VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 * Fax: 703/243-1865 Internet: pro-info@vita.org

Understanding Small-Scale Paper Making ISBN: 0-86619-271-9 [C] 1986, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help People choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA senior editor Margaret Crouch edited this paper, and served as overall project manager, with Suzanne Brooks handling typesetting and layout.

The VITA Volunteers who wrote and reviewed this paper have many years of experience in the paper industry. Jon Vogler, author of Work from Waste, specializes in small-scale industries, particularly those based on recycled materials. Peter Sarjeant, dedicated to keeping alive the processes of the old master papermaker's craft, is the author of Hand Papermaking Manual. I. B. "Bruce" Sanborn is associate director of research and development at Consolidated Papers, Inc.; Phil Barr is fiber logistics manager for the Weyerhaeuser Company; and Dr. Bob Brooks, also of Weyerhaeuser, is the manager of pulp and paper educational activities. William Burger, retired mechanical engineer from Kimberly-Clark Corporation, assisted in the design of equipment for a micro paper factory in Tanzania.

VITA is a privates, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Papyrus, from which the word paper is derived, is known to have been in use as early as 3000 B.C. Developed in the Nile Valley, it was made of strips cut from the papyrus plant stem, soaked, and laid, first lengthwise, then crosswise, to form a mat. The mat was then pounded and pressed into a thin sheet. Later, similar processes elsewhere used other fibers such as silk.

True papermaking, which began in China about A.D. 105, uses an entirely different process than the preparation of papyrus. It begins with rags, straw, bark, wood, or other fibrous materials that are chopped or cut fine. The fibers are pounded or pulped until they are separated from each other and mixed with water. Then the fibers are lifted from the water in a sieve-like screen that allows the water to drain away, leaving a thin mat of fibers. The fiber mat, which can be dried in place or removed and dried separately, becomes a sheet of paper.

The earliest recorded manufacture of paper is credited to one of the first "purchasing officers," Ts'ai Lun, head of the Imperial Supply Department of Emperor Ho of China. Ts'ai Lun experimented with a variety of materials: vegetable fibers, old hemp, cotton rags, old fishnets, and mulberry bark. The paper produced was cheap and durable and the surface was good.

The technology spread to Japan by the third century A.D. and reached India in the seventh. Papermaking spread westward to North Africa and finally reached Europe in the twelfth century A.D.

Early European papers were made from linen or cotton rag. It was thick and rough, and the surface needed to be sized" with gelatin or the ink soaked in. Ulman Stromer set up a mechanized papermill in Nuremberg, Germany, in 1390, using water-powered hammers for beating the material, a method already used by the Chinese. The craft accompanied the early settlers to America.

True mechanization was not achieved until 1799, when the Frenchman Nicholas Robert built a machine with an endless wire mesh and a pair of squeeze rolls. The device was taken to England and marketed by two stationers, the Fourdrinier brothers. In 1804, Brian Donkin, a millwriqht-engineer, built the first successful papermaking machine, in Two Waters Mill, Hertfordshire, England, and another in America in 1827. Crude early designs improved steadily. By the end of the nineteenth century, Fourdrinier technology was widespread; machines just over 2 meters wide supplied 25 metric tons per day to the growing market for newsprint.

Modern machines form paper in a continuous ribbon or web, not a single sheet at a time as did the ancients. A good papermaker in the olden days could make enough sheets in a day to weigh about 90kg. Today, an average machine makes 90,000kg per day! Yet the process of making paper--separating fibers in water and draining them through a fine screen to form an interwoven mat that is then dried--is identical in principle. The actual formation of paper has been the same for almost 2,000 years.

II. MODERN PAPERMAKING

FIBERS AND PULPS

Fibers are the finer thread-like wisps from which paper, textiles, and many other materials are made. Tear a piece of paper and the fibers can be seen at the torn edge (more clearly with a magnifying glass). Paper fibers are made of cellulose, the basic building material of plants and trees. These materials can be made into paper by pulping (breaking them down until the fibers are loose and free of the substances that bind them), then reforming them while wet and finally drying.

Softwood (or coniferous) pulps are used for tough wrapping and packaging papers because of their long fibers; decidous or hardwood pulps provide fine fibers for printing and writing papers.

To understand the paper industry it is important to know about the major types of primary wood pulp used in papermaking: mechanical pulp and chemical pulps, which include kraft pulp and sulphite pulp. Pulp made of recycled paper is known as secondary pulp. Most small-scale paper producers rely primarily on secondary pulp. See also VITA's technical paper "Understanding Paper Recycling" for information on collection and use of waste paper.

Mechanical Pulp

Mechanical pulps yield the most paper per ton of wood, but are the weakest. They are made by pounding or grinding cellulose fiber, such as wood or sugar cane bagasse. One of the commonest uses of mechanical pulps is in the manufacture of newsprint. Newsprint is relatively weak and loses its strength altogether if wetted--a characteristic of mechanical pulp. It is used for rapid newspaper printing because printing ink is soaked up and dries very quickly, but it lacks the permanence of paper made from kraft or sulphite pulp. Strong chemical pulp is often added to mechanical pulp to give newsprint better strength. Mechanical pulp often contains tiny particles of wood that have not been reduced to fiber and are visible to the naked eye, so paper made from it is described as "woody."

