Technical Reviewers Daniel Kuennen Trinidad Martinez

VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Adobe ISBN: 0-86619-224-7 [C]1985, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Maria Giannuzzi as editor, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

The author of this paper, Balla Sidibe, was a VITA Technical Inquiry Coordinator from 1981 to 1983, handling many requests for information in construction and related areas. He is now a consultant for C.A.C.I. The reviewers of this paper are VITA Volunteers. Daniel Kuennen is a community development specialist with the University of Delaware Cooperative Extension Service. Trinidad Martinez has experience in adobe construction as well as construction with stone and concrete, and the design and construction of greenhouses and solar-wall air heaters. He built his own 1200-square-foot adobe home.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Every low-cost housing project seeks to build the most durable house at the lowest cost possible. Emphasis is always given to the maximum use of locally available materials, such as adobe. Common adobe, as it has been known for centuries, is simply a soil mixture with a clay content of at least 40 percent. It becomes a sticky mud when mixed with water. This soil is used to make building blocks using simple wooden molds.

Traditional adobe can be an acceptable alternative to wood, masonry, cement, or steel housing. If the adobe blocks are thoroughly dried before use, the walls should not shrink or crack. Adobe attracts moisture, which erodes its cohesiveness. An annual application of a firm coat of mud plaster will prevent block erosion. One coat is usually sufficient in regions that do not receive large amounts of rainfall; in rainier, more humid areas, two coats are needed. Stabilizing adobe will also prevent moisture degradation.

This paper suggests an approach for improving traditional adobe as a building material. It focuses on soil selection and the proper methods for controlling the moisture content of the material. These two factors influence the performance of the unstabilized adobe, and determine the success or failure of the stabilization process. Stabilizers that are known to be efficient when used with adobe (e.g., straws, cement, asphalt emulsion, and lime) will be discussed.

This paper addresses the use of adobe in block making. Rammed earth construction is not discussed.

II. PREPARATION OF THE ADOBE MIXTURE

SELECTION OF THE ADOBE SOIL

Identifying the Soil

Soils are generally graded according to the size of the particles. They include coarse and fine gravel, fine sands, silt, and clay. A sieve analysis of an equal amount of clay loam and sand gravel used as building material reveals that the portion of the soil that is .05 millimeters (mm) in diameter or less constitutes the silt and clay part. The finest particles are the clay particles (below .005 mm). Particles with diameters above .05 mm are classified as sand or gravel, depending on particle size. In general, the clay content determines the classification of the soil as clay (over 30 percent clay), clay loam (20 to 30 percent), loamy sand (below 20 percent), and sandy loam (below 15 percent). Appendix A describes some simple field methods for identifying the texture of soils. In areas where soil analysis facilities are available, the adobe builder can get more accurate information through a laboratory analysis of various soil samples. For areas where such facilities are not available, a combination of the various simple tests is recommended.

Determining the Soil Standard

The composition of soils varies from one region of the world to another. It is difficult to set a uniform soil standard for making good adobe blocks. The State of California's Uniform Building Code Specification recommends a standard of 55 to 75 percent sand for 25 to 45 percent clay and silt. The following table serves as a guide for the selection of the optimum soil mixture for adobe. The various soil textures in the table are those available in the State of New Mexico.

Table 1. Optimum Adobe Soil Mixtures

Soil Percent Percent

Percent Textural Name Sand

Clay Silt

Loamy sand

70 to 80 0 to 15 0 to 30 Sandy loam

50 to 70 15 to 20 0 to 30 Sandy clay loam 50 to 70 20 to 30 0 to 30

Source: Hohn, C., ABC's of Making Adobe Bricks, Cooperative Extension Service (Las Cruces, New Mexico: New Mexico State University, 1978).

A good mixture of soil used in adobe blocks consists of sand, clay, and silt. A specific range of either sand, clay, or silt content depends on the local soil. Too much of a single component produces poor quality blocks. Although the clay's bonding properties hold the various granular materials together, the amount of clay should not exceed one-third of the adobe mix. A clay content above the one-third limit causes deep cracks in the dry blocks, and reduces its strength. The coarser sand materials reduce shrinkage as they are held together by the clay. But too much sand weakens the bonding effect of the clay, causing the granular elements to crumble. Silt is usually found in combination with the sand. It is very vulnerable to erosion and should not constitute a major proportion in the adobe soil mixture.

The sand, clay, and silt should be mixed in approximately equal proportions. The proportions can be checked to some degree by putting a handful of the earth that is planned for use into a jar of water. The jar should be capped and shaken vigorously. The sand and silt will settle quickly, while the clay tends to remain in suspension for a while and settle last. The resulting layers will provide a preliminary check on the proportions.

The importance of soil testing cannot be overemphasized. A United Nations publication calls for soil testing prior to block production. However, the recommended testing standard may be used only by specialists in a controlled environment. It may be difficult to apply these tests in the field. Simple field tests are found in the Peace Corps' Handbook for Building Houses of Earth, published by the U.S. Department of Housing and Urban Development.

Test blocks can be made with varying combinations of sand, clay, and silt. After thorough drying (two to four weeks), the test block should be hard and should resist the scratching action of a knife and a drop of two feet with no damage. If the block crumbles or breaks, the sand content is probably too high, and soil with a high clay content should be added to the mixture. If large cracks are visible, the clay content is too high, and sand should be added to the mix. If the organic content is too high, or the clay content is too low, it may be necessary to add straw for strength and to quicken its drying.

CONTROLLING THE MOISTURE CONTENT

Another critical factor in adobe block making is an available water supply. Water is mixed with soil to give it a plastic consistency. Any type of water can be used. But water with a high concentration of mineral salts and organic materials should be avoided. Organic material such as humus reduces the durability of the block. Some salts have the same harmful effect, especially when stabilizers are used.

