Reviewed By Timothy Wood Rafe Ronkin

Published By VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax:703/243-1865 Internet: pr-info@vita.org

Portable Metallic Cookstoves ISBN: 0-86619-299-9 [C]1988, Volunteers in Technical Assistance

INDUSTRY PROFILES

Introduction

This Industry Profile is one of a series briefly describing small or medium-sized industries. The Profiles provide basic information for starting manufacturing plants in developing nations. Specifically, they provide general plant descriptions, financial, and technical factors for their operation, and sources of information and expertise. The series is intended to be useful in determining whether the industries described warrant further inquiry either to rule out or to decide upon investment. The underlying assumption of these Profiles is that the individual making use of them already has some knowledge and experience in industry development.

Dollar values are listed only for machinery and equipment costs, and are primarily based on equipment in the United States. The price does not include shipping costs or import-export taxes, which must be considered and will vary greatly from country to country. No other investment costs are included (such as land value, building rental, labor, etc.) as those prices also vary. These items are mentioned to provide the investor with a general checklist of considerations for setting up a business.

IMPORTANT

These profiles should not be substituted for feasibility studies. Before an investment is made in a plant, a feasibility study should be conducted. This may require skilled economic and engineering expertise. The following illustrates the range of questions to which answers must be obtained:

* What is the extent of the present demand for the product, and how is it now being satisfied?

* Will the estimated price and quality of the product make it competitive?

* What is the marketing and distribution plan and to whom will the product be sold?

* How will the plant be financed?

* Has a realistic time schedule for construction, equipment, delivery, obtaining materials and supplies, training of personnel, and the start-up time for the plant been developed?

* How are needed materials and supplies to be procured and machinery and equipment to be maintained and repaired?

* Are trained personnel available?

* Do adequate transportation, storage, power, communication, fuel, water, and other facilities exist?

* What management controls for design, production, quality control, and other factors have been included?

* Will the industry complement or interfere with development plans for the area?

* What social, cultural, environmental, and technological considerations must be addressed regarding manufacture and use of this product?

Fully documented information responding to these and many other questions should be determined before proceeding with implementation of an industry project.

Equipment Suppliers, Engineering Companies

The services of professional engineers are desirable in the design of industrial plants even though the proposed plant may be small. A correct design is one that provides the greatest economy in the investment of funds and establishes the basis of operation that will be most profitable in the beginning and will also be capable of expansion without expensive alteration.

Professional engineers who specialize in industrial design can be found be referring to the published cards in various engineering magazines. They may also be reached through their national organizations.

Manufacturers of industrial equipment employ engineers familiar with the design and installation of their specialized products. These manufacturers are usually willing to give prospective customers the benefit of technical advice by those engineers in determining the suitability of their equipment in any proposed project.

VITA

Volunteers in Technical Assistance (VITA) is a private, non-profit, volunteer organization engaged in international development. Through its varied activities and services, VITA fosters self-sufficiency by promoting increased economic productivity. Supported by a volunteer roster of over 5,000 experts in a wide variety of fields, VITA is able to provide high quality technical information to requesters. This information is increasingly conveyed through low cost advanced communication technologies, including terrestrial packet radio and low-earth-orbiting satellite. VITA also implements both long- and short-term projects to promote enterprise development and transfer technology.

PRODUCT DESCRIPTION

The Product

The product is a metallic, wood-burning cookstove designed to fit a pot of specific dimensions. It uses a small amount of wood and cooks rapidly. It can be made entirely from new or recycled sheet steel, with joints fastened by metal rivets or spot welding. The cookstove is designed for preparation of such foods as the rice and sauce or stew of Africa. Its manufacture is easily adaptable to other locations.

