VITA

1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Hydroponics ISBN: 0-86619-282-4 [C]1989, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Suzanne Brooks and Patrice Matthews handling typesetting and layout, and Margaret Crouch as editor and project manager.

Co-authors Mark Anderson, Larry Bloom, Charles Queen, Mona Ruttenberg, Samart Sukanit, and Dan Thomas originally wrote up this project as a thesis for their curriculum in technology education at West Virginia University in Morgantown, West Virginia, under the guidance of Dr. Edward Pytlik. Kristine Stroad is a freelance technical writer/edit who has experience in Kenya, in Thailand for VITA, and with the United Nations in Geneva.

VITA Volunteer reviewer Ralph Prince is an agricultural engineer with the John F. Kennedy Space Center in Florida. Reviewers Walter Rosen and Ronald Stanley are also VITA Volunteers. Dr. Rosen, a botanist, is on the Board of Biology for the National Research Council. Dr. Stanley, senior biological policy analyst at the U.S. Environmental Protection Agency, is a plant physiologist with experience in Greece, Hong Kong, China, and the Caribbean.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Hydroponics is the growing of plants without soil. The name "hydroponics" implies that the plants are grown in water. Actually the plants are usually grown in "growing beds" that may be filled with gravel or sand or other material, and they get the nutrients they need from a water solution added to the beds.

Some of the important advantages of successful hydroponics over soil culture are:

- Yields in hydroponics can be as much as ten times greater than in soil culture;

- Plants need less space in hydroponics because the nutrients are concentrated;

- The nutrient solution is re-used, so the amount of water needed is much smaller;

- The nutrients are easier to test and adjust to growing conditions; and

- Labor costs are lower.

Another feature of a well-designed hydroponics system is that it does not pollute the environment.

Hydroponics is used mainly as a controlled system for the production of out of season crops, for growing crops in areas where the soil is not suitable for cultivation, or where water supply is limited. It is also useful for studies in plant nutrition, plant diseases, and plant breeding, where growth under exact conditions is needed. Almost any type of plant can be grown hydroponically.

Home gardeners can set up small hydroponics systems in their homes to grow a few crops for home use. In cold climates, large greenhouses are used for profitable hydroponics enterprises providing high quality, out of season produce. A hydroponics enterprise in a warm climate could also be feasible, using a locally-built screened structure to give a growing environment that can be kept free from insects and other pests and reduce heat and humidity.

Hydroponics is intensive agriculture that makes sense in a world where farmlands are disappearing and there is a need for quality, locally-produced food.

This paper will describe the basic features of a medium- to large-scale hydroponics system and prefabricated greenhouse appropriate for cold climates. Some modifications for a system suitable for hot climates are also discussed. Home gardeners in any climate can use the basic theories contained here, but may want a simpler operation, possibly without a greenhouse or special structure.

II. SYSTEM DESIGN

Site Selection

In choosing a good site for a medium- or large-scale hydroponics system, the following should be considered:

- The site should be reasonably level;

- The site should be as free of trees and shrubs as possible;

- There should be a supply of suitable gravel, sand, lava, or other mineral material available nearby;

- For a commercial enterprise, the site should be within reasonable reach of the markets where the produce will be sold;

- Roads and communications to the site must be good, to allow for the delivery of materials and other equipment, and for the shipment of produce;

- Depending on the climatic conditions, the site should have a good southern exposure to make use of solar energy; and

-

Water, electricity, gas, etc., as needed for present or future use, should be available at the site.

Greenhouse Design and Construction

A greenhouse is necessary in cold climates to provide a controlled environment for the successful growing of high quality plants throughout the year. In warm climates, a greenhouse is unnecessary, and a simple structure with a wood, tile, slat, bamboo, or thatch roof to provide partial shading and a dirt floor with pits containing suitable mineral material is recommended. A more advanced structure could include a concrete block foundation, concrete floor, and screened walls. Adobe might be considered for the foundation.

In cold climates, a greenhouse makes possible year-round cultivation. In a climate with hot days and cool nights, the greenhouse provides a controlled environment that not only protects plants from cold at night, but reduces heat and humidity during the day.

If light is likely to be limiting at any time of the year, greenhouses should be positioned to get the most sunlight. This means the long side of the greenhouse should lie east to west as shown in Figure 1.

In designing the interior of a greenhouse, first consider the amount of growing space needed and the size of the land available. Then think about the operations involved, automation, energy considerations and costs, and future expansion. Include areas for preparing the nutrient solution and for storage.

In a commercial greenhouse, an office and service area is needed for administration and to prepare, grade and pack crops for sending to market. An office should have space for visitors and customers, a secretary, and a manager. An employee lunch room, a lavatory, and a parking area are also needed. The office and service area should have sound absorbing material in the wall next to the growing area to protect the area from the sounds made by the greenhouse fans.

There are several advantages to constructing a series of connected greenhouses, with adjoining walls and connected roof gutters:

- They require less land area than detached greenhouses;

- Fewer construction materials are needed for side walls; and

- Less energy is required to heat or cool because there are fewer exposed wall surfaces.

In cold climates, a disadvantage is the difficulty of removing snow from the gutters between connected greenhouses. (Heat lines can be placed under the gutters to melt the snow.) Office and service areas can be located in an adjoining building on the north side of the greenhouses, decreasing heat loss.

Prefabricated buildings may be considered, where available. Materials and labor costs will vary locally and should be compared. Replacement parts for prefabricated units can be ordered from the manufacturer.

Fiberglass (with Mylar), polyethylene film, and glass can be used for greenhouse roofs. Fiberglass panels are made of reinforced plastic and are flexible enough to fit into curved frames. Mylar is a type of polyethylene, and is used as the inner layer with fiberglass. Fiberglass with Mylar lasts much longer and transmits light better than a double layer of polyethylene. The highest quality of polyethelyne film--six millimeter (0.23 inch)--lasts a maximum of a year and a half. Fiberglass with Mylar can last 15-20 years. Glass can also be used, and lasts much longer than even fiberglass, but it is much more expensive than either fiberglass or polyethylene. Whatever the material, it is recommended that double layers are used; the air between the layers acts as insulation and reduces heat loss.