Water is added to the soil mix. The mixture is thoroughly worked until plastic enough to mold. Too much water will reduce the soil's stiffness. The mixture must be firm enough to form a block when the mold is removed. The amount of water determines whether or not the adobe will be properly stabilized. An unstabilized adobe soil requires a moisture content ranging from 16 percent to 20 percent of the dry weight of the soil to reach optimum plasticity. A stabilized soil will require a moisture content of less than 10 percent, especially when a mechanical press is used instead of the traditional wooden form. One simple way of determining the moisture content of the soil is to take several samples of wet soil, weigh them, dry them, and then reweigh them. The percentage of moisture can be determined by dividing the loss in weight by the weight of the wet samples.

STABILIZATION OF THE ADOBE SOIL

The proper soil and water mixture is important to the durability of the adobe block. Moisture absorption must be minimized if adobe blocks are to be a durable building material. Limiting the clay content of the adobe mix and using the optimum amount of water can reduce the moisture absorption. However, even the best mixture can develop some cracks. Therefore, it is important to add other materials to the mix to prevent water from infiltrating the dry block. This process is called stabilization. The addition of a waterproofing or bonding substance to the adobe increases its resistance to the weather (rainfall, snowfall, humidity, and, to a lesser extent, excessive sunlight).

Research has been conducted on the stabilization of soils for highway and housing construction. To some extent, the use of stabilizers in road building has been applied to the field of housing. However, very little research has been done on adobe. One reason is that the use of modern stabilizers in adobe is still experimental. Among those being widely used today are straw, asphalt emulsion, cement, and lime.

The property of a material enabling it to be shaped and to hold its shape.

Straw

Straw is the oldest stabilizer known. It is not a waterproofer and its bonding properties are limited. It prevents some block cracking. Straw is presently used in many developing countries, where the clay content of soils is high. Low-clay content soils do not require straw as an additive. Clean straw is recommended. Contaminated straw (i.e., containing manure) can weaken the adobe block.

Asphalt Emulsion

Asphalt, also known as bitumen, is primarily used for its waterproofing properties. It is used as an emulsion (in water), which provides good waterproofing qualities in the adobe block. But using too much asphalt will lower the compressive strength of the block. Asphalt emulsion also increases the elasticity and toughness of the block, making it less likely to break during handling. The following table can help the adobe builder in the field when consultant advice is not available.

One author suggests the addition of 5 to 15 percent emulsion to provide adequate protection to various soils. The asphalt emulsion is added and thoroughly mixed with the soil before adding water. Despite the excellent properties of asphalt emulsion as a stabilizer, its use may not be economically feasible due to its high cost.

Table 2. Asphalt Emulsion Proportions for Adobe Soils

Percent of Asphalt Emulsion Soil by Dry Weight of Earth

Soil with high sand content 4 to 6 (over 50 percent sand) Soil with medium sand content 4 to 12 (50 percent sand) Fine clay 13 to 20 (below 50 percent sand)

Source: United Nations, Manual on Stabilized Soil Construction (New York, New York: UN, 1958).

Cement

Cement is used as a stabilizer mainly because of its bonding properties. As such it provides strength to the block and prevents softening when the block is exposed to moisture. The soil composition will determine how much is needed to provide the optimum stabilization. Soils with high clay and silt content may require cement stabilizer equal to 20 percent of the dry weight of the soil. Only 5 to 6 percent may be needed for sandy loams. Economical use of cement as stabilizer depends on the soil texture. If soil requires large amounts of cement it can be combined with less costly lime. Lime can be substituted for half the amount of cement required.

Lime

Lime is the most popular stabilizer used in developing countries. It is much less expensive and more available then cement. Lime is both a waterproofer and a binder. It is greatly enhanced when used in combination with cement. In addition, lime loosens clay particles for easy mixing.

Some precautions must be taken when using lime as a stabilizer. If quicklime is used, it is necessary to slake (combine with water) it first. Adobe blocks stabilized with lime or cement require slow curing. Some moisture added during the drying process keeps the block from drying out too quickly.

A final note: stabilizers must be thoroughly mixed into the soil to ensure contact with soil particles; otherwise their effects are greatly reduced. Regardless of the stabilizer selected, it is always recommended to seek the advice of a specialist when available.