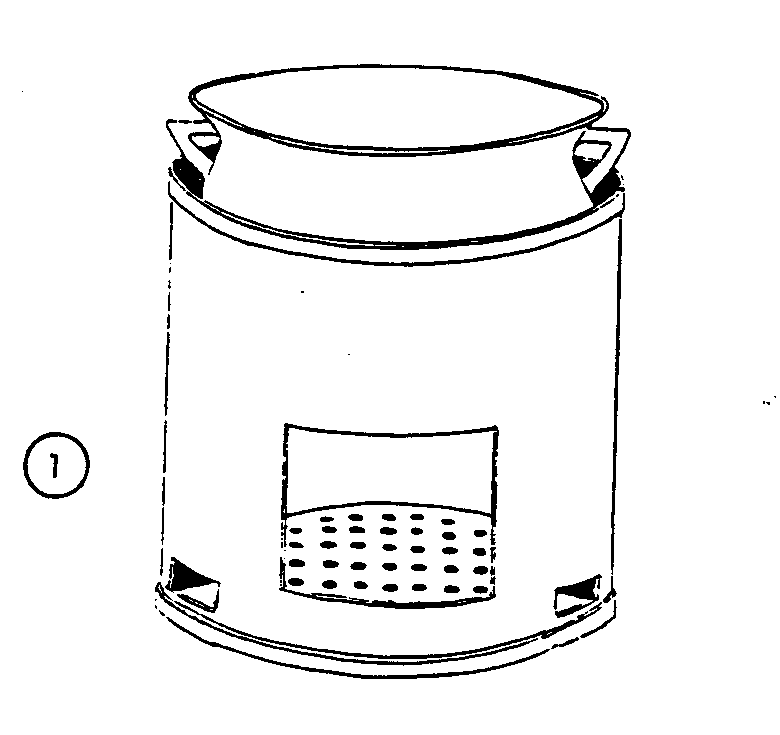

The basic structure is a short cylinder with internal pot supports, an opening for inserting fuelwood, two handles, and a metallic grate with air vents below (Figure 1). Correct dimensions

are extremely important and should follow a few basic principles:

- The distance from the grate to the bottom of the cooking pot should be about 40 percent of the stove diameter.

- The gap between the cylindrical wall of the stove and the cooking pot should be uniform, ranging between 6 mm for small stoves to 9 mm for the larger sizes. If the gap is smaller than this, the fire may smoke excessively. If it is wider, fuel efficiency will be greatly reduced.

- The front opening should be no larger than necessary to accommodate two or three sticks of wood at a time.

Because of the important gap between pot and stove, every potsize requires its own stove. In West Africa, the success of this particular model is due, in part, to the standardized sizes of the popular cast aluminum pots (Table 1).

The design of pot supports is a critical factor in stove performance. These supports must be strong and must keep the pot at the proper height above the fuel bed. They must also center the pot so that its distance from the stove body is uniform all around.

