This article is from ECHO Asia Note # 41.

[Editor’s Note: Anthony Wong the Managing Director of the Frangipani Langkawi Resort in Langkawi, Malaysia and is a longtime steward of green initiatives in Malaysia and the region. Using constructed wetland systems, grey water at his hotels are cleaned and recycled, while large amounts of food waste are up-scaled using an innovative Black Soldier Fly system. Mr. Wong was a recent speaker at the ECHO Asia Agriculture & Development Conference in 2019 and has many years of practical hands-on experience. For further reading and details we would also recommend the Black Soldier Fly Biowaste Processing – A Step-by-Step Guide.]

Integrating Black Soldier Flies on the Farm

The BSF or Black Soldier Fly (Hermetia illucens) brings great potential to any farming system through its ability to consume on-farm waste and produce a highly nutritious feed source. The larvae of the BSF can be grown using nearly any organic waste product, and can be used to up-cycle waste materials into a valuable protein source. BSF have the ability to break down waste resources that cannot be directly fed to humans or livestock, or even worms in a vermicomposting system, thereby making these systems valuable in tightening the nutrient cycle on any farm. In addition to the feed that the larvae becomes, the secondary advantage is their ability to rapidly break down food waste to produce a valuable by-product that can be used as an organic soil amendment.

The Frangipani Langkawi BSF System

Located in the Langkawi UNESCO Global Geo Park, the Frangipani Langkawi Resort is neighbor to a hospitality industry where as much as 60 percent of the waste produced is coming from food waste. The remaining waste comes from recyclable trash and other non-recyclable items. According to The News Strait Time dated on June 17, 2018, some 16,000 metric tons of food waste are produced daily in Malaysia, and every day that number is increasing. Of the food being wasted, these numbers include untouched foods from hotels, businesses, private residences, markets, hawker centers and other sources. The local landfill in Kilim faces capacity and it may one day negatively affect the image and tourism industry in the area.

In response, the Frangipani Resort has partnered with 11 nearby hotels to collect all the food waste they produce, and is using it to supply a large-scale BSF system. In this system, the larvae that are produced are fed as a high-protein feed source to fowl and fish, which are then consumed in the hotel restaurants. Through this project, it is hoped that the island can reduce the amount of food waste going to the landfill, while simultaneously raising fish & fowl, and a rich organic compost for building soil.

This Black Soldier Fly system has attracted the attention of local officials for its capacity to consume large quantities of organic waste including fruit, vegetable residues, offal, and pig & poultry manures, transforming it all into high quality protein that can then be fed directly to livestock.

Collection of Food Waste

Each day, food waste from collaborating hotels is collected and brought back to the Frangipani for processing. Upon arrival, the food waste first undergoes a quality check to insure that none of it contains hazardous contaminants such as plastics, styrofoams, or other synthetic materials. Hard foods such as clam shells and bigger bones are also removed as they cannot be processed in the following stage.

All food waste must be shredded in order to maximize the available surface area, making it easier for the larvae and the associated bacteria to break it down

quickly (Fig. 1).

This shredded food waste will then be drained to remove most of its water content. The simplest way is a passive dewatering system (by gravity), whereby the shredded waste is filled into a plastic basket that acts as a filter, allowing the water to drain through the basket into a bucket below. Two kg of desiccated coconut cake will also be added into a 10 kg batch of shredded food waste and mixed well; the purpose for this is to reduce the moisture content of the food waste.

Egg Collection and Pupa Handling

The first (and last) stage of production in our system is what we call the ‘Love House’. This is where some of the mature pupae will be transferred before emerging into adult flies. (It is worth noting that adult fly does not possess a stinger, and are not a menace to humans). The ‘Love House’ is the place where the adult black soldier flies mate and then lay their eggs, thereby beginning the process over again. BSF can be found in nearly every location in the tropics, and tend to frequent farms where manure and other organic waste are present.

The adult black soldier flies do not actually eat, and the food provided in the enclosure is only there for

females to know where to lay their eggs. Piecing together 4 to 5 small sections of cardboard, we provide a small ‘flute’ directly above a food source within the ‘Love House’, in which the fertile female flies can lay their eggs (Fig. 2). The food below should be kept moist at all times to prevent females from directly laying their eggs on the food source, which will cause inconvenience for management.

Once the eggs are laid in the flutes, they are collected daily and brought to the ‘feeding house’ where the egg clusters will be placed in a container with some processed food waste (Figure 3). After approximately three days, the eggs will hatch (each flute contains approximately 500-800 eggs) and the young larvae will crawl into the food waste and begin to eat, voraciously.

During this stage, larvae will begin to consume food at their maximum rate, and every 1 kg of larvae are capable of consuming up to 1 kg of food waste overnight (Fig. 4). Larvae will stop eating once they have reached the pre-pupae stage, and will begin to crawl out from their food ‘biopods’ to find a dry and cool place where they can anchor. This act of ‘self-harvesting’ makes it easy to know when the larvae are

ready, as they will separate themselves from the food waste, making them easy to harvest. Pre-pupal BSF will empty their gut during their last molting phase and cannot feed any further after that. At this stage, the larvae have everything they need to sustain themselves as they transform into pupae and finally into an adult BSF or fly.