III. PRODUCTION OF THE BLOCKS

EQUIPMENT

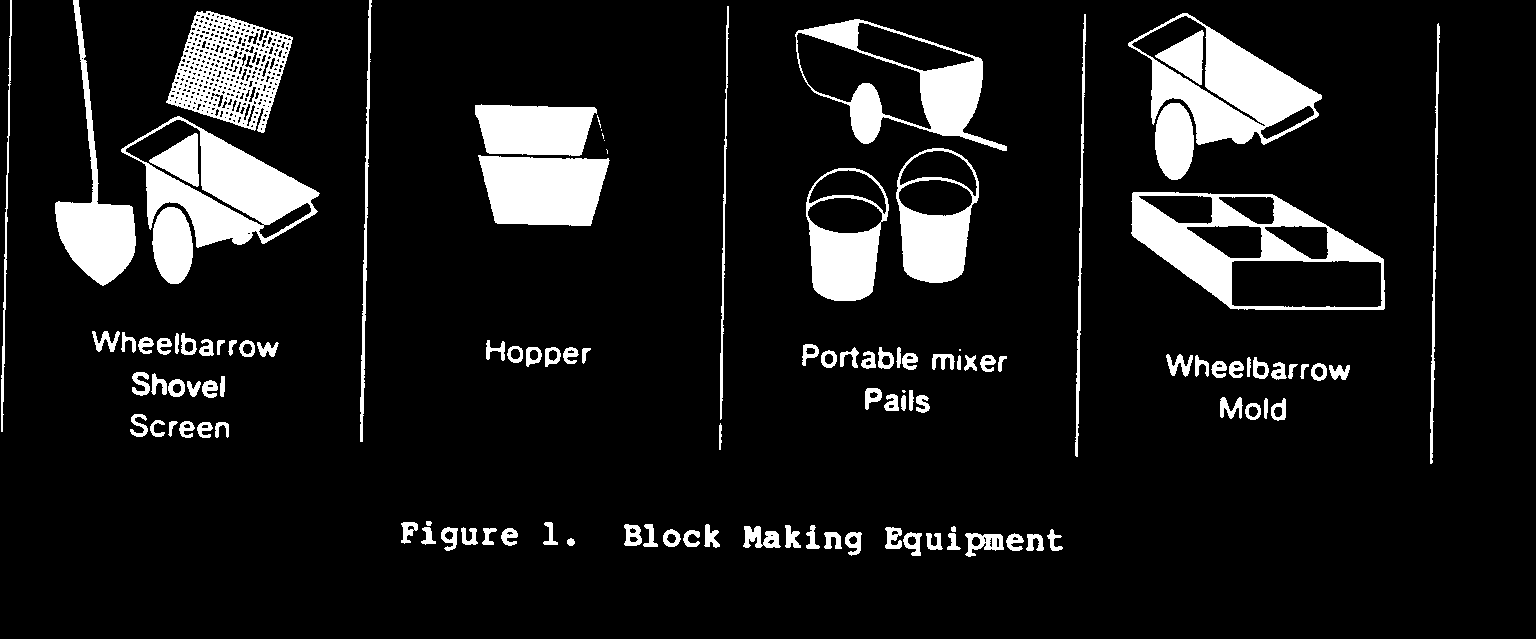

The equipment needed for block making includes: wheelbarrows and

shovels to provide a supply of soil; a hopper for measuring soil; the mixer; a water hose, pails, etc., for handling water and stabilizer; wheelbarrows for hauling mud to the molding areas;

Quicklime is calcium oxide, limestone that is burnt (calcined) in a kiln at a temperature of 900-1100 [degree]C; it must be handled with great care because it burns the skin if you touch it.

and wood or metal molds. At the molding area, a brush and pail of water for cleaning the molds and a rake for smoothing the molding bed will be needed.

Additional equipment may be needed for more efficient production. Experience will determine what is needed to improve production.

MIXING THE ADOBE

Select a large level area for mixing, molding, and curing the adobe. Clear and level an area if necessary. Ideally, block making should be done as close as possible to the construction site. Mixing can be done in a mixing and soaking pit, shown in Figure 2. The pit can be made as large as the adobe maker desires.

Its dimensions can vary but a good depth is about one foot. The deeper the pit below ground level, the harder it is to mix the mud. More than one pit can be used and can be located at convenient points.

A wide variety of techniques can be used for mixing, including the use of shovels and hoes, tractor wheels, the feet of humans, and the hooves of domestic animals (e.g., goats, oxen, horses).

If after mixing the contents appear lumpy (like flour in gravy) and resist efforts to make a smooth mix, let the mixture soak overnight in the pit. Each successive day's batch should also be soaked overnight.

MOLDING BLOCKS

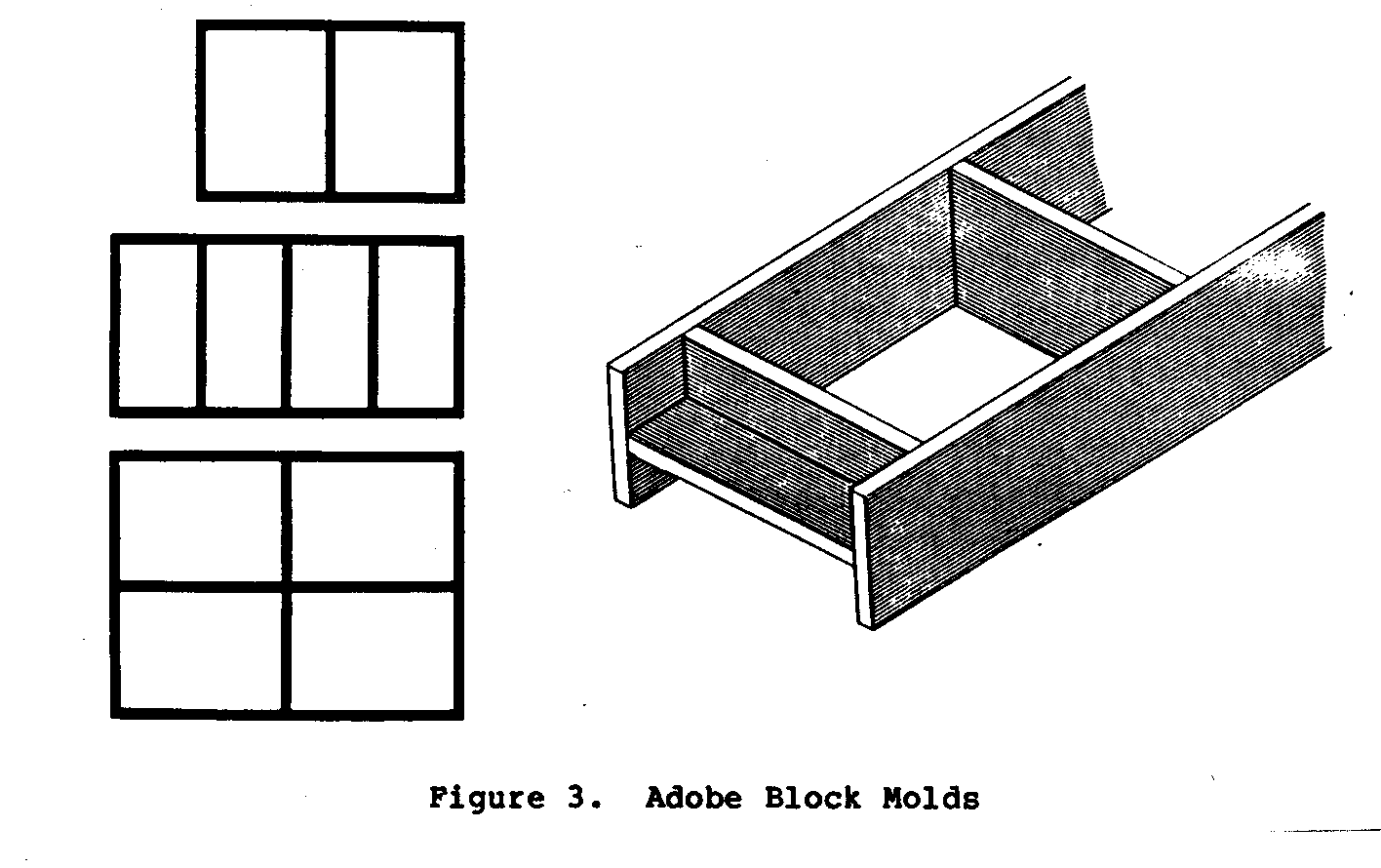

Various sizes of adobe blocks are made to accommodate the prearranged dimensions of the walls and the block mold can be built to the desired dimensions. Regardless of the needed size, the maximum outside dimension of the block mold should not exceed 81.3 centimeters (32 inches).