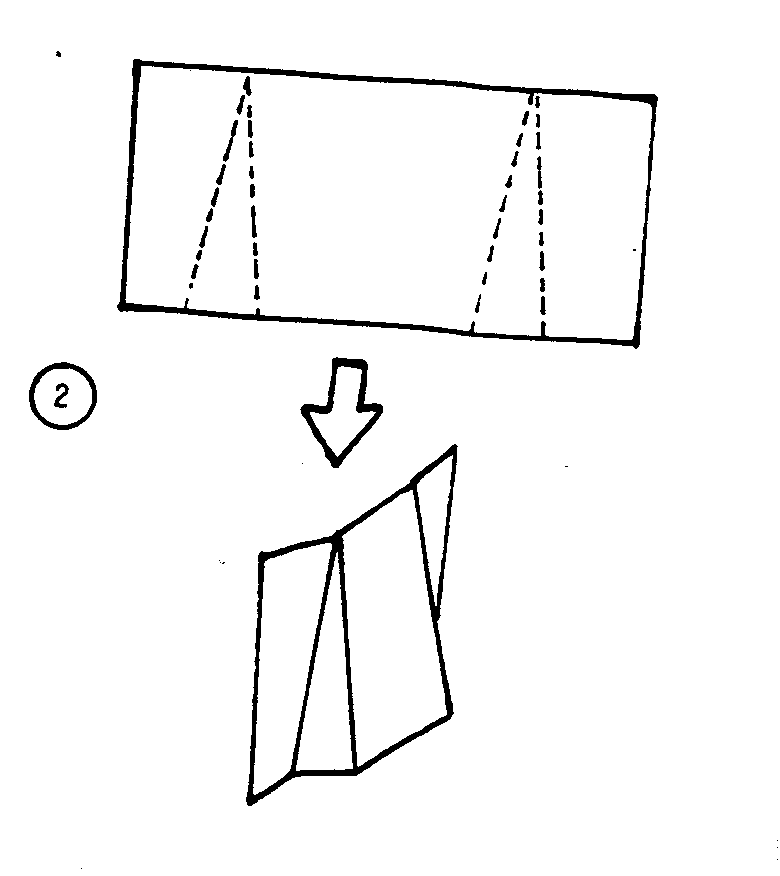

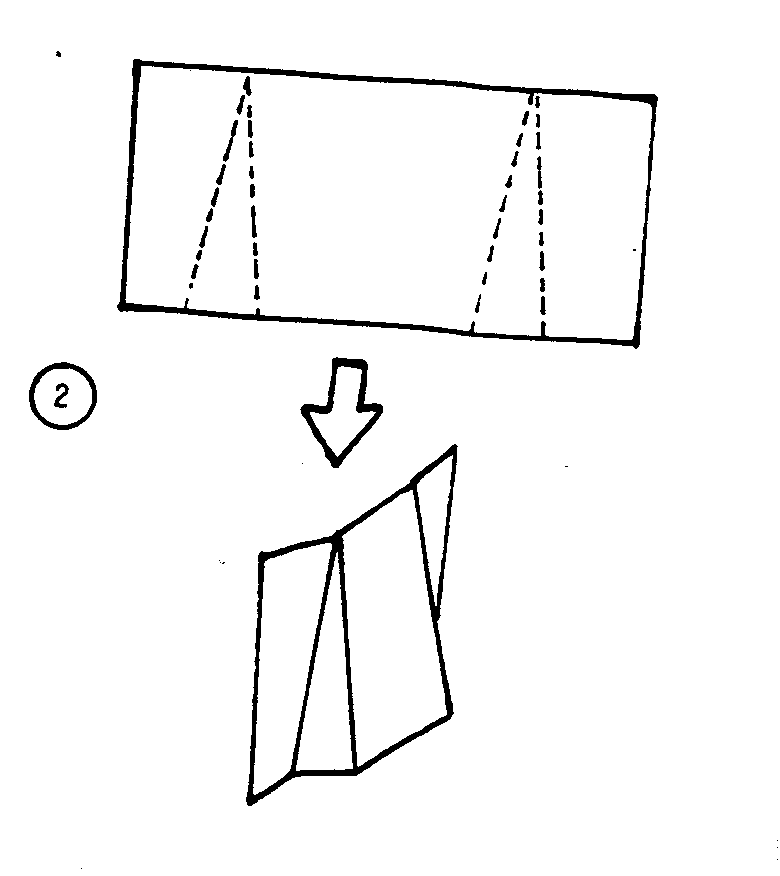

Finally, many women require the pot to be held firmly so it does not slide around while they are stirring. A system that meets all these needs consists of three wedges fashioned from sheet metal (Figure 2). They are fastened to the inside of the stove either

with rivets or by welding. An additional advantage of these supports is that they make good use of metal scraps left after cutting other pieces.

