Special Acknowledgements: In addition to the authors above, Saw Earth Siriraksuk and Songsan Lerdprakun assisted with weighing and feeding. Further recognition and thanks to Ratakarn Arttawuttikun for coordination of farm staff and translation.

Introduction

Farm-generated pig feed can be a cost-effective option for smallholder farmers, particularly in remote settings that produce wild or cultivated feed inputs (Trail et al., 2020). Farmers use farm-generated feed inputs to supplement or reduce commercial feed, lowering overall feed costs. In Northern Thailand, banana plant stalks (pseudostems) are an abundant resource and popular pig feed input for smallholder farmers. Farmers commonly process banana stalks by chopping and boiling them before mixing them with other feed for their pigs (Burnette and Pawkham, 2019).

While farmers can benefit from the accessibility and lower cost of local resources for feed, these inputs may also require more time for pigs to reach market weight (Trail et al., 2020). Extra growth time might be less of a consideration when raising pigs for breeding purposes or as a family asset. But for smallholder farmers looking to maximize profit from meat production, this can be a significant factor. Efficient feed processing and lower input costs become increasingly important with slower growth rates.

Figure 5. Banana stalks boiling over an open flame (left) and fermented banana stalks (right). Source: Jonathan Ribich

At ECHO Asia, we process banana stalks by chopping and fermenting them with the addition of salt and molasses to create silage (http://edn.link/dfy2ay; Figure 5). This method of processing requires minimal labor and no fuel. Another benefit is that, unlike boiling stalks over an open fire (as commonly practiced in the region), fermentation does not produce smoke. Indoor smoke from cooking fires negatively impacts public health. Smoke from open fire cooking also contributes to air pollution from the burning of crop residue and forest floor debris, further exacerbating a dire problem in Northern Thailand and surrounding regions (Prapamontol et al., 2023; Orakij et al., 2017).

Fermenting banana stalks for use as pig feed has the potential to reduce input costs and smoke emissions while increasing or retaining equal weight gain of pigs compared to pigs reared on boiled banana stalks.

Research purpose

We conducted a 22-week pig feed trial to assess the potential effects of different banana stalk processing methods on pig weight gain. The trial also tracked the input costs of feed preparation for each treatment. The trial took place at the ECHO Asia Regional Impact Center in Chiang Mai, Thailand.

Materials and methods

Our trial compared three treatments:

Figure 6. Pig in a deep litter pit pen. Source: Jonathan Ribich

- farm-generated feed containing fermented banana stalks

- farm-generated feed containing boiled banana stalks

- farm-generated feed containing raw banana stalks (the control)

Each treatment group contained three pigs housed individually in deep litter pens (Figure 6).2 Farm staff fed the pigs once in the morning and once in the afternoon each day and provided all treatment groups with constant access to water. We weighed the pigs every 2 weeks over 154 days (22 weeks), the time it takes our pigs fed with farm-generated feed to reach a marketable weight (Trail et al., 2020).

Figure 7. Side view of deep litter pit layers. Source: Jonathan Ribich

Figure 8. Weighing pig feed treatments. Source: Jonathan Ribich

After weaning and at two additional stages of pig growth (when average pig weights reached 30 kg and 60 kg, as noted in table 1) we adjusted our farm-generated feed recipe to account for their changing dietary needs (lowering the protein content and increasing the banana stalk input at each stage; Figure 8). This accounts for a natural slowing of growth rate as the pigs age. The feed ratios and the dry feed components were the same across all treatments and were adjusted in the same way at each stage, throughout the duration of the experiment. Our farm-generated pig feed recipes are shown in table 1 and feeding ratios by stage are outlined in table 2. We chopped the banana stalks to the same size for all treatments, using an electric chipper with a rotary blade (Figure 9).