Chemical Pulps

A stronger paper product is most cheaply made by pulping cellulose fibers in such a way that they are not weakened by mechanical damage. The wood or stalks are first reduced mechanically to small chips, then cooked at high pressure with chemicals that attack the bonds between the fibers. The chemicals most commonly used are:

1. Caustic soda and sodium sulfate, which produce coarse, very strong papers known as kraft, suitable for paper sacks and boxes that hold heavy weights.

2. Various sulfites (such as ammonium and calcium), which produce finer fibers, suitable for making high quality, strong (but expensive) printing and writing papers (usually bleached white).

Secondary Pulp

Secondary or recycled pulp is made by vigorously agitating wastepaper in water (usually in a hydro-pulper, a tank containing rotating blades) to separate the fibers bonded during the original papermaking process. As these bonds are weaker than those of the original cellulose plant, hydro-pulping is a more gentle process than primary wood pulping and consumes less energy. Even so, each time paper is recycled, it becomes weaker. Secondary pulp is, therefore, never as strong as the primary fiber from which it was made. It can be almost as good, provided pure waste paper of the same type is used. For example, pulp made by hydro-pulping clean kraft sacks will make new sacks of only slightly lower quality, particularly if mixed with a proportion of primary kraft pulp. If, however, the secondary pulp is made from material that contains newspapers, or dirt, dust, or clay or some other weaker mechanical pulp product, it will not be strong enough to make sack paper.

Coated Papers. In some cases the matted, absorbent surface of a paper is coated with a material that makes it glossy and smooth. This coated paper is better for printing. Coated papers are frequently used in magazines that are financed by the advertisements printed. In the process of hydro-pulping coated waste paper, the coating is washed out; thus, the weight of fiber obtained from a ton of coated paper is less, often by 20 percent, than that obtained from a ton of uncoated paper. As a result, the value of scrap coated paper to the paper mill, and its selling price, will be lower.

If the coating is plastic or other material that will not dissolve in water, the waste paper will require specialized machinery to recycle it and may reduce the value of more pure paper with which it is mixed. The same is true of polyethylene film, cellophane, glued paper, string, and any material that will not break down in water. Some of the various coated papers can be kept warm and wet in storage, then cooked in a hot caustic solution in order to biodegrade and break down the coating to release the fibers. Again, these papers require special machinery and handling to recycle and they may not be as valuable as simpler, plain paper.

Printed and Colored Papers. Both printing and tinting reduce the value of paper to be recycled. They make the pulp, and the paper made from it, dull gray in color unless bleached (which is expensive), or de-inked (which is also expensive). Tinting colors the Pulp, which must then either be used for a limited range of similarly colored products (or cheap grey products), or must be bleached. Therefore, white waste paper is more valuable than similar material that is colored. Unprinted waste paper is of a greater value than the same material printed.

STRUCTURE OF THE PAPERMAKING INDUSTRY

The manufacture and use of paper is one of the world's biggest industries; it takes place in:

1. pulp mills, which process wood chips or other materials to make pulp;

2. paper mills and board mills, which use pulp or waste paper to produce finished paper and board;

3. Paper converters, which use paper or board to produce boxes, tubes, rolls of tissue, boxes of blank office paper, stacks of printing paper cut to standard sizes, etc.;

4. printers, who usually buy from converters, although larger firms such as newspaper presses may buy directly from the paper mills; and

5. "integrated" mills, which make pulp and then use it themselves to make paper.

These industries are huge, highly mechanized, and efficient. There are many of them, so they compete fiercely for the available markets. In countries where huge markets, skilled managers and technicians, and the massive capital needed for investment are available, handmade and small-scale paper manufacturers find it very hard to compete. In the developing world, opportunities may be better, but are rarely undertaken largely due to insufficient technology, skill, capital, and other inputs.

To put small-scale or handmade paper production in perspective, it is important to realize the vast range of production capabilities within the industry. For example, one person working out of a home workshop with minimal equipment can possibly produce as much as 45kg of paper per day, while a partially mechanized micro factory can turn out about 225kg daily. By contrast, the International Labor Office defines small scale to include production capacity of up to 27 metric tons per day. And a single machine in a large modern operation can produce 270 metric tons of paper per day. It should be obvious that only in very special circumstances and for very special markets can small-scale operations compete effectively in today's paper industry.

One field in which hand and small-scale papermakers do find a niche is the production of the very highest quality "art" papers, or the manufacture of a variety, of paper products or small local markets that are not served by large producers. Another area in which papermaking processes can be applied on a small scale is the manufacture for local markets of a variety of products such as egg cartons, flower or plant pots, rough boxes, or roofing materials. These are considered in detail in later sections of this paper.

