VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virginia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

Understanding Poultry Meat and Egg Production ISBN: 0-86619-212-3 [C]1984, Volunteers in Technical Assistance

PREFACE

This paper is one of a series published by Volunteers in Technical Assistance to provide an introduction to specific state-of-the-art technologies of interest to people in developing countries. The papers are intended to be used as guidelines to help people choose technologies that are suitable to their situations. They are not intended to provide construction or implementation details. People are urged to contact VITA or a similar organization for further information and technical assistance if they find that a particular technology seems to meet their needs.

The papers in the series were written, reviewed, and illustrated almost entirely by VITA Volunteer technical experts on a purely voluntary basis. Some 500 volunteers were involved in the production of the first 100 titles issued, contributing approximately 5,000 hours of their time. VITA staff included Leslie Gottschalk and Maria Giannuzzi as editors, Julie Berman handling typesetting and layout, and Margaret Crouch as project manager.

Dr. H.R. Bird, the author of this paper, is a professor emeritus and former chairman of the Department of Poultry Science at the University of Wisconsin. He has taught poultry nutrition, feeding, management, and general animal nutrition at the Universities of Wisconsin and Maryland. He has also consulted on these topics in Brazil, Indonesia, Belize, and Nepal. Leonard Z. Eggleton is the Chairman of Agricultural Projects with the Iowa-Yucatan Peninsula Partners project at Iowa State University. He has consulted on poultry in Uruguay and Mexico. Ralph Ernst is a Poultry Specialist with the cooperative extension program of the Department of Avian Sciences, University of California at Davis. He has worked with game bird, duck, and turkey producers. Herman Pinkston is a returned Peace Corps Volunteer who worked in animal husbandry in the Philippines, which included developing a vaccine program for poultry, engaging in incubation of eggs, and raising swine.

VITA is a private, nonprofit organization that supports people working on technical problems in developing countries. VITA offers information and assistance aimed at helping individuals and groups to select and implement technologies appropriate to their situations. VITA maintains an international Inquiry Service, a specialized documentation center, and a computerized roster of volunteer technical consultants; manages long-term field projects; and publishes a variety of technical manuals and papers.

I. INTRODUCTION

Since ancient times, chickens, ducks, and geese have served farming communities by gleaning the fields of grain that otherwise would be lost; picking up grain that is dropped by the wayside in threshing, drying, and transportation; making productive use of the scraps from the family table; and, supplementing those feed items by foraging for grass, weed seeds, and insects. With such a diet these animals are able to produce eggs and meat, which provide protein of high quality plus several essential vitamins and mineral elements. Eggs and meat are ideal supplements for the cereal grains, tubers, and roots that provide much of the energy in many human diets.

Besides being recoverers of waste grain and users of scraps and by-products, poultry can function to provide a food reserve. Any farming community that can do so would like to produce more grain than the people need. Maybe the excess can be sold; but, if not, it can be fed to poultry. Then if there is decreased production of grain in a certain year, the poultry flock can be decreased instead of decreasing the grain that is supplied to the people.

Small flocks of poultry--from a few birds to a few hundred--were the rule all around the world, until the 20th Century. In the early 1900s, flocks numbering in the thousands began to appear in North America and Europe. In the 1920s and 1930s, geneticists, nutritionists, physiologists, and disease specialists developed improved breeds and strains of chicken and improved methods of feeding and managing them and protecting them against disease. The rapid introduction of new technologies so increased the efficiency of producing eggs and poultry meat that costs to consumers went down at a time when prices for most other consumer goods were climbing.

This paper addresses the following important questions to help you decide whether poultry raising is for you:

* How can poultry flock owners in developing countries take advantage of modern technology?

* Is it better to use native birds or import improved modern strains?

* Is it possible with local feedstuffs to approximate the composition and the efficiency of feeds based on corn (maize) and soybean meal?

* Can vaccines, coccidiostats, antibiotics, vitamins, and mineral supplements be imported economically? Can any of them be made locally?

* Is it possible to make feeding and watering equipment, cages, and nests locally?

II. POULTRY PRODUCTION: VARIATIONS AND ALTERNATIVES

FREE-RANGING POULTRY VERSUS CONFINED POULTRY

When one thinks of free-ranging poultry that find their own food, require no care, and provide food for the family table, one sees obvious advantages. However, there are disadvantages too. Most communities that take a serious interest in their poultry, practice some degree of confinement.