The average weight of an adobe block with a volume of .009 cubic meter (one-third cubic foot) is 16.8 kilograms (37 pounds). Figure 3 illustrates the various types of molds that can be

constructed. Note the end handles in the drawing on the right.

For more efficient production by one worker, a gang form that will mold eight .009 cubic meter (one-third cubic foot) adobe blocks that are 25.4 centimeters x 10.2 centimeters x 35.6 centimeters (10 inches x 4 inches x 14 inches) can be used. A larger form will require two people to manage it. Two adobe molders can manage a sixteen-block mold. Whether two people are working or one, two forms should be made, one for soaking, the other for molding. For long-term production, line the inside walls of the form with tin. Handles can be constructed on the mold by extending the ends of two opposite sides (see Figure 3).

The mold should be thoroughly soaked before putting the adobe mixture into it. Soaking will keep soil particles from sticking to the inside of the mold, make the block easier to remove, and help ensure a smooth finished block.

Two adobe molders are best for a smooth, rhythmic operation. The molders place the mold at the prepared level site. The adobe mud is carefully dumped from a wheelbarrow or other container into the mold compartments. The mud is then filled into the corners and edges of the mold.

The molders usually use their hands to work the mud gently but firmly into all parts of the mold.

The excess mud on top is removed by hand or with a straight-edged piece of wood or other rigid material. Next, the now level surface is made smooth. (If the block is too wet, water will form on its surface). Even and level distribution of the mud is needed for quality blocks. Rough or unlevel top surfaces and nicks in the corners cause cracks to develop during drying.

The mold is removed by slowly and evenly lifting the mold upwards from the level ground surface away from the blocks. After the mold has been removed, the surface is again made smooth.

The process is repeated over again by moving the mold to the next molding location, which should be as close as possible to the previously finished blocks. Mud is brought to fill the mold and the same steps are followed.

The cleaning of molds and tools during block manufacturing, especially at the end of the work day or before work breaks, helps to ensure good quality blocks.

In molding the blocks, the following points should be kept in mind:

- A team of two molders supplied with properly mixed adobe can produce 1,000 25.4 centimeters x 10.2 centimeters x 35.6 centimeters (10 inches x 4 inches x 14 inches) blocks per day. This size block is .009 cubic meter (one-third cubic foot) and is optimum in terms of wall strength, weight, and insulation. It weighs 15.9-18.1 kilograms (35-40 pounds).

- A portable cement mixer can supply four or five molding teams with mud.

- Molding teams need to develop an evenly paced work rhythm.

- Wooden molds should be soaked in water before each day's use. Moistened molds produce smooth blocks that are less likely to crack.

- Adobe mud should be wet enough to be worked into the mold's corners and angles. Mud that is too wet will run out of the bottom of the mold.

- Mixed mud will dry on its surface if left standing. Mud should not be left in wheelbarrows or mixers for long periods of time or in direct sunlight. The mixture should be covered to keep it from drying out before it can be worked.

Workmanship always improves with practice.

DRYING AND CURING BLOCKS

The relatively long drying time requires a large site undisturbed by traffic, etc. While the adobe block mold is moist, it is placed on a layer of building paper or other flat, smooth substance. If building paper is not available, blocks can be placed on a thin layer of sand. The width of the paper or flat surface should be at least as large as the dimensions of the mold. The clean level area prevents undesirable elements from becoming embedded in the wet adobe, as well as excessive breakage or malformation.

The drying area should be close to the mixing site to provide easy access to needed material. The first row of blocks should be placed at the farthest point from the mixing area. Advance determination of a location for drying will save steps, time, and energy.

On very hot days in direct sunlight, rapid drying occurs and blocks may crack. Paper, leaves, straw, and similar coverings placed on the drying blocks will prevent cracks due to quick drying.

The blocks should be dried for 14 days. After several days of drying, the blocks can be carefully placed on end (their edge) to dry more uniformly.

Warning: rain will quickly destroy unstabilized blocks that are unprotected during this drying time. Stabilized blocks are not as easily damaged by normal rains.

A hot, dry period is most favorable for curing. Dry seasons are ideally suited for production. Under these conditions, only seven to 10 days are normally needed for drying. Asphalt-stabilized adobe requires more time to dry than untreated adobe.

The blocks should not be moved more than necessary. Before moving blocks, determine whether they are ready by testing several. Break the blocks in half and examine their centers for dryness.

