This oven was designed and built for use in the Godavari School in Kathmandu, Nepal. It is built of solid brick, with a sheet iron door. A wood fire is burned in the oven, the ashes removed, and the bread slipped in to bake in the heat retained by the thick brick wall. The oven for the school has a baking space of about 122cm x 122cm (4' x 4'), but some have been built with oven floors as large as 183cm x 183cm (6' x 6'). (For larger sized baking areas, of course, the size of the entire structure has to be adjusted.)

The designer and author, Rev. Bertrand Saubolle, is a Jesuit priest who, in addition to all the time spent in teaching and mission work in India and Nepal, has developed and refined skills in such areas as beekeeping, solar heater construction, production of methane from animal dung, and gardening, Father Saubolle has been an enthusiastic VITA Volunteer for more than ten years. VITA welcomes this opportunity to bring notice of Godavari School and Father Saubolle's work to a wider audience.

Please send testing results, comments, suggestions, and requests for further information to VITA.

Revised May 1981

ISBN 0-86619-091-0

VITA 1600 Wilson Boulevard, Suite 500 Arlington, Virgnia 22209 USA Tel: 703/276-1800 . Fax: 703/243-1865 Internet: pr-info@vita.org

WOOD-BURNING OVEN

(FOR A BAKERY)

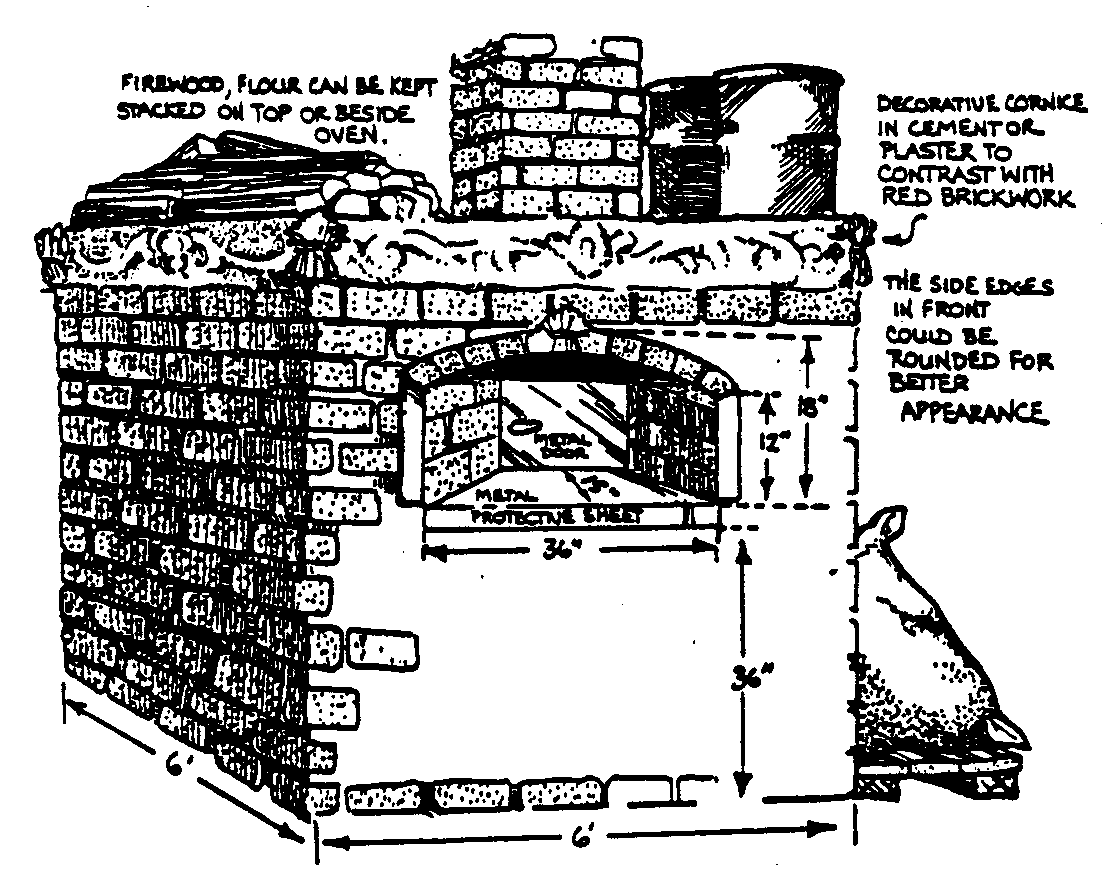

This oven is constructed of brick and mortar--a cube with an

outside dimension of 183cm (72"). The baking space is 91.5cm (36") from the floor, measures about 122cm X 122cm (48" X 48"), and is set back into the face of the brick about 38cm (15"). This inset helps the oven retain heat and provides a ledge or shelf in front of the door on which to maneuver pans and things. The chimney is located above the ledge, outside the oven door.

The roof of the baking space is not a dome but a simple arch--46cm to 56cm (18" to 22") high in the center and sloping to about 30.5cm (12") high at the sides. There is no slope from front to back. It is not a good idea to make the arch more than 61cm (24") high, because a higher arch requires more firewood to heat the oven and also puts the source of the radiated heat that bakes the tops of the loaves further away.

The floor of the baking space should be of firebrick, if available. Ours is of the hardest ordinary building brick we could find. We chose burnt bricks (which are mostly rejected by masons), not just red baked bricks, but bricks burnt black, at least in part. As far as possible, the same kind of bricks should be used for the arch.