To reduce start up costs, a new hydroponics enterprise may want to consider starting out with polyethylene and changing to fiberglass after one to two years.

Acrylic sheets can be used for the greenhouse side walls and some parts of the end walls. Acrylic sheets are stiff, are highly resistant to impact, insulate heat, and transmit light well--about 73 percent.

Compressed limestone gravel, six inches (15 cm) thick for good drainage, is recommended for the greenhouse floor. Other types of gravel, or sand or dirt could also be used.

Pathways in the greenhouse, made of asphalt, or concrete, should be wide enough for a cart to pass through easily--about six feet (1.8 m) wide--if carts are ever expected to be used in the operation.

The greenhouse foundation does not need to be continuous around the base of the building. Poured concrete footings can be placed one foot (30 cm) below the frost line in cold climates.

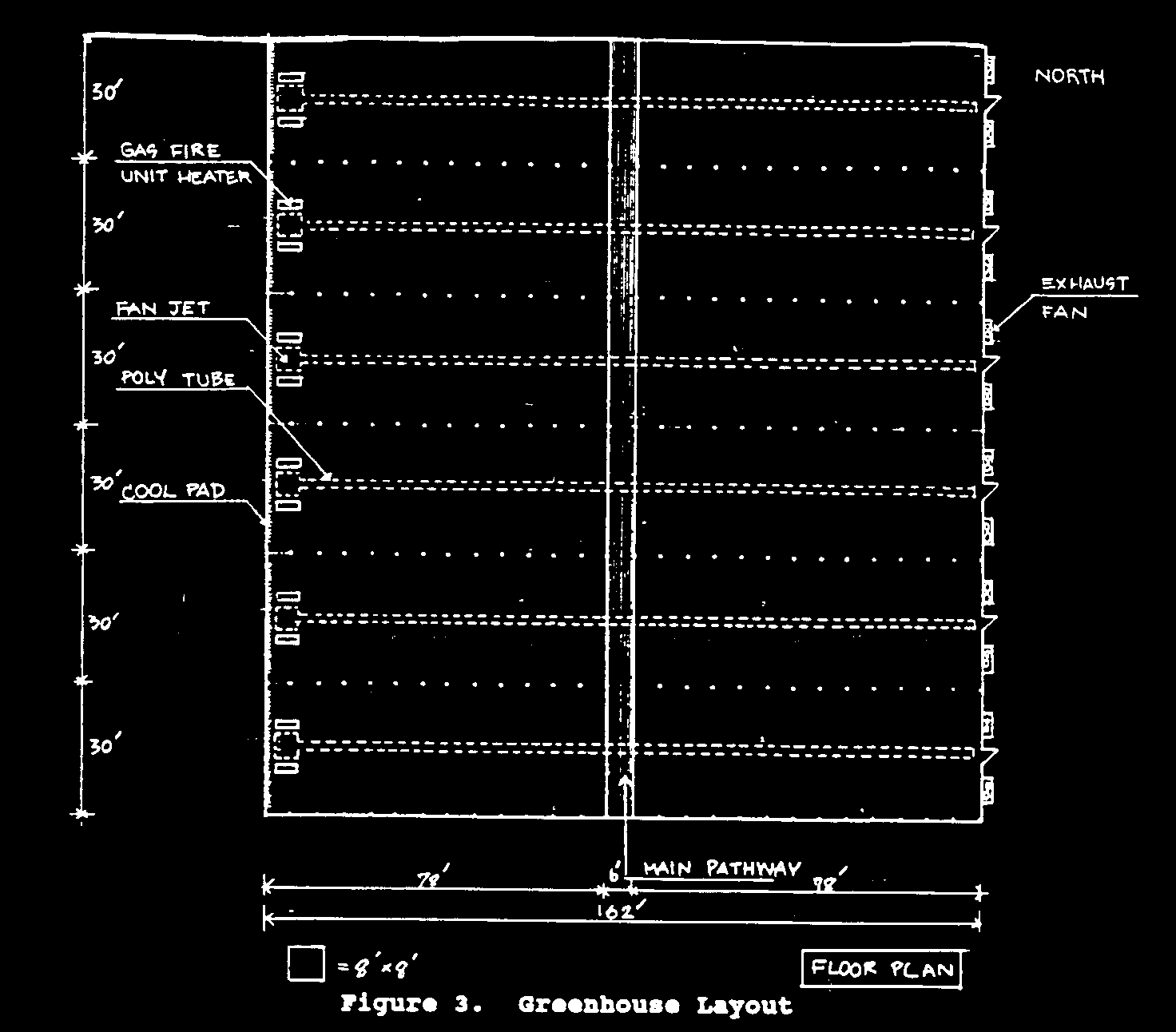

Gas-fired unit heaters, are used when necessary to blow warm air to fan jets (see Figure 2), which hang between them. The fans

distribute the warm air through a polyethylene tube to the entire growing area (see Figure 3). Heat escapes in small jet streams

from holes on either side of the tube. The heat mixes rapidly with the surrounding air and sets up a circulation pattern. Thermostats should be located at the height of the plants, to measure the greenhouse average temperature.

An insulating ceiling cover is stored on a reel and rolled out at night. In the morning, a wheel attached to the reel is turned to roll the cover back to the storage position. A cover with an insulating value of R-4 insulates much less than normal ceiling insulation, but saves a lot in heating costs. The cost of such a ceiling cover can be regained in three years in savings on heat.

Ventilation is needed, to:

- Reduce air temperature when it becomes too hot;

- Exchange air to renew the supply of carbon dioxide for photosynthesis; and

- Reduce the relative humidity in the greenhouse.

In hot weather, large volumes of air must be cooled and brought into the greenhouse. The coal air must pass in a smooth stream through the entire growing area. A cooling system using evaporation is used for this purpose.

