in much the same manner. The trick is to drive the car along the length of the rope until it is out of the difficult area. With wide tires this is not difficult, and is a very satisfactory way of extricating the car. (See Figure 4.00b.)

A POOR PRACTICE is that of attaching a rope to the propeller shaft to get pulling power. The shaft was not meant to handle a pulling load from the side; it is intended only to transfer a twisting motion from the gearbox to the differential. The use of a propeller shaft in this way may bend the shaft or damage the universal joints.

STURDY VINES can often be used as ropes if not enough manufactured rope is available. Generally the vines should be twisted to separate the fibers at the point where a knot is to be made, or else the vine will break. In many tropical areas there are vines that will serve very well as towing cables, taking a surprising amount of strain without breaking. Residents of the area will probably know which vines are useful for this work.

TWO-WAY RADIO is not a resource in the same way as the other items listed here, but it is a great aid in many cases. With it advice can be sought, and if the car cannot be extricated the radio can be used to send for assistance. Where radio is in common use in this manner, everyone seems to make check calls on the hour, with resulting confusion and jammed frequencies. A much more satisfactory arrangement is to make check calls at some less common time, perhaps 20 minutes after the hour.

4.01 Stuck in Mud or Snow

Cars get stuck in mud or snow in two basic ways: They either lose traction on a slick surface or become bogged down when the frame is hung up. A combination of both is also common. This section considers the loss of traction.

Since 4WD increases traction and eliminates "dead" wheels, the problem of loss of traction is most commonly faced on a hill. In flat areas the 4WD will usually overcome lack of traction, especially if used with tire chains on all four wheels. A hill requires greater traction than flat ground.

If a car slips while trying to climb a hill, it may be useful to remove some of the load from the vehicle and make another attempt. As outlined in Section 3.05, there is a reason why most foreign drivers soon learn to say "Everybody get out and push!" in the local language. This method, though admittedly primitive, lightens the load and increases the traction.

Spinning the wheels in an effort to get out of a muddy or snowy spot will rarely do any good at all. The temptation is to use a heavy foot on the accelerator; it often seems that sheer power should get the car out. This is not the case, however. The spinning will soon overheat the tires, bonding the inner tubes to the tires, melting the inner tubes, or even setting fire to the tires. A little experimentation will reveal that the greatest traction is obtained by creeping the car out of such a spot as slowly as possible so that the wheels stick to the surface rather than spin.

Another technique of little value in an extended swamp, muddy hill, or snowy area is rocking the car back and forth, which may be done with the engine or by pushing it. While it may get the car out of the slippery spot if it is small, a 4WD car is not likely to get stuck in a small slippery spot. In a swamp, for example, it will take a great deal of rocking to get to the other side.

There are a number of useful methods that can be applied when stuck in snow or mud for lack of traction. They are presented here in no particular order, and should be selected in relation to the problem at hand.

A LIMITED SLIP DIFFERENTIAL may be aided in its work by lightly pressing the brake pedal with the left foot while operating the accelerator with the right foot. This will simulate traction for one of the wheels if both wheels on an axle are spinning. Then the special differential will be able to do its job of providing power to the wheel with better traction.

A SPINNING WHEEL on a car without a limited slip differential can often be slowed by lightly pressing the brake pedal, as outlined above.

MOMENTUM may help get a car through a slick spot. If stuck, back up as far as possible, then charge into the obstacle with as much speed as possible. Momentum may get the car through; it should at least move it a few feet more from where it had been. The process can then be repeated.

BRANCHES, brush, sand, boards, grass, rags, or anything else that might increase traction can be put in front of the wheels if the car can back up a bit. This improvement may be combined with the momentum method mentioned above to get the car moving again.

THE JACK can be used to lift the wheels if the car cannot move backward or forward. Raise a wheel and put in rocks, sticks, burlap, grass, branches, a truck tarpaulin, or anything else that may increase traction. Let the wheel down with the jack and repeat the process on the other wheels.