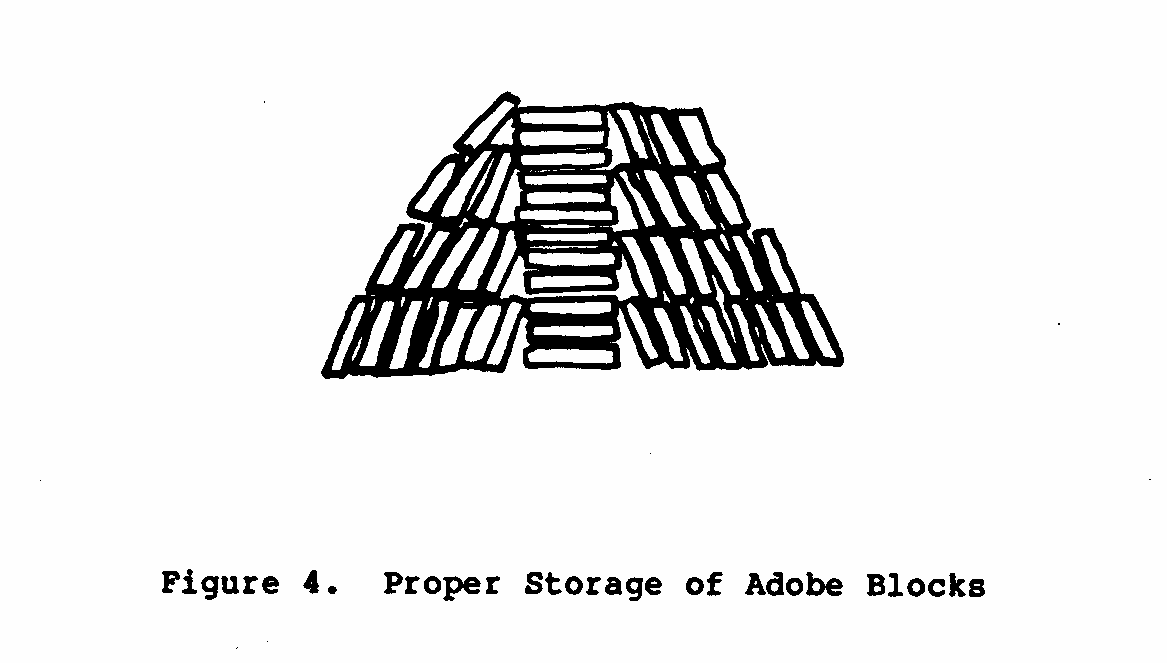

STORAGE OF BLOCKS

The adobe blocks must be stacked on end to minimize erosion. If the blocks are laid flat, they will break of their own weight. They should be placed on edge, against a center pillar, and stacked not more than three or four rows high (see Figure 4).

Some bottom blocks can be expected to break, and should be allowed for. Should the stack be left for any period of time, it should be protected with a waterproof covering.

IV. CONCLUSION

Making durable adobe blocks efficiently and economically requires careful Planning and organization. Site selection, in particular, should be given careful consideration. After the planning phase is completed, the preliminary work consists of selecting, digging, grading, and mixing the soil. Some critics of adobe point to the fact that adobe is labor intensive. This criticism is correct, especially when basic equipment like a hoe is used for mixing the soil. There are, however, many appropriate technologies that can cut labor and improve the quality of the block. VITA can provide valuable technical bulletins on how to make a Buck Scraper, Fresno Scraper, and Barrel Fresno Scraper. The Fresno scraper and barrel Fresno scraper (which can be powered by oxen or horses) move large quantities of soil from the digging area to the block-making site. A fourth VITA publication, How to Get Waterproofing Substances from Plants (formerly Waterproofing Soil Construction), helps the adobe user identify and tap local trees and other plant materials for their waterproofing substances.

A more sophisticated but durable block made of earth with cement or other stabilizer added is described in Making Building Blocks with the CINVA-Ram Block Press. This VITA publication provides detailed step-by-step instructions with illustrations on how to use the portable block press. Included is a list of CINVA-Ram distributors. See also VITA Technical Paper #2, Understanding Stabilized Earth Construction.

These technical bulletins are also included in the VITA publication, Village Technology Handbook, April 1978.

BIBLIOGRAPHY/SUGGESTED READING LIST

Articles

Tibbets, Joe. "The Pressed Earth Block Controversy,' Adobe Today, No. 37, pp. 24-27 (undated).

"Adobe Brick," Mineral Information Service. Vol. 12. No. 7. Sacramento, California: State of California, Division of Mines, 1959.

Manuals and Handbooks

Action Peace Corps. Handbook for Building Home's of Earth. Washington, D.C.: Department of Housing and Urban Development. (undated)

Adobe Craft. Building Your Adobe Home. Pre-publication draft. Castro Valley, California: Adobe Craft, 1976.

Fitzmaurice, Robert. Manual On Stabilized Soil Construction. New York, New York: United Nations, 1958.

Groben, Ellis W. Adobe Architecture: Its Design and Construction. Seattle, Washington: The Shorey Book Store, 1975.

International Institute of Housing Technology. The Manufacture of Asphalt Emulsion Stabilized Soil Bricks. Fresno, California: California State University, 1972.

National Bureau of Standards. Methods for Characterizing Adobe Building Materials. Washington, D.C.: National Bureau of Standards, 1978.

Newbauer, L.W. Adobe Construction Methods. Berkeley, California: Agricultural Publications, 1964.

Salvadorean Foundation for Development and Low Cost Housing Research Unit. Stabilized Adobe. Washington, D.C.: Organization for American States, (undated).

U.S. Department of Agriculture. Building with Adobe and Stabilized Earth Blocks. Washington, D.C.: United States Department of Agriculture, 1972.

U.S. Department of Housing and Urban Development. Earth and Homes. Washington, D.C.: Housing and Urban Development, 1970.

Reports and Papers

Kimmons, G.; Fern, R.L.; and Matleson, R. Asphalt Stabilized Building Blocks." (unpublished, but available from VITA), 1968.

Lunt, M.G. Stabilized Soil Blocks for Building. Garston, Watford, England: Building Research Establishment, 1980.

Maginnis, Howard. The Classification of Soil Construction for Architectural Use. St. Louis, Missouri: Washington University, 1970.

Whittlemore, Herbert L.; Stang, Ambrose; Hubbel, Elbert; and Dill, R. Building Materials and Structures: Structural, Heat-Transfer, and Water Permeability Properties of Five Earth-Wall Constructions. Washington, D.C.: National Bureau of Standards, 1941.

VITA Publications

Volunteers in Technical Assistance. How to Get Waterproofing Substances from Plants. Arlington, Virginia:

VITA, undated). (Although this publication is out of print, a photocopy may be obtained by special request to VITA's Information Service.)

Volunteers in Technical Assistance. Making Building Blocks with the CINVA-Ram Block Press. Arlington, Virginia: VITA, 1975.

Volunteers in Technical Assistance. Village Technology Handbook. Arlington, Virginia: VITA, 1978.