A 30-inch (76 cm) fan is hung between two unit heaters (where needed). The fan blows air into the polyethylene tube, which is attached to the fan jet. The air blown into the tube may come from the heaters, the outside of the greenhouse, or from the inside of the greenhouse, depending on the temperature and humidity required. Continuous circulation within the greenhouse is set up by controlling heaters, fan jet, and shutters. The shutters prevent fresh outside air from passing to the fan jets when it is not needed. The shutters may be motorized or not, according to labor and equipment costs.

The cooling system is based on the process of heat absorption during the evaporation of water. Along the western wall of the greenhouse, water passes through vertical pads. There are two exhaust fans on the opposite wall, drawing the air from inside the greenhouse to the outside (see Figure 3). Warm outside air is drawn through the pads at the same time. Through evaporation, water in the pads absorbs heat from the air passing through. The air coming in to the greenhouse can be as much as 10 to 25 degrees Fahrenheit (5 to 15 degrees Centigrade) cooler than the outside air. This cooling system uses cooling pads, plumbing, valves, strainers, and supports. Two pumps and reversible drive motors are used to recycle the water in the pads.

While natural sunlight should be used wherever possible, supplemental lighting is sometimes needed in the greenhouse. Lighting fixtures holding two 90-watt fluorescent bulbs are used in our sample greenhouse. The bulbs are turned on an average of 12 hours per day in their cold climate. In tropical areas overheating due to excessive natural sunlight will often be a more serious problem and shading has to be provided.

The growing beds in the sample greenhouse are constructed of fiberglass, 25 feet (7.6 m) long, three feet (91 cm) wide, and 10 inches (25 cm) deep. The beds are placed in clusters of six beds each. Support for the beds is provided by two-by-fours (5 cm high by 10 cm wide pieces of wood) made into a frame. The tops of the beds are four feet 1.2 m) off the ground so that the space underneath can also be used for growing. The bottom of each bed should be sloped for good drainage. Beds may also be made of wood, concrete, or metal, but should be painted with a high-grade asphalt-base paint on the inside. Porcelain, pottery, or glass containers may be used in smaller systems.

Gravel, sand, cinders, shale, coral limestone treated with phosphate, wood shavings, vermiculite, perlite, plastic chips, or other material can be used as the medium in the growing beds. The more inert the material the less likely it is that problems will develop. For example, wood shavings generally contain chemicals that inhibit plant growth; these may leach into the nutrient solution or be taken up by the plant roots and stunt the crop. Similarly, untreated limestone usually will increase the pH of the growing medium; acid-loving plants would not be able to grow in such a medium.

The size should be from 1/16 to 1/2 inch (1.58 mm to 12.7 mm) diameter, with no sharp edges that could cut the roots of young plants. Gravel should be 1/4 to 1/2 inch (6.4 to 12.7 mm) diameter. When the plants grow, their root structure grows down into the medium. Once a year the medium should be replaced, and the growing beds sterilized. This might be accomplished by flushing with a large amount of near-sterile water (for example, "clean" ground water) or by using a chemical, such as sodium hypochlorite. If a chemical is used, the residues need to be taken into account. For example, sodium hypochlorite will leave residues of sodium chloride (ordinary salt), which might stunt crops that are especially sensitive to salt.

Pipes used should be iron or plastic. Galvanized pipe should not be used since zinc from the galvanizing will cause trouble with the nutrient solution.

Nutrient Solution and Delivery

The nutrient solution is the heart of the hydroponics system. The plants get the basic chemicals needed for successful growth from the solution.

Nutrient solutions can be purchased ready-mixed in some countries, or they can be mixed by hand. Hand mixed solution is recommended over ready-mixed, since it costs much less and the grower has greater control over the contents. The grower can adjust hand mixed nutrient solutions according to plant characteristics, temperature, light intensity, composition of the water, etc.

Thousands of different chemical combinations have been used successfully; however, certain chemicals are essential for plant growth. These include nitrogen, phosphorus, potassium, magnesium, sulphur, and calcium. Trace chemicals, in much lower concentrations, are iron, boron, manganese, zinc, and copper. An example of a nutrient mixture and its cost, for a commercial hydroponics greenhouse in the United States, is in Table 1. Costs are given in 1987 U.S. dollar amounts.

Native sources of nutrients, such as animal manures, might be usable, but can cause many problems. Most animal manures contain high levels of nitrogen in the form of ammonia, to which many plants are sensitive. Also, manures can be a source of diseases from organisms that infected the plants on which the animals fed. Perhaps most important, getting the correct balance of nutrients may be difficult with a source in which the concentrations are not clearly defined. Nonetheless, if no other sources are readily available, or if available sources are too expensive, it would be worthwhile to test some native sources on a small scale with the intended crop.

In a relatively humid area, .12 gallons (.45 liters) of nutrient solution should be used for every square foot (.3 sq. m.) of growing area, and the solution should be changed every four weeks. In areas with lower humidity more solution should be used and should be changed more often because of evaporation losses.

The mixing tank can be made of fiberglass or other non-porous material. Several mixes may need to be made to complete the solution change. It is wise to mix up a little extra solution in case of spills or other accidents. You will need enough nutrient solution to bring the water level to 1/2 to 1 inch (1.3 to 2.5 cm) from the top of the growing beds. The nutrients should be mixed first in a small amount of water.

Table 1: Nutrients Needed Per Year

Nutrient Essential Price/ Pounds Total solutions elements pound needed (US$)

Sodium nitrate Nitrogen $0.30 216.5 $ 64.95

Potassium Potassium sulphate Sulphur $0.20 72.2 $ 14.44

Super- Phosphorus phosphate Calcium $0.08 160.4 $ 12.83

Magnesium sulphate Magnesium $0.16 64.2 $ 10.27

Iron Iron sulphate Sulphur $0.96 16 $ 15.63

Manganese sulphate Manganese $0.32 5.5 $ 1.76

Boric acid Boron $0.32 5.5 $ 1.76

Zinc sulphate Zinc $0.26 2.5 $ 0.65

Copper sulphate Copper $0.88 2.5 $ 2.20

$124.22

If there is a problem with the nutrient solution, the plants will show deficiency or toxicity symptoms. You may wish to consult a reference book such as The Guide to Commercial Hydroponics (see Bibliography) to know the symptoms related to each chemical.