Letting poultry range freely is an economical way to provide them with feed. On the other hand, it exposes them to predators. Moreover, they cannot be guaranteed a balanced diet from just foraging. To achieve a well-balanced diet, they must be periodically supplemented with hand-fed food.

Free-ranging poultry are not crowded and therefore may be less susceptible to disease, but Newcastle disease--a virus that often plagues poultry--can exterminate even a free-ranging population and the protozoa that cause coccidiosis live everywhere that chickens live. Regardless of whether they are confined or free-ranging, chickens must be vaccinated or medicated against these diseases as well as many others. It is much easier to vaccinate and treat confined flocks. Free-ranging poultry do require less labor than confined poultry, but in finding waste feed and pools of water they are more likely also to find parasites, bacteria, and molds.

Free-ranging poultry incubate their own eggs and thus reproduce themselves, but they may lay eggs in unexpected places so that some are lost. Furthermore, the process of becoming broody and incubating eggs decreases the rate of egg production. Genetically improved laying strains are non-broody and often will not incubate their own eggs.

Confining poultry and providing sanitary feeders and waterers have a number of advantages:

* better control of diseases;

* protection from predators;

* more efficient collection of eggs; and

* easier access to poultry.

The disadvantage of confinement is that poultry can neither glean nor forage. In the Orient, to overcome this problem, poultry attendants drive their flocks of ducks to the rice fields and then return them to their living quarters. Similarly, a flock of chickens can be confined in a house and yard next to a threshing floor, for example, and let out when there is grain to recover. Particularly when birds are confined, poultry production can be a successful enterprise. There are three distinct production systems to consider, and each has gone through dramatic changes. These systems are designed to produce chicken eggs, chicken meat, and duck meat. There have not been parallel developments in goose production. Most geese are still kept in small flocks and depend on grazing and gleaning for much of their feed.

The changes in the system involve changes in the birds themselves, in their feed, in disease control (vaccines, medicines, sanitary practices) and in equipment and management.

THE BIRDS

What kinds of birds are best for the enterprise? This is the first question the small producer (200 birds or less) will have to answer. In many parts of the world there are varieties of local birds that have been selected, to some degree, for better production of eggs and meat. There are also available, in most areas, chicks of egg strains and meat strains that have been developed by selection and strain crossing in North America, Europe, Japan, and Australia. Imported strain crosses are always more productive and more uniform than improved local breeds. But they are also more expensive and cannot reproduce themselves. Flock owners must continue to buy chicks, for as long as they use this kind of stock.

Unfortunately, there appears to be no published information on the levels of productivity available with local breeds of chickens, given the advantages of modern feeds, sanitation and management. Such birds are kept in small confined flocks for egg production, and both floor pens and battery cages are used for this purpose. It is important to cull such flocks to eliminate the poor egg producers. The comb and wattles of a good layer are large, soft, warm, and red. The vent is enlarged and moist and the pubic bones are spread apart. They can be felt, to the right and left of the vent. A poor layer or non-layer will have shrunken, pale, dry comb and wattles, a small dry vent and closely spaced pubic bones.

Commercial production of eggs and broilers, with flocks numbering in the thousands, is now widespread and depends entirely on strain crosses rather than local varieties. Reports from India and Pakistan emphasize the importance of imported strain crosses in the development of their commercial production in those countries.

The establishment of a small flock of ducks is not likely to involve the same choices as in the case of chickens. In most situations one would have to depend on locally available stock of a local strain.

FEED

Poultry feeds usually consist of combinations of energy and protein sources, which make up 90 percent or more of the total feed. The remainder of the feed consists of calcium and phosphate supplements and salt, which make up two to eight percent; and trace mineral, vitamin, and amino acid supplements, which make up one or two percent, or sometimes more. In the United States, for example, a feed would consist of corn (maize), which is an excellent energy source and supplies some protein; soybean meal, which is a very good protein source and supplies some energy; limestone (for calcium); dicalcium phosphate (for phosphorus and calcium); salt; methionine (an amino acid not abundantly provided by soybean meal); and trace mineral and vitamin supplements. Trace mineral and vitamin supplements are shipped all over the world, and are priced so low that they usually are not major cost items. Cereal grains and legumes, unlike mineral and vitamin supplements, are costly to produce and often in short supply in many developing countries. Due to their scarcity and to the competition with human food supplies, their use for poultry feed in the Third World is usually kept to a minimum.