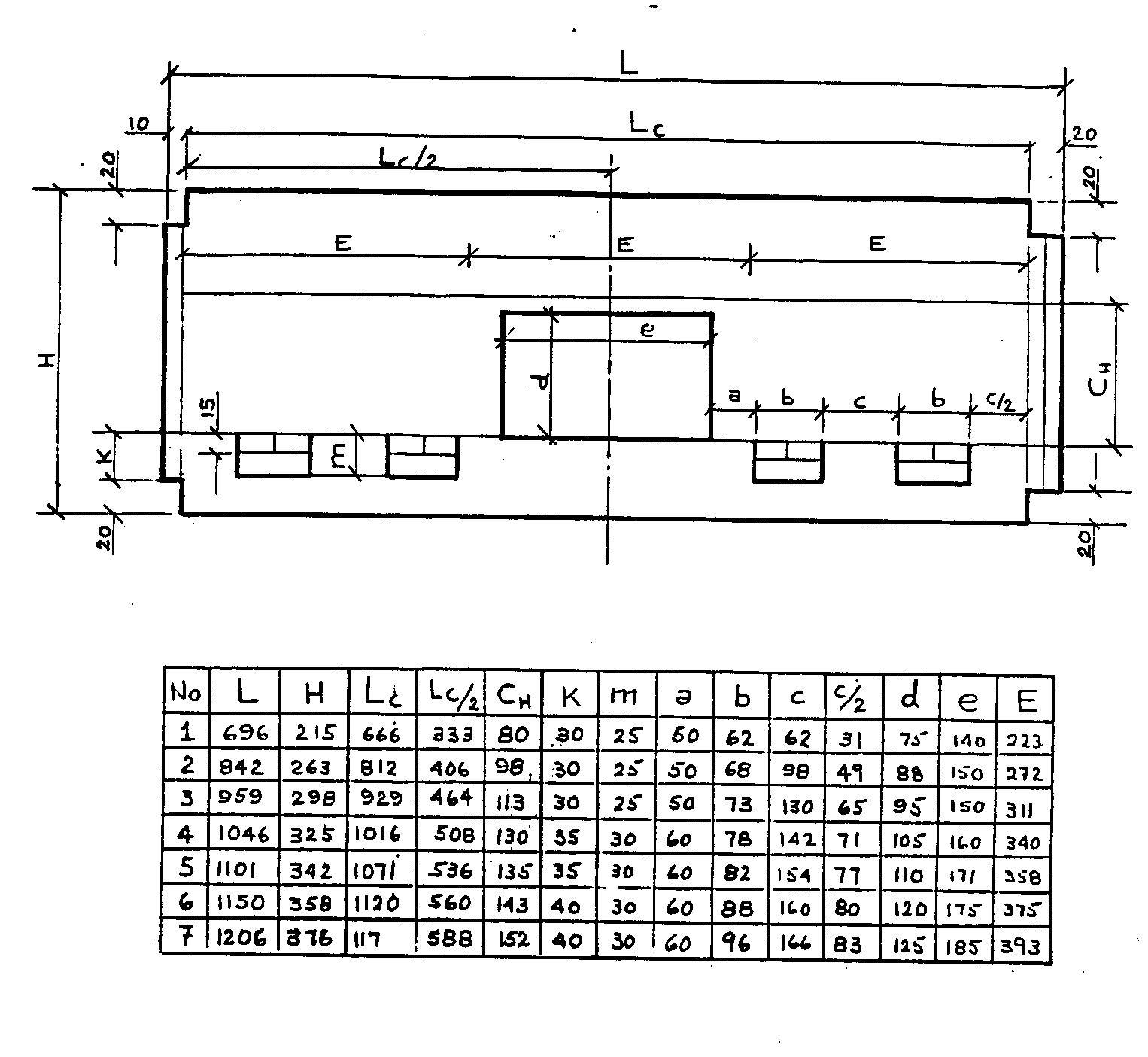

Table 1. Metallic Cookstove Sizes, in Millimeters; Examples from West Africa.

Pot Size No. 2 No. 4 No. 6 Range of pot diameter 241-247 310-312 343-345

Stove diameter 245 311 344 Stove height 238 295 328 Fuel opening, h x w 88X150 105x160 120x175 Draft vent, h x w 45x45 45x56 45x67 Size of sheet needed 263x842 325x1046 358x1150

The draft vents are equally spaced below the grate around the base of the stove. Common stove sizes (for Pot Nos. 1-7) have four vents, larger sizes have six.