The nutrient delivery, or irrigation, system keeps the growing medium damp at all times, while allowing plenty of oxygen to get to the roots of the plants. The growing beds are flooded one to three times a day for half an hour. After flooding, the liquid is drained back into the tank, to be reused later. Irrigation can be done manually, automatically by using a pump and a timer, by a gravity-fed system, by wick, or by drip methods.

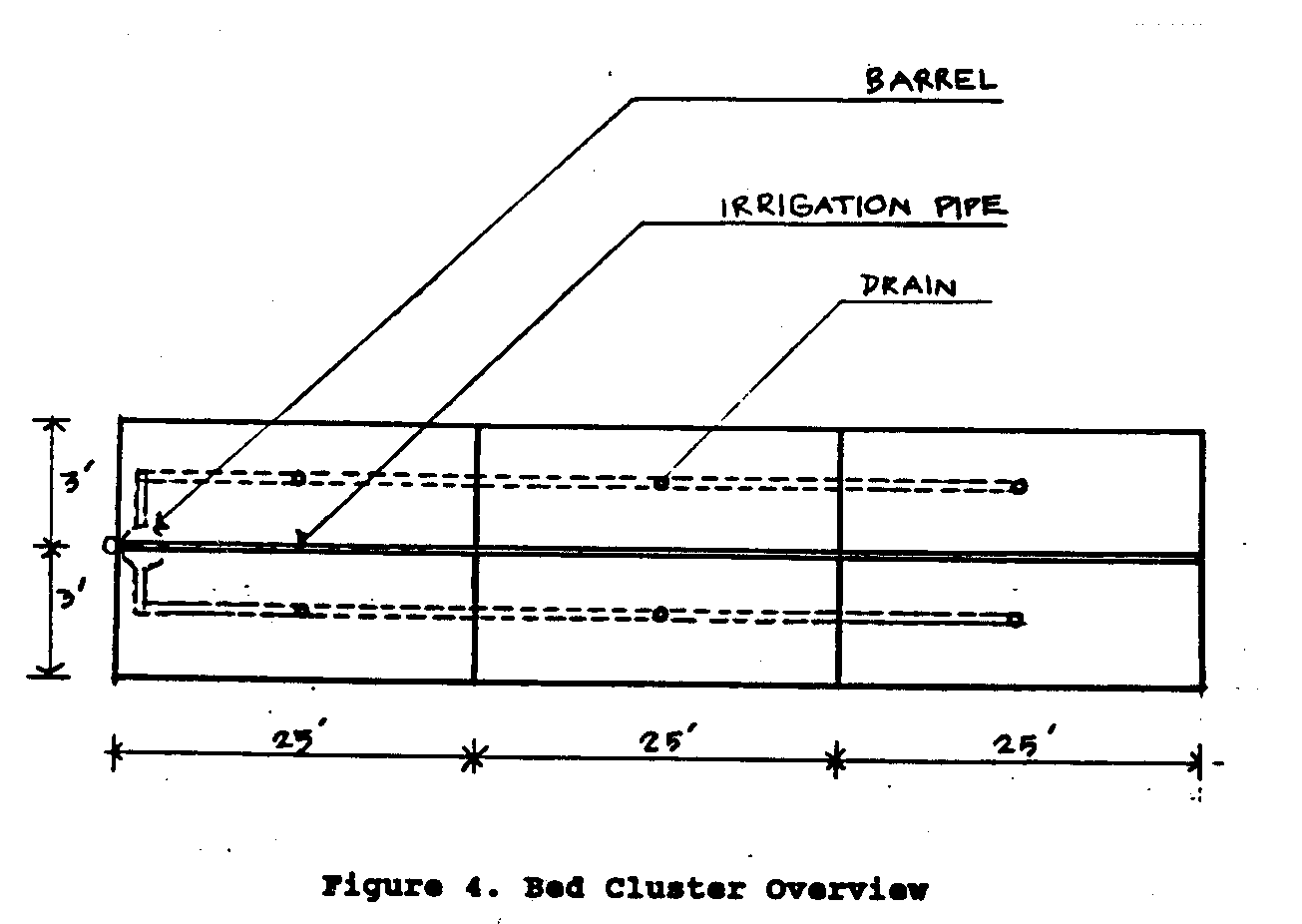

An automated system can be constructed from one 55-gallon (208 liters) drum, one 1/4 horsepower centrifugal pump, one electric timer, and 1/2 inch (1. 3 cm) PVC piping for each cluster of six growing beds (see Figures 4 and 5). This automatic system ensures

the timing and amount of nutrient solution delivered, and reduces labor costs.

In a gravity-fed system, the growing beds are divided into sections, each on a slightly higher elevation and slightly longer than the one after it. Two tanks of nutrient solution are used. A larger tank is at the lower end of the beds, below ground. It is connected by a channel to a smaller tank at the level of the highest beds. The smaller tank is filled by pump from the larger tank before an irrigation is made. The solution flows from the smaller tank through all the beds, and empties into the large tank. The solution needs to be pumped only once, at the beginning.

For the nutrient solution to work best, beds should be completely irrigated in 30 minutes or less. The solution should be pumped at a rate of at least two gallons per minute. It should take one hour for the beds to drain into the drain pipes and back into the solution tank. The drain holes in the beds should be one inch (2.5 cm) in diameter for fast drainage. In cold weather, one irrigation every other day, in mid-morning, is enough. In hot weather, three irrigations a day are recommended. Young plants need three irrigations a day regardless of the weather.

If three irrigations a day are done, the first should be between seven and nine o'clock in the morning, the second one between ten and twelve o'clock, and the third between two and four o'clock in the afternoon. An automated system would have a timer set according to this schedule.

As mentioned earlier, the nutrient solution should be changed every four weeks. In an automated system, the solution can be drained from the solution tanks by removing the connector pipe from the pump and attaching it to tubing through which the solution would be pumped out to the sewer, or into the ground, away from sources of drinking water.