PATIENCE can be a virtue if the sun is shining on a car stuck in mud. Using a shovel, remove mud from around the vehicle, and let the sun dry the area sufficiently to allow the car to move. Often this may take some time, but the time would otherwise be spent in hard physical labor trying to get the car out, and it is much easier to wait for the sun to do the work.

MOVING WATER in a swampy area can also be used to carry mud away. It will be necessary to channel the water, using a shovel, so that it will move the mud from the area where the car is stuck. If the mud rests on a hard base it will probably soak up the water and make more mud, worsening the problem.

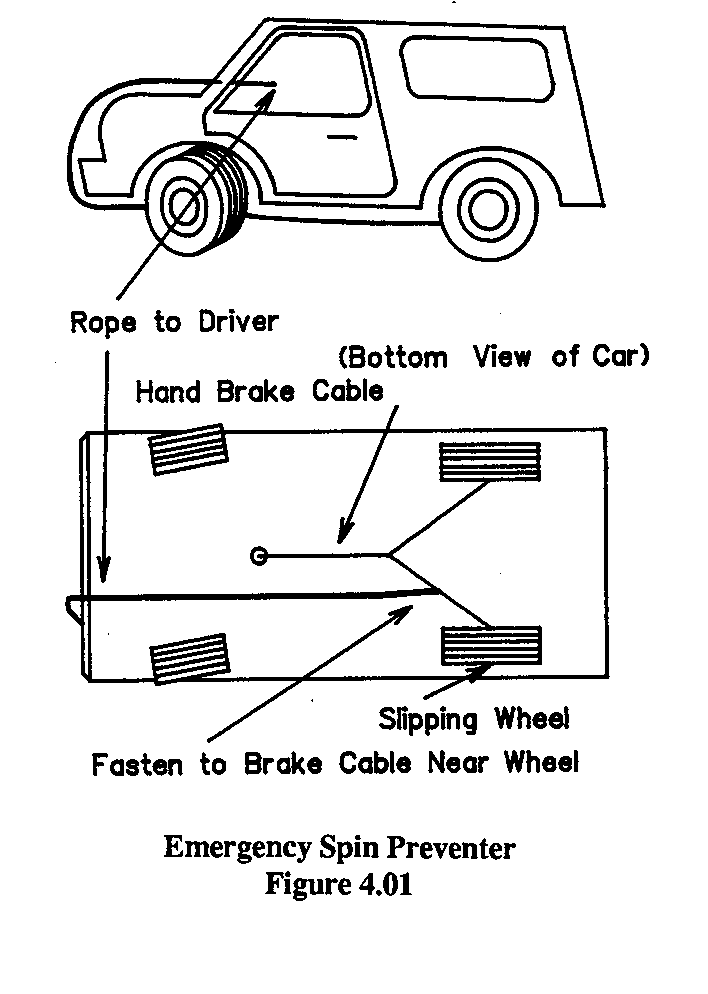

THE PARKING BRAKE can often be used to hold a spinning wheel so that the other wheel on that axle can be used to move the car. If the car has parking brakes on each rear wheel rather than a single brake on the transmission, fasten a rope to the wire cable that operates the brake on the spring wheel using a C-clamp or locking pliers. Pass the rope under the chassis, under the front of the car, and into the cab. Pull hard on the rope, possibly using a short lever such as a stick of wood or hammer handle, and this will pull the wire cable, setting the brake on one wheel. While holding the brake on, gently apply power. As the car begins to move, release the parking brake extension rope and drive out of the difficult area. (See Figure 4.01)

If this method cannot be used, almost any means can be tried to stop a wheel from spinning. Some suggestions include wedging the space between the spinning wheel and the body with a big plank, chaining the wheel to the chassis so it cannot turn, or jamming it with rocks under the fender. The other wheel on that axle will then get the power that was wasted on spinning, possibly moving the car. Of course, such wedging or other fastening must be removed as soon as the car is free or the wheel will be dragged and may halt the car.

All of these expedients are made unnecessary on the Mercedes-Benz Unimog, which has locks for both differentials. Both wheels on the axle lock together so that if either one gets traction it will move the Unimog, and the other won't spin.