| Feed Source | Amount | Protein (%) | Protein (Total) |

| 20% protein Feed – For pigs weighing 10-30 kg | |||

| Banana stalk | 40 | 6 | 2.4 |

| Rice bran | 12 | 12 | 1.44 |

| Corn meal | 15 | 9 | 1.35 |

| Fish meal | 10 | 60 | 6 |

| Soy meal | 22 | 40 | 8.8 |

| Premix | 1 | 0 | 0 |

| Total | 100 | 20 | |

| 18% protein Feed – For pigs weighing 30-60 kg | |||

| Banana stalk | 45 | 6 | 2.7 |

| Rice bran | 12 | 12 | 1.44 |

| Corn meal | 12 | 9 | 1.08 |

| Fish meal | 5 | 60 | 3 |

| Soy meal | 25 | 40 | 10 |

| Premix | 1 | 0 | 0 |

| Total | 100 | 18 | |

| 16% protein Feed – For pigs weighing 60+ kg | |||

| Banana stalk | 55 | 6 | 3.3 |

| Rice bran | 10 | 12 | 1.2 |

| Corn meal | 10 | 9 | 0.9 |

| Fish meal | 6 | 60 | 3.6 |

| Soy meal | 18 | 40 | 7.2 |

| Premix | 1 | 0 | 0 |

| Total | 100 | 16 | |

| Pig weight (kg) | % protein | Feeding time | kg feed per pig per day | kg per pig per feeding time |

|---|---|---|---|---|

| 10-30 | 20 | Morning | 1.5 | 0.75 |

| Evening | 0.75 | |||

| 30-60 | 18 | Morning | 2.25 | 1.15 |

| Evening | 1.15 | |||

| 60+ | 16 | Morning | 3 | 1.5 |

| Evening | 1.5 |

Figure 9. Electric chipper used to chop banana stalks. Source: Jonathan Ribich

Figure 10. Open flame wood fire for cooking. Source: Jonathan Ribich

For the boiled treatment, we boiled chopped banana stalks in a pot filled with water over an open wood fire (Figure 10). The recipe for pigs at the first growth stage (10-30 kg) required a daily cooking time of approximately 25 minutes, which burned about 2.4 kg of wood. The second growth stage recipe (for pigs weighing 30-60 kg) required a daily cooking time of approximately 40 minutes, which burned about 3 kg of wood. The third growth stage recipe (for pigs over 60 kg) required a daily cooking time of 60 minutes, which burned about 3.4 kg of wood. Time spent chopping banana stalks averaged 8 minutes per day (Figure 11). Our total time input for firewood collection and processing was around 7 hours, which we used with research on firewood cost quantification to set a price for fuel input (Crawford, 2018). At the Thai minimum wage of 1.37 USD per hour, calculated based on an 8-hour day (Thailand Ministry of Labour, 2025), the combined cost for the boiled treatment was approximately 163 USD over the duration of the experiment.

Figure 11. Chopping banana stalks for farm-generated feed. Source: Jonathan Ribich

We made the fermented treatment in batches sufficient to feed a treatment group for 5 days. For every 10 kg of chopped banana stalks, our recipe calls for 120 g of molasses and 140 g of salt. The ingredients were layered together and allowed to ferment in a covered bin for 5 days before use. The price of salt was 0.17 USD per kg and the price of molasses was 0.41 USD per kg. The combined input cost of salt and molasses over the duration of the experiment was approximately 3 USD. The average time spent chopping banana stalks and mixing the batch ingredients was 23 minutes every 5 days. At the Chiang Mai minimum wage of approximately 1.37 USD per hour, the labor cost for the fermented treatment processing over the duration of the experiment was about 16 USD. The combined cost for the fermented treatment was approximately 19 USD over the duration of the experiment.

To avoid spoilage, the raw treatment was chopped fresh every day. The average daily time input for chopping was about 8 minutes. At the Thai minimum wage of 1.37 USD per hour, the raw treatment labor cost was approximately 27 USD over the duration of the experiment.

We weighed the banana plant stalk inputs for each treatment before processing to avoid skewed measurements from any weight changes that might occur during processing. We added appropriate amounts of water to the fermented and raw treatments before feeding to account for additional water input from the boiled treatment (additional water weight was determined by weighing the banana stalks in the cooking water before and after cooking to account for water loss from evaporation).