The grate is supported by tabs formed when the sides and bottom of draft vents are cut and then bent upwards. After the stove blanks are cut from a 1 x 2-meter metallic sheet, the remaining metal is used to make the grates, handles, and pot supports. Openings in the grate must be large enough for ash to drop through naturally without losing small coals. If the grate is positioned with the rough side up, it will hold a small bed of insulating ash and reduce heat loss.

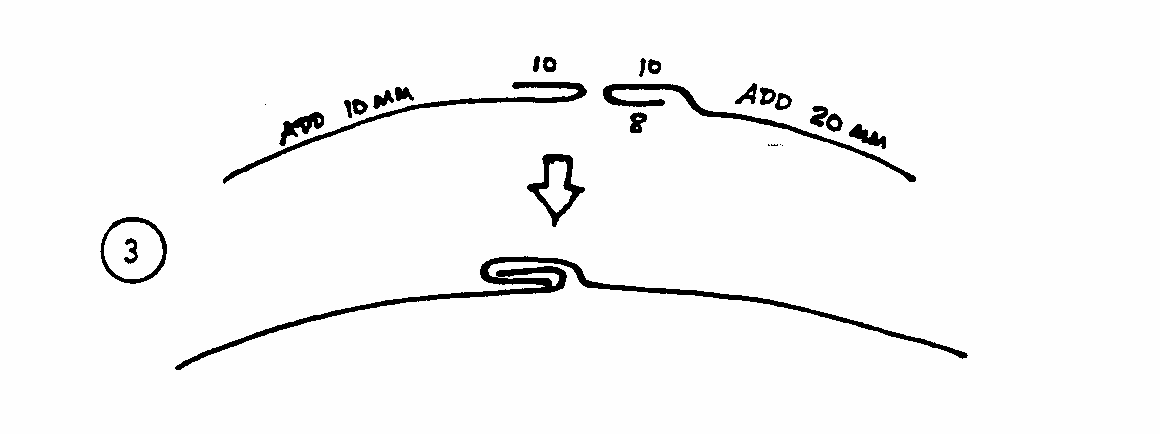

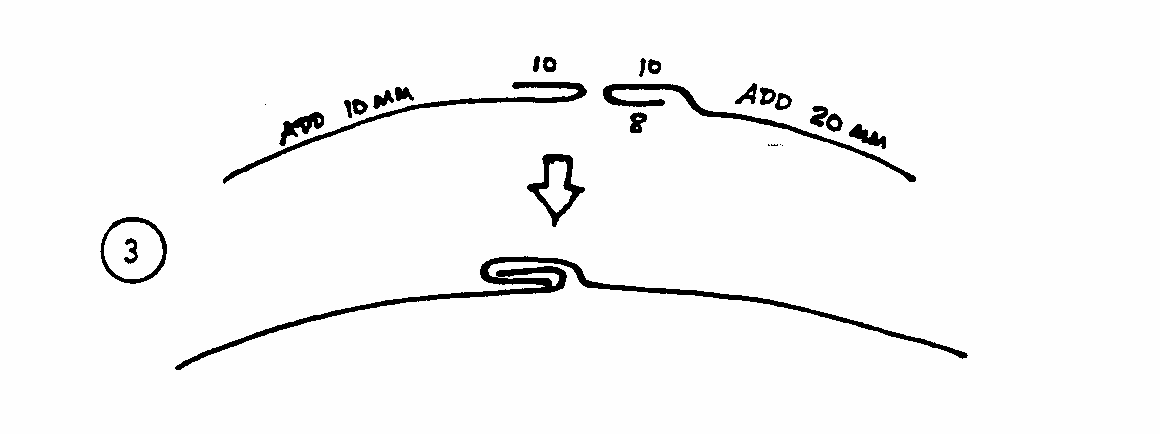

Folds at the top and bottom rims of the stove eliminate sharp edges, provide rigidity, and give an attractive appearance.