4.02 Hung Up in Mud or Snow

The second major threat from mud or snow is snow deep enough in it to allow the chassis to become hung up. This creates so much drag on the car that the tires lose traction, and the car cannot proceed.

This difficulty is often more easily dealt with than that of pure loss of traction, since the driver is able to see the obstacle and can either remove it or go around it. Perhaps the most common method of extricating a car from deep snow or mud is to dig it out, thus removing the obstacle.

As outlined in Section 3.05, there are snow conditions in which it is unreasonable to expect a car to operate without a plow. If snow is two feet (1/2 meter) or less in depth, a 4WD car with chains should be able to get through.

If the front end is hung up in the snow or mud, try backing out. It may help to add some traction under the wheels using sand, gravel, sticks, leaves, grass, planks, or whatever else is at hand. Once off the obstacle, cut it down with shovels and try again.

If a snow drift threatens to block forward progress, the driver can try pushing ahead into the deep section, stopping before becoming hung up on the snow, then backing out and trying again. A short distance will be gained each time until the car breaks through the drift. Drivers who hit the drift at full speed generally get hung up before breaking through.

Removing part of the load is another useful expedient. It allows the frame to rise on the springs, since the springs are not so heavily loaded. This increase in ground clearance may make it possible to get the car out. It should at least make it easier to free the car. The axles may rise slightly as a result of reduced load on the tires, but will not rise as much as the chassis.

If the car cannot be backed up, it will be necessary to lift it over the obstacle. With a small car and a large number of people it may be possible to lift the car enough by hand to get off the obstacle. Otherwise jack up the wheels one by one and pack the space under them with logs, sticks, or planks. This will provide a raised roadway, albeit rather crude, on which the car can be driven over the trouble spot.

Once the car is moving again, use every means to keep it going. Momentum is a great aid to getting a car through deep snow or mud, and keeping a car moving slowly is much easier than getting it started from a dead stop. If the hazard is an extensive one, it may be advisable to drive with one side of the car off the road, up on the ridge of snow or mud, if the ridge is packed hard enough. Once moving, Sections 3.04 and 3.05 will provide some assistance on how to keep the car going.

4.03 Hung Up on a Solid Obstacle

Although similar to being hung up in mud or snow, the problem of getting stuck on a rock, stump, or other solid obstacle presents its own difficulties. The prime concern is to avoid damage to the car, since a rock can rip a hole in the crankcase or gas tank or cause damage to the steering or drive train.

It is not usually practical to pull a solid obstacle out from under the car, since the weight of the car is resting on it. If the car has a winch, it may be possible using the technique described in Section 6.52. The only alternative is to lift the car off the obstacle. The most common way of doing this is with a jack, lifting the car and placing logs or planks under the wheels to raise the chassis off the obstacle. It may only be necessary to raise one side of the car, particularly if the obstacle is off center.

4.04 Log Bridges

Getting stuck in a log bridge can mean either the inconvenience of having to extricate the car from between the logs or the major calamity of losing the car into the water. Difficulties involving submerging are discussed in Section 5.01.

If the tires are stuck between the logs of a bridge, spinning will rarely get them out. As explained in Section 4.01, the heat that results from the friction will only damage the tires. Much greater tractive power results if the wheels do not spin.

Often it may be possible for several people to lift a car upward and forward while it is driven off the bridge.