Results

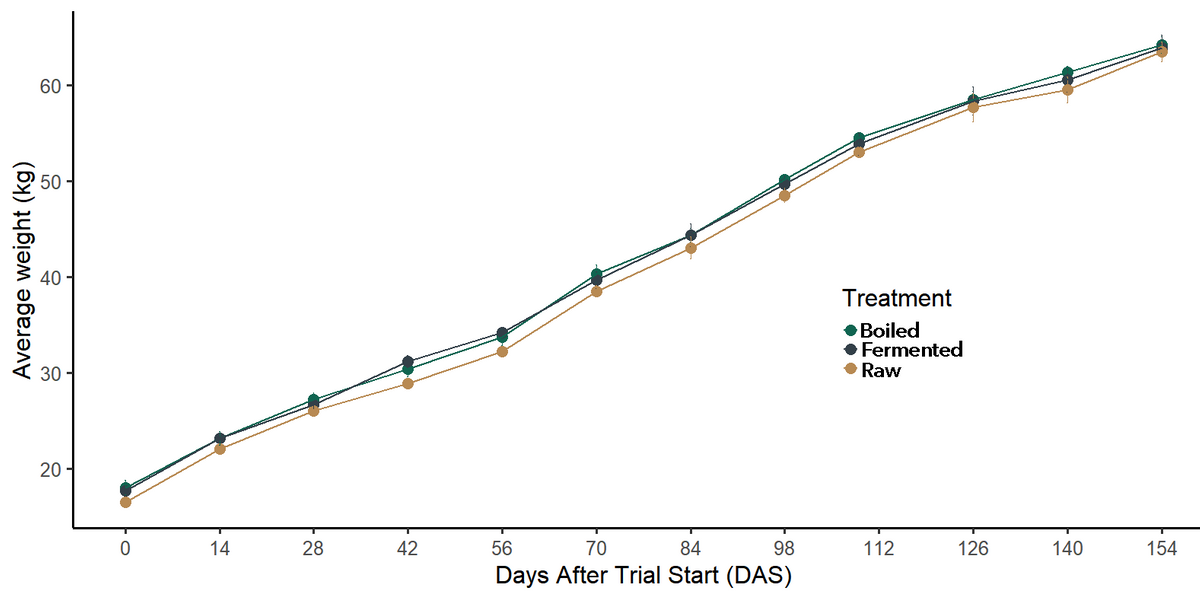

From the beginning to the end of the trial, pigs gained an average of 46.2 kg with boiled and fermented banana stalks and 47.0 kg with raw banana stalks. The difference between 47.0 and 46.2 kg was not statistically significant. Gender did not significantly impact observed differences in weight (P=0.993). Over time, the rate at which pigs gained weight (Figure 12) did not vary statistically between treatments (P = 0.82). The separation of the raw treatment from the boiled and fermented treatment, as seen in figure 12, is attributed to the initial smaller size of the three pigs and not feed processing differences.

Figure 12. Average weight gain of pigs for three feeding treatments: raw, boiled, and fermented feed.

The boiled treatment had the highest overall cost of treatments in our trial at approximately 163 USD (Table 3). The price of fuel was equated to the hourly expense of labor for collecting and processing firewood, totaling 10 USD. Time spent chopping banana stalks and time spent cooking banana stalks were also expensed at hourly rates for totals of 27 USD and 126 USD, respectively.

| Cost | Processing labor (USD) | Inputs (USD) | Description | Total |

|---|---|---|---|---|

| Boiled Treatment | 153 | 10 | fuel | 163 |

| Fermented Treatment | 16 | 3 | salt, molasses | 19 |

| Raw Treatment (control) | 27 | - | - | 27 |

| Time | Chopping banana stalks (hrs) | Collecting/processing wood (hrs) | Cooking (hrs) | Total (hrs) |

| Boiled Treatment | 20 | 7 | 92 | 119 |

| Fermented Treatment | 12 | - | - | 12 |

| Raw Treatment (control) | 20 | - | - | 20 |

The control had the second highest overall cost at approximately 27 USD. The only expense for the control was the hourly rate for daily time spent chopping banana stalks.

The fermented treatment resulted in the lowest overall cost at approximately 19 USD. The time spent chopping banana stalks and layering them with inputs for fermentation was charged at an hourly rate for a total of 16 USD. This treatment required less time than the control due to preparation in batches every 5 days (the preservation properties of fermentation allow for longer storage) instead of daily preparation. The cost of molasses and salt inputs totaled 2 USD and 1 USD, respectively.

We calculated and prepared the necessary feed and input weights based on the needs of three pigs for each treatment group.