III. HAND PAPERMAKING

Whether paper is made in the home workshop or the micro factory, the production processes for hand papermaking are quite similar. The scale of the equipment changes with the volume of production and the raw materials vary with what is available and the quality of paper to be produced.

PAPERMAKING PROCESSES

Pre-processing

Cotton or other rags and waste paper to be recycled are sorted thoroughly to remove all non-fibrous materials such as staples, paper clips, cellophane, nails, buttons, zippers, etc. Both rags and paper are cut or shredded into small pieces.

Pulping

The cleaned and shredded raw materials are brought to the boiling point and cooked for two to six hours. They are rinsed thoroughly to remove impurities that might have separated out during the cooking process.

The beater--this can range from a kitchen blender to a specially made tank--is filled with the required quantity of water, and the cooked, chopped rags or paper are added gradually with high speed agitation. Bleaching powder or liquid bleach (1 percent) is then added. The pulp is washed thoroughly, a process that may take another six to eight hours. Additives that may be used include titanium dioxide or other fillers, dyes (for colored paper), or optical bleaching agents (for white paper). Rosin soap and alum are added later.

Lifting, Couching, and Stacking

When the pulping process is complete, the pulp is transferred to storage containers or vats. Depending on the scale of the operation, the pulp is then mixed with a sufficient quantity of water to dilute it to form a uniform suspension, free of lumps. In the home workshop, the pulp is mixed in quantities to make one sheet at a time. In the small factory, a larger quantity may be mixed at one time. The diluted pulp is then lifted from the water on wire screens, and the resulting sheets are covered by felt or other absorbent cloth. With the cloth in place, the still wet pulp layer is carefully lifted from the screen. This process is called couching (pronounced cooching). The couching cloth, paper side down, is placed on a felt covered board and smoothed to remove wrinkles or air bubbles. Each succeeding sheet is placed in a stack over the first.

Pressing and Drying

When a sufficient number of sheets have been formed, they are put under a press to remove the water. The sheets are then separated and, to avoid shrinkage, placed under absorbent boards and pressed again. The sheets are hung to dry in bunches of three to six, according to thickness, or dried in a warm oven.

Sizing

Sizing gives paper a harder finish so that water based paints and inks will not bleed or run. Paper may be sized internally, by adding the sizing agents to the pulp, or externally, by painting or dipping the dried sheets. For internal sizing, alum, rosin, gelatin, cornstarch, or linseed oil may be added in very small quantities at the end of the pulping stage. For external sizing, the dried sheets are dipped in a dilute glue or starch solution, Pressed to remove the excess, and hung up to dry again. In the home workshop, the individual sheets may be painted with the dilute solution.

Blotting paper, filter paper, toilet tissue, grey board, and some art papers may require very little, if any, sizing.

Calendering

The dried sheets are placed alternately between metal plates into a stack or "post." The stack is passed between calender rollers to obtain the desired smoothness. This can be done in the home workshop by pressing the paper sheet between sheets of aluminum foil with a hot iron.

Sorting and Cutting

After calendering, the sheets are carefully sorted and cut to size for packing and shipment. MAKING PAPER IN THE HOME WORKSHOP

Papermaking at this scale can be done as a hobby, for gifts, or as demonstrations in schools. Or, if the market exists for top quality handmade sheets, it can form the basis for a small business. Artists, bookbinders, and museums--or individuals seeking fine writing paper--are potential customers. The necessary equipment may already be available in some kitchens, but the markets should be considered carefully before any investment is made.

This process assumes that waste paper or cotton cloth will be used to make the paper. Approximately 50 sheets (21.5cm x 28cm) can be made from a pound of waste paper. Household bleach, alum, gelatin, cornstarch, and animal glue may also be needed. And ordinary fabric dyes can be used to produce tinted or colored papers. The process also assumes the availability of adequate water and electrical or other power supplies.

Equipment and Materials

The following equipment is needed:

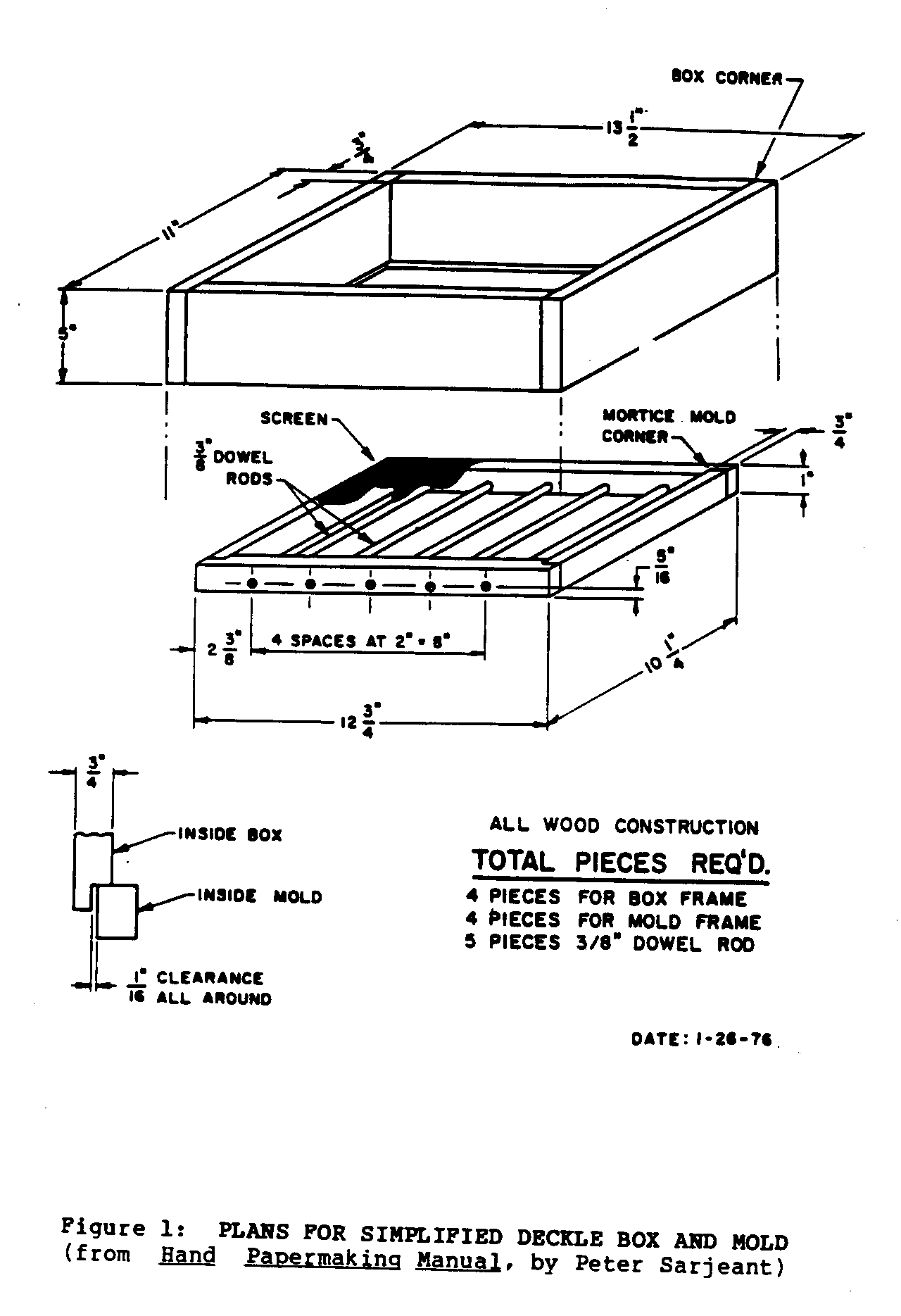

Deckle box and mold, made of oiled wood (Figure 1)

Power food mixer or blender Stainless steel or enamel pot (not aluminum) Steam iron Stove with oven Sink, tub, or wash basin Couching cloth (i.e., cotton sheeting), cut to size Felt or absorbent terry cloth, cut to size Thin metal sheet Flat "receiving" board, lcm plywood or other board

Pulping

Choose paper with minimal printing. Old envelopes are good for this reason: the glue on the flap won't matter. Colored paper is acceptable; the dye usually comes out when it is boiled. Avoid paper that has wet "strength" such as paper towels. Be careful how many brown paper bags you use. Unbleached kraft paper lowers the brightness or whiteness of the pulp, but it is Strong and will give your paper toughness. Newsprint alone makes a weak pulp, grey in color. It adds little but bulk. Cotton or other cloth or yarns may also be used. They must be cut or shredded into very small pieces to avoid jamming the mixer.

Cut or tear the paper into small pieces, about 5cm x 5cm. Shred any cloth that may be used. Put the pieces in the pot, cover with water, and add a few tablespoonfuls of household bleach. Turn on the heat, cover the pot, and bring to a gentle boil. Stir occasionally for a couple of hours to ensure that the bleach is mixed and all the paper is wetted down well, then cool.

After the batch has cooled, try to break up the lumps and any remaining pieces of paper still holding together. The smaller the pieces in the beginning, the easier this step is now. The pulp can then be drained and stored in plastic bags in a refrigerator until you are ready to make the sheets. It will keep for weeks without any change.

Making the Sheets

Take a lump of the semi-moist pulp you have prepared. Press as much moisture out of it as possible to leave-a ball about the size of a pigeon egg (7g dry weight). This is enough pulp to make one 21.5cm x 28cm sheet. Make the sheets, one at a time, as follows:

1. Blend and mix pulp in blender 3/4 full of water. Add additives.

2. Put mold in box, screen side up and immerse in sink. Rap box to get rid of air bubbles.

3. Pour pulp into box.

4. Holding box down, agitate the water in the box with fingers so that the pulp spreads evenly over the mesh.

5. Grasp box and mold firmly and lift quickly and evenly to surface (feel suction).

6. Hold for 10 seconds or so to drain.

7. Lift up out of water and hold vertically to drain. If sheet looks okay, proceed; if flawed, put box and mold back into sink and repeat steps 4 to 7.