Volunteers in Technical Assistance. Understanding Stabilized Earth Construction. Arlington, Virginia: VITA, 1984. APPENDIXES

APPENDIX A: Field Method for Identification of Soil Texture

Soil Visual Detection of Particle Squeezed in Hand and Soil Ribboned Texture Size and General Appearance Pressure Released Between Thumb and of the Soil Finger when Moist When Air When Dry Moist

Sand Soil has a granular Will not Forms aCannot be appearance in which form a Which ribboned. the individual cast and will grain sizes can be will fall crumble detected. It is apart when when free-flowing when pressure is lightly in a dry, condition. released. touched.

Sandy Essentially a granular Forms a Forms a Cannot be Loam with sufficient silt and cast cast ribboned. clay to make it somewhat which which coherent. Sand readily will characteristics falls apart bear predominate.

when careful lightly handling touched. without breaking

Loam A uniform mixture of sand, Forms a Forms a Cannot be silt and clay. Grading of cast cast ribboned. sand fraction quite uniform which which from coarse to fine. It is will can be mellow, has somewhat gritty, bear handled feel, yet is fairly, smooth careful freely and slightly plastic. handling without without breaking breaking

Silt Contains a moderate amount of Forms a Forms a Will not Loam the finer grades of sand and cast cast ribbon only a small amount of clay which which but has - over half of the particles can be can be a broken are silt. When dry it may freely freely appearance, appear quite cloddy; can handled. handled. feels readily be broken and Pulverized When wet, smooth, and pulverized to a powder. it has a soil may be soft runs slightly flour-like together plastic.

feel. and puddles.

Soil Visual Detection of Particle Squeezed in Hand and Soil Ribboned Texture Size and General Appearance Pressure Released Between Thumb and of the Soil

Finger when Moist When Air When Dry Moist

Silt Contains over 80% of silt Forms a Forms a It has a tendency particles with very little cast cast to ribbon with a fine sand and clay. When which which broken dry, it may be cloddy; can be can be appearance, feels readily pulverizes to handled handled. smooth. powder with a soft without When flour-like feel. breaking. wet, it readily puddles.

Clay Fine textured soil breaks Forms a Forms a Forms a thin Loam into hard lumps when dry. cast cast which readily Contains more clay than which which breaks, barely silt loam. Resembles clay can be can be sustaining its in a dry condition. handled handled own weight. Identification is made without freely on physical behaviour breaking. breaking. of moist-soil. It can be worked into a dense mass.

Clay Fine textured soil breaks Forms a Form a Forms long thin into very hard lumps when cast cast flexible dry. Difficult to pulverize which which ribbons. Can be into a soft flourlike can be can be worked into a powder when dry. freely

handled dense compact Identification based on

handled freely mass. cohesive properties without without Considerable of the moist soil. breaking. breaking. plasticity.

Organic Identification based on the high organic content. Muck consists of thoroughly Soils decomposed organic material with considerable amount of mineral soil finely divided with some fibrous remains. When considerable fibrous material is present, it may be classified as peat. The plant remains or sometimes the woody structure can easily be recognized. Soil colour ranges from brown to blacks. They occur in lowlands in swamps or swale, They have high shrinkage upon drying.

APPENDIX B

Recommended Standards and Methods of Testing for Construction Related Applications of Adobe Standard 1. SOIL: a) Sufficient clay to bind particles (approx. 15%) (Not less than 25% or more than 45% silt-clay. Clay and silt are defined as particles which will pass through a #200 mesh sieve.) Balance to be made up of "hard particle" material such as sand, crushed rocks, decomposed granite etc. not to exceed more than approximately 1/4 [inches] in diameter.

b) Minimize effects of soluble salts upon bonding of asphalt film to soil particles. Soil mix shall not contain more than 0.2% soluble salts.

- MOISTURE RESISTANCE: Soil stabilizer to be used. a) Absorption: Shall not be greater than 2 1/2% of dry weight in seven days. Average of five 4 [inches] sections cut from each of 5 bricks.)

b) Moisture Content: not to exceed 4% by weight.

c) Erosion: (average of three bricks) Average less than 1/16 [inches] with no significant pitting.

SHRINKAGE: (average 5 blocks, top surface approx. 1 sq. ft.)

Not more than three cracks, maximum of 3 [inches] long and 1/8 [inches] wide.

Method of Testing

Fill tall glass jar or cylinder to about 1/3 capacity with sample of pre-mixed soil. Add water to about 2/3 capacity of container. Shake thoroughly and let stand for about 15 minutes. Particles will separate themselves in the following order: (top to bottom) Clay Silt Fine sand Medium sand Coarse sand or small gravel-rock

Mix soil and water samples. Filter through filter paper. Test filtrate with PH paper. Rating of 7 or less is satisfactory.

State Specification Mixing Grade Asphalt Emulsion SS-1 or SSlH to be used, Mix one part asphalt emulsion with approximately 4 parts water. To this stir in soil sample. Mold and dry block.

Dry sample block to constant weight in oven at 140 [degrees] F, After cooling to room temperature place on constantly saturated porous surface enclosed in moist cabinet. Weight gain is percentage of dry weight.

Using field run samples weigh and follow procedure above. Dry to constant weight and calculate weight loss.

Direct spray from standard 4 [inches] shower head, 20 lbs. pressure, horizontally against adobe surface for two hours. Slight erosion or pitting is not considered unfavorable.

Visual inspection. Adapt this principle as appropriate to smaller or larger surfaces being tested, e.g. coursed, poured or sprayed surfaces.

*Condensed and adapted from: Uniform Building Code sections on "Unburned Clay Masonry" and ASTM Manual Designator E-72 - 74a "Standard Methods for Conducting Strength Testing of Panels for Building Construction"

psi = pounds per square inch lbs.= pounds

Method of Testing

Standard

Block Samples Panel Samples

- STRENGTH: Average of five blocks: Wall panel 4 [feet] x 8 feet

a) Compressive Strength: Average of 300 psi Compressive Load Test: Capability of with tolerance of supporting vertical 250 psi for one loads. block in five.

b) Flexion: Modulus of Rupture: Wall Panel 4 [feet] Capability of Average of five x 8 feet tolerance of 30 psi Transverse Load Test: for one block in five.