Production

Metal stoves are often made with a hammer and chisel in rural areas where recycled oil drums or other metal items are available. These can be worked into flat, rectangular sheets according to stove size (Table 1). Blanks are traced on the metal with the help of a template. The various openings are then chiseled out. The two 180 degree folds are made lengthwise at the edges. These reinforce the top and bottom rims. The stove is then shaped to specifications, using a Dutch fold to join the ends in a cylinder (Figure 3).

In some areas, special hand tools can be used to ensure correct dimensions every time and reduce fabrication time. Such tools could include:

- A press for forming the pot supports shown in Figure 2.

- A set of forms to make smooth curve for the cylinder and to ensure a correct diameter. Each consists of a partial cylinder for each stove model. These are quickly interchangeable on a common holder. When the cylinder is formed and the seam is made, the-cylinder is put back on its form and made truly round with the help of a rubber hammer.

- A hand operated bench shear for cutting the grate into a circular disc. Even with this tool the operation is tedious. circular shear is better; it operates on the same principle as a can opener.

- A piece of steel pipe about 15 cm diameter and 60 cm long to provide solid support when the Dutch fold is hammered closed.

The hammer and chisel method permits production of five stoves daily by two workers. The tooling-aids package permits production of up to 25 units daily by two workers.

The Facility

Stoves can be made in any space that accommodates two workers, a work table, and storage of materials and products.

GENERAL EVALUATION

The product was designed in response to deforestation of such areas as the West African Sahel. Its main objective is to reduce the use of fuelwood. The stove itself has the added advantage of decreasing the exposure of the cook to smoke, and since the fire is contained, the user is less susceptable to burns. Cooking time is also reduced about half.

Outlook

A. Economic

A fabricator can meet a demand of up to 2, 000 stoves per year. Bigger markets will require more fabricators. Stove making is a labor intensive process that creates jobs.

B. Technical

The stove is a simple product, easily manufactured by unskilled workers under supervision.

Manufacturing Equipment Flexibility

Either of two methods are used to achieve the accurate dimensions that are needed: the basic hammer and chisel, and tooling aids mounted on a table. The tooling aids include forms specifically designed for each stove size. Joints may be riveted if spotwelding equipment is not available. Knowledge Base

No special knowledge is required. Training requires only a few days.

Quality Control

The tooling aids enable fabrication of each stove to dimension tolerances.

Constraints and Limitations

Local cooking pots must be available in standard sizes. Production is slowest with the hammer and chisel method. Hearing can be permanently damaged by prolonged exposure to loud noise; workers should therefore use ear plugs or muffs.

MARKET ASPECTS

Users

Women, housewives. In addition to reducing fuel costs, cooking times are shortened, and health and safety are improved. This stove improves women's working conditions.

Suppliers

Any supplier of sheet steel, whether new or recycled.

Sales Channels and Methods

Retail sales may be done directly by fabricator to buyer. Distribution and pricing of products may involve a wholesaler. Door-to-door sales, advertising (radio, TV), demonstrations, etc. may be used. Endorsement and promotion or support from local and national women's groups and by popular leaders and personalities would help.

Geographic Extent of Market Cities and towns where extensive fuelwood consumption takes place.

Competition

This stove is likely to compete with and offer a ready market alongside of gas, charcoal, petroleum, traditional, and unimproved stoves.

Market Capacity

In households normally using two pots to cook a meal, there would need to be a minimum of two stoves per family of ten persons. In many places, the stove pays for itself within two months with the savings made from the purchase of fuelwood. Stove life is over two years. The potential market is 100,000 stoves per million population.