We noted above that poultry served early farming communities by utilizing scraps and otherwise wasted food materials. Modern poultry can also utilize by-products of food processing. There is a prevalent notion that modern high-producing strains of poultry must have modern high-protein, high-energy diets. The modern chicken still functions well on by-product diets even though it is descended from many generations of ancestors that were fed high energy, high protein corn-soy diets. To illustrate, strain-cross layers in an experiment at the Univeristy of Wisconsin maintained 67 percent of egg production on the following diet:

Rice bran 90.0 percent Fish meal 1.0 percent Alfalfa meal 1.0 percent Ground limestone 5.4 percent Iodized salt 0.5 percent Dicalcium phosphate 1.0 percent Methionine hydroxy analogue 0.1 percent Vitamin trace - mineral 1.0 percent supplement Free choice limestone grit.

The vitamin-mineral supplement provided, per kilogram (kg) of diet: 6000 International Units (I.U.) of vitamin A, 900 International Chick Units (I.C.U.) of vitamin D3, 22 I.U. of vitamin E, 10 milligrams (mg) of riboflavin, 0.7 mg of folic acid, and 200 mg of zinc carbonate.

Costa (1981) observed good performance with a broiler starter feed of the following composition:

Rice bran and polishings 32.5 percent Grain sorghum 30.0 percent Soybean meal, solvent process 17.0 percent Meat and bone meal 15.0 percent Molasses 4.0 percent Salt 0.5 percent Vitamin-trace mineral supplement 1.0 percent

The vitamin trace mineral supplement provided, per kilogram of diet: 8000 I.U. of vitamin A, 1000 I.C.U. of vitamin D3, 5 I.U. of vitamin E, 6 mg of menadione sodium bisulfite, 4 mg of riboflavin, 30 mg of niacin, 12 mg of d-pantothenic acid, 301 mg of choline chloride, 20 micrograms of vitamin B12, 100 mg of BHT, 70 mg of zinc (as zinc oxide), 50 mg of manganese (as manganous oxide), 0.25 mg of iodine (as ethylene diamine dihydroiodide), 50 mg of iron (as iron sulfate), and .10 mg of selenium (as sodium selenite).

The two formulas given above are examples of poultry rations that would be economically feasible in some areas. It is beyond the scope of this report to provide formulas for a wide range of circumstances or to present a treatise on feed formulation. Table 1 gives the requirements of different classes of poultry for energy, protein, calcium, and phosphorus; and Tables 2 and 3, respectively, give the levels of these nutrients in various feed ingredients and mineral supplements. Using this information, one could calculate formulas to supply these four nutrients. One almost always has to add 0.5 percent of salt (NaCl); since most ingredients do not supply it. One must also use a vitamin-trace mineral supplement similar to the one used for adult birds or for young growing birds in the two diets presented earlier.

Table 1. Nutrient Requirements of Broilers, Laying Hens, Growing Ducks, and Growing Geese

Metabolizable Type of Energy Protein Calcium Phosphorus Poultry (kcal(*)/kg) (Percent) (Percent) (Percent)

Starting broilers 3200 23.0 0.9 0.7

Laying hens 2850 15.0 3.25 0.5

Growing ducks 2900 16.0 0.6 0.6

Growing geese 2900 15.0 0.6 0.4

(*) Kilocalorie: a unit of heat energy equal to 1,000 calories.

Table 2. Composition of Feed Ingredients (as fed)

Metabolizable Crude Type of Feed Energy Protein Calcium Phosphorus Ingredient (kcal/kg) (Percent) (Percent) (Percent)