Impact Load Test:

c) Shear: Capability of

Wall panel 8 [feet] resisting earth

x 8 feet forces. Racking (shear) Load Test:

- TEST SAMPLES: one unit of adobe (block or wet mix) to be tested for each 1000 units used in construction.

- MORTAR: To bond and seal joints, 1 shovel cement, 2 shovels adobe soil, 3 shovels sand, 1 pint asphalt stabilizer, 4+ pints water APPENDIX C Mortar for Adobe Brick

Mortar must provide a strong bond between bricks and must resist the forces of vibration, violent windstorm, contraction due to temperature changes and earthquake. The mortar must be at least as strong as the bricks it binds. Complete safety from nature's violence is not possible, but high quality workmanship and construction practice go far in reducing the effects of these forces.

Properly designed and constructed footings and foundations, proper use of pilasters, reinforcing, lintels, and the proper size and shape of quality bricks along with the necessary quality of workmanship are of utmost importance in the construction of a sound, safe adobe building. Lime or clay is used in mortar to obtain plasticity, workability, and water-holding capacity. On burned brick, tile, and cement block, mortars containing lime seem to bond better, while mortars containing fireclay tend to shrink and cause cracking. On asphalt stabilized adobe brick, lime tends to cause deterioration of the asphalt which results in reduced adhesion to asphaltstabilized bricks, particularly when subjected to cycles of wet and dry weather. In very dry climates where moisture resistance is not an important consideration, lime-cement mortar should be satisfactory. Good mortar requires proper materials of good quality, properly mixed.

Adobe bricks should be laid with full bed and head joints 1/2 inch thick. This is necessary to obtain the most strength and moisture resistance possible. The bed joint should be spread thick and not furrowed. This will assure a full joint without voids. Joints should be finished with a trowel or pointing tool for appearance and watertightness. Without good workmanship the full advantages of stabilized adobe bricks cannot be realized.

Cement Mortar 1 cement, 2 1/2-3 sand (by volume), 1 1/2 gallon asphalt emulsion per sack of cement

Cement-lime Mortar 1 cement, 1 hydrated lime, 4 sand

Cement-soil Mortar 1 cement, 2 soil (use same soil bricks are made from), 3 sand, 1 1/2 gallon asphalt emulsion per sack of cement

Mixing Procedures

- Mix dry ingredients thoroughly.

- Add water to stiff consistency.

- Add emulsion - continue thorough mixing.

Use additional water to proper consistency. Mortar should work easily, slide from trowel.

Adobe Mortar

The same mixture as the bricks are molded from should be used.

Good soil containing about 15% clay and 85% sand stabilized with 5% asphalt emulsion or its equivalent of RC2 road oil can be used. This mortar is slow-curing and requires working around the building, laying no more than 2-3 courses and allowing adequate drying time. Extra sand may be needed if shrinkage in the mortar occurs. Soil which makes good bricks should make good mortar.

Use of RC2 as a Substitute for Asphalt Emulsion

When using RC2 in mortar, the amount required is much less than the amount of asphalt emulsion. The proportion should be 1 cement, 2 soil, 3 sand, 2-3 quarts RC2 per sack of cement for cement-soil mortar or 1 cement, 2 1/2-3 sand and 2 quarts RC2 per sack of cement for cement mortar.

A slurry of soil, RC2 and water may be pre-mixed and added to dry ingredients. Continue thorough mixing and addition of water to proper consistency. Thorough mixing is essential to provide a waterproof mortar. RC2 requires even more care in mixing than does asphalt emulsion.

To make the slurry, mix about 5 shovels full of soil and enough water to form a sloppy wet mud. Add 2 quarts (4 pounds) RC2. Mix thoroughly. This will make a stiff sticky mixture. Continue mixing and add water to make 5 gallons total volume. This is enough stabilizer to mix with 1 sack of cement and can be proportioned into batches of lesser amounts easily. The slurry breaks the RC2 into small particles and distributes the relatively small amount of RC2 into the mixture more evenly. When only part of the slurry is used and the remainder allowed to stand for any length of time it must be stirred carefully before use.

APPENDIX D English and Metric Conversion Factors

Multiply By To Obtain

Centimeters ..............................0.3937 ....................Inches Centimeters ..........................0.01 ......................Meters Centimeters ..........................10 ........................Millimeters

Cubic Centimeters ........................3.531 x [10.sup.5] ........Cubic feet Cubic centimeters ....................6.102x [10.sup.2] .........Cubic inches Cubic centimeters ....................[10.sup.6] ................Cubic meters Cubic centimeters ....................1.308x [10.sup.6]..........Cubic yards Cubic centimeters ....................2.642x [10.sup.4]..........Gallons Cubic centimeters ....................10 [10.sup.3] .............Liters Cubic centimeters ....................2.113x [10.sup.3] .........Pints (liquid) Cubic centimeters ....................1.057x [10.sup.3] .........Quarts (liquid)

Cubic Feet ...............................2.832x [10.sup.4] .........Cubic centimeters Cubic feet ...........................1728 ......................Cubic inches Cubic feet ...........................0.02832 ...................Cubic meters Cubic feet ...........................0.03704 ...................Cubicyards Cubic feet ...........................7.48052 ...................Gallons Cubic feet ...........................28.32 .....................Liters Cubic feet ...........................59.84 .....................Pints (liquid) Cubic feet ...........................29.92 .....................Quarts liquid)

Cubic inches .............................16.39 .....................Cubic centimeters Cubic inches .........................5.787x [10.sup.4] .........Cubic feet Cubic inches .........................1.639x [10.sup.5] .........Cubic meters Cubic inches .........................2.143x [10.sup.5] .........Cubic yards Cubic inches .........................4.329x [10.sup.3] .........Gallons Cubic inches .........................1.639x [10.sup.2] .........Liters Cubic inches .........................0.03463 ...................Pints (liquid) Cubic inches .........................0.01732 ...................Quarts (liquid)