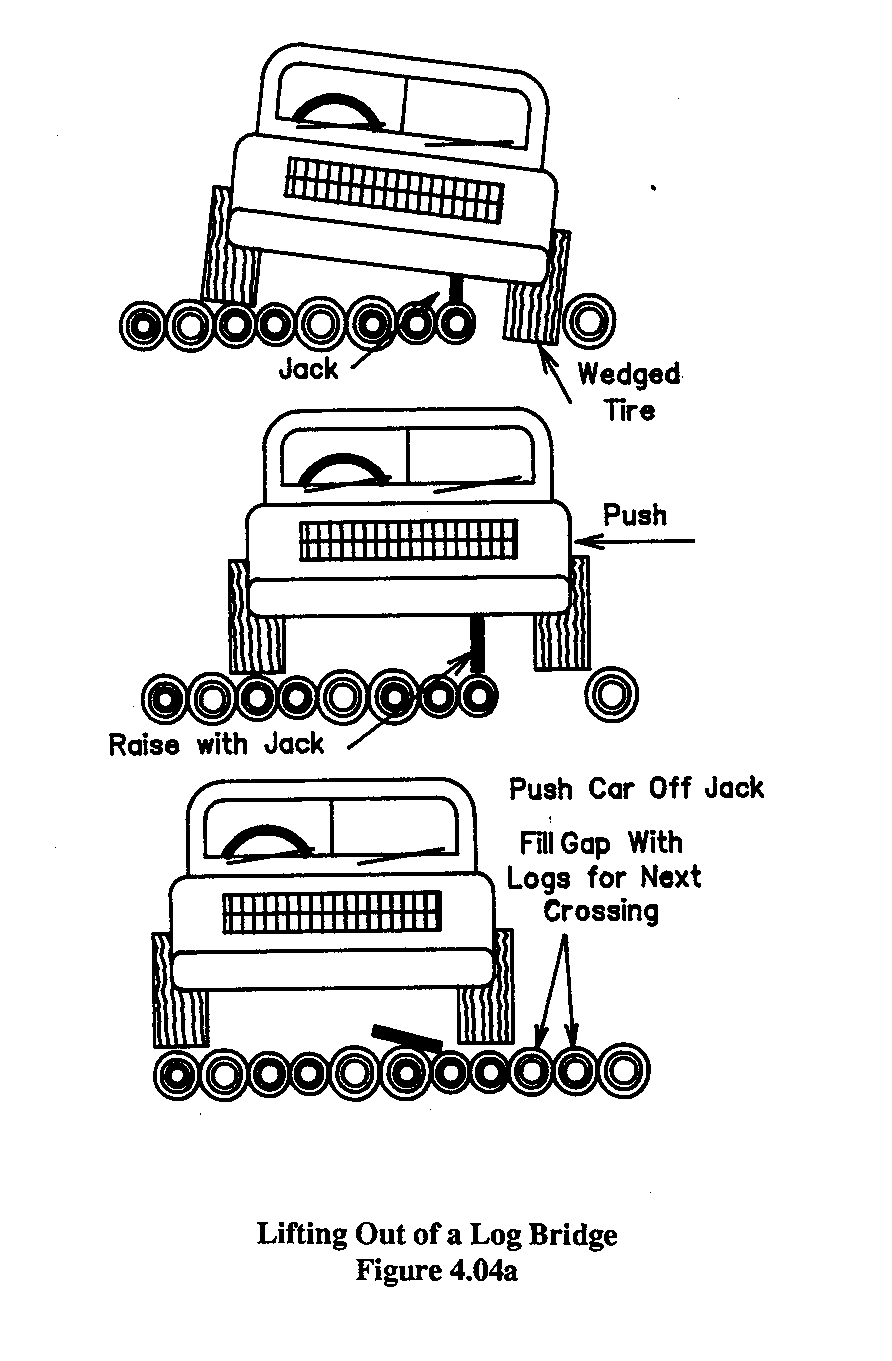

A jack can be used to lift the wheel from the space between the logs, and the car can then be intentionally pushed sideways off the jack, dropping the wheel onto a log. (See Figure 4.04a)

A plank can be used to fill the space between logs. The tire should be jacked up from the hole and the plank inserted under it to provide a temporary roadway. The tire is then lowered onto the plank and the car driven off the bridge.