After the solution is drained, water should be put in the solution tanks and the beds flushed with water. The water is then pumped out to the sewer or ground. Fifty-five gallon (208 liters) drums, stored in the storage area, are filled with new nutrient solution from the mixing tank, taken to the greenhouse area by carts, and siphoned into the storage tanks.

Pest Control

Because the plants are grown indoors in an inert medium, pests are not the problem they are in soil culture. Plants would be very quickly contaminated, however, if disease were introduced into the system. Regular replacement of the growing medium is recommended to guard against contamination.

In order to restrict the entrance of pests from the outdoors, sponge pads soaked with bleach should be placed at all entrances to the greenhouse or building. This will help kill pests that are in the dirt carried by shoes., Cigarette smoking should not be allowed in the greenhouse, since it could introduce tobacco mosaic, which is harmful to tomato plants.

Observation of the plants is an important step in controlling pests. Plants should be checked every day. At the first sign of pests, the plants and/or the insects themselves must be removed or destroyed. If the pests are localized on one or a few plants, those plants should be uprooted and removed from the growing area. If the pests are fairly large and/or immobile, they can be handpicked. If a pressurized water system is available, especially if it is chlorinated, a vigorous spray of water may be sufficient to dislodge and disrupt small insects. If these sanitation measures are not effective, chemicals may need to be used. In any case, the source of the pests must be identified. If workers have carried them in from other greenhouses or from field crops, steps will have to be taken to prevent the same thing from happening again. If the source is nearby infected or infested plants, those plants may need to be removed and/or destroyed. Also note that some pests cannot be destroyed by burning; in fact, viruses may be spread by burning. Therefore, if any diseased plants are to be destroyed by burning, it should be done a long distance from the growing area.

Two pesticides that are fairly safe for plants and humans may be used. Whitmire's White Fly Control Spray has low toxicity to humans and is used to control white flies in tomato plants, which are highly susceptible to the pest. The spray should be applied every six weeks. It is also effective against fungus gnats, thrips, and cucumber beetles. Rotenone, an organic contact and stomach poison, is largely non-toxic to warm-blooded animals. It is particularly effective against aphids, a major carrier of tobacco mosaic, and against chewing insects. Because it has little residual effect, it must be applied every two weeks. Even though these pesticides are not very toxic to humans, to prevent dust and spray inhalation, workers should wear respirators when applying them. As with all chemicals, precaution should be taken to minimize contact with the skin.

Equipment Costs

Costs for construction materials, equipment, and supplies will vary widely locally. In addition to the construction materials already mentioned, basic office equipment and shop tools are needed.

III. PRODUCE

Careful thought and analysis should be given to the selection of crops to be grown. Consult books, current seed catalogues, and food production and marketing specialists.

Plan your crops to make the most use of space. Plant root crops next to leafy crops, and short, leafy vegetables in the partial shade of larger plants.

In a hydroponics enterprise, crops grown should be competitive for their superior quality and local origin. Although there may be one crop in particular that can be produced with superior quality, planting a variety of crops is recommended for the following reasons:

- to avoid overloading the market; + to protect the business from price fluctuations; and + to achieve temperature control.