Dehydrated alfalfa 1370 17.5 1.44 0.22

(lucerne) Barley 2640 11.6 0.03 0.36

Beans, field 2300 23.0 0.13 0.6

Brewers' grains 2080 25.3 0.29 0.52

Cane molasses 1960 7.8 1.10 0.12

Cassava meal 2.6 0.03

Coconut (copra) meal 1773 20.7 0.21 0.62

Corn (maize) 3430 8.8 0.02 0.28

Cottonseed meal, solvent process 2400 41.4 0.15 0.97

Crab meal 1819 31.4 15.0 1.57

Distillers' grains with solubles 2480 27.2 0.17 0.72

Fish meal 2820 60.5 5.11 2.88 Meat and bone meal 1960 50.4 10.1 4.96

Millet 12.2 0.05 0.28

Mustard seed meal 31.9

Palm nut meal 18.2 0.68

Peanut (groundnut) meal, solvent process 2200 50.7 0.20 0.63

Poultry by-product meal 2670 58.0 3.0 1.7

Rapeseed meal, expeller process 2040 35.0 0.72 1.09

Rice bran 1630 12.9 0.07 1.50

Sesame meal, expeller process 2210 43.8 1.99 1.37

Sorghum grain 3370 8.9 0.03 0.28

Soybean meal, solvent process 2230 44.0 0.29 0.65

Sunflower seed meal, solvent process dehulled 2320 45.4 0.37 1.0

SWEET POTATO MEAL 4.9 0.15 0.15

Wheat, soft 3120 10.2 0.06 0.31

Wheat bran 1300 15.7 0.14 1.15

Wheat middlings 1800 16.0 0.12 0.90

Table 3. Composition of Mineral Supplements

Type of Feed Calcium Phosphorus Ingredient (Percent) (Percent)

Bone meal 29 12.6

Defluorinated phosphate 32 18

Dicalcium phosphate 21 8.5

Limestone 38 0

Oyster shell 38 0

By-product feeds vary greatly depending on the method of processing. Processing methods are well standardized in developed countries, but may be highly variable in developing countries. The resulting products may also be highly variable and quite different from those listed in Table 2.

Some feed ingredients have special disadvantages that must be noted. Cottonseed meal contains gossypol, which discolors egg yolks and inhibits growth of young birds. Cooking the meal during processing decreases the free gossypol and results in a product that is usually satisfactory for growing birds but may still discolor yolks. Mustard seed meal contains a growth inhibitor and should not represent more than five percent of the diet. Rapeseed meal contains a goitrogenic compound that interferes with thyroid function, and also should not represent more than five percent of the diet, unless improved strains of the plant are used.

Soybeans contain an inhibitor of one of the important amino acids, trypsin, which, interferes with digestion but can be destroyed by cooking. The processing of soybean meal is now so well standardized that this inhibitor is seldom a problem.

To know whether soybean meal is cooked thoroughly enough, follow this simple procedure:

* Place 10 teaspoons (about 30 grams) of the meal in a small jar with a tight lid.

* Add 1 teaspoon (about 4 grams) of fertilizer grade or feed grade urea and 5 teaspoons of water.

* Stir the contents and cover the jar with the lid.

* Wait 20 minutes. Sniff for the odor of ammonia.

* If ammonia is present, the soybean meal contains the enzyme urease and has not been heated enough.

Field beans (navy, pinto, kidney, etc.), like soybeans, contain a growth-inhibiting material which can be destroyed by cooking.

The information provided here is intended to help in evaluating the feasibility of starting a poultry production enterprise as an important source of food and income. Now you must ask yourself: What feeds are available locally, at what volume, and at what price? Are they, or substitutes, available year round? Can they be combined to make a suitable formula, or will other ingredients have to be shipped in from other areas? If you are considering a medium-sized or large-scale operation, you should get local feed ingredients analyzed. The final test of the quality of the ingredients and the formulation is how well the poultry perform.

DISEASE CONTROL

No poultry business can succeed very long unless measures are taken to control diseases. With this in mind, here are some general guidelines that will help in maintaining a healthy flock:

* Feeding poultry a well-balanced diet will prevent them from developing deficiency diseases. To illustrate how important this is, note that a marked deficiency in the ration may retard growth, decrease the rate of egg production, and lower resistance to infections.

* Whether your poultry flock is large or small, it is a good idea to keep it separated as much as possible from other poultry. Do not encourage visitors. Do not "change help" with neighbors who have poultry. Do not buy adult or half-grown birds and add them to your flock. If a flock is purchased, birds should be isolated for a period of 5 to 15 days for observation. Raise young birds separately from mature stock.

* When selling birds, empty the poultry house completely. Clean it thoroughly, wash with a disinfectant (e.g., lye), and let it stand empty for four weeks before putting in new birds.

* Provide your poultry with clean, sanitary waterers and feeders, and well-ventilated houses.

* For birds housed in floor pens, provide litter such as wood shavings, straw, sawdust, rice hulls, or similar materials. Provide sufficient ventilation to keep the litter dry enough so the birds can scratch in it. It should not be wet or sticky.