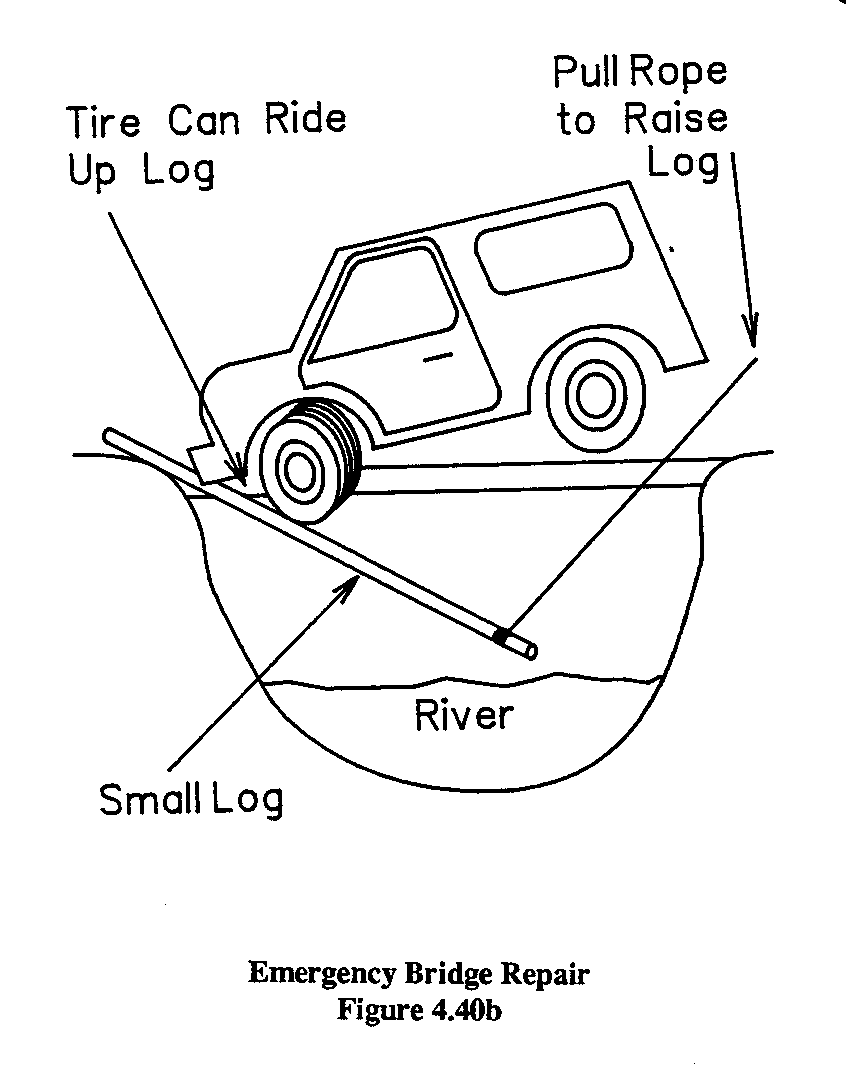

A small tree trunk or branch can be used as a ramp from below the bridge in some cases. Insert one end of the log, perhaps four inches (10 cm) in diameter, in between the separated logs in front of the stuck tire from the underside of the bridge. Push it forward as far as it will go, and then raise the free end from the river until it meets the tire. A rope can be used to haul the lower end of the log upward and secure it temporarily while the car is driven off. (See Figure 4.04b)

4.05 Fording

Being stuck while fording a stream is no different from being stuck elsewhere, with one principal exception: if the car is stuck with the engine or tailpipe under water, do not try to restart the engine once it has stopped. Pull the car out of the water with other power: people, another car, animals, etc.

Otherwise, all the expedients listed elsewhere in this section apply to a car stuck in water.

5.00 PROCEDURES WHEN STRANDED

In the event that none of the advice given in Sections 4.00 through 4.05 or any other attempts will extricate the vehicle, then it may be considered stranded, and additional assistance will be necessary. In this event one must either await the arrival of help or go and look for assistance.

There are many parts of the world where being stranded is a serious matter, due to intemperate weather, wild animals, lack of food or water, or simply the remoteness of the area. This book is not intended as a survival course, but there are several items to review in advance, before you find yourself stranded.

Because of the variety of supplies that may be needed in a vehicle used in a remote area, a complete section (Section 14. 10)has been devoted to this subject.