Production of a Healthy Feed & a Rich Compost

BSF larvae are highly nutritious and can contain up to 35-42% protein, are rich in calcium, fats & lipids, and other nutrients, making it a high quality feed (Dortmans et al., 2017). BSF are at their highest nutritional quality at the final larval stage, prior to transforming into pupae, and should ideally be fed to livestock at this stage (Fig. 5).

Beyond their ability to produce a protein rich feed source, BSF have the amazing ability to transform food waste into a readily usable organic fertiliser sources, by consuming and breaking down previously uncycled waste (Fig. 6).

Conclusion

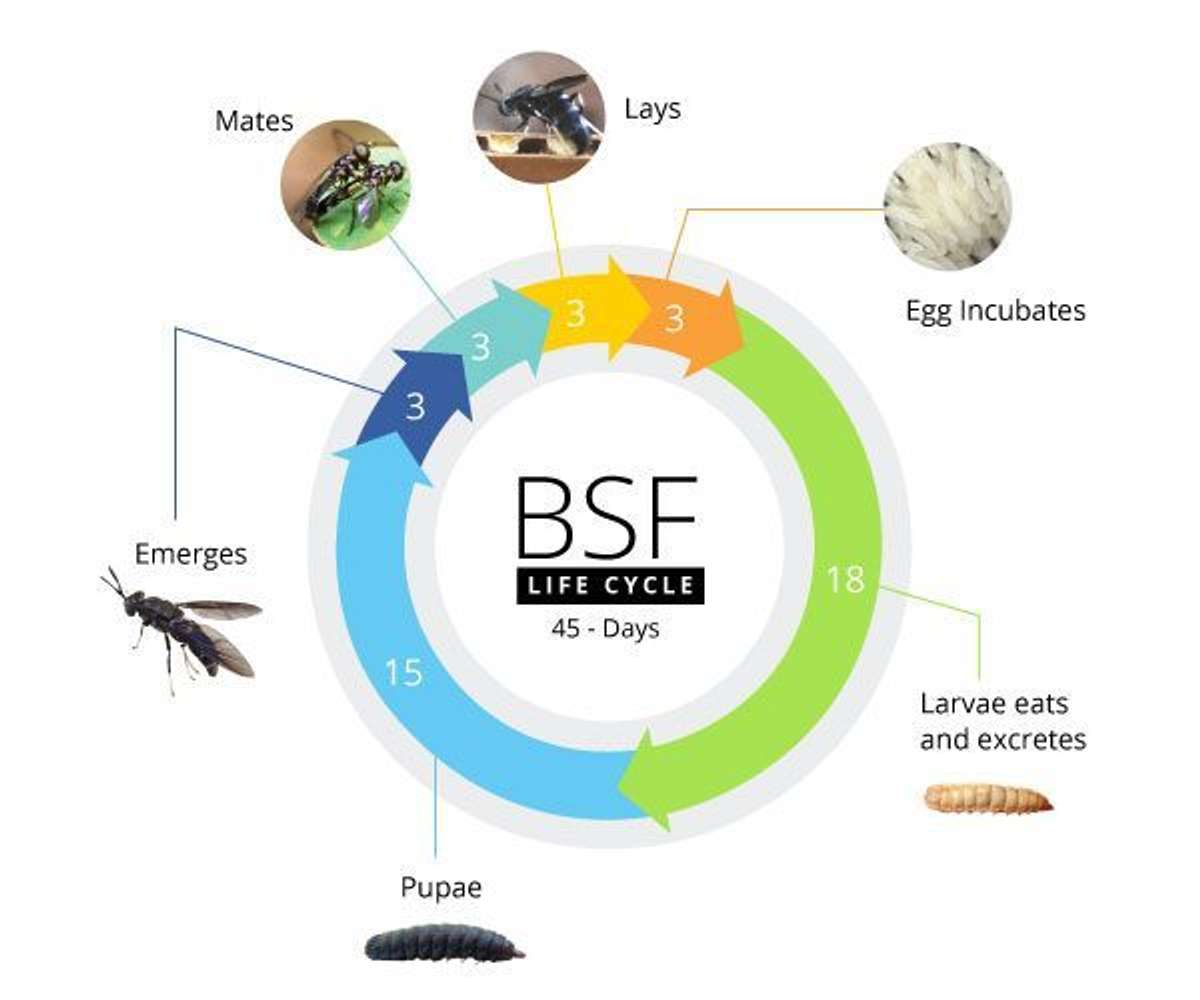

The BSF larvae transform food waste into a readily usable organic fertiliser apart from being a high protein-source feed for livestock. The entire life cycle of the BSF is only 45 days in length (Fig.7), making this one of the fastest producible sources of protein. From egg laying to final larval stage (ready for feeding to livestock), the length of time is as short as 20 days. Indeed, the BSF technology is incredibly economical and it brings about the dual advantage of recycling waste materials and producing a high-protein animal feedstock.

In Frangipani Langkawi Resort, we provide short courses to local communities and guests interested to learn about BSF farming. It is very important to promote awareness about BSF since they do not just reduce the landfill waste and carbon dioxide emissions, but also make our farm operation sustainable.

References

Tancho, A. 2017. Maejo Maggots. Thai language resource on BSF. Available: https://bookstore.nstda.or.th/shop/product/web-406348-3381