* If your birds are housed in cages, the cages should be constructed with a slatted bottom to allow manure to fall through to the floor. For small numbers of birds, the manure can be collected in pans, which must be scraped and cleaned once or twice each week. The manure can be composted and used to fertilize your crops or sold as fertilizer. The sale of recycled manure can be an important source of income. For large flocks, the cages are arranged so that the manure falls on the ground or floor where it can be allowed to accumulate for several months or possibly even one year. Longer periods of accumulation are possible in dry rather than humid climates. If manure becomes wet, fly breeding may occur. This is usually best controlled by weekly removal and processing (drying, composting, etc.) of manure. It may also be necessary to add an insecticide to the manure under the cages to prevent development of flies. Local authorties should be consulted to learn which pesticides are permitted.

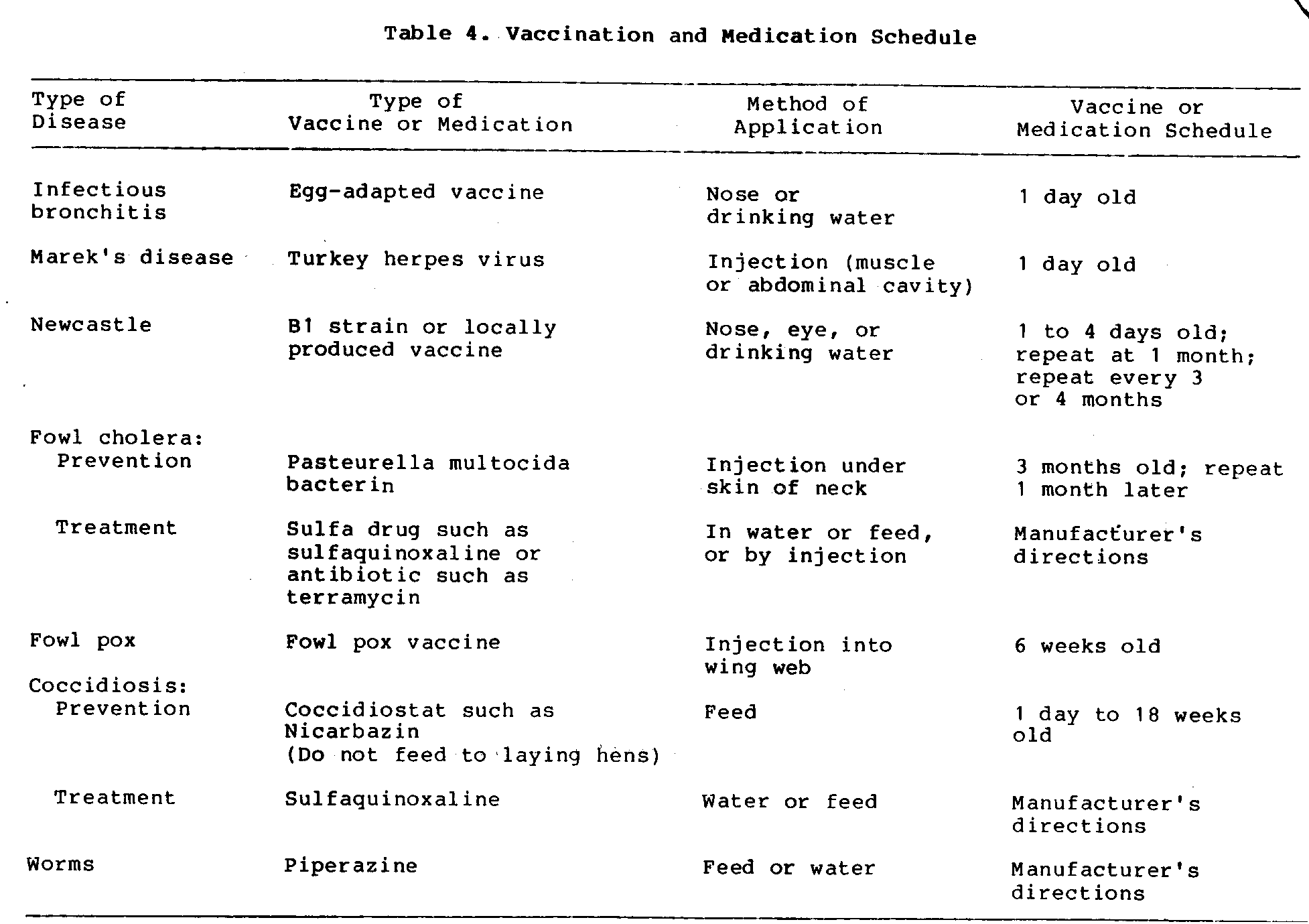

Table 4 presents a general vaccination and medication schedule

for chickens. It is not necessary to follow the entire schedule at all times in all locations. In tropical areas, it is safe to assume that Newcastle virus is present and to vaccinate against it. Furthermore, the strains of the virus that occur in the tropics are commonly more virulent and more damaging than those in temperate areas. Therefore it is sometimes recommended that poultry farmers use a Newcastle vaccine produced locally rather than an imported product.