LEAVING THE CAR is generally not a good idea unless you (or a member of your party) are absolutely sure of where you are and where the nearest source of help is, and how to get there. In hot areas such as deserts the car provides shelter and shade, which are not available elsewhere. The best shelter in a desert will be found by digging a hole under the car.

In very cold climates the vehicle will provide shelter from wind, and the bulk of the car makes it more easily seen by potential rescuers than an individual person walking alone.

In any climate the car will provide shelter from animals. Even if the car has turned over, it is generally safer and more comfortable to sleep in it than on the ground. A check should be made to see that no gas is leaking to cause a fire hazard.

A WATER SUPPLY should be carried in the car in any area where drinking water is not readily found.

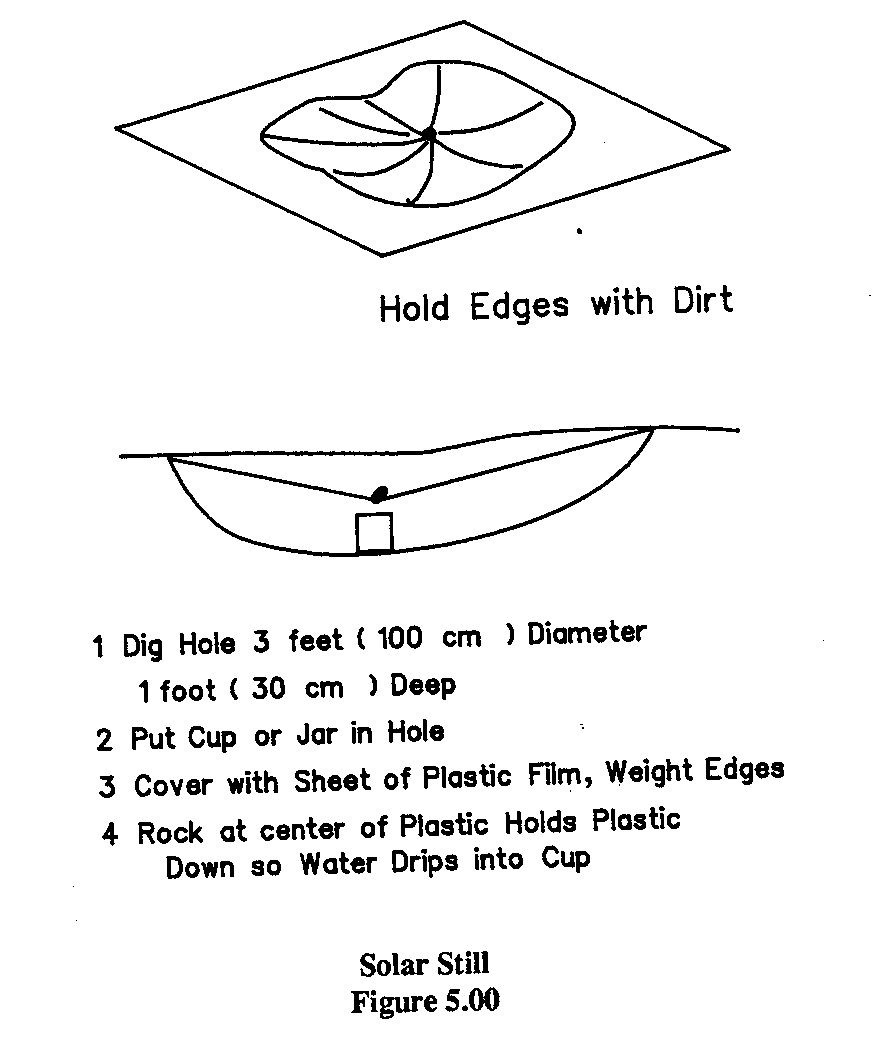

In a warm climate, if no water is available, a simple solar still can be constructed. Dig a hole about a foot deep and three feet in diameter and place a cup or other container in the middle of it. Lay a sheet of clear plastic over the hole and weight the edges with a ring of dirt to hold it in place. Into the center of the plastic drop a small stone so that the plastic points downward into the cup. Water will condense from the soil due to the heat of the sun, and will drop from the center of the plastic sheet into the cup. (See Figure 5.00)

In snow-covered areas, snow can be melted to provide drinking water. If there is no wood Or Other local fuel, consider putting a small amount of gasoline on a disposable air cleaner element and burning it. Snow can be contained in a hubcap or a tool box for heating over the fire.