8. Set box on flat surface and carefully remove box. Note: Water drops on wet web will make marks!

9. Carefully lay cotton couching cloth over web and smooth gently.

10. Place absorbent felt over couching cloth. Smooth and press down from center out.

11. Remove felt and wring out water.

12. Repeat 10 and 11 until no more water comes out.

13. Couch off sheet, starting at corner and peeling back quickly.

14. Place couched sheet, paper side up or down on flat absorbent surface. Smooth and press down to remove trapped air.

15. Repeat for each sheet until a neat stack is built up.

Pressing and Drying

The sheets can be dried quickly by pressing them with a hot iron and an aluminum sheet or slowly (2-3 hours) by placing them in a 120 [degrees] C oven, with the couching sheets tacked down to the receiving board all along the edges of the paper sheets. The first method gives a smooth surface on one side, embossing with cloth marks on the other; the second gives embossing on both sides.

A very slick surface can be obtained by smoothing the couching cloth, paper side down, against an aluminum or oiled galvanized sheet. A squeegee can be used to get rid of all the air. Dry in air or in a 120 [degrees] C oven.

Sizing and Coating

A simple method of internal sizing uses a combination of pure gelatin and cornstarch (either laundry or cooking type). The gelatin is dissolved in boiling water and cornstarch is added to make a clear, thick mixture to add to the pulp. Use about one teaspoon of this per 21.5cm x 28cm sheet.

Another simple internal sizing procedure is to add about 1/4 teaspoon of linseed and/or a teaspoon of cornstarch solution while the pulp is being mixed at Step 1. The oil is dispersed in the water and precipitates on the fiber. The starch will be caught on the fibers and during the drying stage will set to give a stiffer sheet.

External sizing is done when the sheet is coated with a water based solution after the paper has been dried. With an ordinary 4cm paint brush, coat each sheet with a 7 percent straight corn starch solution. One tablespoonful of cornstarch added to a cup of water will be enough for 20 to 25 sheets (both sides). Animal glue can be added to the starch to improve the water resistance. Modern glues can be added also.

When the coated sheets are nearly dry to the touch, place them in a neat stack. They should be somewhat limp but not wet. Put a metal sheet or smooth board on top. Allow the stack to dry overnight. The sheets can then be trimmed if necessary and packaged for sale.

MAKING PAPER IN THE MICRO FACTORY

On a somewhat larger scale, but still in an essentially hand process, paper can be made in a micro factory capable of producing about 240kg (1/4 ton) of paper per day. Such small factories are fairly common in India, and VITA has assisted at least one such operation in Tanzania. This process uses wastepaper or rags to make pulp, or pulp purchased from a pulp mill. It can produce good quality bond or drawing paper, card stock, school tablets, filter paper, toilet tissue, grey board, and album or blotting paper. It can also turn out such articles as egg cartons, flower pots, seed flats, hospital trays, etc.

In addition to an identified, reliable market, the small factory requires a steady, reliable supply of raw materials, water, and power. Suggested facilities include a building of about 300 square meters for operations and a shed of about 185 square meters for collecting and sorting the materials. Six administrative staff and as many as 100 laborers working in two or three shifts are needed. The U.N. Industrial Development Organiztaion (UNIDO) estimates an investment of approximately US$26,000 for the total cost of installation. Production may be increased by installing one or two more beaters and operating the vats in three shifts. Beyond that capacity, however, economies of scale decline. For larger production, a mechanized small-scale plant should be considered (See Section IV).

The following lists of equipment, supplies, and staffing are drawn largely from UNIDO's monograph on small-scale paper production. Molds and presses for specialty items are not included. Production processes follow the steps given at the beginning of this section.

Machinery and Equipment

Vomiting type digester, 1.5m x 1.2m Rag chopper, 25.5cm blade with 3-hp motor Beater, 61cm x 76cm roll size (x2) Electric motor for beaters of 20 hp, 960 rpm, slip-ring with oil-immersed starter (x2) Lifting semi-automatic vats (x6) Hydraulic press, 102cm x 127cm plate size, double ram with 5 hp motor Screw press (91.5cm x 107cm or 89cm x 114cm plate size for processing of sized paper, etc.) Calender machine for paper glazing (30.5cm x 91.5cm roll size, complete with accessories) Electric motor for calender machine (10 hp, 960 rpm, with starter) Paper-cutting machine (107cm x 122cm blade size) Small beater of 2 kg capacity with 1/2 hp motor for experiments Washing machine Chain pulley block with tripod, 2-t capacity Platform weighing balance, 500 kg capacity Pulp storage tanks for lifting vats (x6) Washing cradles for pulp washing Press boards for calender machine, 1.2m x lm(x40) Woollen felts x(400) Complete sets of carpentry tools, pipe-fitting tools, etc. Small (2 kg) pan balance Towel horses for keeping felts (x6) Sizing trays Grinder Dusting frame Spare parts for molds, etc. Couching tables (x6) Stools for vats, paper separation Drying arrangement Other miscellaneous articles: buckets, brushes, hardware stores, etc. Miscellaneous office equipment: typewriter, cupboards, tables, chairs, racks, clocks, etc. Storing arrangements for finished paper, chemicals, etc.