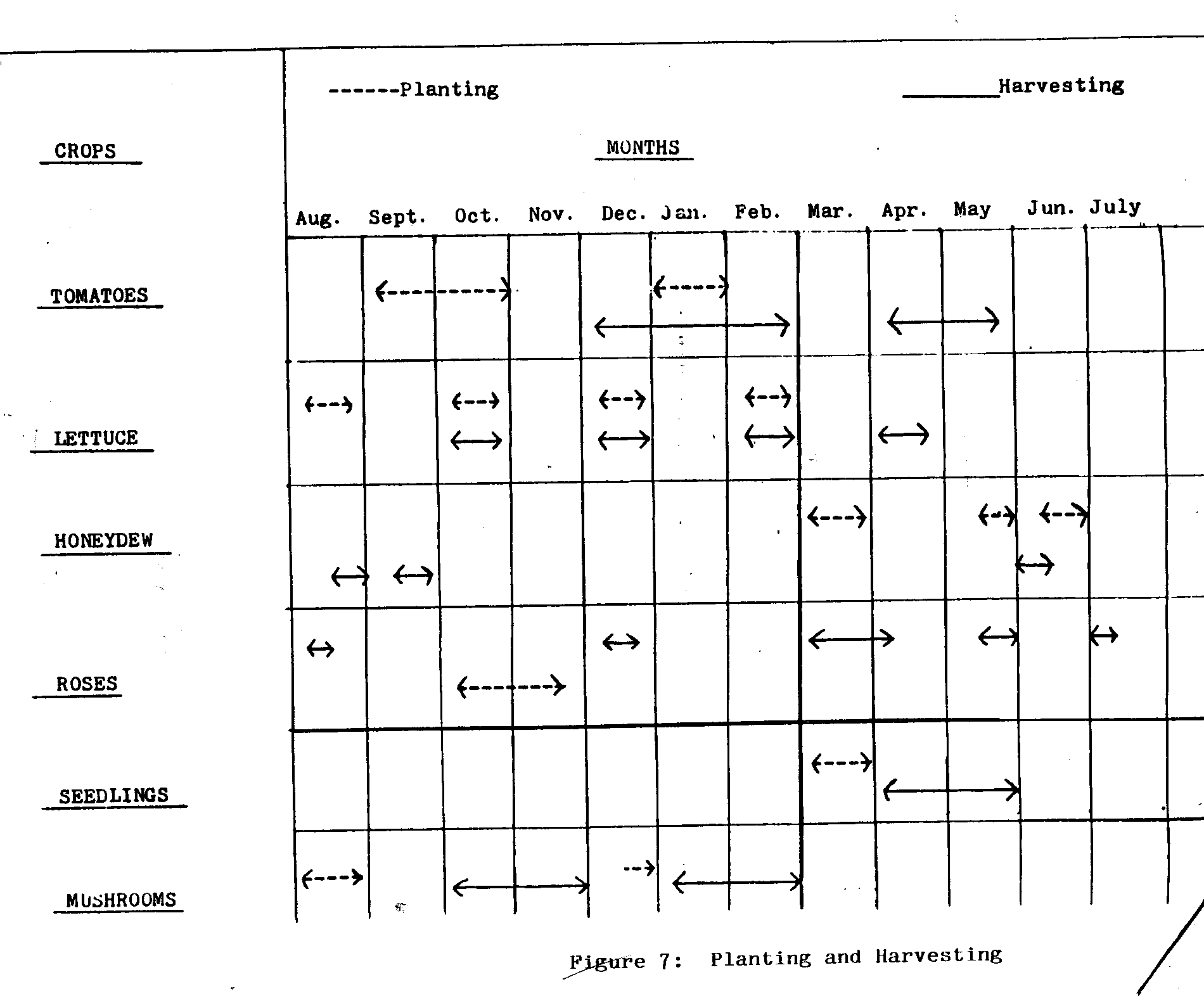

Information on crops selected for production in a commercial hydroponics greenhouse in the United States is included here as an example. Reasons are given for selecting the particular crops, as are a crop rotation chart (Figure 6), the planting and harvesting

schedule (Figure 7), and the layout of the crops within

the greenhouse. Table 2 gives crop income figures.

Table 2. Crop Production and Yearly Income

Crop Per plant Per bed yr. Beds Total Value (US$) Tomatoes 16 lbs. 32 plants 270 138,240 lbs. 45,619

Lettuce 1/2 lb. 136 plants 720 48,960 lbs. 25,949

Seedlings (1) 300 trays 18 5,400 trays 9,450

Honeydew 10 pcs. 18 plants 270 48,600 pcs. 41,310

Mushrooms 3.5 lbs/ 138 sq.ft. 432 208,656 lbs. 198,223 sq.ft. bed

Roses 2 pcs. 75 plants 36 5,400 pcs. 4,320

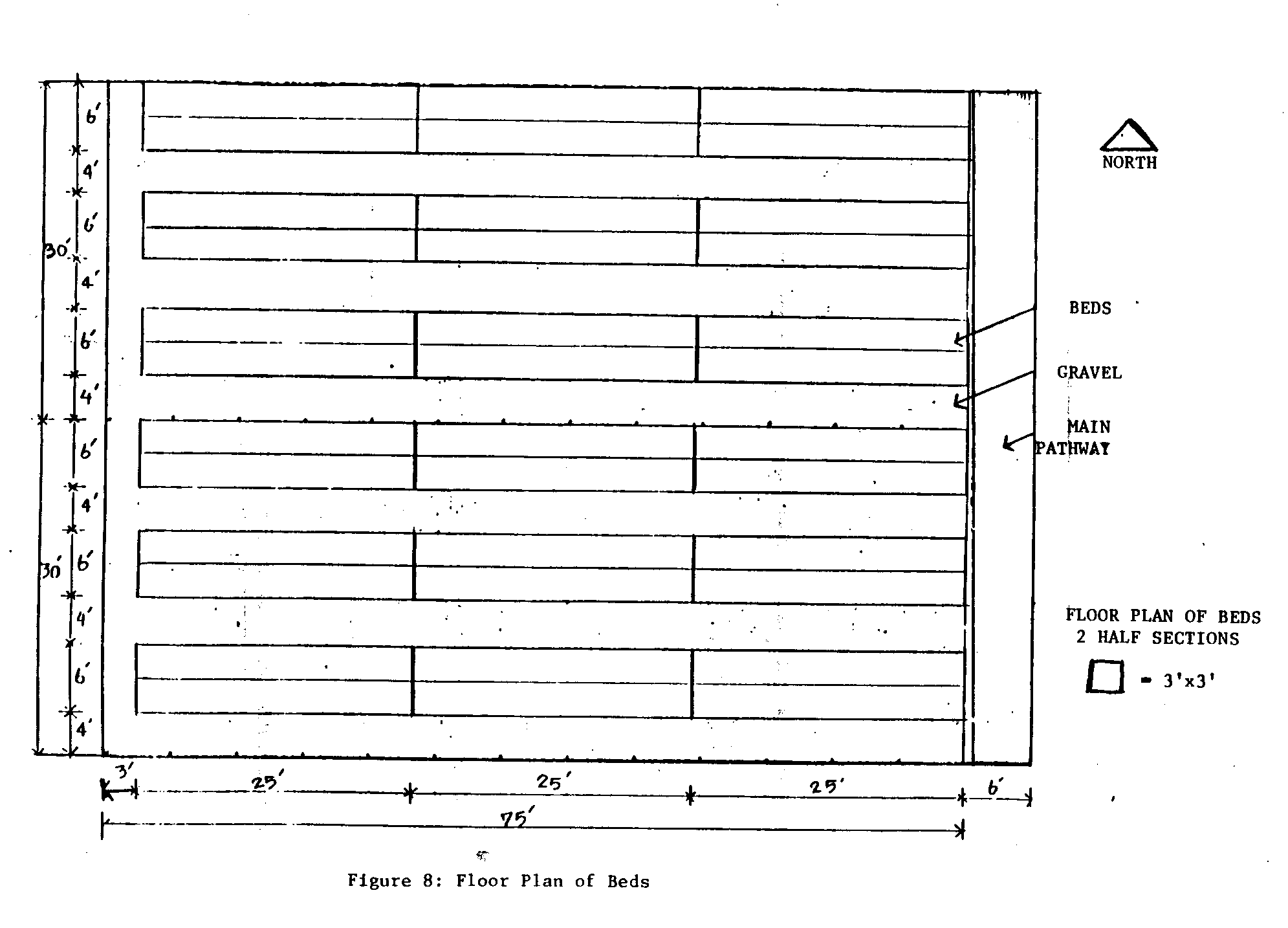

The greenhouse consists of six connected sections, each one 30 feet (9.1 m) wide (for a total width of 180 feet--54.9 m) by 162 feet (49.3 m) long. Each growing bed is three feet (91 cm) wide and 25 feet (7.6 m) long. The beds are laid out in pairs, with aisles between each pair. (See Figure 8). There are three-foot,

four-inch (1 m) walkways between the six foot (1.8 m) double beds, and the greenhouse has a center aisle six feet (1.8 m) wide.