WALK FOR HELP only along the road, if there is one, unless a member of the party is very familiar with the area. In general, even though the distance is greater, it is better to follow the road when searching for assistance. This is especially true if there are any other vehicles in the area that might use the same road or a connecting road.

SIGNALS can be made to attract attention, either by day or night. If people are known to be nearby, it may be possible to attract their attention by sounding the car horn.

In the daytime, a smoky fire will usually be seen from a distance of many miles on a calm day. Gasoline from the car can be used to start the fire. For fuel, either sticks or a tire can be used. Once a good fire has been made with dry sticks, green branches can be added to make smoke. If using a tire pick the worst one on the car, take it off the rim, and arrange a good pile of kindling to get it started. A tire is hard to ignite, and some rags soaked in gas or some other source of heat will be needed to start it burning. Once started, the fire will produce a great deal of thick black smoke.

At night, make a fire on high ground so that it can be seen.

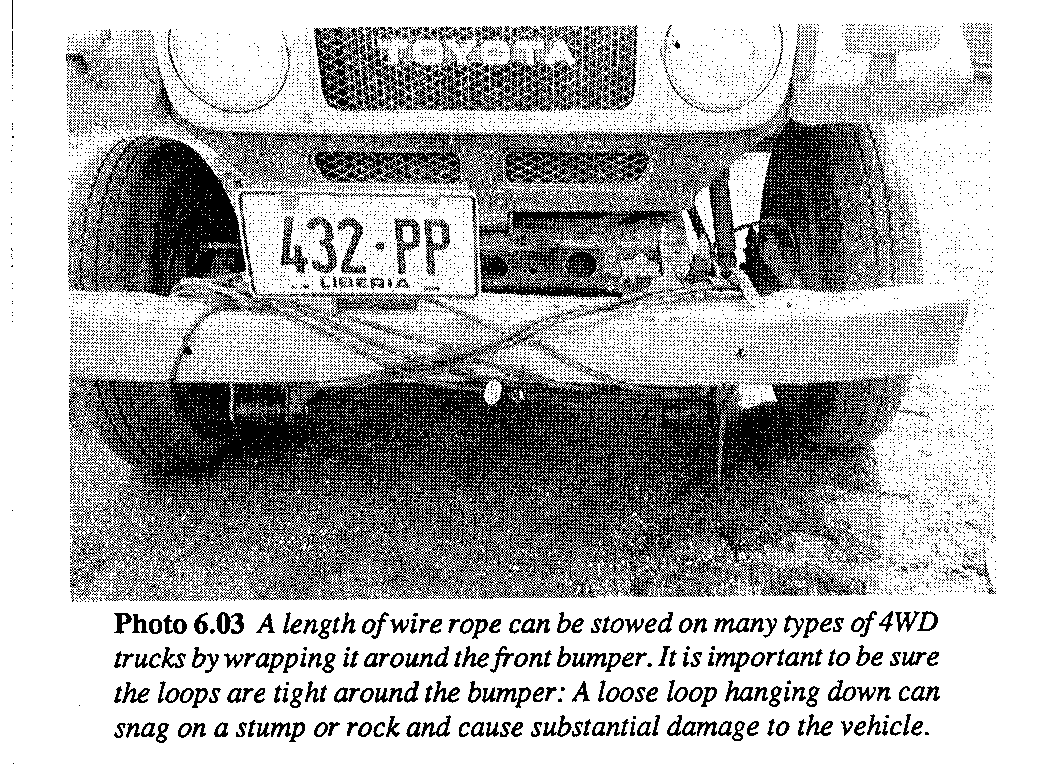

5.01 Vehicle Submerged