Raw Materials and Chemicals

New rags and clean waste paper, 90 tons Caustic soda flakes, 1 percent: 900 kg Bleaching powder, 1 percent: 900 kg Titanium dioxide, 1 percent: 900 kg Rosin, 1.5 percent: 1,350 kg Soda ash, 400 kg Alum (non-ferric), 3 percent 2,700 kg Glue flakes, 3 percent: 2,700 kg optical bleaching agent: 50 kg Formalin, 720 1: approximately 700 kg Diacol M, 15.5 percent: 450 kg Miscellaneous: dyes, soap kerosene, ultramarine blue, etc.

Labor No. of persons Remarks

Rag sorters 6 General shift Rag dusters 4 General shift Rag cutters 22 In shifts Digester operators 2 In shifts Beater operators 4 In shifts Beater assistants 4 In shifts Vat operators 12 In shifts Couchers 12 In shifts Press and wet paper separating 8 In shifts Paper drying 4 General shift Paper sorting 6 General shift Glue sizing 4 General shift Calendering 2 General shift Paper cutting and packing 1 General shift Miscellaneous work 5 In shifts Night watchmen 4 In shifts Carpenter/mechanic 1 In shifts Helper 1 In shifts

IV. SMALL-SCALE MECHANICAL PAPERMAKING

Mechanical papermaking--even on a small scale--is highly technical and complex. More detailed descriptions may be found in the publications listed in the Bibliography. The following sections give an overview of the basic processes for producing paper from waste paper for two different scales of operation. ONE-TON-PER-DAY PAPERMAKING PLANT

In India, very small (one-ton per day) "cylinder mold" machines are used to produce paper. These machines are simple to operate and can use either waste paper or agricultural wastes such as sugar cane, sisal, banana, or bamboo. Cotton rag, widely available in India, is also used.

The raw material is first passed through a chopper, then broken down to basic fibers in a "Hollander Beater." This takes between one and a half and three hours. The pulp is washed and bleached if required, then diluted with plenty of water and fed into the "cylinder mold" machine, which forms the paper.

A wire mesh covered cylinder revolves in a vat full of pulp. Water is sucked out through a drain in the cylinder, leaving a layer of pulp on the wire mesh surface. At the top of the cylinder an endless band of wool felt picks up the layer of wet pulp and conveys it to the cutting roll where an operator makes a cut parallel to the roll axis and peels off the pulp in sheets that are stacked for squeezing in a hydraulic press. Finally, the sheets are dried and calendered (squeezed between smooth rollers).

Each sheet is 86 x 56cm. The weight of the paper ranges from 65 grams per square meter (gsm) for writing and printing papers to over 300gsm for packaging. Among the many applications are envelopes, file covers, file cards, insulation, and filter paper.

Most of the water used in the process is recovered but there is a net consumption of about 46,000 liters in 24 hours. The plant includes a number of three-phase electric motors. It employs 12-16 workers per shift, plus management. According to UNIDO estimates, capital investment in a mill in this size range would be about US$100,000.

FIVE- TO THIRTY-TON-PER-DAY PAPER PLANTS

A typical machine in this range is illustrated in Figure 2. A 30-ton-per-day

machine would not be greatly different: it would have more dryers, probably a third press, and would run faster, fed with suitable stock. Capital investment for a 10- to 25-TPD machine is estimated by UNIDO to be approximately US$4 million.

A simple hydropulper is used for making pulp. It has a cylindrical steel tank with a rotary "impeller" (like a strongly constructed fan) in the base. The impeller swirls the water, chops the paper, then mixes the pulp. The process is performed in batches and some contraries are physically removed at intervals. Other contraries, such as string, wires, wet-strength papers, or plastic, are continuously removed by a "ragger rope" or, occasionally, a "junk trap." High-density centrifugal cleaners and pressurized or vibrating screens are also used. This is followed in some instances by low-density cleaners with up to three stages, for removing plastics and adhesives.

The output of the pulp mill requires beating or refining before it can be made into paper. This is done with a "Hollander," a roll carrying heavy bars that rotates in a strong trough, at the bottom of which are more bars. The roll batters the fibers against the trough bars and also pumps the pulp around the trough. Refining strengthens the paper product, and produces a more consistent pulp.

Consistency is the percent by weight of the weight of dry pulp to the weight of the wet slurry (or semi-dried mixture of pulp and pulp plus water). For example, 6 percent consistency is about 6kg of dry pulp plus 100kg of water, and this is like a thick soup; 30 percent consistency is like a wet but not dripping newspaper.