Below the layer of firebricks, or burnt building bricks, or ordinary building bricks, ia a 10cm (4") layer of sand and crushed glass. This, we were told, retains heat better than plain brickwork. I don't believe it. But since we had plenty of broken window panes and old broken bottles, we crushed them all up and mixed them in. Below the sand, if you use it, or below the firebrick, is just plain brickwork right down to the floor of the room.

Our chimney is a dream. If you construct your oven well, especially the chimney part, not the faintest wisp of smoke will enter the bakery. After ten years of use the front of our oven is not even the least bit discolored. The chimney is constructed outside the oven door (see drawing) and not through

the center of the arch, as some make it. The chimney should have an inside diameter of 23cm or 25.5cm (9" or 10"). Ours rises straight up through the roof. Our bakery is in a one-story building. If yours is not, there should be no difficulty in leading the smoke out by the side wall of the bakery through a metal stovepipe.

Make the door-frame of the oven of 3.75cm or 5cm (1-1/2" or 2") angle iron with the angle facing the brickwork all around, so that the bricks fit snugly into the angles, and the metal protects the brick edges from chipping. Suit yourself for the size of the opening. I recommend 35.5cm (14") wide so that 30.5cm (12") baking sheets can fit easily without tilting, and say 30.5cm or 35.5cm (12" or 14") high. Have four hooks of thin iron rod fixed to the door-frame and protruding from it the width of a brick so as to anchor the frame to the brickwork. Make the door itself of .32cm (1/8") sheet iron. The bottom of the door-frame should be fixed flush with the floor of the oven.

The inner dimension of the ledge or shelf just outside the oven door is the same as the width of the door-frame. The outer measurement is 91.5cm (36"). This allows maneuvering room needed to get at the extreme right and left inside the oven. The ledge is protected with a sheet of galvanized iron which bends down for several centimeters (inches) in front as well. As with the floor of the oven, the surface of the ledge should also be flush with the bottom of the door-frame. All three should be quite level. This facilitates the shoving in and pulling out of loaves. The hardest bricks should be opposite the door where most shoving and scraping take place.

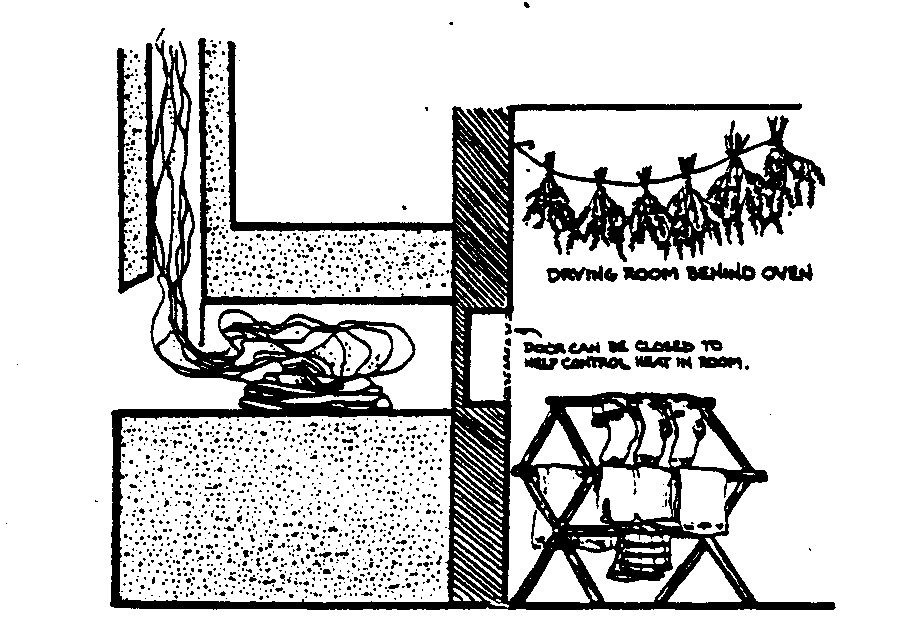

Our oven has no back wall of its own. We built it against the end wall of the room--and for a special purpose. The room behind our bakery is used as a storeroom for things that need to be kept dry, especially during the monsoon--things like flour, biscuits, cake mixes, spaghetti. If you want a room like this heated by your oven, dig a hole into the wall at the level of the oven floor, 91.5cm (36") long and 46cm (18") high, leaving only a thin partition--12.75cm (5") thick, the width of a brick--between the oven and the room. The room will get very dry and pleasantly warm. <see drawing>

To control the admission of heat, put a door to the dug out space. This room is excellent for drying wet clothes during the rains.

HOW TO OPERATE THE OVEN

Build a fire inside the oven with a good armful of logs. Leave the door wide open until the wood is all burned. Pull out the embers and ashes and put the bread in. Then close the door.

After baking the bread, the oven is still hot enough to bake lighter things like cookies, muffins, or buns.

The handles for the scraper for removing the embers, and for the paddle for putting in and pulling out the loaves, could be either of light wood or of that light metal tubing used for electric wires--although the metal tubing may get too hot to handle without some kind of protection for the user's hands.

Make them 183cm (72") long. The paddle blade could be 30.5cm or 20.5cm (12" or 8") of strong galvanized iron or thin iron sheeting.

Note: Drawings were taken from Cloudburst II article based on the original VITA/Father Saubolle design.

VITA Technical Bulletins offer do-it-yourself technology information on a wide variety of subjects.

The Bulletins are idea generators intended not so much to provide a definitive answer as to guide the user's thinking and planning. Premises are sound and testing results are provided, if available.

Evaluations and comments based on each user's experience are requested. Results are incorporated into subsequent editions, thus providing additional guidelines for adaptation and use in a greater variety of conditions.