Discussion and conclusions

Despite the high cost of the boiled treatment, in the form of labor and fuel input, we observed no benefit to its use over the other treatments trialed.

While we did not observe a significant difference in weight gain between the three treatments over the duration of this trial, fermentation still holds benefits that may warrant the additional processing. Fermenting chopped banana stalks is a method of feed preservation that reduces the chance of spoilage (DuPonte et al., 2016). This allows us to chop larger batches of banana stalks because they can be safely used and stored over a longer period, reducing labor costs required in additional setup and clean up for feed processing. Fermentation also yields a feed with live cultures, which may be beneficial for the pig’s digestion, reduce smell, and improve overall health. These benefits are not captured in measuring weight gain alone.

Banana stalks are high in fiber and various minerals, including iron and potassium (DuPonte et al., 2016). Dietary fiber is another important factor in the digestive health of pigs, due in part to potential prebiotic effects in the gut (Lindberg, 2014). Further research could explore the potential relationship between fiber derived prebiotic effects and beneficial microbes in fermented banana stalks.

There are additional factors that should be considered when assessing the potential benefits of fermented feed. The process of fermentation itself requires passive time input. Some additional planning is necessary to ensure that the preparation of batches is timed properly to meet feed demands. It is also worth noting that we have access to relatively inexpensive molasses and salt. Molasses can be substituted with other sugar sources, if the cost difference and availability is favorable. With experimentation, the amount of molasses (or other sugar source) and salt can be adjusted as well, to potentially reduce costs further. An alternative recipe that ECHO has successfully used calls for more molasses (4%) and less salt (1%).

With some minor changes in processing practices, our results indicate that fermenting banana stalks offers a superior alternative to boiling banana stalks for farm-generated pig feed. The time and cost saving aspects of fermenting banana stalks could be particularly helpful for farmers looking to shift from a sustenance model to an agribusiness model.

References

Burnette, R. and J. Pawkham. 2019. Basics of Backyard Pig Production in Upland Villages of the Golden Triangle. Posted on ECHO Community in 2019. Pig feed options in the tropics - Animal Options - ECHOcommunity: Conversations.

Crawford, K. 2018. The cost of firewood: An actualistic quantification of collection tasks. Hunter Gatherer Research. 4 (4). https://doi.org/10.3828/hgr.2018.31

DuPonte, M.W., K. Cowell, and R. Jha. 2016. Banana Silage: An Alternative Feed for Swine. University of Hawaii College of Tropical Agriculture and Human Resources. Livestock Management 31.

Lindberg, J.E. 2014. Fiber effects in nutrition and gut health in pigs. J Animal Sci Biotechnol. 5 (15). https://doi.org/10.1186/2049-1891-5-15

Orakij, W., T. Chetiyanukornkul, T., Chuesaard, Y. Kaganoi, W. Uozaki, C. Homma, Y. Boongla, N. Tang, K. Hayakawa, and A. Toriba. 2017. Personal inhalation exposure to polycyclic aromatic hydrocarbons and their nitro-derivatives in rural residents in northern Thailand. Environmental monitoring and assessment. 189(10), 510. https://doi.org/10.1007/s10661-017-6220-z

Prapamontol, T., D. Norbäck, N. Thongjan, N. Suwannarin, K. Somsunun, P. Ponsawansong, K. Radarit, S. Kawichai, and W. Naksen. 2023. Respiratory infections among junior high school students in upper northern Thailand: The role of building dampness and mould, biomass burning and outdoor relative air humidity (RH). Environmental Research. 231 (1). https://doi.org/10.1016/j.envres.2023.116065.

Swartz, S. and N. Elhardt. 2023. Animal Production Litter Systems. ECHO Technical Note No. 100.

Thailand Ministry of Labour. 2025. Workers Celebrate: Wage Committee Approves 400 Baht Minimum Wage in 4 Provinces and 1 District Effective January 1, 2025. https://www.mol.go.th/en/news/workers-celebrate-wage-committee-approves-400-baht-minimum-wage-in-4-provinces-and-1-district-effective-january-1-2025

Trail, P., B. Thansrithong, and S. Bhalermliamthong. 2020. Making on-Farm Pig Feed: Farm-Generated Formulas vs. Commercial Feeds. ECHO Research Notes 2(3).