Papermaking involves the handling and processing of very thin layers of pulp, which is weak in its wet state. Maintaining the proper consistency is therefore vital. But one of the problems of small-scale papermaking is that the necessary controls for maintaining the right consistency may be omitted to reduce costs. Stock preparation also includes cleaning, screening (to remove lumps of pulp or foreign matter), and the addition of chemicals or dyes.

In more modern mills, refiners are used. In a refiner, pulp stock is fed into the center of two flat plates with bars for brushing the fiber. One plate is fixed, the other rotating. As the fiber, at 3-4 percent consistency, moves from the center to the edge, it is brushed by the bars.

In India (but almost nowhere else), small Fourdrinier machines are cheap and readily available. The pulp is dispensed from the "head box" onto a continuous loop of fine wire mesh supported by rapidly rotating rollers that suck the water from the pulp. The roller sucks out sufficient water for the sheet, now semi-solid, to leave the mesh wire and, supported on porous felt belts, to pass through two or three sets of press-rolls. It leaves these with about 60 percent water. The excess water is removed by the dryer, an array of 16 steam-heated drying cylinders, each about 1.5m in diameter, against which the paper is firmly held by felts and smaller rollers. A set of shiny-smooth calender rolls gives a hard, smooth surface finish to the paper, which is then wound in a continuous length onto strong cardboard cylinders, to form a reel of over a meter in diameter, containing hundreds of meters of continuous paper.

The width of the small Fourdrinier machines is rarely more than 1.75 to 2.5 meters. Plants of this kind can produce papers from 50gsm to 150gsm in most grades, and run at over 100 meters per minute. The tonnage of paper finally produced will be around 85 percent of the weight of waste paper input, and this can be improved if the water is cleaned and recirculated, so that no fiber is lost.

V. ALTERNATIVE PRODUCTS FROM WASTE PAPER

FRUIT AND EGG CARTONS PROM WASTE PAPER PULP

Another process makes egg cartons from paper pulp using a small-scale paper plant called the Super Melbourne. Waste paper is first soaked, then pulped and refined. Pulping can be done in a domestic washing machine.

The equipment includes a refiner that reduces the pulp to basic fibers. The slurry that results is poured onto a sheet of mesh stretched over the forming tank of the Super Melbourne and a valve in the tank is opened. The water draining from the tank sucks moisture from the layer of pulp, which is then pulled from the tank on its sheet of mesh. The layer of pulp is folded over once and pressed between specially shaped dies, then it is laid to dry.

The process employs four people, but labor costs are reduced when Super Melbourne machines are batched together for greater output. Output is 60 egg trays per hour, or 60 sheets of paper 84 x 66cm. The machine requires only 300 watts of electrical power. Most of the water used is recycled. Floor space required is 2 square meters for the machinery and 5 square meters for drying.

More sophisticated machinery is available for producing from 200 to 4,000 30-egg trays or equivalent products per hour. Such a machine is made by Tomlinsons, but careful market research is essential before contemplating the heavy cost of a machine that tends to saturate any but the largest market.

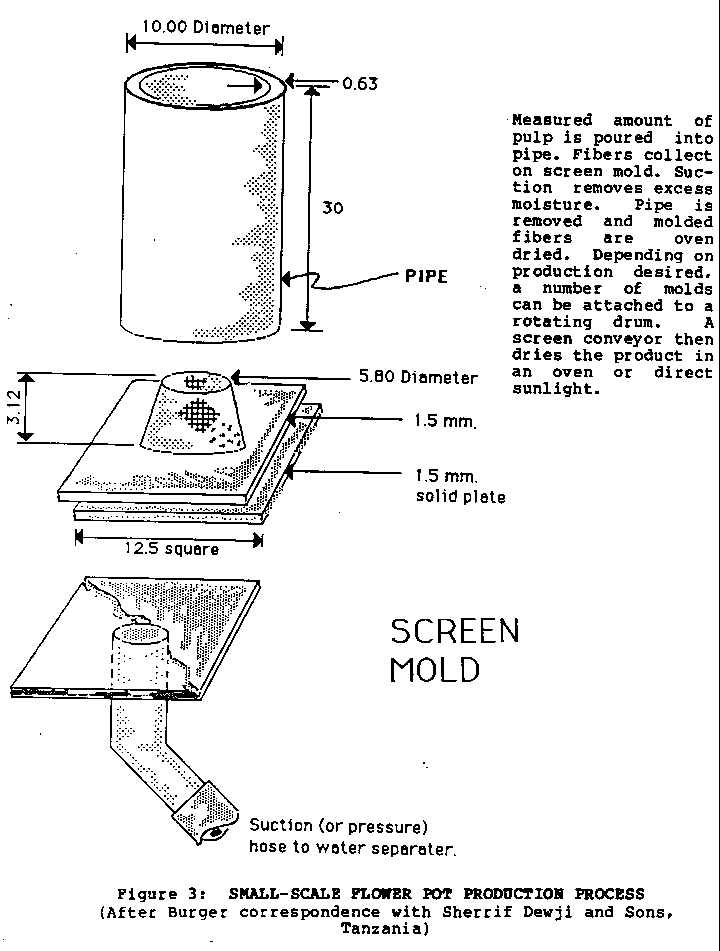

Similar machinery is available or can be specially designed to produce flower pots, seed flats, hospital trays, etc. (Figure 3).