PRODUCTION AND PLANT REQUIREMENTS, SMALL PLANT

Requirements Amount

- Infrastructure, Utilities

Land Building According to Power local Fuel conditions Water

- Major Equipment & Machinery

Tools & Machinery Fabrication table $125 Pot holding tab forming press 47 Set of nine forms with support 156 Pipe mandrel to hammer fold 16 Rubber hammer 9

Support Equipment & Parts Templates 84

(*) TOTAL ESTIMATED COST of equipment & machinery only $437

(*) Based on US$ 1987 prices. The estimated costs are provided only for general guidance. Actual costs will depend on local conditions and may differ significantly from these estimates.

- Materials & Supplies

Raw Materials Sheet metal. One 1x2 m sheet makes:

3 #3 stoves and 3 #4 stoves, or 2 #7 stoves, 3 #2 stoves, and 1 #1 stove, or 2 #10 stoves, or 6 #3 stoves, etc.

- Labor

Skilled 0 Semi-skilled 0 Unskilled fabricators 2

PRODUCT ILLUSTRATIONS

Figure 1. Metallic cookstove with pot.

Figure 2. Wedge-shaped pot support made from scrap sheet metal.

(Three are needed.) Figure 3. A Dutch fold.

Figure 4. Universal pattern for stove blanks with a key for

dimensions in each of seven pot sizes

REFERENCES

- Technical Manuals & Textbooks

Biomass Stoves (1987). Samuel F. Baldwin. Arlington, Virginia: VITA. 287 pp.

Burning Issues: Implementing Pilot Stove Programs: A Guide for Eastern Africa (1984). Stephen Joseph and Philip Hassrick. London: UNICEF/IT Publication. 184 pp.

Improved Cooking Stoves in Developing Countries. Technical Report No. 2 (1983). Gerald Foley and Patricia Moss. London: Earthscan. 175 pp.

Wood-Stove Dissemination, Proceedings of the Conference held at Wolfheze, The Netherlands (1985). Edited by Robin Clarke. London: IT Publications. 202 pp.

- VITA Resources

VITA has a number of documents on file dealing with industrial processes. On request, VITA will supply dimension tables and pattern drawings for metallic cookstoves used in West Africa.

- VITA Venture Services

VITA Venture Services, a subsidiary of VITA, provides commercial services for industrial development. This service-for-fee includes the following: technology and financial information, technical assistance, marketing, and joint ventures. For fee schedule, contact VITA.

`INDUSTRY PROFILE SERIES'

VITA is pleased to present this series of industrial profiles. These Profiles provide basic information for starting manufacturing plants in developing nations. Specifically, they provide general plant description, financial, and technical factors for their operation, and sources of information and expertise. Dollar values are listed only for machinery and equipment costs, and are primarily based on equipment in the United States. The price does not include shipping costs or import-export taxes, which must be considered and will vary greatly from country to country. No other investment costs are included (such as land value, building rental, labor, etc.) as those prices also vary.

The series is intended to be useful in determining whether the industries described warrant further inquiry either to rule out or to decide upon investment. The underlying assumption of these Profiles is that the individual making use of them already has some knowledge and experience in industrial development.

These profiles should not be substituted for feasibility studies. Before an investment is made in a plant, a feasibility study should be conducted. Each profile contains a list of questions to which answers must be obtained before proceeding with implementation of an industrial project.

All profiles are available in English only. They are priced at $9.95 each. You may take advantage of the introductory offer and order any three profiles for just $25.00 or order the entire set of nineteen profiles for a bargain price of only $150.00.

BAKED, LEAVENED BREADS Richard J. Bess Describes a small bakery operating with a single shift and producing 100 tons of baked products a year. It also describes a medium-sized plant operating on the same basis but producing 250 tons of baked goods a year. (IP # 19) 6pp.

BLUE JEANS Edward Hochberg Describes one plant operating with one shift and making 15,000 dozens of blue jeans a year, and another that produces 22,000 dozens a year. (IP # 6) 8pp.

DIMENSION HARDWOOD Nicolas Engalichev Describes a medium-sized mill operating with one shift that produces 4,500 cubic meters of dimension hardwood per year. Some information is also provided for a mill twice as large. (IP # 16) 8pp.