Three crops--tomatoes, lettuce, and mushrooms--are planted together in one bed, between August and March. Honeydew melons, roses, and seedlings are also grown.

As in some other places with cold climates, off season production of tomatoes is a good choice, since most tomatoes are shipped from a great distance and are picked when hard and green. Hydroponically-grown tomatoes are reportedly tastier and juicier than other tomatoes. They can be planted closer together and therefore yield more. In this greenhouse, tomatoes are planted in two rows, one and a half feet (45 cm) apart. One half of the greenhouse is planted in tomatoes, three times a year. That is 8,640 plants per year. At 16 pounds (7.3 kg) per plant, the yield is 138,240 pounds (62,800 kg) per year.

Tomato seeds are sown directly into the gravel in the beds. The temperature for germination and growth is 70-75 degrees Fahrenheit (20-25 Celsius) during the day, and 65 (17 Celsius) in the evening. Tomatoes are self-germinating, although some shaking of the plants may help the process. During the winter months fluorescent lights are used over the beds whenever the sun is not shining, or at night, in order to provide the light needed for fruit production. Each tomato plant is staked, for maximum production in minimum space.

Harvesting is done over a four- to six-week period. During the period of from 80 to 130 days after planting, harvesting is done every other week. After the harvest period, the tomato plants are uprooted and new seed sown in the same place.

In the hydroponics greenhouse, a full crop of Boston-type lettuce, which is popular and has high market value, can be produced every two months. Lettuce is planted in the same bed with tomatoes, increasing the yield per bed tremendously. There is no problem with the spacing of the plants when the amount of nutrients is very carefully measured and fed to the beds. The only consideration is that the lettuce receive enough light. Each plant yields approximately .5 pound for a total yield of 48,960 pounds (22,228 kg) a year. Lettuce makes a good companion to tomatoes and honeydew melon because it needs less light and can therefore be grown easily between and below the other crops. However, lettuce does not withstand heat well, and cannot be grown during the summer months or in a hot climate.

The lettuce is harvested every 60 days. Harvesting is easy--the entire plant is pulled up. Although many pieces must be picked within a very short time (two to three days), there is little danger of damage or loss. The beds are immediately replanted. Forty-five beds of lettuce are sown per week, so that a fresh harvest of lettuce is ready for market every week.

The production of honeydew melons in the greenhouse is profitable due to the controlled conditions. It can be planted three times a year, instead of only one time outside. Honeydew was chosen because of its higher market value than either of the other more common melon varieties--cantaloupe and watermelon. As with the tomatoes, three successive plantings of one-half the greenhouse are made. The melons produce fruit approximately 90 days after planting the seed. Harvesting takes place over a two week period. Each plant produces an average of 10 melons. At 18 plants per bed, there is a yield of 48,600 melons a year.

Melon seed is planted in March, directly into the growing beds, and the plants grow up trellises. Melons like temperatures of 75 degrees Fahrenheit (25 Centigrade), so the temperature is raised in the greenhouse by a few degrees during that month. Melons are harvested over a two-week period. They have a predicted harvest date of 90 days, but they are not as highly perishable as tomatoes. Melons are sent to market in two shipments, one per week.

The mushroom crop is one of the most profitable crops produced in the sample greenhouse. The ushrooms are not grown hydroponically, but rather in two layers underneath the growing beds, making maximum use of space. They need little or no light. The space underneath every bed in the greenhouse is divided into two shelves with a heavy wire mesh. Two crops are produced a year.

Two special machines--a choke feeder and a compost turner--are used to prepare the growing medium for the mushrooms. The machines are not very complicated and could probably be manufactured locally in many areas. The compost used must not contain any heavy metals since it is used for food production, so city wastes cannot be used.

The compost is placed into the choke feeder, which in turn pushes it into the compost turner. The compost turner must be kept moist and the turning activated every four to five days for two weeks. After that, the trays can be filled. For one week they are left to "sweat out." During this time the temperature of the compost rises and the mushroom spawn can be planted.

Once the spawn has been planted, it is best to maintain a temperature of approximately 70 degrees Fahrenheit (20 C) for three weeks. After that, the trays should be covered with one inch (2.5 cm) of topsoil, the temperature in the greenhouse lowered a few degrees, and the trays watered well. Mushrooms are harvested on a daily basis, beginning approximately one month later. From the time the trays are filled, there is a two month growing period. Harvesting lasts approximately 45 days. Mushrooms are planted in August and December.

The compost and soil material left over from the mushroom production is used for the production of seedlings. One whole section of the greenhouse is devoted to seedlings, which are sold in the spring on a retail basis. They are a profitable product since seeds are inexpensive and the compost material is recycled. Seedlings are grown with roses in two 18-bed clusters. The seedlings occupy the area for a three-month period. During the other nine months the area is used for research and development of new crops. The seedlings receive the same nutrient feeding as the rest of the greenhouse, although they sit on top of the gravel in the beds.

The greenhouse produces seedlings of the most common plants that local gardeners tend to buy as plants rather than grow from seed themselves. The main crop comes from the tomato seed saved from the production of tomatoes. Six growing beds are used for the tomato seedlings, two for sweet peppers, one for hot peppers, two for broccoli, two cauliflower, two cabbage, one for melons, one marigold, and one for various types of squash and flowers.

Long-stem roses are grown in nine beds holding 75 bushes each. Seven beds are for red roses, one is for yellow, and one pink. This works out to 80 percent red, 10 percent yellow, and 10 percent pink. Each bush produces two roses four times a year, for a total yield of 5,400 roses.

Half the roses are planted in October, and the three-month production schedule produces roses at the holidays of Christmas (December), Easter (March or April), July 4th, and again in October. The second planting is made in November, producing flowers for Valentine's Day (February 14), Mother's Day (May), and the end of August. The blooming can be accurately controlled by pruning and pinching at the right times. The rose bushes need to be replaced every five years. They need eight hours of light a day to produce flowers, so in the winter, fluorescent lights are used throughout the day.