A careful market study should be made before investing in such equipment.

ASPHALTED ROOFING SHEETS

Low-quality, low-cost roofing sheets with a life of about five years can be made from the very lowest grades of mixed waste paper grades that would not be acceptable for papermaking due to the amount of dirt and contraries present. A factory with three molding machines costs about $200,000 for plant and machinery and can produce about 8,000 sheets daily, each about 1 square meter in area (over two million square meters annually). About 35 people are employed and 50 metric tons of paper per week are used. In India, the roofing material retails at around $0.25 per sheet; in South America, at about $0.60 per sheet. The manufacturing process consists of the following steps:

1. The waste paper is washed and pulped in a hydropulper. A mechanical hammer mill or a Hollander beater may be used instead.

2. The pulp is passed through a screen, to remove dirt, grit, or other impuities, and a board-forming machine (similar to that already described for a one-ton-per-day paper machine), to produce a continuous length of board that is cut to length as it comes off the machine.

3. The board is spread on the ground and dried in the open air. The edges are trimmed on a rotating slitter.

4. The board passes through an oven at the end of which are corrugating rollers. The corrugated sheets are then trimmed again and stacked in cradles.

5. Next, they are dipped in a bath of hot asphalt. (Asphalt is flammable so the means of heating must be carefully chosen.) The asphalt hardens rapidly at air temperature and the sheets are unloaded and stacked.

6. When quite hard the sheets are either:

- taped in bundles for sale as third quality;

- sprinkled with mineral chips (while asphalt is soft) prior to packing as second quality; or

- hand painted and packed as first quality.

BIBLIOGRAPHY/SUGGESTED READING LIST

Ainsworth, J.H. "Paper the 5th Wonder," Thomas Printing and Publishing Company, 1959.

Appropriate Industrial Technology for Paper Products and Small Pulp Mills. Vienna, Austria: United Nations Industrial Development Organization (UNIDO), 1979.

Brook, S. "The Fine Art of Printing," Atlantic Monthly, April, 1974 (112-115) .

Becker, W.J. "The First Ten Years of the Fourdrinier," Paper Trade Journal, April 17, 1972 (34-41).

Becker, W.J. "The First 145 Years of the Paper Machine in the U.S.," Paper Trade Journal, May 27, 1972 (140-150).

Casey, James P. "Papermaking," Pulp and Paper, Vol. II, New York, New York: Interscience Publishers, Inc., 1960.

Goodwin, Rutherford "The William Parks Paper Mill at Williamsburg, Virginia", Lexington, Virqinia: Bibliographical Society of America, 1939.

Hunter, Dard Papermaking Pilgrimage to Japan, Korea, and China, New York, 1936.

Hunter, Dard Papermaking, New York, New York: Alfred A. Knopf, 1967.

Hunter, Dard Papermaking in the Classroom, the Manual Arts Press Peoria, Illinois.

Hunter, Dard "Watermarking Handmade Papers," Scientific American, March 26, 1921.

Norris, F.H. Paper and Paper Making, New York, New York: Oxford University Press, 1951.

Sarjeant, Peter T. Hand Papermaking Manual. Covington,Virginia: Paper Make, 1976.

Small-scale Paper-making, ILO Technical Memorandum No. 8. Geneva, Switzerland: International Labour Office, 1985.

Sweetman, J. "Making Paper by Hand," Appropriate Technology, Vol. 3, No. 4. London: Intermediate Technology Publications Ltd.

Thomas, C. The Paper Chain. London: Earth Resources Research Ltd., 1977.

Tsein, Tsuen-Hsuin "China, the Birthplace of Paper, Printing an Moveable Type," Pulp and Paper International Journal, February, 1974.

von Hagen, V.W. The Aztec and Maya Papermakers, New York, New York: Hacker Art Books, 1944.

Western, A.W. Small Scale Pulp and Paper Manufacture, London Intermediate Technology Publications Ltd., 1979.

EQUIPMENT SUPPLIERS

Paper Mill Plant and Machinery Manufacturers Ltd. 181 S V Road Jogeshwari, Bombay 400060 India

Hindon Engineering Works Clubley, Bajoria Marg, Saharanpur 247001 UP India

Indo Berolina Industriea, Pvt. Ltd. I.B.I. House 5-86 Andheri Kurla Road Bombay 400059 India

Jessop and Co Ltd. 63 Netaji Subhas Road P.O. Box 108 Calcutta, India

SOURCES OF INFORMATION

Association of the Pulp and Paper Industry One Dunwoody Park Atlanta, Georgia 30341

Write for free four-page booklet, "How You Can Make Paper": American Paper Institute 260 Madison Avenue New York, NY