FISH OIL AND FISH MEAL S. Divakaran Describes two plants. The first is a 20-ton per day plant operating with an eight-hour shift and producing 8,000 tons of fish meal and 4, 000 tons of fish oil a year. The second is a 40-ton plant operating an eight-hour shift and producing 8,000 tons of fish oil and 16,000 tons of meal per year. (IP # 8) 8pp.

GLASS CONTAINERS (BATCH PROCESS) William B. Hillig Describes small batch production plants with a work force of 10 to. 50 people that produce 500 to 25,000 containers per day. (IP 118) 8pp.

GLUCOSE FROM CASSAVA STARCH Peter X. Carrell Describes a plant that can operate 250 days a year on a three-shift continuous basis and produce 2,500 tons of glucose syrup. (IP #17) 8pp.

LIQUID PETROLEUM GAS Jon I. Voltz Describes two plants, operating with three shifts for 52 weeks per year. The smaller has an annual manufacturing capacity of 2,220,000 barrels; the larger plant has an annual capacity of 4,440,000 barrels. (IP #12) 8pp.

MEN'S DRESS SHIRTS Edward Hochberg Describes one small plant operating with one shift and manufacturing 15,000 dozen men's dress shirts a year. It also describes a larger plant running a single shift and manufacturing 22,000 dozen shirts a year. (IP #13) 8pp.

MEN'S WASH AND WEAR PANTS Edward Hochberg Describes one plant operating with one shift and producing 15,000 dozens pairs of pants a year, and another that produces 22,000 dozens a year. (IP # 4) 8pp.

MEN'S WASH AND WEAR SHIRTS Edward Hochberg Describes a plant operating with one shift, manufacturing 15,000 dozen men's wash and wear shirts a year, and another that manufactures 22,000 dozen shirts a year. (IP # 5) 7pp.

MEN'S WORK SHIRTS Edward Hochberg Describes one plant operating with one shift and manufacturing 15,000 dozen men's shirts a year. It also describes a larger plant running a single shift and producing 22,000 dozen shirts a year. (IP # 2) 8pp.

PAINT MANUFACTURING Philip Heiberger Describes a small plant that will serve local needs, mainly in the trade-sales-sector. Its output may exceed 4, 000 liters per week (L/wk). (IP #14) 10pp.

PORTABLE METALLIC STOVE Andre Charette Describes a facility that accommodates two workers, a work table, and storage of materials and products. The hammer and chisel method permits production of five stoves daily. The tooling-aids permits production of up to 25 units daily. (IP # 10) 9pp.

PORTLAND CEMENT Dave F. Smith & Alfred Bush Describes a small plant producing 35,000 metric tons of cement a year. (IP # 9) 10pp.

ROUGH-SAWN LOGS Nicolas Engalichev Describes plants (sawmills) operating with one shift that can produce 10,000 and 30,000 cubic meters (cu m) of product per year. (IP # 15) 8pp.

SMALL CERAMICS PLANT Victor R. Palmeri Describes a small plant operating with one shift and producing 16,000 pieces a year. It also describes a medium-sized plant running a single shift producing about 80,000 units a year. (IP # 11) 8pp.

STARCH, OIL, AND FEED FROM SORGHUM GRAIN Peter K. Carrell Describes a small plant operating with three shifts on a seven-day work schedule and processing about 200 tons of sorghum a day. Two shifts are down per week for maintenance. This facility may be considered a heavy industry because of the emission from the boiler and dryers and the noise from its high speed machinery. (IP # 1) 8 spp.

UNFERMENTED GRAPE JUICE George Rubin Describes a plant operating with one shift and producing 125,000 gallons of grape juice a year, and another that produces 260,000 gallons a year. (IP # 7) 8pp.

WOMEN'S BROADCLOTH DRESSES Edward Hochberg Describes a plant operating with one shift and manufacturing 72, 000 women's dresses a year (1,440/week, 288/day). It also describes a larger plant running a single-shift and producing 104,000 dresses a year. (IP # 3) 8pp.