Cubic Meters .............................[10.sup.6] ................Cubic centimeters Cubic meters .........................35.31 .....................Cubic feet Cubic meters .........................61,023 ....................Cubic inches Cubic meters .........................1.038 .....................Cubic yards Cubic meters .........................264.2 .....................Gallons Cubic meters .........................[10.sup.3] ................Liters Cubic meters .........................2113 ......................Pints (liquid) Cubic meters .........................1057 ......................Quarts (liquid)

Cubic Yards ..............................7.646x [10.sup.5] .........Cubic centimeter Cubic yards ..........................27 ........................Cubic feet Cubic yards ..........................46,656 ....................Cubic inches Cubic yards ..........................0.7646.....................Cubic meters Cubic yards ..........................202.0 .....................Gallons Cubic yards ..........................764.6 .....................Liters Cubic yards ..........................1616 ......................Pints (liquid) Cubic yards ..........................807.9 .....................Quarts (liquid)

Feet .....................................30.48 .....................Centimeters Feet .................................12 ........................Inches Feet .................................0.3048 ....................Meters Feet .................................1/3 .......................Yards

Gallons ..................................3785 ......................Cubic centimeters Gallons ..............................0.1337 ....................Cubic feet Gallons ..............................231 .......................Cubic inches Gallons ..............................3.785x [10.sup.3] .........Cubic meters Gallons ..............................4.95lx [10.sup.3] .........Cubic yards Gallons ..............................3.785 .....................Liters Gallons ..............................8 .........................Pints (liquid) Gallons ..............................4 .........................Quarts (liquid)

Gallons, Imperial ........................1.20095 ...................U.S. Gallons Gallons, U.S .........................0.83267 ...................Imperial Gallons

Gallons Water ............................8.3453 ....................Pounds of water

Grams ....................................0.03527 ...................Ounces Grams ................................2.205x [10.sup.3] .........Pounds

Grams/Cu. Cm. ............................62.43 .....................Pounds/cubic foot Grams/Cu. cm .........................0.03613 ...................Pounds/cubic inch

Inches ...................................2.540 .....................Centimeters

Liters ...................................[10.sup.3] ................Cubic centimeters Liters ...............................0.03531 ...................Cubic feet Liters ...............................61.02 .....................Cubic inches Liters ...............................[10.sup.3] ................Cubic meters Liters ...............................1.308x [10.sup.3] .........Cubic yards Liters ...............................0.2642 ....................Gallons Liters ...............................2.113 .....................Pints (liquid) Liters ...............................1.057 .....................Quarts (liquid)

Meters ...................................100 .......................Centimeters Meters ...............................3.281 .....................Feet Meters ...............................39.37 .....................Inches Meters ...............................[10.sup.3] ................Kilometers Meters ...............................[10.sup.3] ................Millimeters Meters ...............................1.094 .....................Yards

Pounds ...................................16 ........................Ounces Pounds ...............................0.0005 ....................Tons (short) Pounds ...............................453.5924 ..................Grams

Pounds of Water ..........................0.01602 ...................Cubic feet Pounds of water ......................27.68 .....................Cubic inches Pounds of water ......................0.1198 ....................Gallons

APPENDIX E

Finishes For Asphalt-Stabilized Adobe Brick Walls and Specifications

Wall Finishes

Exterior or interior walls shall be left unfinished, or smoothed and washed, or given a transparent protective seal coat, or painted, as designated for each job.

- Smoothing and Washing -- The wall surface shall be cleaned by wetting and rubbing smooth with wet burlap, then washing.

- Paint Coat, Prime Coat, Transparent Sealer --

a. Paint. The following paints are satisfactory when applied on emulsified asphalt treated soil brick dry surfaces to serve as finish paint coat, exterior or interior. No prime coat is required.

Caladium Paint, made by Bishop-Conklin, Los Angeles, California, distributed by "Treasure Tones," dealers in various cities.

Gelvatex Exterior or interior Paint, made by Gelvatex Coatings Corporation, sales offices at Oakland and Los Angeles, California.

b. Asphalt Base Aluminum Prime. After the walls are smoothed and cleaned (1) and are thoroughly dry, a good grade of asphalt base aluminum paint, formulated with drying oils, shall be used as prime. When the coating is dry, one or more coats of a good grade of exterior or interior paint may be applied. (Note: Aluminum paint is not recommended to be applied during wet seasons, or on walls when damp. When wall is damp, use instead cement wash, paragraph c. below.)

c. Cement Wash. The clean wall surface shall be wetted, then primed with a cement wash consisting of one sack of medusa or equal White Cement mixed with about six gallons of water to a paint consistency, applied by vigorous brushing. After initial set, the prime coat shall be fogged with water several times daily for five or six days, until the cement is fully set and hardened.

A second application of cement wash, tinted with pigment if desired, may be applied as final coat; or after setting, the cement-primed surface may be painted with a good grade of exterior or interior paint. (Cement wash coats are best applied when damp; cloudy weather aids moist curing.)

1Chevron Research Company. The Manufacture And Use Of Asphalt Emulsion Stabilized Adobe Bricks. April 16. 1963 (Mimeographed)

d. Transparent Protective Sealer. A nonglossy protective finish, not altering natural color of the bricks, may be obtained by applying on the clean wall surface Caldotone Rubberized Transparent Sealer, made and sold by Caldow Paint Company, Oakland, California. The sealer is made for exterior or interior use.

e. Linseed Oil, For interior Finish Only. For harder, tougher interior surfaces a prime coat or a transparent protective seal coat may be provided by painting with raw linseed oil (imparting to the brick surface a richer, darker color). When used as prime coat, allow to cure thoroughly, at least two weeks, then paint with 50% raw linseed oil, 50% "50-50 Du Pont Paint."

- Plaster. Expanded metal lath or 1-inch 18-gage galvanized wire shall be fastened to the walls with furring nails driven into the bricks. Cement stucco or hardwall plaster is then applied in scratch, brown, and finish coats according to standard practice.