The greenhouse is experimenting with other flowers as well. Carnations root easily, produce heavily, and the flowers last a long time. They grow three feet tall and like a lot of light. The lily can be a hardy perennial if it is grown from bulbs or tubers. It also likes a lot of sunlight and takes at least two years to produce flowers. Snapdragons are also being tested, and orchids are a long-term project, taking from three to seven years to bloom. Orchid production is expected to be very profitable, for both plants and blossoms. The terrestrial variety loves an airy growing medium, and does well in inert growing materials.

Local research and development efforts are needed to determine the types of crops and products that can be successfully grown and marketed, and the composition and sources for the nutrient solutions to support them.

IV. MARKETING

Marketing is obviously a very important question for a hydroponics enterprise. There must be local demand for a product, or good transportation service to get the produce to distant customers. Perishable produce must be marketed with a minimum of delay. Production of off-season crops is likely to find ready local markets, when field-grown produce transported from distant places is expensive.

Hydroponic vegetables are labelled when they are packed for retail sales to identify them as hydroponically-grown, vine-ripened produce. This has been a major marketing factor in selling the produce, where hydroponically-grown produce has become known and is popular with buyers for its excellent flavor, good color, and perfect shape.

The local market potential should be thoroughly examined before undertaking a business venture. Do most of the local businesses buy their produce from wholesalers? Is there an interest in high quality, off-season produce, or special items? Are there hotels or specialty restaurants that might be interested in contracting for specific crops? Businesses may be interested in bypassing the wholesalers for a higher quality product. The hydroponics greenhouse may consider selling produce to wholesalers at the greenhouse, avoiding transportation costs. The enterprise may start out in the wholesale market and move into the retail market as the business grows.

There may be seasonal markets which can be served by the hydroponics greenhouse enterprise, such as flowers for holidays or seedlings in the Spring. In this case advertising on local radio and in area newspapers should be considered.

Advertising at the greenhouse should include an informational brochure to show the advantages and superior products of hydroponics. The brochure can also be placed at information centers and major tourist areas within 100 miles (60 km) of the greenhouse. Advertisements on local radio or in local newspapers help to inform the public about the operation of a hydroponics greenhouse. Printed advertisements have the added advantage of showing the public the name and logo of the company.

If possible, packaging for the produce should bear the company's logo. Depending on what crops are selected, it may be possible to use one size of box for all the produce that has to be shipped.

V. ORGANIZATION

A medium- to large-scale hydroponics enterprise needs staff in each of the areas described below. A smaller operation would need to consider these work areas and assign one or more persons as appropriate.

- Manager--responsible for purchasing, public relations, sales, and personnel;

- Supervisor--with training in horticulture, responsible for disease and parasite control, crop selection and scheduling, maintaining the nutrient supply and the growing environment, and for research and development;

- Maintenance--responsible for maintenance and repair of the nutrient system, growing beds, and environmental systems;

- Secretary--responsible for maintaining records, personnel files, correspondence, and acting as receptionist;

- Laborer--maintaining the plants and growing beds, harvesting, packing, and storing the crops.

- Bookkeeping or accounting services may also be needed.

VI. SUPPLIERS AND MANUFACTURERS

Johnny's Selected Seeds 299 Foss Hill Road Albion, Maine 04910

Stokes Seeds -- tomatoes Box 548 Buffalo, New York 14240 USA

Willhite Seed Company -- cantaloupe and melon seeds P.O. Box 23 Poolville, Texas 76076 USA

Hydroponic and Greenhouse Supplies, Division of E.R.I., Inc. 6433 Sepulveda Blvd. Van Nuys, California 94101 USA

Hydroponic Industries, Inc. 5650 S. Syracuse Circle Englewood, Colorado 80110 USA

BIBLIOGRAPHY

Boyle, G. and Harper, P. Radical Technology. Gloucester, Massachusetts: Undercurrents Books, 1976.

Dale, E. Management: Theory and Practice. New York: McGraw Hill, 1973.

DeKorne, J. Survival Greenhouse. PeacePress, 1975

Dickerman, Alexandra and John. Discovering Hydroponic Gardening. Santa Barbara, CA: Woodbridge Press Publishing Company, 1975.

Douglas, J.S. Advanced Guide to Hydroponics. New York: Drake Publishers, 1976.

Douglas, J.S. Gardening Without Soil: A Complete Guide to Hydroponics. New York: KeyBook Publishing Co., 1977.

Dutta, R. Water Gardenina Indoors and Out. New York: Crown Publishers, 1977.

Ellis, C. and Swaney, M.W. Soilless Growth of Plants. New York: Reinhold Publishing, 1947.

Hanan, J.J., Holley, W.D., and Goldsberry, K.L. Greenhouse Management. New York: Springer-Verlag, 1978.

Laughans, R.W. Greenhouse Management: A Guide to Structures, Environmental Control, Materials Handling, Crop Programming. and Business Analysis. Ithaca, New York: Halcyon Press, 1980.

Marvel, M.E. Hydroponic Culture of Vegetable Crops. Gainesville, Florida: Agricultural Extension Service, University of Florida, 1966.

McCullagh, J.C. The Solar Greenhouse Book. Emmaus, Pennsylvania: Rodale Press, 1978.

Nelson, K.S. Greenhouse Management for Flower and Plant Production. Danville, IL.: The Interstate Printers and Publishers, 1973.

Parsins, R. Small Plastic Greenhouses. Berkeley: University of: California Press, 1975.

Rodale, R., ed. Organic Gardening Encyclopedia. Emmaus, Pennsylvania: Rodale Press, 1980.

Schwarz, M. Guide to Commercial Hydroponics. Jerusalem: Israel University Press, 1968.

Stokes Seed Company Catalogue, Buffalo, New York, 1981.

Turner, W. I. and Henry, V. M. Growing Plants in Nutrient Solutions. New York: John Wiley and Sons, 1939.

United States Department of Agriculture, Agricultural Research Service Growing Crops Without Soil. Beltsville, Maryland: USDA, 1970.

Yanda, B. The Food and Heat Producing Greenhouse. Santa Fe, New Mexico: John Muir Publications, 1977.