Fowl cholera and fowl pox are two common diseases found all over the world, but this does not necessarily mean that they are prevalent in your areas. So, inquire first before starting a vaccination or inoculation program. Fowl pox is caused by a virus; fowl cholera is caused by a bacterium.

As shown in Table 4, vaccines are available against infectious bronchitis and Marek's disease. Both of these are caused by viruses, but are less likely to cause trouble than Newcastle disease, fowl cholera, or fowl pox. The microscopic protozoan organisms that cause coccidiosis are present wherever there are chickens. Young chickens encounter these organisms early in life and may show bloody diarrhea, weight loss, sluggishness, and ruffled feathers. The number of deaths may be few or it may be many. Most survivors will recover and carry some degree of resistance to the organism thereafter. Drugs known as coccidiostats protect against this disease and are widely available. Maintenance of dry conditions in pens will minimize this disease.

Chickens kept on the ground or in floor pens are always exposed to intestinal worms (ascarids). Chickens may carry considerable numbers of the parasites without showing disease symptoms, but a heavy infestation decreases egg production.

Ducks are affected by fewer diseases than chickens. They may harbor roundworms and tapeworms without showing symptoms. Such infestations may cause problems if ducks have access to stagnant water or muddy, poorly drained soil.

If disease is suspected, it is desirable to seek expert advice, including diagnosis and possible post-mortem examination.

EQUIPMENT AND MANAGEMENT

During its first week of life, a baby chick should have access to a brooding area at a temperature of 32 to 35[degrees]C. After the first week, the temperature can be decreased 2 to 3[degrees] each week. The typical small square poultry house is about six or seven meters on a side. It will house 400 broilers or 100 layers. Early attempts to increase the size of poultry farms were achieved by increasing the number of houses, but it was obviously more labor-efficient to increase the size of the house. However, even in temperate climates with moderate rainfall it is difficult to ventilate a house that is more than 13 meters wide. For the humid tropics, 10 meters is probably the limit. The length is limited only by the topography of the land or the poultry owner's bank account. In the tropics, the house may well be open on one or both sides except for wire netting or woven wire. A house open on both sides should be equipped with a canvas that can be pulled up or let down on the windward side in order to prevent drafts at night and during storms. The house should be closed at both ends, and it should have a floor and a gable roof, which should provide at least 0.8 meter of overhang on each side. A covered opening at the peak of the roof can be used to provide ventilation.

Roosts are not required but are often preferred to make upkeep easier. A laying house that has a solid wall on one side may have a row of roosts arranged against the wall. The front, or lower, row should be about 0.8 meters above the floor. Two or more additional rows of roosts go between it and the wall, with each roost slightly higher than the one in front. The area under the roosts may be closed with wire netting to prevent access by the chickens. It then serves to collect most of the droppings without giving the chickens access to them.

If both front and back of the house are open, movable roosts may be provided along the center line of the house, or to the front or back. If the house is more than about 20 meters long, nests can be installed not only along the ends but also along partitions.

Nests should be about 30 centimeters (cm) square and 30 cm high. They are usually arranged in rows two to three tiers high. There should be a perch below the entrance of each nest, and the lowest row of nests should be about 0.5 meter above the floor. There should be about one nest for every four layers.

Nests for ducks should be on the floor, one nest for each four or five birds. Partitions between nests are 30 cm by 35 cm. They are fastened at 28-cm intervals to a 15-cm board at the back along the house walls and have a 5-cm board along the bottom front. This leaves the top and front open.

Feeding troughs can be made of bamboo, wooden boards, pottery, or metal. Mechanical feeders are available for large flocks. Waterers can be made from bamboo or from recycled glass or metal containers, or automatic watering devices may be purchased. Allow 3 cm of feeder space per chicken in the first three weeks of life, then 5 cm until they are eight weeks old, and 9 to 10 cm after that. A feeder 100 cm long provides 200 cm of feeder space.

In temperate and subtropical zones, it is customary to provide artificial light for layers. A 14-hour day is optimal for egg production. This may not be necessary in equatorial regions. In Java, for example, strains imported from the United States achieve the same annual egg production without lights as they do in the United States with lights. Day length varies by only a few minutes throughout the year in Java. However, at the latitude of Delhi, India, day length varies annually (from 10 hours 20 minutes to 13 hours 57 minutes) and artifical lighting is beneficial.

LABOR REQUIREMENTS

In every poultry house, cleaning and refilling waterers and feeders should be the first maintenance task in the morning. Clean waterers every day, whether they are automatic or handfilled. If they are hand-filled, they must be filled often enough so that water is always available. Feeders should never be empty, but they should not be overly full either. Adding feed frequently encourages the birds to eat and prevents waste.

In a laying house, eggs should be collected at least four times a day: morning, noon, afternoon and late afternoon. Making a second collection in the morning would be even better.

The following additional daily chores are recommended:

* Dispose of dead birds.

* Observe nest boxes. Clean when necessary. Add litter.

* Remove wet litter around waterers.

* Observe height of feed hoppers. Edge of trough should be at level of birds' backs. Adjust when necessary.

* Add limestone or oyster shell to hoppers when needed.

* Sweep down wire netting.

* Watch for evidence of rodents, and eliminate them.

* Add disinfectant to foot bath or pad at entrance to house.

* Watch for sick birds.

* Observe condition of litter. Stir when necessary, perhaps weekly.

* Observe light bulbs. Clean when necessary.

* If electric fans are used for ventilation, clean blades and oil motor.

The following are recurring specialized jobs that require extra help:

* Distribute day-old birds in the house. * Move pullets from growing house to laying house. * Catch broilers (or old hens) and send them to market. * Vaccinate against poultry diseases.

Thirty years ago in the United States, two hours per year of labor were required for each laying hen kept, and one hour of labor for each pullet raised. Now it is customary to calculate about seven minutes per year of labor for each laying hen and four or five minutes for each pullet raised. This dramatic change resulted from mechanization, larger flocks, the change from floor pens to laying cages, and some miscellaneous improvements in the organization of the operation. In many parts of the world, existing economic and social structures favor labor-intensive rather than capital-intensive operations. In those situations, the labor requirement will lie somewhere between the extremes indicated.

CARE OF EGGS AND MEAT

Gather eggs several times each day (see section on "Labor Requirements"). Clean eggs with a clean, damp cloth or in an egg washer. If an egg washer is used, the water should be slightly warmer than the temperature of the eggs and should contain a detergent-sanitizer. Eggs should be as fresh as possible when consumed or sold. For whatever time they are held before use, they should be placed small end down in a cool place, preferably a refrigerator.

Kill chickens the same day the meat is to be used unless a refrigerator is available to keep the meat from spoiling. To kill chickens, hang them by their feet and cut across the veins in the throat with a sharp knife. Let all of the blood drain into a container. The blood can be cooked, dried, and added to feed for other chickens.

To remove feathers, place the bird (after it has been bled) in water at 60[degrees]C. That temperature is well below boiling, but too hot to put your hand in. As soon as the feathers are well soaked with hot water, pluck them as quickly as possible.

De-feathering ducks is more difficult than de-feathering chickens. Slightly higher scalding temperatures are used for ducks. The temperature of the water should not be above 65[degrees]C and the length of scald varies from one and a half to three minutes.

In hand-scalding, grasp the bill with one hand and the legs with the other hand and submerge the rest of the body, breast downward, in the water. The bird is then pulled repeatedly through the water against the feathers.

OPERATING COSTS

Because costs vary so much from area to area, it is impossible to make accurate generalizations. The operating cost breakdowns for egg production and broiler production in the United States and India are shown in Tables 5 and 6. In all cases, the major cost item is feed. A large part of the increase in efficiency of poultry meat and egg production is the result of more efficient conversion of feed to product. About 2 kg of feed are now required to produce 1 kg of broiler; 50 years ago, 4.5 kg of feed were required. And while about 1.7 kg of feed are required now to produce one dozen eggs, 50 years ago, 2.3 kg of fed were needed.

Table 5. Egg Production Costs

India United States (Percent of Total) (Percent of Total)

Pullet cost 21.6 20.4 Feed 51.9 58.2 Depreciation of buildings and equipment 6.9 9.2 Labor 2.6 4.9 Miscellaneous 17.0 7.3

Table 6. Broiler Production Costs

India United States (Percent of Total) (Percent of Total)

Chick 26.4 19.4 Feed 44.4 73.6

CONTRACT GROWER

1.7 Labor 2.9

Depreciation 5.5

Miscellaneous 20.8 5.3

The cost of baby chicks has gone up with inflation, but genetic improvement has increased productivity so that chick cost per unit of product has remained nearly the same.

It is difficult to compare labor costs for broilers. In the United States, the contract grower furnishes some labor, and some is provided by special crews under "miscellaneous." The feed is delivered into an automatic feeding system, so some labor cost is included in the feed cost. High interest rates contribute to the high miscellaneous costs in India. In the United States, broiler costs may allow for depreciation under "Miscellaneous" and/or "Contract grower," but the allowance appears to be inadequate.

III. DESIGNING THE RIGHT SYSTEM FOR YOU

Table 7 summarizes the poultry requirements for small-, medium-, and large-scale poultry operations. Note, however, that all poultry farms, regardless of size, should try to use modern disease control methods. Modern vaccines and medications are widely distributed in many parts of the world.

Table 7. Requirements for Egg or Meat Production According to Flock Size

Less than 200-1000 More than 200 Birds Birds 1000 Birds

Stock Local or imported Imported Imported strain-cross strain-cross strain-cross

Feed Crop residues, Formulated Formulated table scraps, local feed feed by-products or emphasizing emphasizing formulated feed local local by-products by-products

Disease Isolation, Isolation, Isolation, Control sanitation, sanitation, sanitation, vaccination, vaccination, vaccination, medication medication medication

Buildings Homemade Homemade Homemade or and commercial Equipment

Labor Family Family or Hired or hired mechanized

Even the smallest poultry farm can practice isolation and sanitation. Small operations may choose between local and imported stock and between formulated feed and a feeding program based on what is available from day to day. Large operations will surely use imported stock and formulated feed.

Small units will use homemade buildings and equipment and family labor. Large units may choose either homemade or commercial equipment and either hired labor or a combination of mechanization and labor. In some tropical countries laying flocks numbering in the thousands are housed in homemade, two-level, stair-step laying cages of bamboo and wood slats. Such cages do not last long in the tropics, but they can be replaced at relatively low cost.

Table 8 summarizes the requirements for different classes of poultry.

Table 8. Requirements for Different Masses of Poultry

Chickens Ducks Eggs Meat

Stock Local or imported Local or imported Local strain-cross strain-cross

Feed Crop residues, Crop residues, Crop residues table scraps, table scraps, recovered by local by- local by- herding in products, or products, or fields, table formulated feed formulated feed scraps, local by-products, formulated feed

Disease Isolation, Isolation, Isolation, Control sanitation, sanitation sanitation vaccination, vaccination, medication medication

Buildings Homemade or Homemade or Homemade or and commercial commercial commercial Equipment

Labor Family, hired, Family, hired, Family, hired, or mechanized or mechanized or mechanized

BIBLIOGRAPHY

Costa, M.A. "The Evaluation of Indigenous Feedstuffs for the Nutrition of Swine and Poultry in Belize, Central America." M.S. Thesis, Michigan State University, 1981.

Gupta, S. P., ed. Indian Poultry Industry Yearbook, 1975-1976.

Khan, A.S.; Chaudhry, A. M.; and Aslam, M. Economics of Modern Poultry Production in West Pakistan. Lyallpur, Pakistan: West Pakistan Agricultural University, 1969.

Maurer, A.J., and Maurer, E.A. Raising Chickens in Eastern Nicaragua. Wisconsin-Nicaragua Partners and Centro para el Desarrollo Regional.

National Academy of Sciences. Atlas of Nutritional Data on United States and Canadian Feeds. Washington, D.C.: National Academy Press, 1972.

National Academy of Sciences. Nutrient Requirement of Poultry. Washington, D.C.: National Academy Press, 1977.

North, M. O. Commercial Chicken Production Manual. Second edition. Westport, Connecticut: AVI Publishing Co., Inc., 1978.

Orr, H.L. Duck and Goose Raising. Publication 532. Ontario, Canada: Ministry of Agriculture and Food.

Piliang, W.G.; Bird, H.R.; Sunde, M.L.; and Pringle, D.J. "Rice Bran as the Major Energy Source for Laying Hens." Poultry Science 61 (1982): 357.